sensor TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 76 of 3000

2GR-FE COOLING – COOLING FAN SYSTEMCO–5

CO

ON-VEHICLE INSPECTION

1. INSPECT COOLING FAN SYSTEM

(a) Put the vehicle in the following conditions:

(1) The engine switch is off.

(2) The coolant temperature is less than 95

C

(203

F).

(3) The battery voltage is between 9 and 14 V.

(4) The A/C switch is OFF.

(b) Clamp the 400 A probe of an ammeter over the M+

wire of each cooling fan motor.

(c) Turn the ignition switch to the ON position and wait

for approximately 10 seconds. Check that the fan

stops.

(d) Start the engine. Check that the fan stops with the

engine idling.

HINT:

• Make sure that the radiator engine coolant

temperature is less than 95

C (203F).

• Turn the A/C switch OFF.

(e) Check that the fan operates when the A/C switch is

turned ON (MAX COOL and the magnetic clutch is

operating).

Standard current

HINT:

The coolant temperature is less than 95

C (203F).

(f) Check that the fan operates when the engine

coolant temperature sensor connector is

disconnected.

Standard current

Item Specified Condition

No. 1 cooling fan motor 5 to 14 A

No. 2 cooling fan motor 4 to 12 A

Item Specified Condition

No. 1 cooling fan motor 5 to 19 A

No. 2 cooling fan motor 4 to 16 A

Page 81 of 3000

2GR-FE IGNITION – IGNITION COIL AND SPARK PLUGIG–7

IG

(3) Check the spark plug (See page EM-1).

Result

(4) Check the power supply to the ignition coil.

1. Turn the ignition switch to the ON position.

2. Check that there is battery voltage at the

ignition coil positive (+) terminal.

Result

(5) Measure the resistance of the crankshaft

position sensor (See page ES-514).

Result

(6) Check the IGT signal from the ECM (See page

ES-233)

Result

(e) Using a 16 mm (0.63 in.) plug wrench, install the

spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(f) Connect the 6 fuel injector connectors.

(g) Install the ignition coil assembly (See page IG-10).

