oil TOYOTA SIENNA 2007 Service Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 200 of 3000

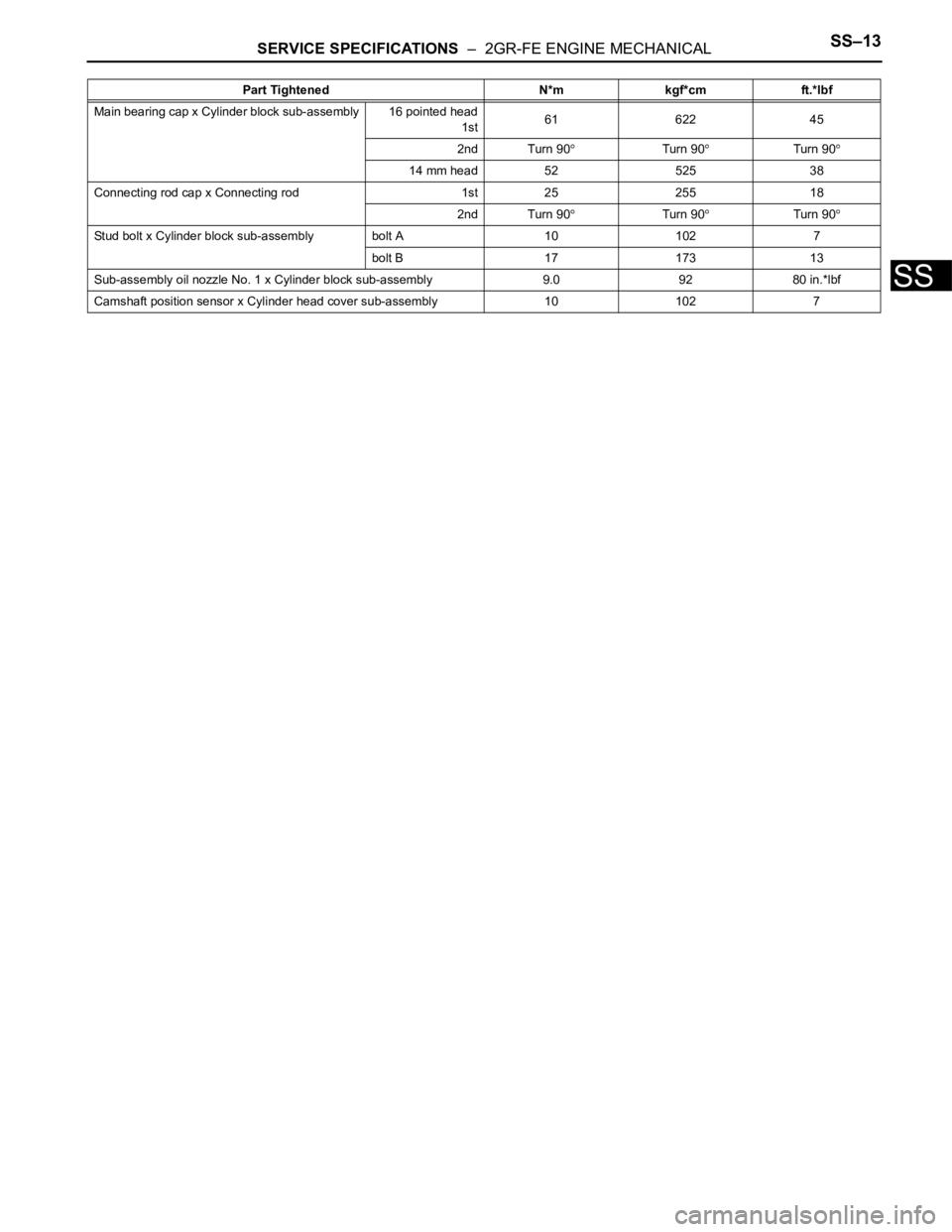

SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICALSS–13

SS

Main bearing cap x Cylinder block sub-assembly 16 pointed head

1st61 622 45

2nd Turn 90

Turn 90Turn 90

14 mm head 52 525 38

Connecting rod cap x Connecting rod 1st 25 255 18

2nd Turn 90

Turn 90Turn 90

Stud bolt x Cylinder block sub-assembly bolt A 10 102 7

bolt B 17 173 13

Sub-assembly oil nozzle No. 1 x Cylinder block sub-assembly 9.0 92 80 in.*lbf

Camshaft position sensor x Cylinder head cover sub-assembly 10 1027 Part Tightened N*m kgf*cm ft.*lbf

