engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 723 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–437

ES

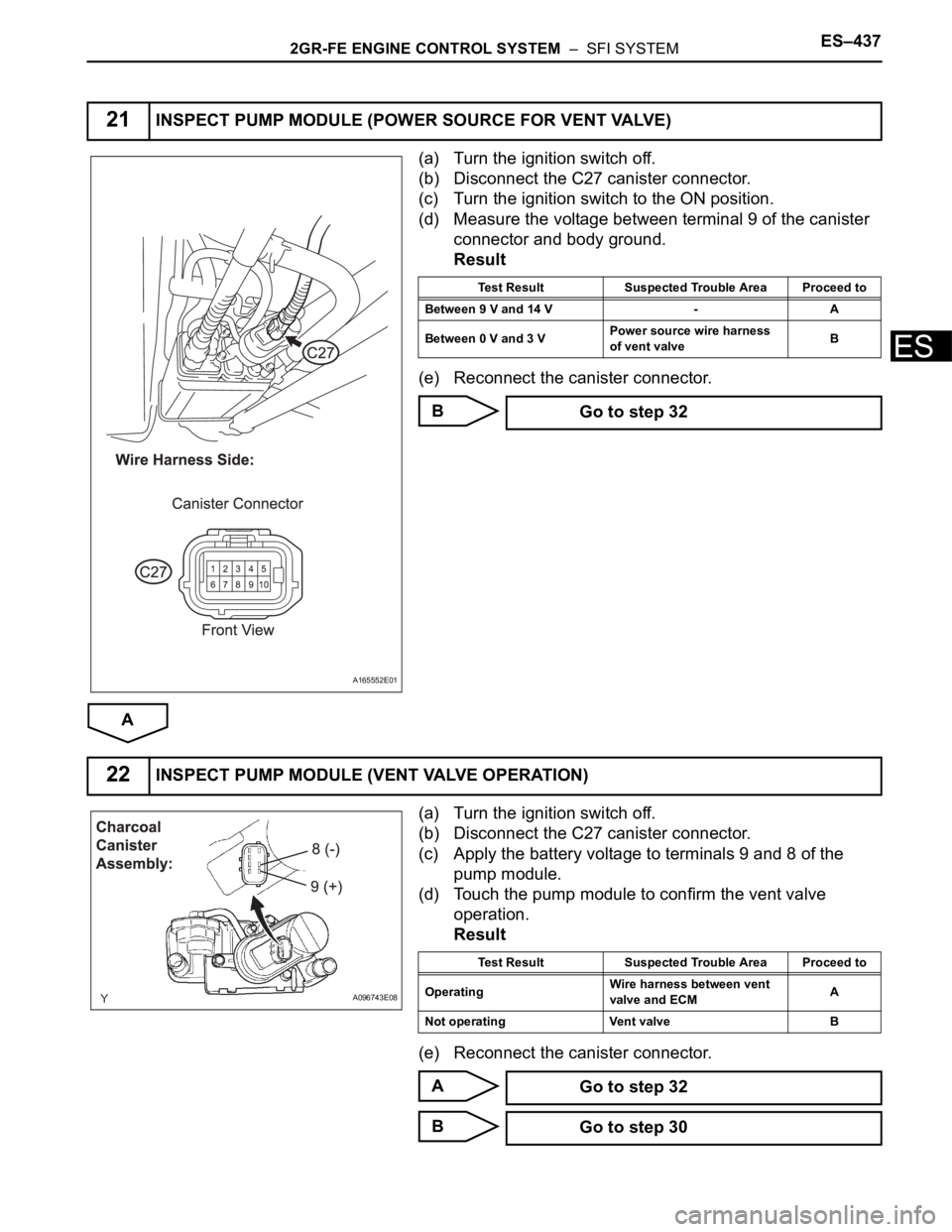

(a) Turn the ignition switch off.

(b) Disconnect the C27 canister connector.