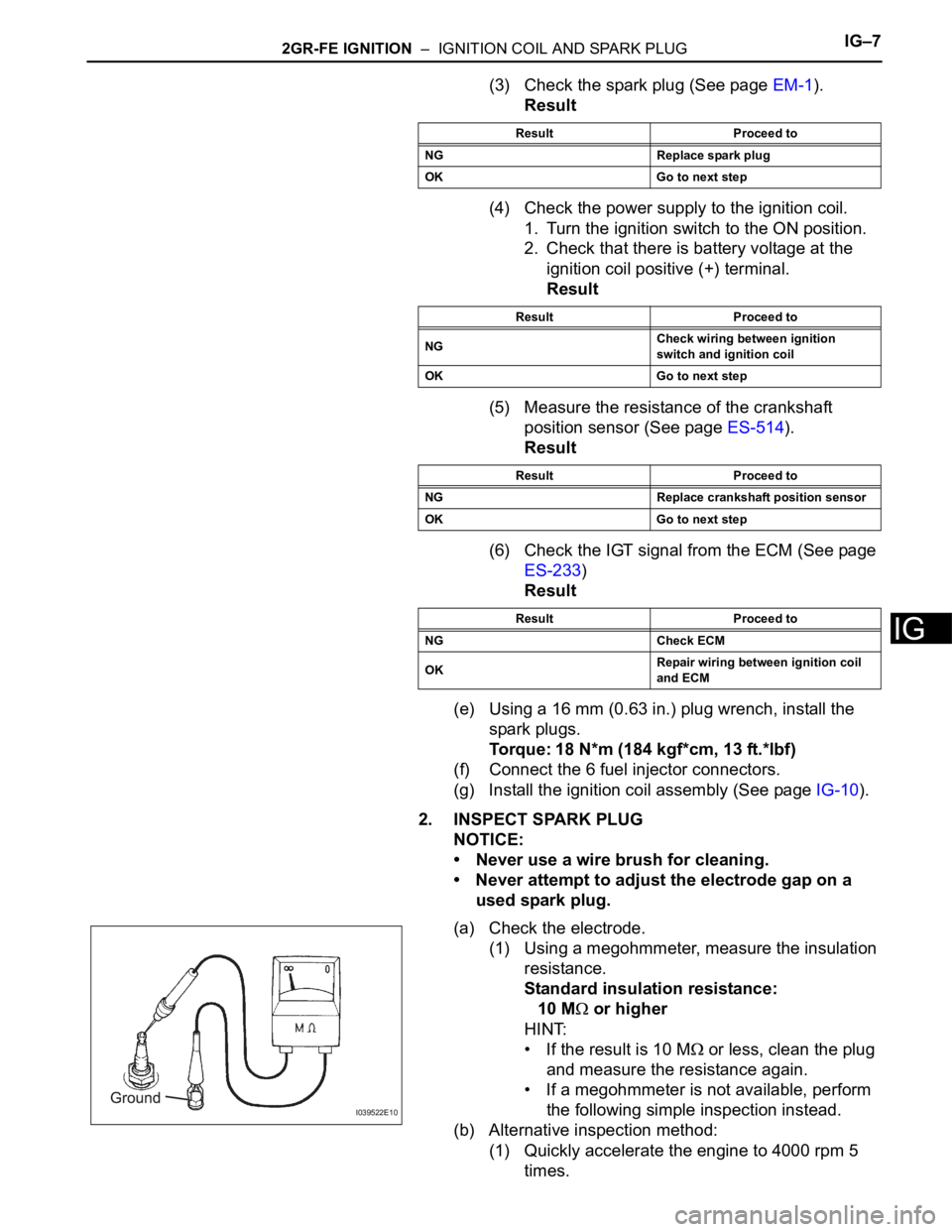

2. INSPECT SPARK PLUG

NOTICE:

• Never use a wire brush for cleaning.

• Never attempt to adjust the electrode gap on a

used spark plug.

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or higher

HINT:

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

• If a megohmmeter is not available, perform

the following simple inspection instead.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4000 rpm 5

times.