Page 208 of 3000

AC–238AIR CONDITIONING – CONDENSER

AC

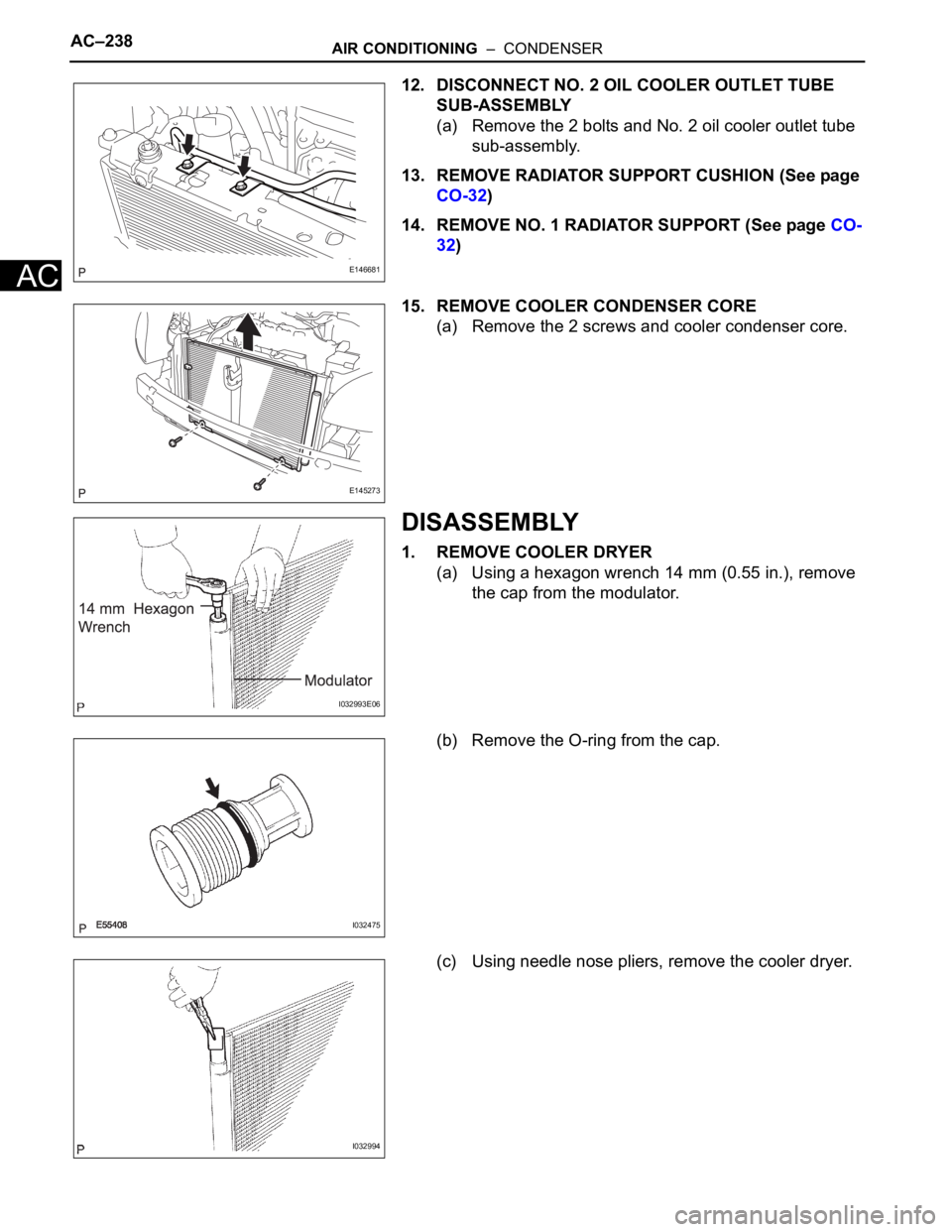

12. DISCONNECT NO. 2 OIL COOLER OUTLET TUBE

SUB-ASSEMBLY

(a) Remove the 2 bolts and No. 2 oil cooler outlet tube

sub-assembly.

13. REMOVE RADIATOR SUPPORT CUSHION (See page

CO-32)

14. REMOVE NO. 1 RADIATOR SUPPORT (See page CO-

32)

15. REMOVE COOLER CONDENSER CORE

(a) Remove the 2 screws and cooler condenser core.

DISASSEMBLY

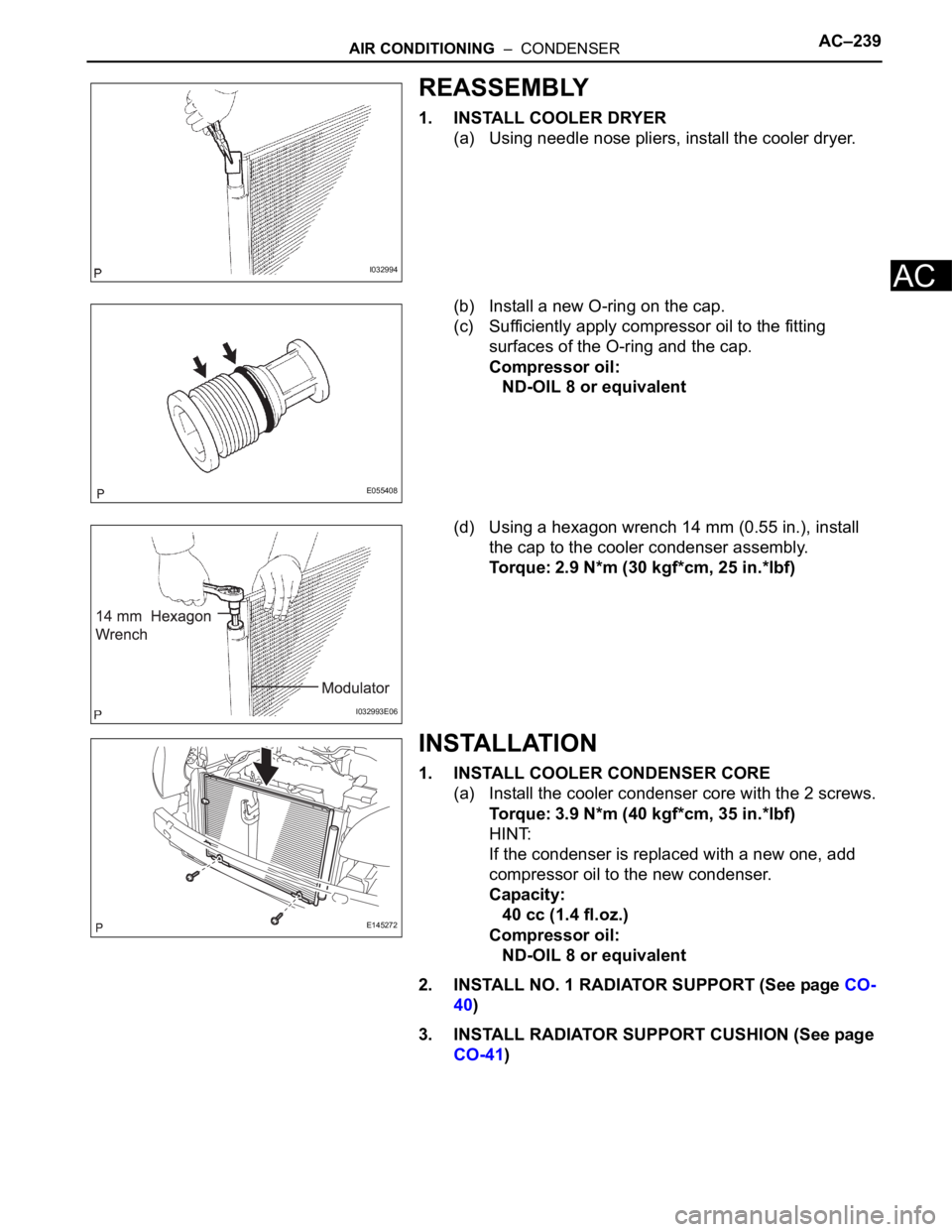

1. REMOVE COOLER DRYER

(a) Using a hexagon wrench 14 mm (0.55 in.), remove

the cap from the modulator.

(b) Remove the O-ring from the cap.

(c) Using needle nose pliers, remove the cooler dryer.

E146681

E145273

I032993E06

I032475

I032994

Page 209 of 3000

AIR CONDITIONING – CONDENSERAC–239

AC

REASSEMBLY

1. INSTALL COOLER DRYER

(a) Using needle nose pliers, install the cooler dryer.

(b) Install a new O-ring on the cap.

(c) Sufficiently apply compressor oil to the fitting

surfaces of the O-ring and the cap.

Compressor oil:

ND-OIL 8 or equivalent

(d) Using a hexagon wrench 14 mm (0.55 in.), install

the cap to the cooler condenser assembly.