(c) Turn the ignition switch to the ON position.

(d) Measure the voltage between terminal 9 of the canister

connector and body ground.

Result

(e) Reconnect the canister connector.

B

A

(a) Turn the ignition switch off.

(b) Disconnect the C27 canister connector.

(c) Apply the battery voltage to terminals 9 and 8 of the

pump module.

(d) Touch the pump module to confirm the vent valve

operation.

Result

(e) Reconnect the canister connector.

A

B

21INSPECT PUMP MODULE (POWER SOURCE FOR VENT VALVE)

A165552E01

Test Result Suspected Trouble Area Proceed to

Between 9 V and 14 V - A

Between 0 V and 3 VPower source wire harness

of vent valveB

Go to step 32

22INSPECT PUMP MODULE (VENT VALVE OPERATION)

A096743E08

Test Result Suspected Trouble Area Proceed to

OperatingWire harness between vent

valve and ECMA

Not operating Vent valve B

Go to step 32

Go to step 30

Page 724 of 3000

ES–4382GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

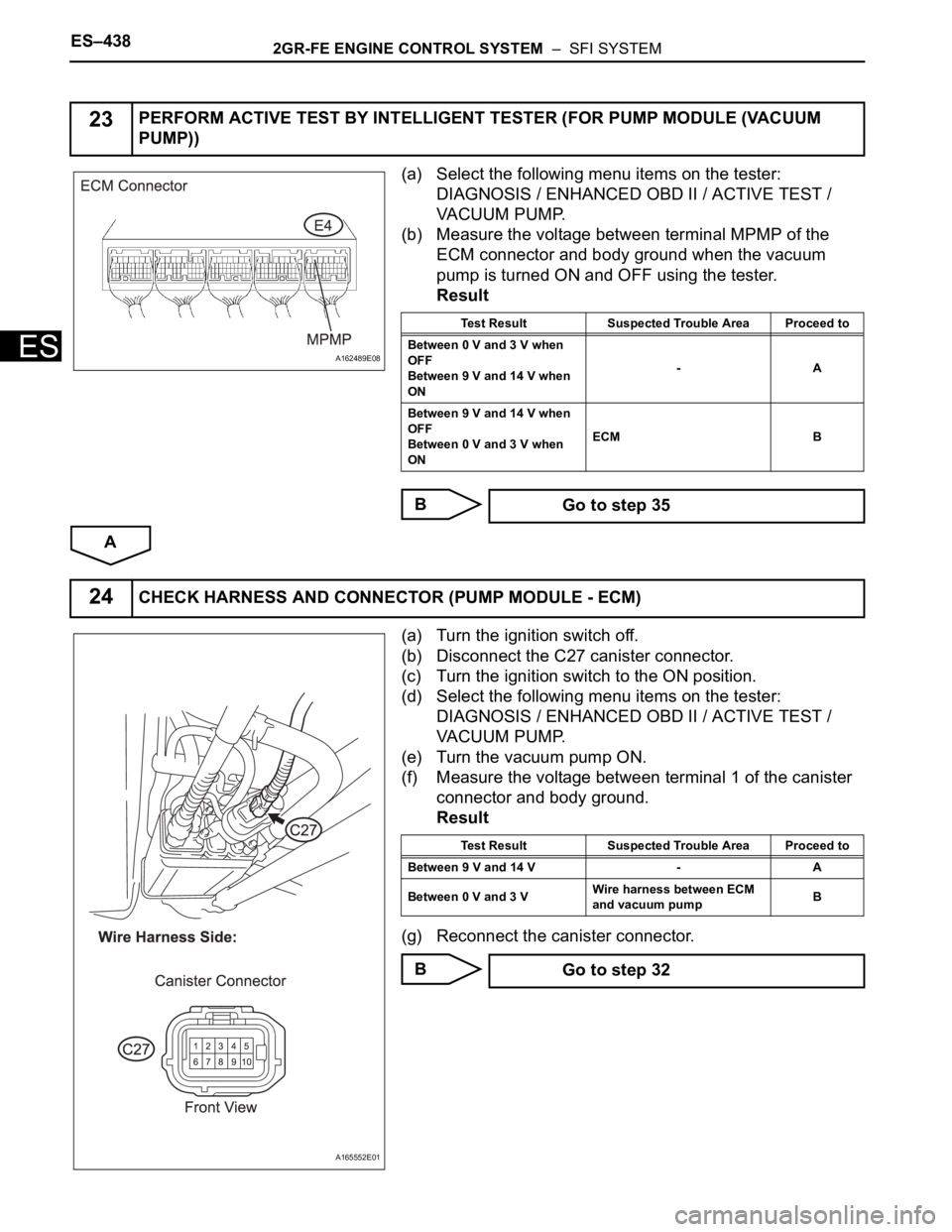

(a) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST /

VACUUM PUMP.

(b) Measure the voltage between terminal MPMP of the

ECM connector and body ground when the vacuum

pump is turned ON and OFF using the tester.

Result

B

A

(a) Turn the ignition switch off.

(b) Disconnect the C27 canister connector.

(c) Turn the ignition switch to the ON position.

(d) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST /

VACUUM PUMP.

(e) Turn the vacuum pump ON.

(f) Measure the voltage between terminal 1 of the canister

connector and body ground.

Result

(g) Reconnect the canister connector.

B

23PERFORM ACTIVE TEST BY INTELLIGENT TESTER (FOR PUMP MODULE (VACUUM

PUMP))

A162489E08

Test Result Suspected Trouble Area Proceed to

Between 0 V and 3 V when

OFF

Between 9 V and 14 V when

ON-A

Between 9 V and 14 V when

OFF

Between 0 V and 3 V when

ONECM B

Go to step 35

24CHECK HARNESS AND CONNECTOR (PUMP MODULE - ECM)