Result Proceed to

NG Replace spark plug

OK Go to next step

Result Proceed to

NGCheck wiring between ignition

switch and ignition coil

OK Go to next step

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM

OKRepair wiring between ignition coil

and ECM

I039522E10

Page 88 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–3

AX

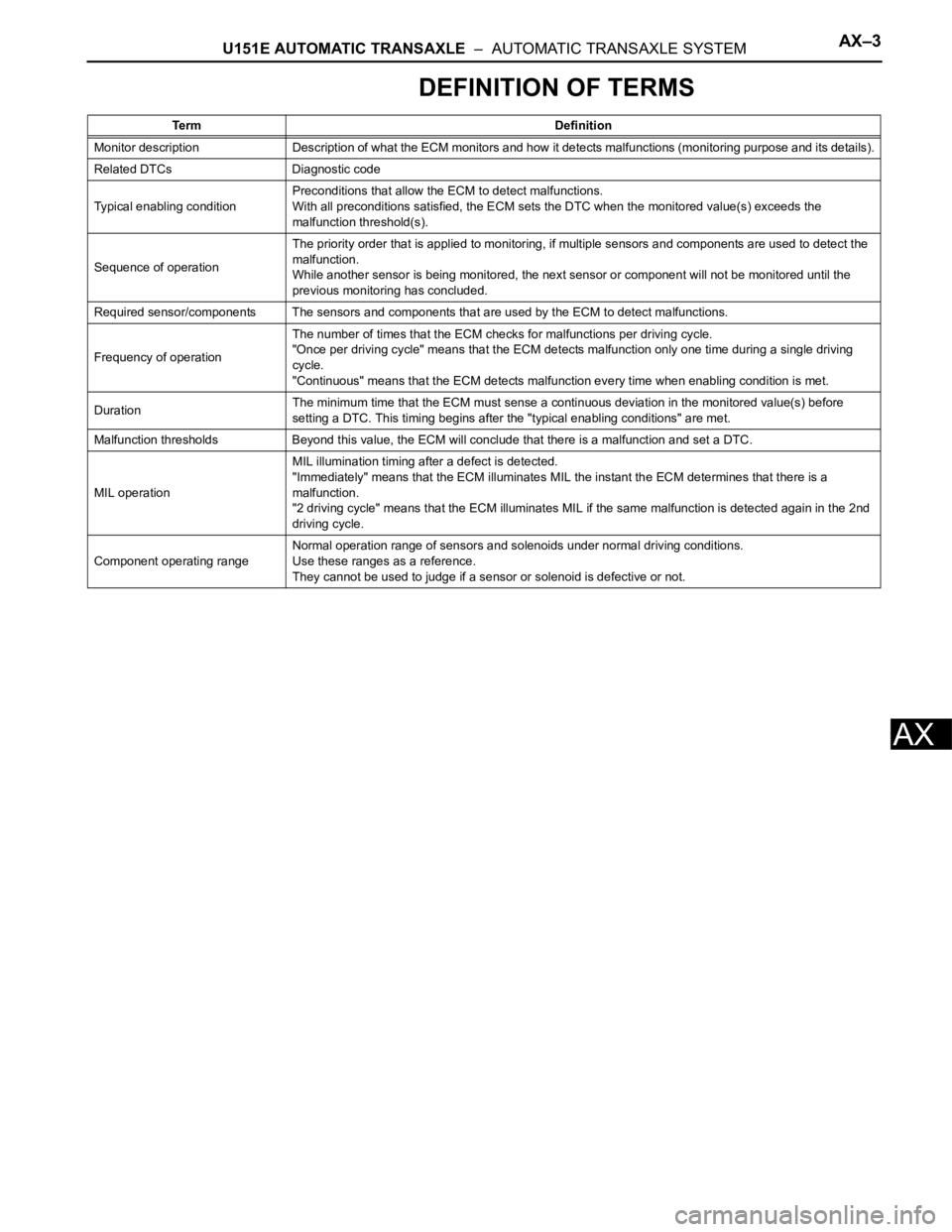

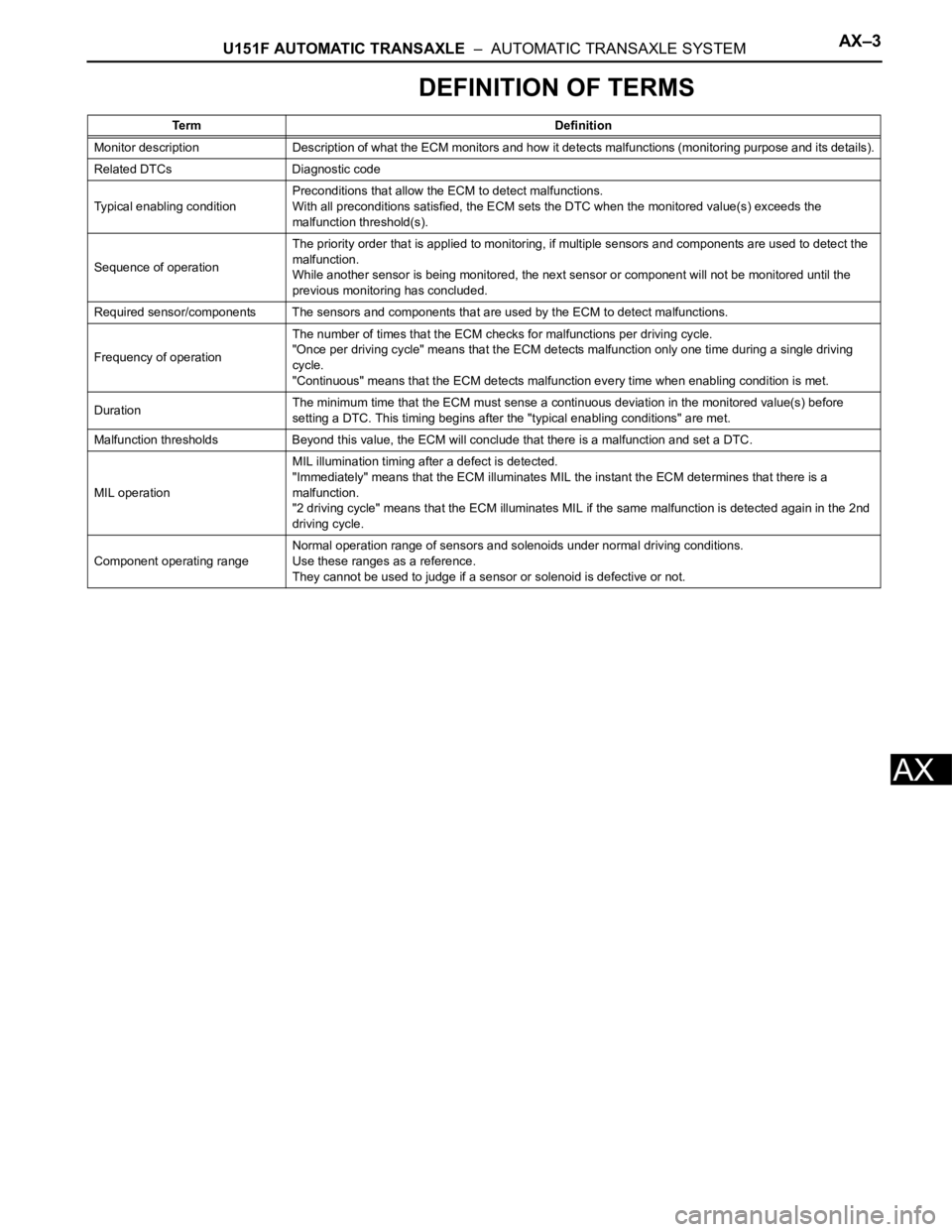

DEFINITION OF TERMS

Te r m D e f i n i t i o n

Monitor description Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and its details).

Related DTCs Diagnostic code

Typical enabling conditionPreconditions that allow the ECM to detect malfunctions.

With all preconditions satisfied, the ECM sets the DTC when the monitored value(s) exceeds the

malfunction threshold(s).

Sequence of operationThe priority order that is applied to monitoring, if multiple sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored until the

previous monitoring has concluded.

Required sensor/components The sensors and components that are used by the ECM to detect malfunctions.

Frequency of operationThe number of times that the ECM checks for malfunctions per driving cycle.

"Once per driving cycle" means that the ECM detects malfunction only one time during a single driving

cycle.

"Continuous" means that the ECM detects malfunction every time when enabling condition is met.

DurationThe minimum time that the ECM must sense a continuous deviation in the monitored value(s) before

setting a DTC. This timing begins after the "typical enabling conditions" are met.

Malfunction thresholds Beyond this value, the ECM will conclude that there is a malfunction and set a DTC.

MIL operationMIL illumination timing after a defect is detected.

"Immediately" means that the ECM illuminates MIL the instant the ECM determines that there is a

malfunction.

"2 driving cycle" means that the ECM illuminates MIL if the same malfunction is detected again in the 2nd

driving cycle.

Component operating rangeNormal operation range of sensors and solenoids under normal driving conditions.

Use these ranges as a reference.