Torque: 2.9 N*m (30 kgf*cm, 25 in.*lbf)

INSTALLATION

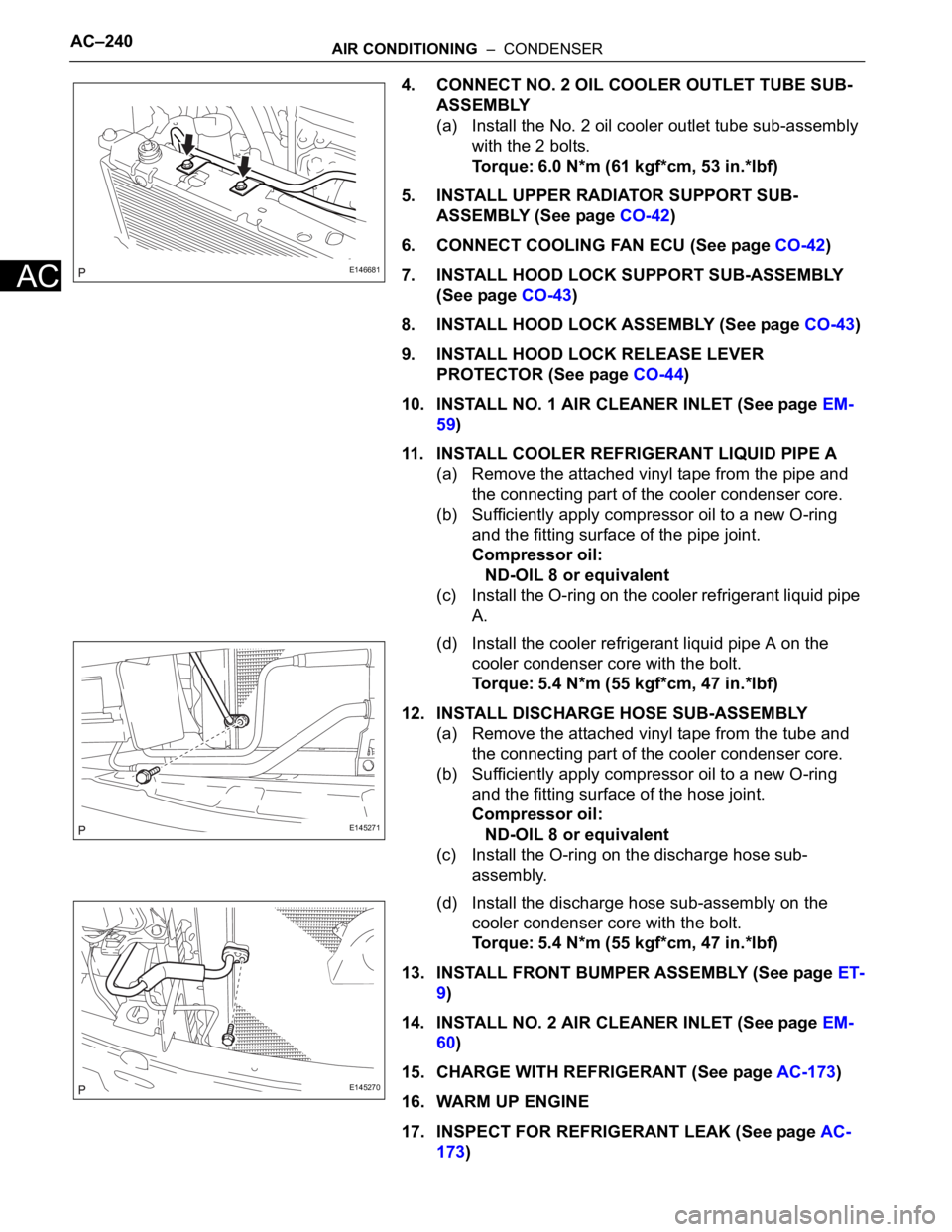

1. INSTALL COOLER CONDENSER CORE

(a) Install the cooler condenser core with the 2 screws.

Torque: 3.9 N*m (40 kgf*cm, 35 in.*lbf)

HINT:

If the condenser is replaced with a new one, add

compressor oil to the new condenser.

Capacity:

40 cc (1.4 fl.oz.)

Compressor oil:

ND-OIL 8 or equivalent

2. INSTALL NO. 1 RADIATOR SUPPORT (See page CO-

40)

3. INSTALL RADIATOR SUPPORT CUSHION (See page

CO-41)

I032994

E055408

I032993E06

E145272

Page 210 of 3000

AC–240AIR CONDITIONING – CONDENSER

AC

4. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUB-

ASSEMBLY

(a) Install the No. 2 oil cooler outlet tube sub-assembly

with the 2 bolts.

Torque: 6.0 N*m (61 kgf*cm, 53 in.*lbf)

5. INSTALL UPPER RADIATOR SUPPORT SUB-

ASSEMBLY (See page CO-42)

6. CONNECT COOLING FAN ECU (See page CO-42)

7. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-43)

8. INSTALL HOOD LOCK ASSEMBLY (See page CO-43)

9. INSTALL HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-44)

10. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

11. INSTALL COOLER REFRIGERANT LIQUID PIPE A

(a) Remove the attached vinyl tape from the pipe and

the connecting part of the cooler condenser core.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the pipe joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant liquid pipe

A.

(d) Install the cooler refrigerant liquid pipe A on the

cooler condenser core with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 47 in.*lbf)

12. INSTALL DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the attached vinyl tape from the tube and

the connecting part of the cooler condenser core.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the hose joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the discharge hose sub-

assembly.

(d) Install the discharge hose sub-assembly on the

cooler condenser core with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 47 in.*lbf)

13. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

14. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

15. CHARGE WITH REFRIGERANT (See page AC-173)

16. WARM UP ENGINE

17. INSPECT FOR REFRIGERANT LEAK (See page AC-

173)