A165552E01

Test Result Suspected Trouble Area Proceed to

Between 9 V and 14 V - A

Between 0 V and 3 VWire harness between ECM

and vacuum pumpB

Go to step 32

Page 725 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–439

ES

A

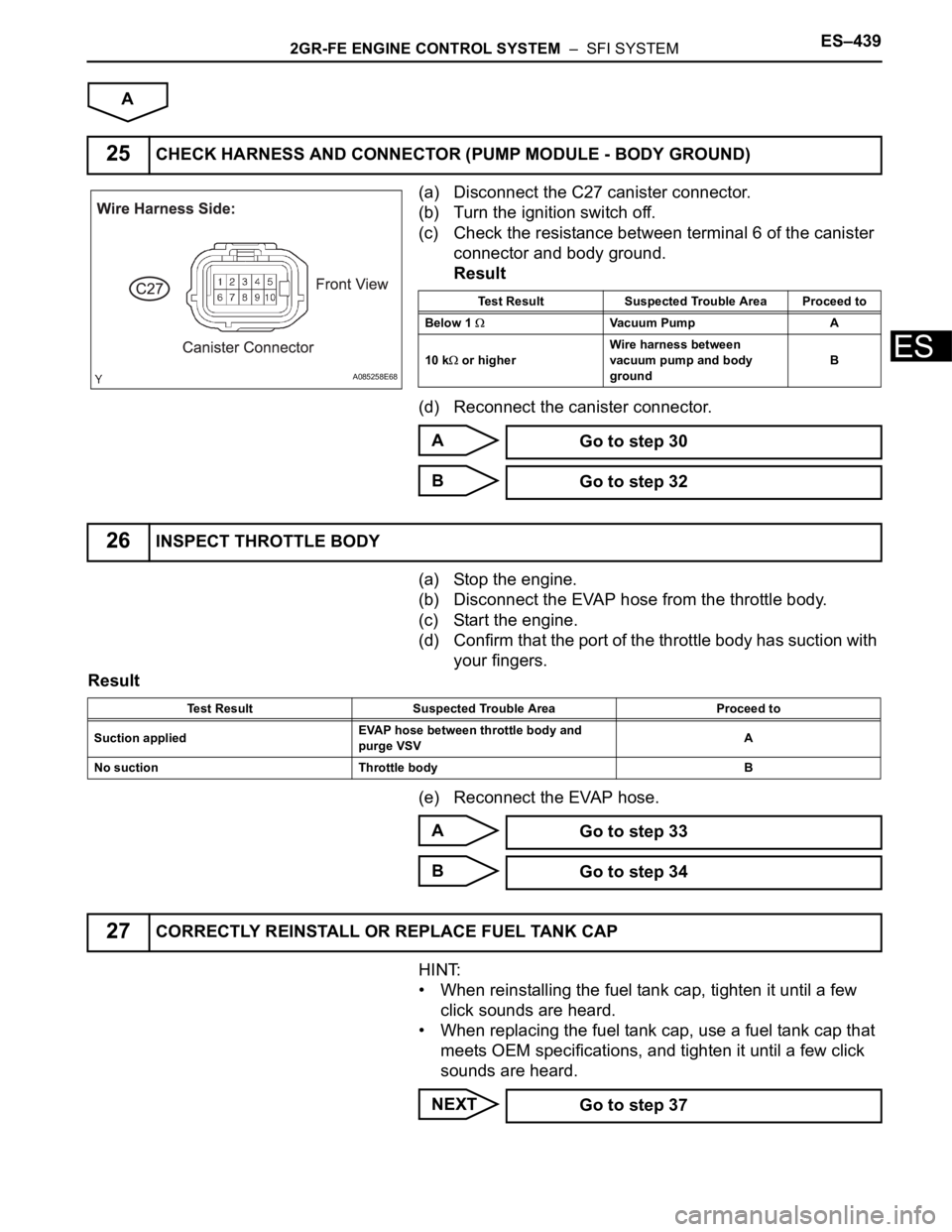

(a) Disconnect the C27 canister connector.

(b) Turn the ignition switch off.

(c) Check the resistance between terminal 6 of the canister

connector and body ground.

Result

(d) Reconnect the canister connector.

A

B

(a) Stop the engine.

(b) Disconnect the EVAP hose from the throttle body.

(c) Start the engine.

(d) Confirm that the port of the throttle body has suction with

your fingers.

Result

(e) Reconnect the EVAP hose.

A

B

HINT:

• When reinstalling the fuel tank cap, tighten it until a few

click sounds are heard.

• When replacing the fuel tank cap, use a fuel tank cap that

meets OEM specifications, and tighten it until a few click

sounds are heard.

NEXT

25CHECK HARNESS AND CONNECTOR (PUMP MODULE - BODY GROUND)

A085258E68

Test Result Suspected Trouble Area Proceed to

Below 1

Vacuum Pump A

10 k

or higherWire harness between

vacuum pump and body

groundB

Go to step 30

Go to step 32

26INSPECT THROTTLE BODY

Test Result Suspected Trouble Area Proceed to

Suction appliedEVAP hose between throttle body and

purge VSVA

No suction Throttle body B

Go to step 33

Go to step 34

27CORRECTLY REINSTALL OR REPLACE FUEL TANK CAP

Go to step 37

Page 726 of 3000

ES–4402GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

HINT:

When installing the fuel tank cap, tighten it until a few click

sounds are heard.