They cannot be used to judge if a sensor or solenoid is defective or not.

Page 91 of 3000

AX–164U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

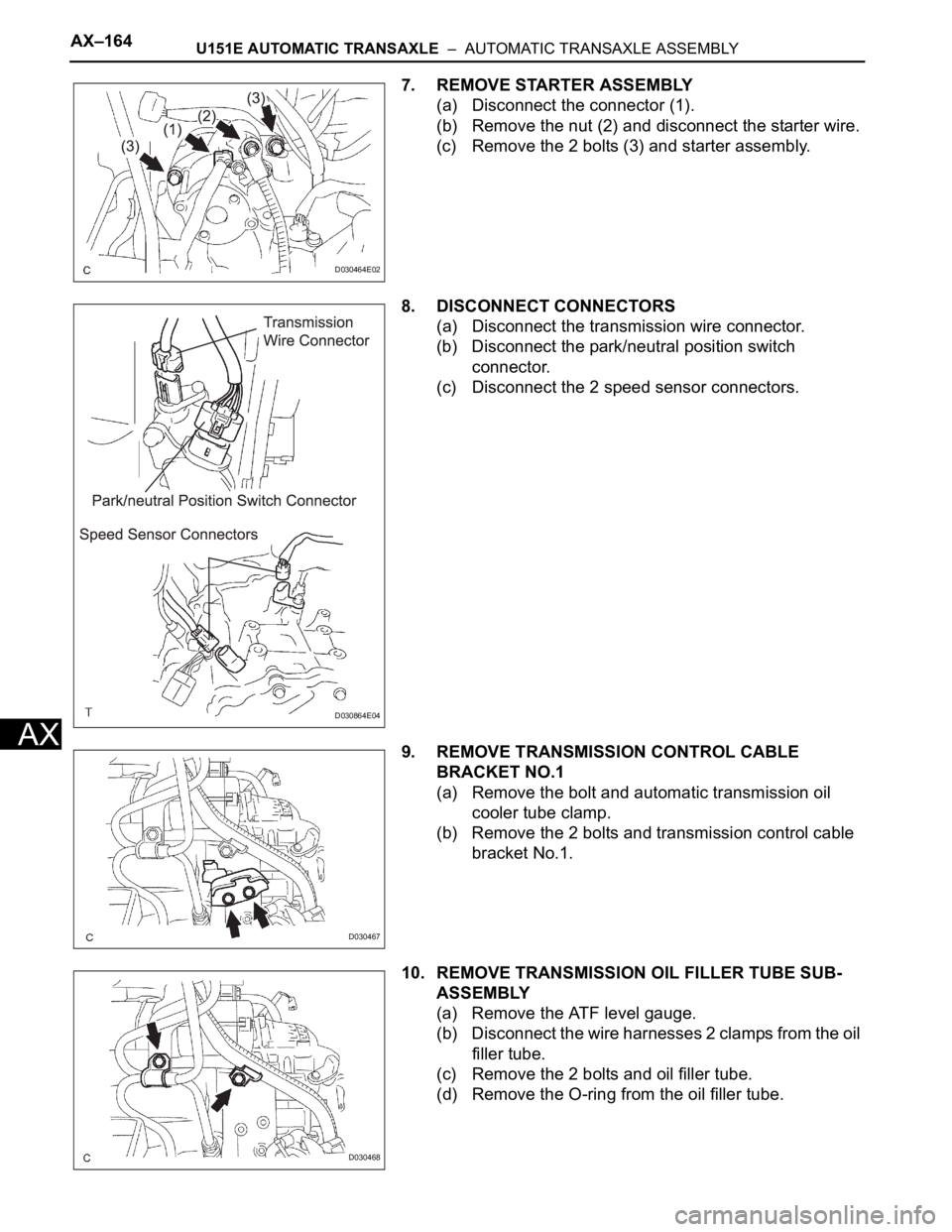

7. REMOVE STARTER ASSEMBLY

(a) Disconnect the connector (1).

(b) Remove the nut (2) and disconnect the starter wire.

(c) Remove the 2 bolts (3) and starter assembly.

8. DISCONNECT CONNECTORS

(a) Disconnect the transmission wire connector.

(b) Disconnect the park/neutral position switch

connector.

(c) Disconnect the 2 speed sensor connectors.

9. REMOVE TRANSMISSION CONTROL CABLE

BRACKET NO.1

(a) Remove the bolt and automatic transmission oil

cooler tube clamp.

(b) Remove the 2 bolts and transmission control cable

bracket No.1.

10. REMOVE TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Remove the ATF level gauge.

(b) Disconnect the wire harnesses 2 clamps from the oil

filler tube.

(c) Remove the 2 bolts and oil filler tube.

(d) Remove the O-ring from the oil filler tube.