E146681

E145271

E145270

Page 214 of 3000

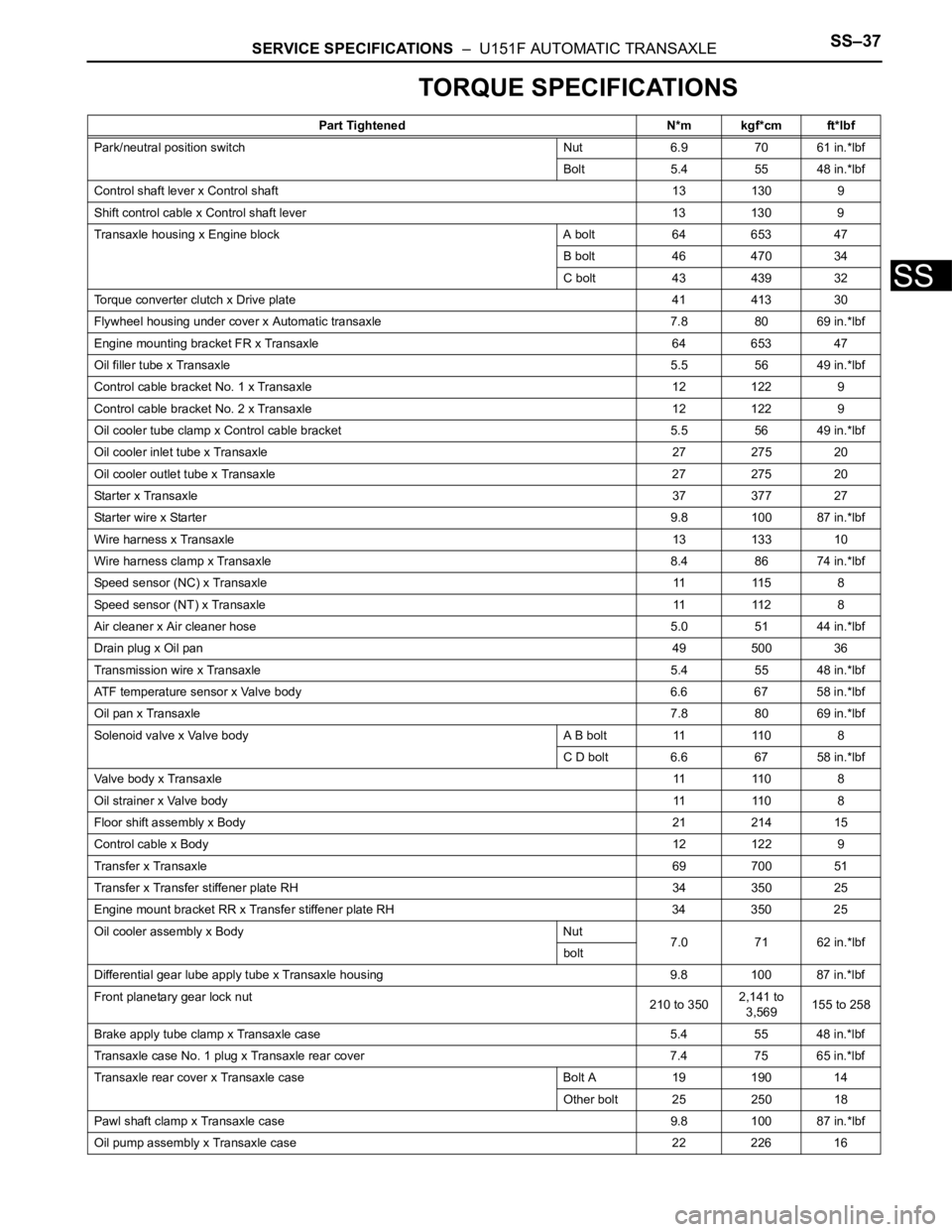

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLESS–37

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 130 9

Shift control cable x Control shaft lever 13 130 9

Transaxle housing x Engine block A bolt 64 653 47

B bolt 46 470 34

C bolt 43 439 32

Torque converter clutch x Drive plate 41 413 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Engine mounting bracket FR x Transaxle 64 653 47

Oil filler tube x Transaxle5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler tube clamp x Control cable bracket 5.5 56 49 in.*lbf

Oil cooler inlet tube x Transaxle27 275 20

Oil cooler outlet tube x Transaxle 27 275 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 87 in.*lbf

Wire harness x Transaxle13 133 10

Wire harness clamp x Transaxle8.4 86 74 in.*lbf

Speed sensor (NC) x Transaxle11 11 5 8

Speed sensor (NT) x Transaxle11 11 2 8

Air cleaner x Air cleaner hose5.0 51 44 in.*lbf

Drain plug x Oil pan49 500 36

Transmission wire x Transaxle5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body A B bolt 11 110 8

C D bolt 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 0 8

Oil strainer x Valve body11 11 0 8

Floor shift assembly x Body21 214 15

Control cable x Body12 122 9

Transfer x Transaxle69 700 51

Transfer x Transfer stiffener plate RH 34 350 25

Engine mount bracket RR x Transfer stiffener plate RH 34 350 25

Oil cooler assembly x Body Nut

7.0 71 62 in.*lbf

bolt

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut

210 to 3502,141 to

3,569155 to 258

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 190 14

Other bolt 25 250 18

Pawl shaft clamp x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Page 215 of 3000