D030464E02

D030864E04

D030467

D030468

Page 95 of 3000

AX–168U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

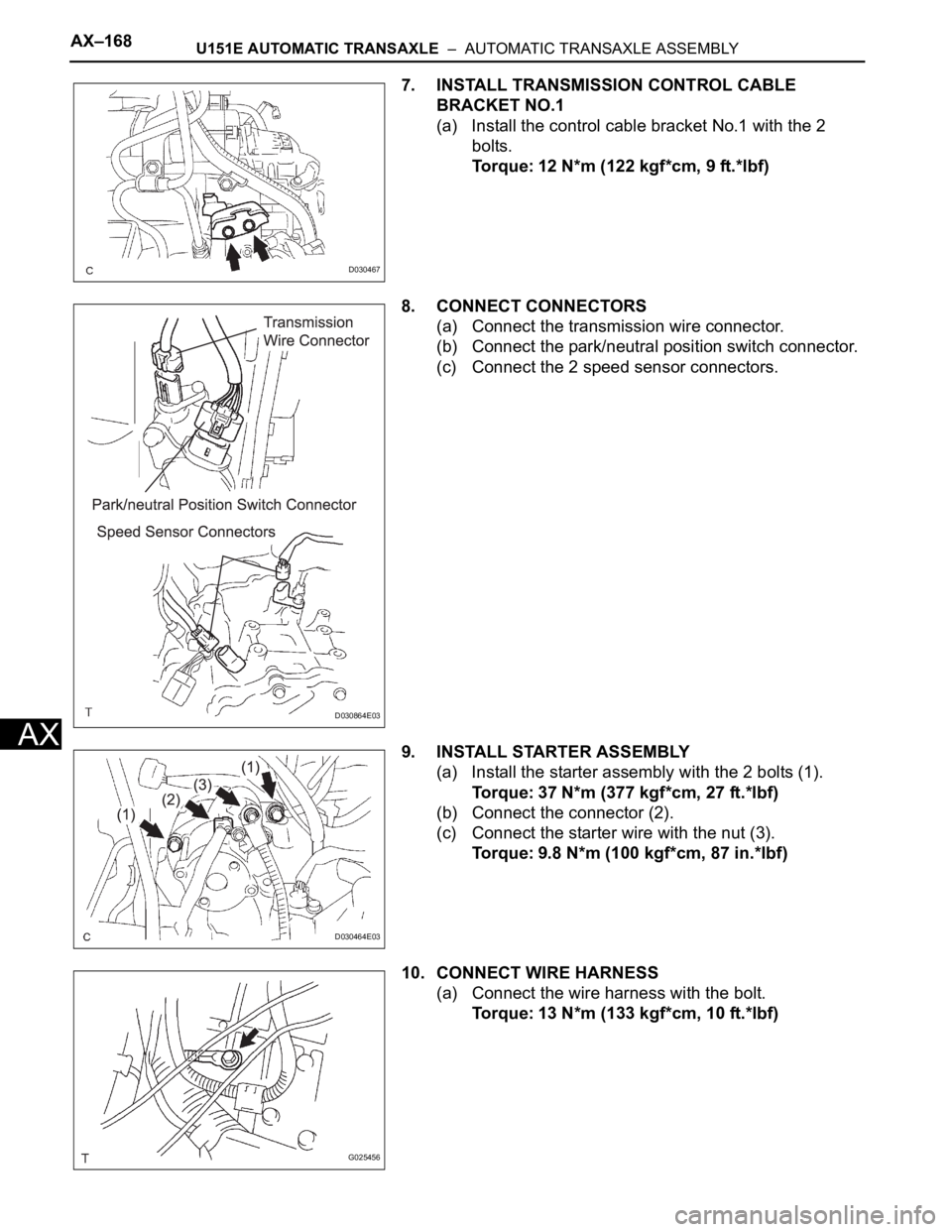

7. INSTALL TRANSMISSION CONTROL CABLE

BRACKET NO.1

(a) Install the control cable bracket No.1 with the 2

bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

8. CONNECT CONNECTORS

(a) Connect the transmission wire connector.

(b) Connect the park/neutral position switch connector.

(c) Connect the 2 speed sensor connectors.

9. INSTALL STARTER ASSEMBLY

(a) Install the starter assembly with the 2 bolts (1).

Torque: 37 N*m (377 kgf*cm, 27 ft.*lbf)

(b) Connect the connector (2).

(c) Connect the starter wire with the nut (3).

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

10. CONNECT WIRE HARNESS

(a) Connect the wire harness with the bolt.

Torque: 13 N*m (133 kgf*cm, 10 ft.*lbf)

D030467

D030864E03

D030464E03

G025456

Page 97 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–3

AX

DEFINITION OF TERMS

Te r m D e f i n i t i o n

Monitor description Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and its details).

Related DTCs Diagnostic code

Typical enabling conditionPreconditions that allow the ECM to detect malfunctions.

With all preconditions satisfied, the ECM sets the DTC when the monitored value(s) exceeds the

malfunction threshold(s).

Sequence of operationThe priority order that is applied to monitoring, if multiple sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored until the

previous monitoring has concluded.

Required sensor/components The sensors and components that are used by the ECM to detect malfunctions.

Frequency of operationThe number of times that the ECM checks for malfunctions per driving cycle.

"Once per driving cycle" means that the ECM detects malfunction only one time during a single driving

cycle.

"Continuous" means that the ECM detects malfunction every time when enabling condition is met.