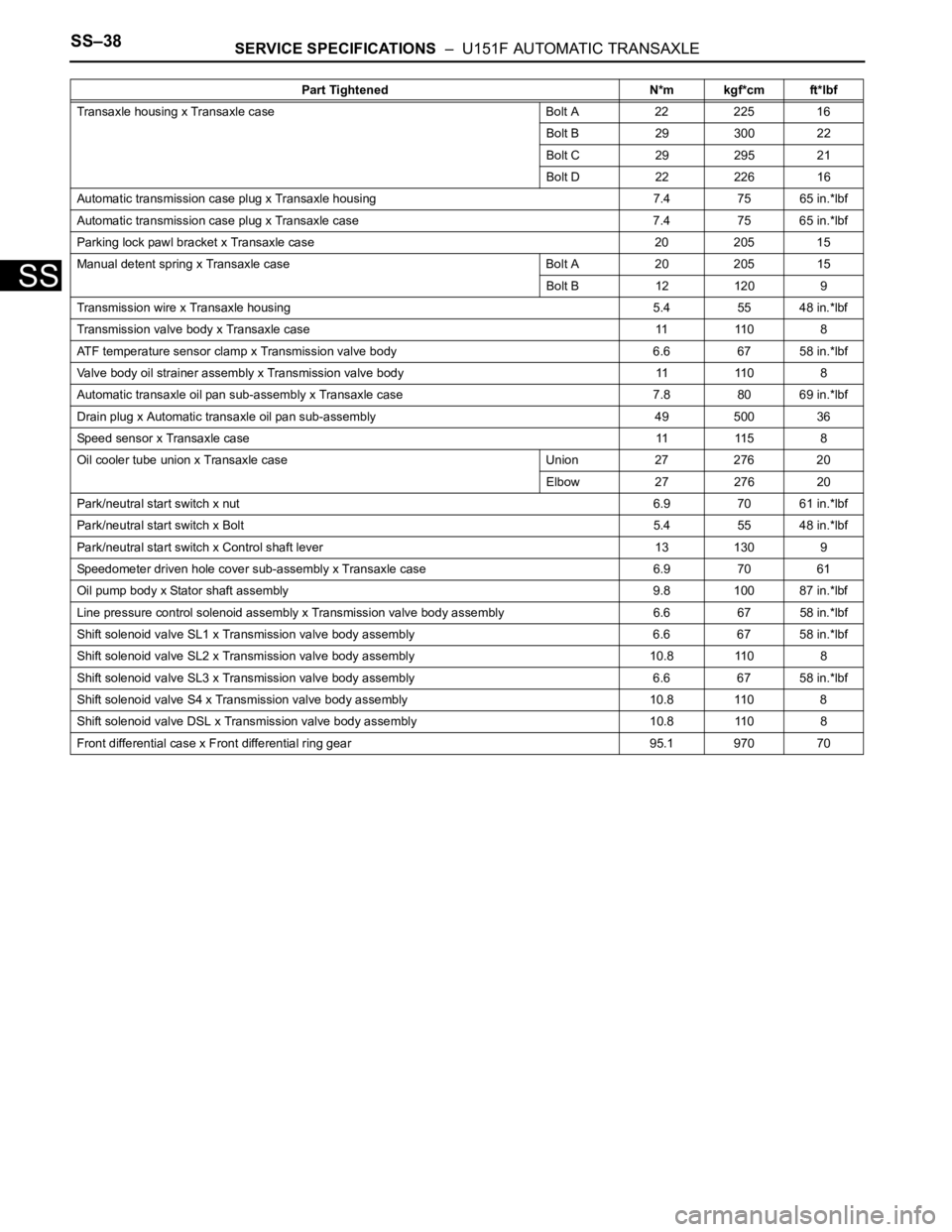

SS–38SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLE

SS

Transaxle housing x Transaxle case Bolt A 22 225 16

Bolt B 29 300 22

Bolt C 29 295 21

Bolt D 22 226 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Transmission wire x Transaxle housing 5.4 55 48 in.*lbf

Transmission valve body x Transaxle case 11 110 8

ATF temperature sensor clamp x Transmission valve body 6.6 67 58 in.*lbf

Valve body oil strainer assembly x Transmission valve body 11 1108

Automatic transaxle oil pan sub-assembly x Transaxle case 7.8 80 69 in.*lbf

Drain plug x Automatic transaxle oil pan sub-assembly 49 500 36

Speed sensor x Transaxle case11 11 5 8

Oil cooler tube union x Transaxle case Union 27 276 20

Elbow 27 276 20

Park/neutral start switch x nut6.9 70 61 in.*lbf

Park/neutral start switch x Bolt5.4 55 48 in.*lbf

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 6.9 7061

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Line pressure control solenoid assembly x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve SL1 x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve SL2 x Transmission valve body assembly 10.811 0 8

Shift solenoid valve SL3 x Transmission valve body assembly 6.6 67 58 in.*lbf

Shift solenoid valve S4 x Transmission valve body assembly 10.8 110 8

Shift solenoid valve DSL x Transmission valve body assembly 10.811 0 8

Front differential case x Front differential ring gear 95.1 970 70Part Tightened N*m kgf*cm ft*lbf

Page 216 of 3000

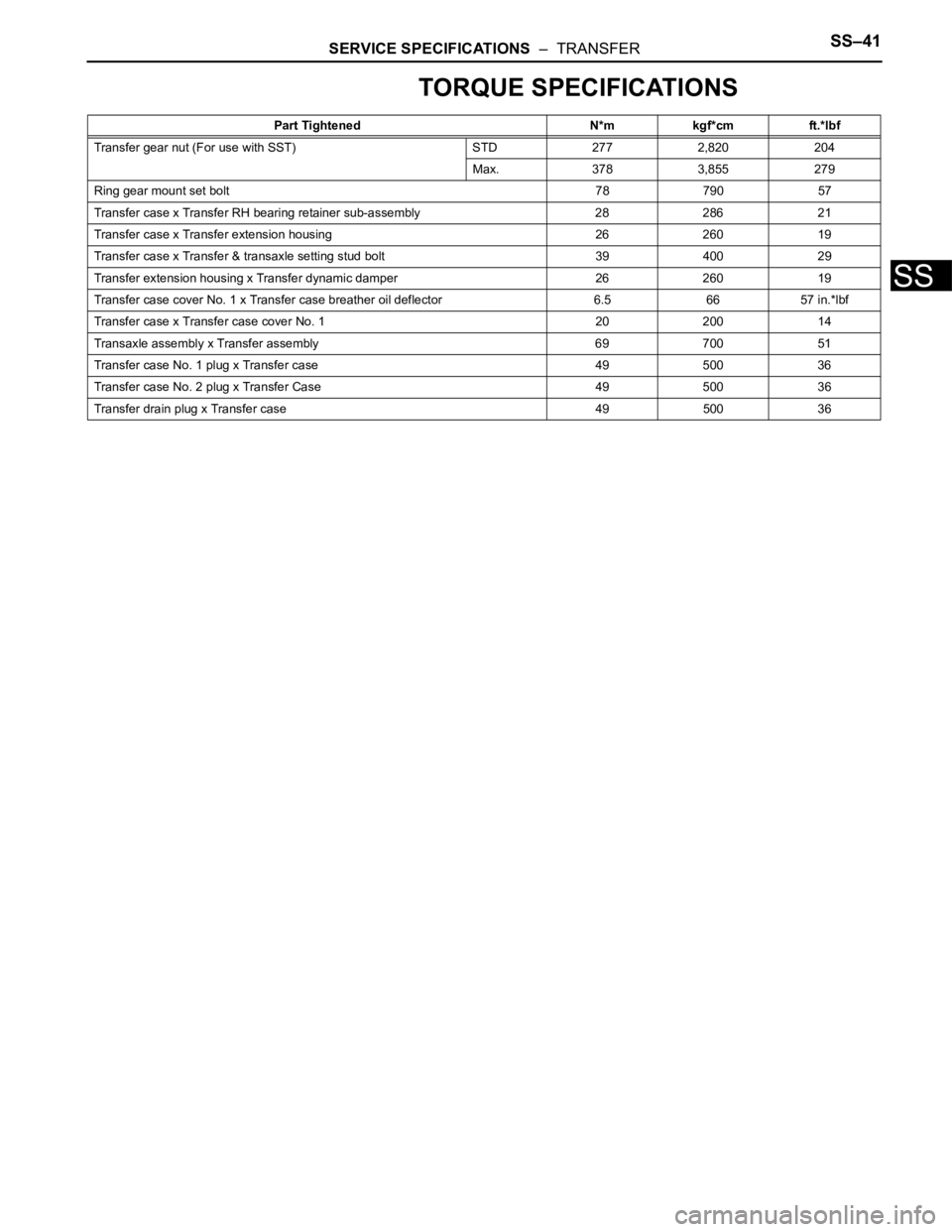

SERVICE SPECIFICATIONS – TRANSFERSS–41

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft.*lbf

Transfer gear nut (For use with SST) STD 277 2,820 204

Max. 378 3,855 279

Ring gear mount set bolt 78 790 57

Transfer case x Transfer RH bearing retainer sub-assembly 28 286 21

Transfer case x Transfer extension housing 26 260 19

Transfer case x Transfer & transaxle setting stud bolt 39 400 29

Transfer extension housing x Transfer dynamic damper 26 260 19

Transfer case cover No. 1 x Transfer case breather oil deflector 6.5 66 57 in.*lbf

Transfer case x Transfer case cover No. 1 20 200 14

Transaxle assembly x Transfer assembly 69 700 51

Transfer case No. 1 plug x Transfer case 49 500 36

Transfer case No. 2 plug x Transfer Case 49 500 36

Transfer drain plug x Transfer case 49 500 36

Page 218 of 3000

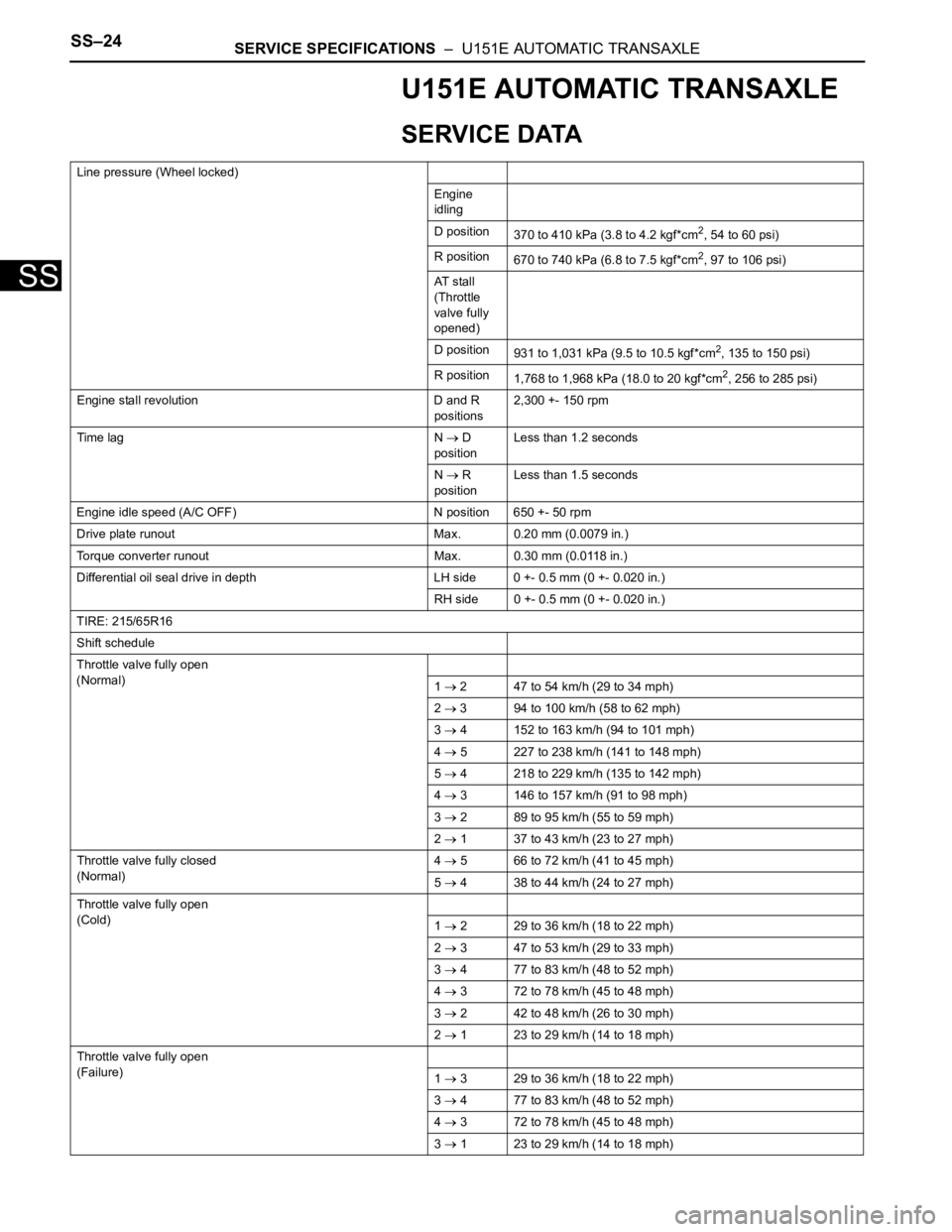

SS–24SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

U151E AUTOMATIC TRANSAXLE

SERVICE DATA

Line pressure (Wheel locked)

Engine

idling

D position

370 to 410 kPa (3.8 to 4.2 kgf*cm

2, 54 to 60 psi)

R position

670 to 740 kPa (6.8 to 7.5 kgf*cm

2, 97 to 106 psi)

AT s t a l l

(Throttle

valve fully

opened)

D position

931 to 1,031 kPa (9.5 to 10.5 kgf*cm

2, 135 to 150 psi)

R position

1,768 to 1,968 kPa (18.0 to 20 kgf*cm

2, 256 to 285 psi)

Engine stall revolution D and R

positions2,300 +- 150 rpm

Time lag N

D

positionLess than 1.2 seconds

N

R

positionLess than 1.5 seconds

Engine idle speed (A/C OFF) N position 650 +- 50 rpm

Drive plate runout Max. 0.20 mm (0.0079 in.)

Torque converter runout Max. 0.30 mm (0.0118 in.)

Differential oil seal drive in depth LH side 0 +- 0.5 mm (0 +- 0.020 in.)

RH side 0 +- 0.5 mm (0 +- 0.020 in.)