DurationThe minimum time that the ECM must sense a continuous deviation in the monitored value(s) before

setting a DTC. This timing begins after the "typical enabling conditions" are met.

Malfunction thresholds Beyond this value, the ECM will conclude that there is a malfunction and set a DTC.

MIL operationMIL illumination timing after a defect is detected.

"Immediately" means that the ECM illuminates MIL the instant the ECM determines that there is a

malfunction.

"2 driving cycle" means that the ECM illuminates MIL if the same malfunction is detected again in the 2nd

driving cycle.

Component operating rangeNormal operation range of sensors and solenoids under normal driving conditions.

Use these ranges as a reference.

They cannot be used to judge if a sensor or solenoid is defective or not.

Page 100 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–165

AX

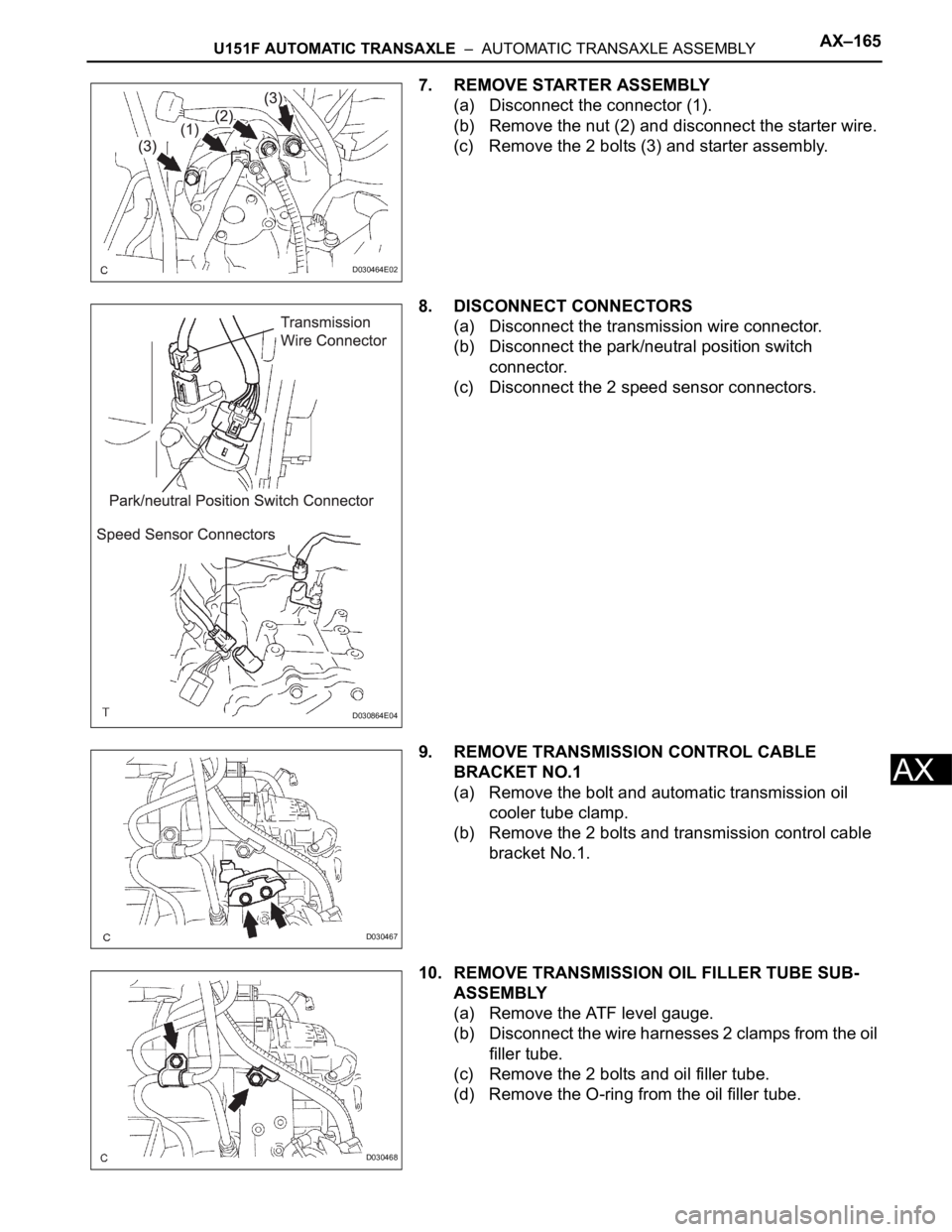

7. REMOVE STARTER ASSEMBLY

(a) Disconnect the connector (1).

(b) Remove the nut (2) and disconnect the starter wire.

(c) Remove the 2 bolts (3) and starter assembly.

8. DISCONNECT CONNECTORS

(a) Disconnect the transmission wire connector.

(b) Disconnect the park/neutral position switch

connector.

(c) Disconnect the 2 speed sensor connectors.

9. REMOVE TRANSMISSION CONTROL CABLE

BRACKET NO.1

(a) Remove the bolt and automatic transmission oil

cooler tube clamp.

(b) Remove the 2 bolts and transmission control cable

bracket No.1.

10. REMOVE TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Remove the ATF level gauge.

(b) Disconnect the wire harnesses 2 clamps from the oil

filler tube.

(c) Remove the 2 bolts and oil filler tube.

(d) Remove the O-ring from the oil filler tube.

D030464E02

D030864E04

D030467

D030468

Page 105 of 3000

AX–170U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

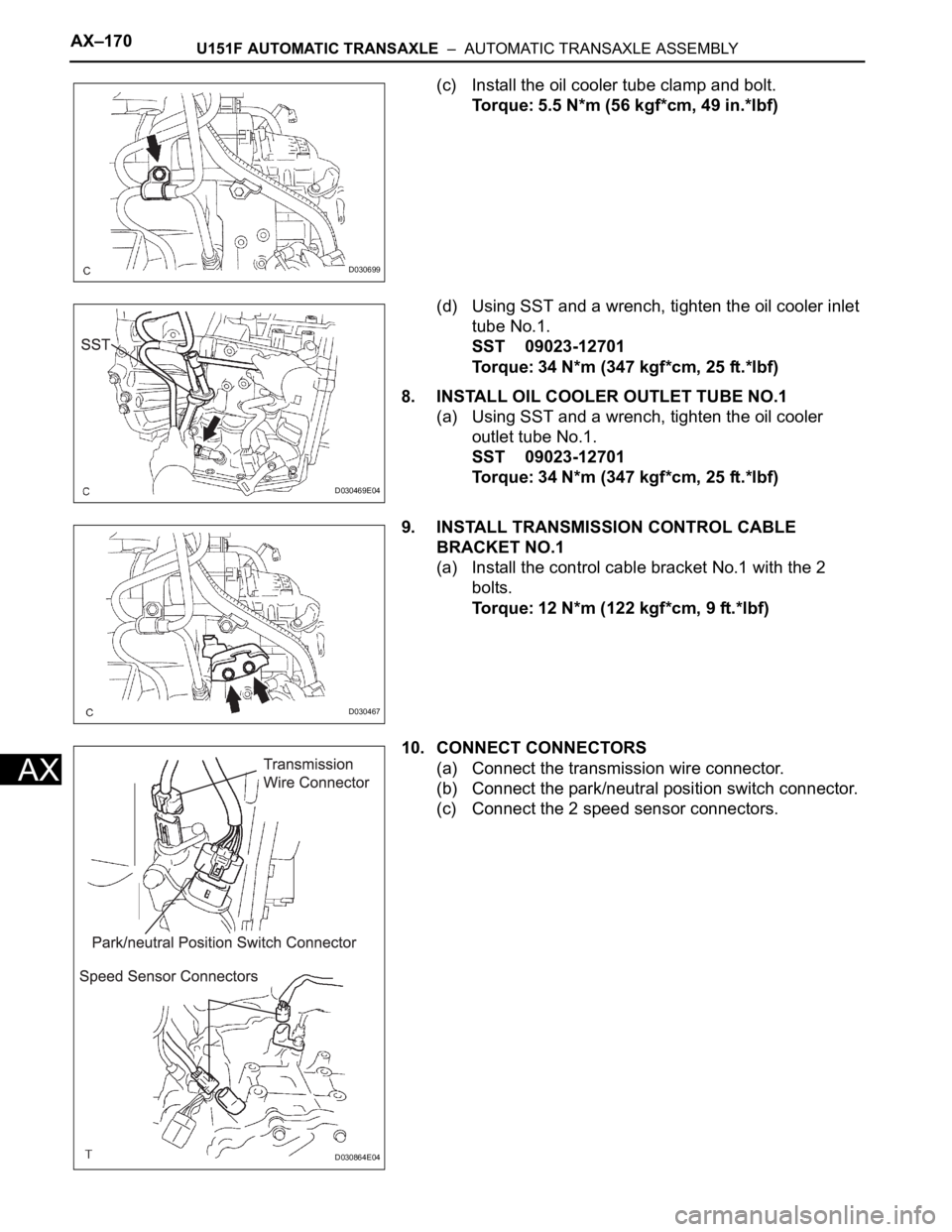

(c) Install the oil cooler tube clamp and bolt.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(d) Using SST and a wrench, tighten the oil cooler inlet

tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

8. INSTALL OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, tighten the oil cooler

outlet tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

9. INSTALL TRANSMISSION CONTROL CABLE

BRACKET NO.1

(a) Install the control cable bracket No.1 with the 2

bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

10. CONNECT CONNECTORS

(a) Connect the transmission wire connector.

(b) Connect the park/neutral position switch connector.

(c) Connect the 2 speed sensor connectors.

D030699

D030469E04

D030467

D030864E04

Page 108 of 3000

TF–10TRANSFER – TRANSFER ASSEMBLY

TF

6. INSTALL NO. 1 TRANSFER CASE PLUG

(a) Add oil up to 0 to 5 mm below the lower side of the

plug hole.

Oil quantity:

0.9 L (0.95 US qts, 0.71 lmp. qts)

HINT:

When adding oil, pour it slowly.