TIRE: 215/65R16

Shift schedule

Throttle valve fully open

(Normal)

1

2 47 to 54 km/h (29 to 34 mph)

2

3 94 to 100 km/h (58 to 62 mph)

3

4 152 to 163 km/h (94 to 101 mph)

4

5 227 to 238 km/h (141 to 148 mph)

5

4 218 to 229 km/h (135 to 142 mph)

4

3 146 to 157 km/h (91 to 98 mph)

3

2 89 to 95 km/h (55 to 59 mph)

2

1 37 to 43 km/h (23 to 27 mph)

Throttle valve fully closed

(Normal)4

5 66 to 72 km/h (41 to 45 mph)

5

4 38 to 44 km/h (24 to 27 mph)

Throttle valve fully open

(Cold)

1

2 29 to 36 km/h (18 to 22 mph)

2

3 47 to 53 km/h (29 to 33 mph)

3

4 77 to 83 km/h (48 to 52 mph)

4

3 72 to 78 km/h (45 to 48 mph)

3

2 42 to 48 km/h (26 to 30 mph)

2

1 23 to 29 km/h (14 to 18 mph)

Throttle valve fully open

(Failure)

1

3 29 to 36 km/h (18 to 22 mph)

3

4 77 to 83 km/h (48 to 52 mph)

4

3 72 to 78 km/h (45 to 48 mph)

3

1 23 to 29 km/h (14 to 18 mph)

Page 220 of 3000

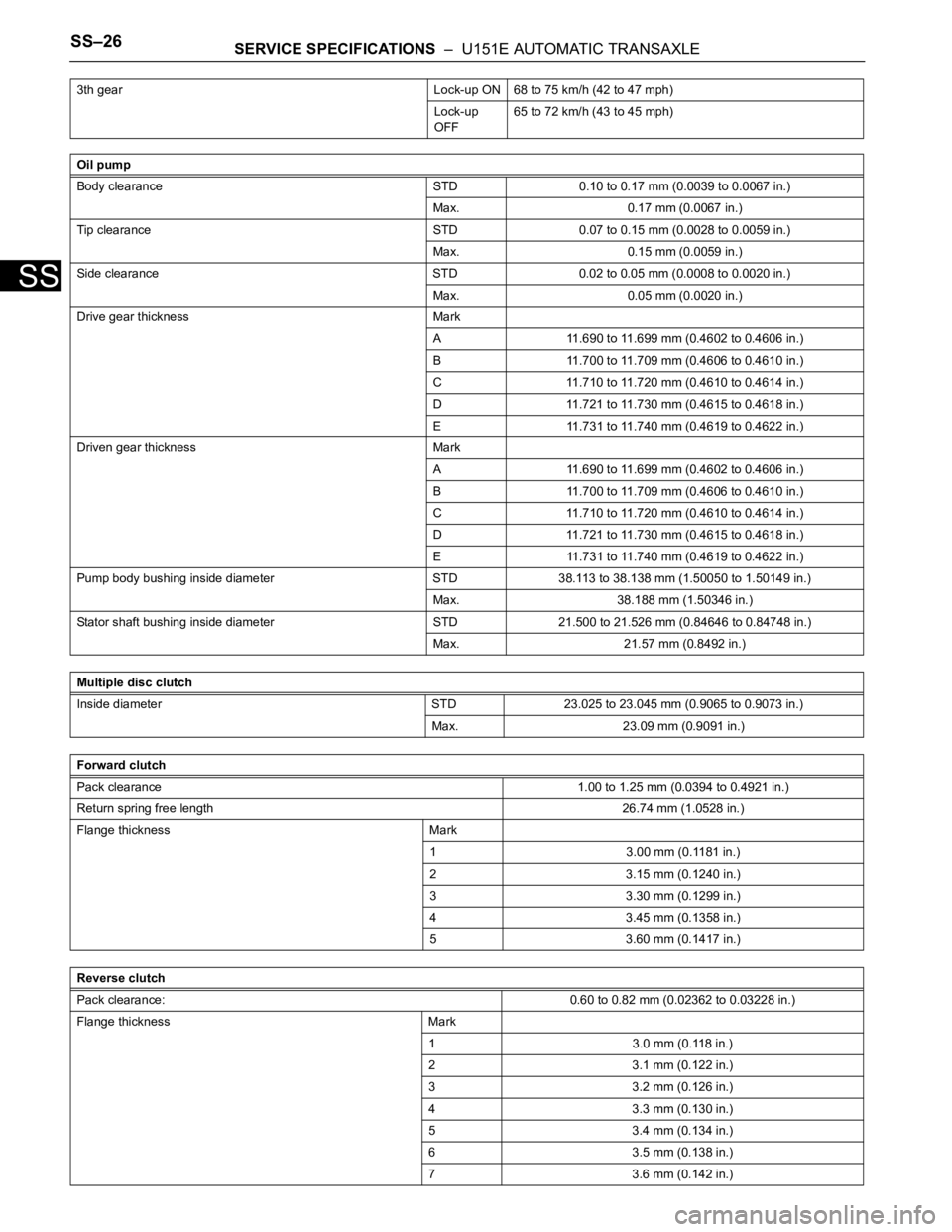

SS–26SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

3th gear Lock-up ON 68 to 75 km/h (42 to 47 mph)

Lock-up

OFF65 to 72 km/h (43 to 45 mph)

Oil pump

Body clearance STD 0.10 to 0.17 mm (0.0039 to 0.0067 in.)

Max. 0.17 mm (0.0067 in.)

Tip clearance STD 0.07 to 0.15 mm (0.0028 to 0.0059 in.)

Max. 0.15 mm (0.0059 in.)

Side clearance STD 0.02 to 0.05 mm (0.0008 to 0.0020 in.)

Max. 0.05 mm (0.0020 in.)

Drive gear thickness Mark

A 11.690 to 11.699 mm (0.4602 to 0.4606 in.)

B 11.700 to 11.709 mm (0.4606 to 0.4610 in.)

C 11.710 to 11.720 mm (0.4610 to 0.4614 in.)

D 11.721 to 11.730 mm (0.4615 to 0.4618 in.)

E 11.731 to 11.740 mm (0.4619 to 0.4622 in.)

Driven gear thickness Mark

A 11.690 to 11.699 mm (0.4602 to 0.4606 in.)

B 11.700 to 11.709 mm (0.4606 to 0.4610 in.)

C 11.710 to 11.720 mm (0.4610 to 0.4614 in.)

D 11.721 to 11.730 mm (0.4615 to 0.4618 in.)

E 11.731 to 11.740 mm (0.4619 to 0.4622 in.)

Pump body bushing inside diameter STD 38.113 to 38.138 mm (1.50050 to 1.50149 in.)

Max. 38.188 mm (1.50346 in.)

Stator shaft bushing inside diameter STD 21.500 to 21.526 mm (0.84646 to 0.84748 in.)

Max. 21.57 mm (0.8492 in.)

Multiple disc clutch

Inside diameter STD 23.025 to 23.045 mm (0.9065 to 0.9073 in.)

Max. 23.09 mm (0.9091 in.)

Forward clutch

Pack clearance1.00 to 1.25 mm (0.0394 to 0.4921 in.)

Return spring free length26.74 mm (1.0528 in.)

Flange thickness Mark

1 3.00 mm (0.1181 in.)

2 3.15 mm (0.1240 in.)

3 3.30 mm (0.1299 in.)

4 3.45 mm (0.1358 in.)

5 3.60 mm (0.1417 in.)

Reverse clutch

Pack clearance:0.60 to 0.82 mm (0.02362 to 0.03228 in.)