(b) Install the No. 1 transfer case plug with a new No. 1

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

7. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

8. CHECK ABS SPEED SENSOR SIGNAL

HINT:

(See page BC-3)

Page 110 of 3000

DRIVE SHAFT – FRONT DRIVE SHAFTDS–5

DS

REMOVAL

1. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

2. DRAIN TRANSFER OIL (for 4WD)

HINT:

(See page TF-8)

3. REMOVE FRONT WHEEL

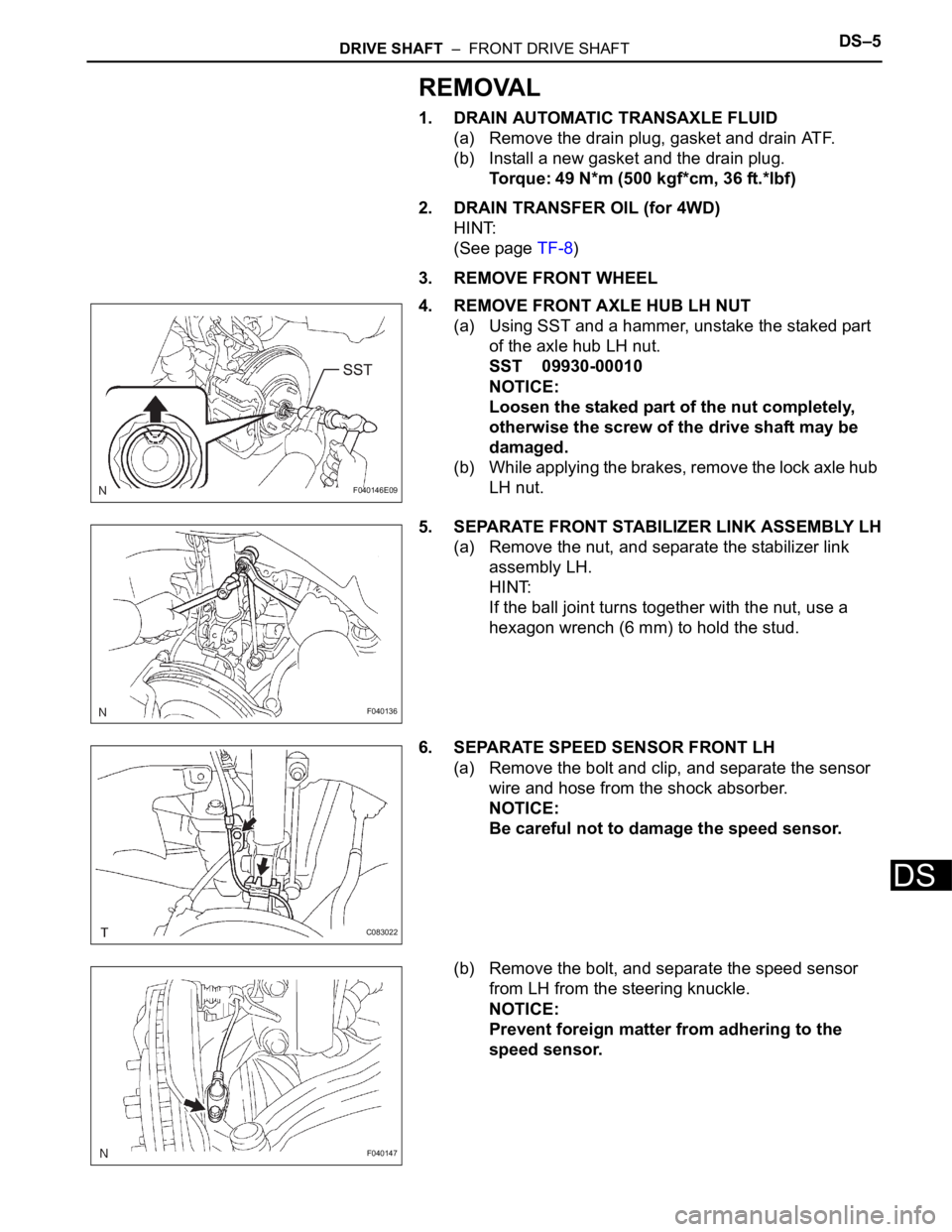

4. REMOVE FRONT AXLE HUB LH NUT

(a) Using SST and a hammer, unstake the staked part

of the axle hub LH nut.

SST 09930-00010

NOTICE:

Loosen the staked part of the nut completely,

otherwise the screw of the drive shaft may be

damaged.

(b) While applying the brakes, remove the lock axle hub

LH nut.

5. SEPARATE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the nut, and separate the stabilizer link

assembly LH.

HINT:

If the ball joint turns together with the nut, use a

hexagon wrench (6 mm) to hold the stud.

6. SEPARATE SPEED SENSOR FRONT LH

(a) Remove the bolt and clip, and separate the sensor

wire and hose from the shock absorber.

NOTICE:

Be careful not to damage the speed sensor.

(b) Remove the bolt, and separate the speed sensor

from LH from the steering knuckle.

NOTICE:

Prevent foreign matter from adhering to the

speed sensor.

F040146E09

F040136

C083022

F040147