Flange thickness Mark

1 3.0 mm (0.118 in.)

2 3.1 mm (0.122 in.)

3 3.2 mm (0.126 in.)

4 3.3 mm (0.130 in.)

5 3.4 mm (0.134 in.)

6 3.5 mm (0.138 in.)

7 3.6 mm (0.142 in.)

Page 224 of 3000

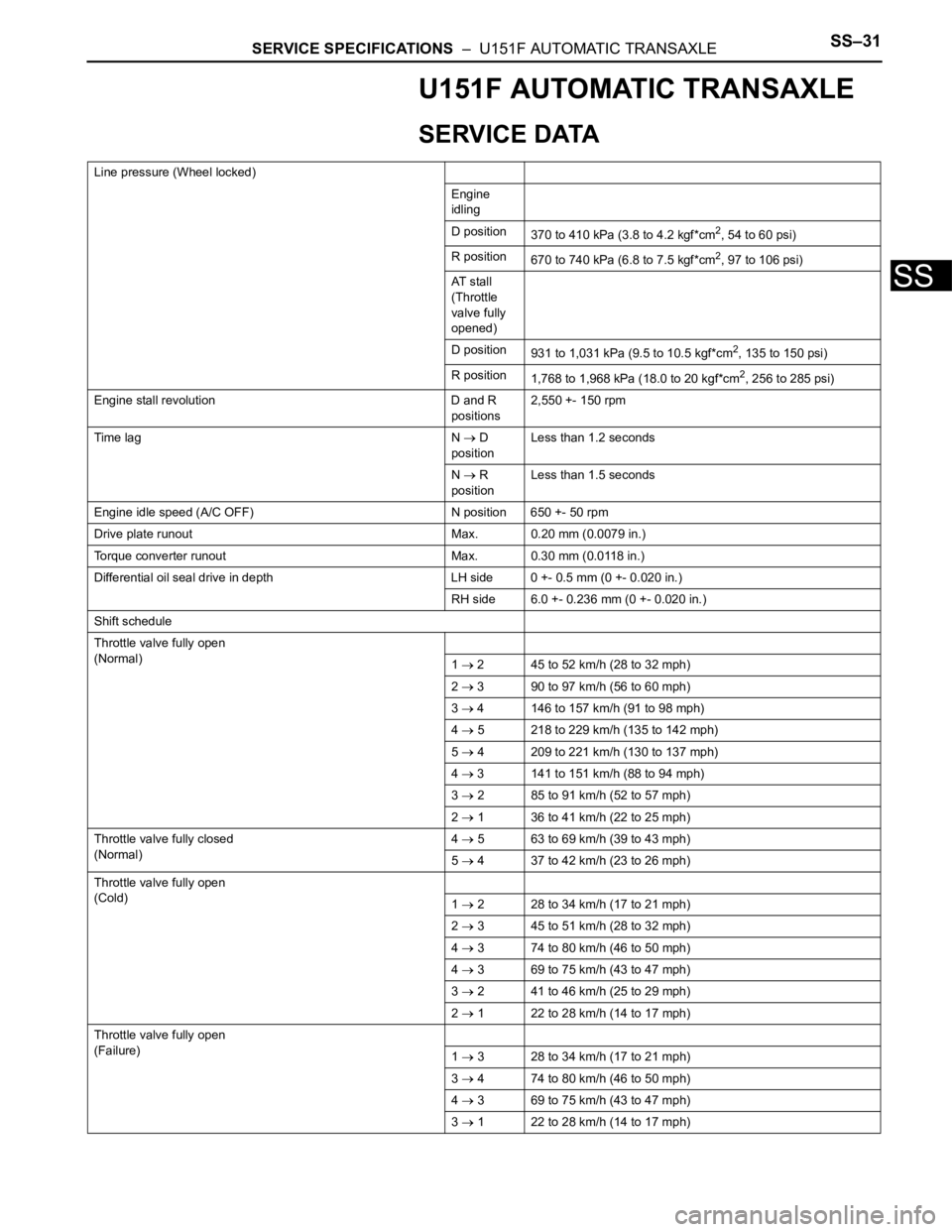

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSAXLESS–31

SS

U151F AUTOMATIC TRANSAXLE

SERVICE DATA

Line pressure (Wheel locked)

Engine

idling

D position

370 to 410 kPa (3.8 to 4.2 kgf*cm

2, 54 to 60 psi)

R position

670 to 740 kPa (6.8 to 7.5 kgf*cm

2, 97 to 106 psi)

AT s t a l l

(Throttle

valve fully

opened)

D position

931 to 1,031 kPa (9.5 to 10.5 kgf*cm

2, 135 to 150 psi)

R position

1,768 to 1,968 kPa (18.0 to 20 kgf*cm

2, 256 to 285 psi)

Engine stall revolution D and R

positions2,550 +- 150 rpm

Time lag N

D

positionLess than 1.2 seconds

N

R

positionLess than 1.5 seconds

Engine idle speed (A/C OFF) N position 650 +- 50 rpm

Drive plate runout Max. 0.20 mm (0.0079 in.)

Torque converter runout Max. 0.30 mm (0.0118 in.)

Differential oil seal drive in depth LH side 0 +- 0.5 mm (0 +- 0.020 in.)

RH side 6.0 +- 0.236 mm (0 +- 0.020 in.)

Shift schedule

Throttle valve fully open

(Normal)

1

2 45 to 52 km/h (28 to 32 mph)

2

3 90 to 97 km/h (56 to 60 mph)

3

4 146 to 157 km/h (91 to 98 mph)

4

5 218 to 229 km/h (135 to 142 mph)

5

4 209 to 221 km/h (130 to 137 mph)

4

3 141 to 151 km/h (88 to 94 mph)

3

2 85 to 91 km/h (52 to 57 mph)

2

1 36 to 41 km/h (22 to 25 mph)

Throttle valve fully closed

(Normal)4

5 63 to 69 km/h (39 to 43 mph)

5

4 37 to 42 km/h (23 to 26 mph)

Throttle valve fully open

(Cold)

1

2 28 to 34 km/h (17 to 21 mph)

2

3 45 to 51 km/h (28 to 32 mph)

4

3 74 to 80 km/h (46 to 50 mph)

4

3 69 to 75 km/h (43 to 47 mph)

3

2 41 to 46 km/h (25 to 29 mph)

2

1 22 to 28 km/h (14 to 17 mph)

Throttle valve fully open

(Failure)

1

3 28 to 34 km/h (17 to 21 mph)

3

4 74 to 80 km/h (46 to 50 mph)

4

3 69 to 75 km/h (43 to 47 mph)

3

1 22 to 28 km/h (14 to 17 mph)