NEXT

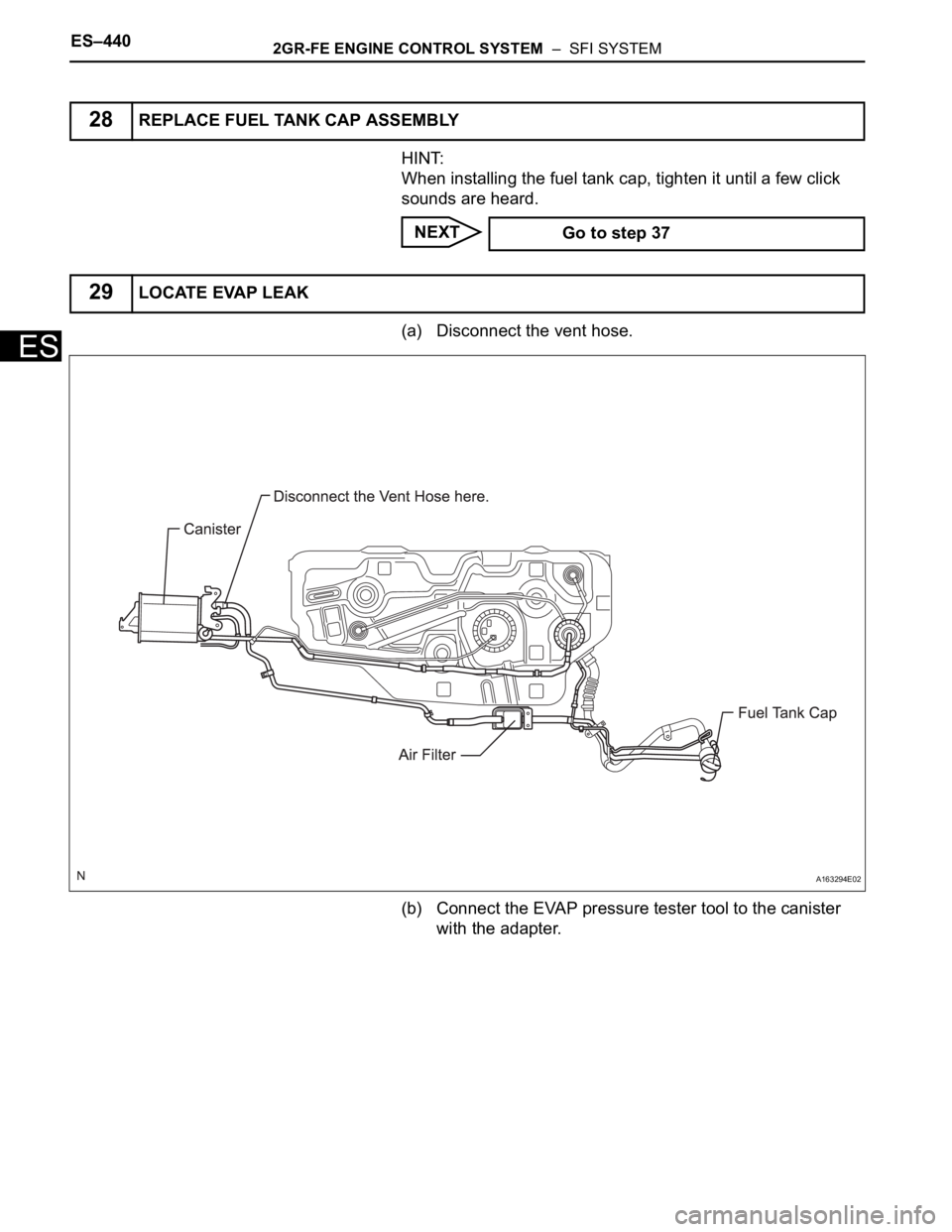

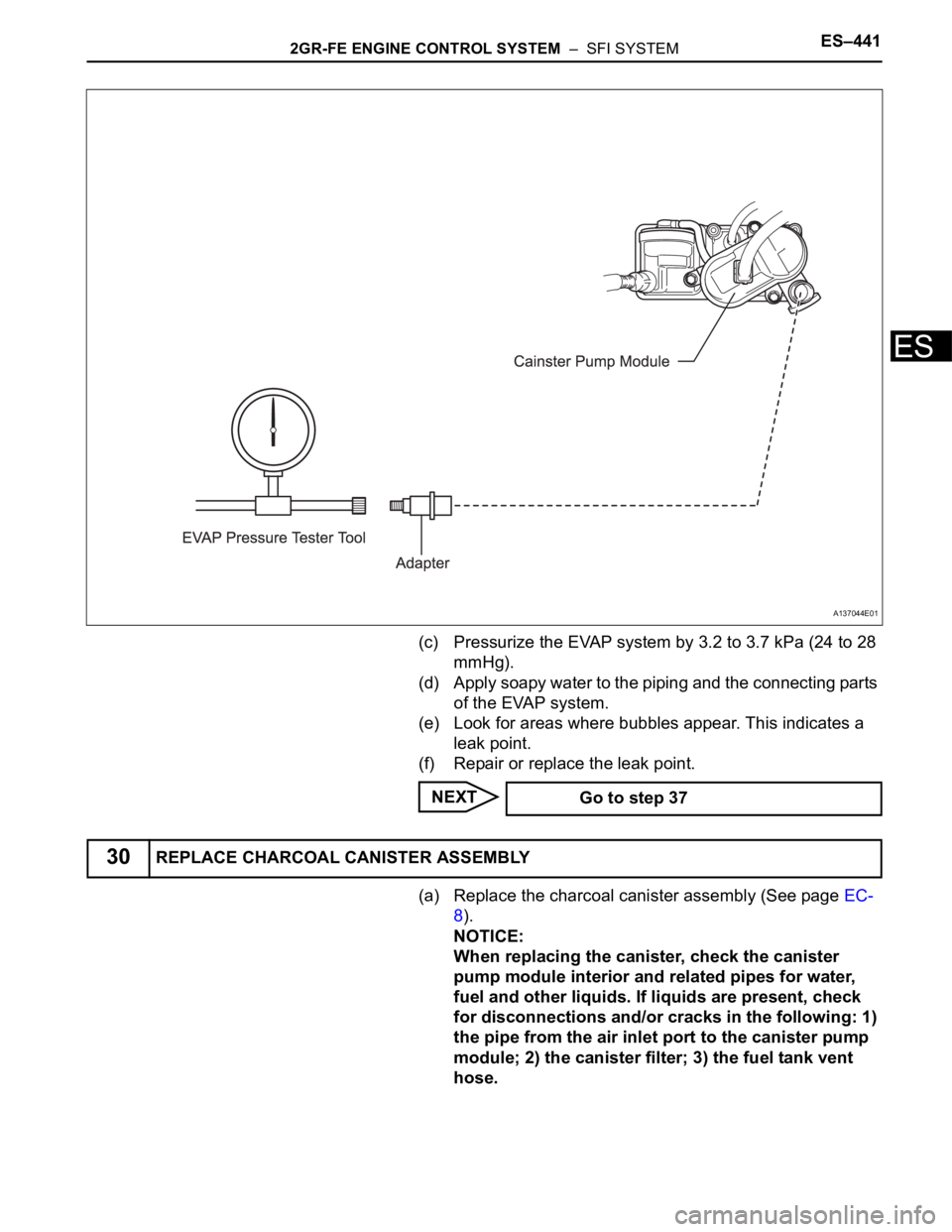

(a) Disconnect the vent hose.

(b) Connect the EVAP pressure tester tool to the canister

with the adapter.

28REPLACE FUEL TANK CAP ASSEMBLY

Go to step 37

29LOCATE EVAP LEAK

A163294E02

Page 727 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–441

ES

(c) Pressurize the EVAP system by 3.2 to 3.7 kPa (24 to 28

mmHg).

(d) Apply soapy water to the piping and the connecting parts

of the EVAP system.

(e) Look for areas where bubbles appear. This indicates a

leak point.

(f) Repair or replace the leak point.

NEXT

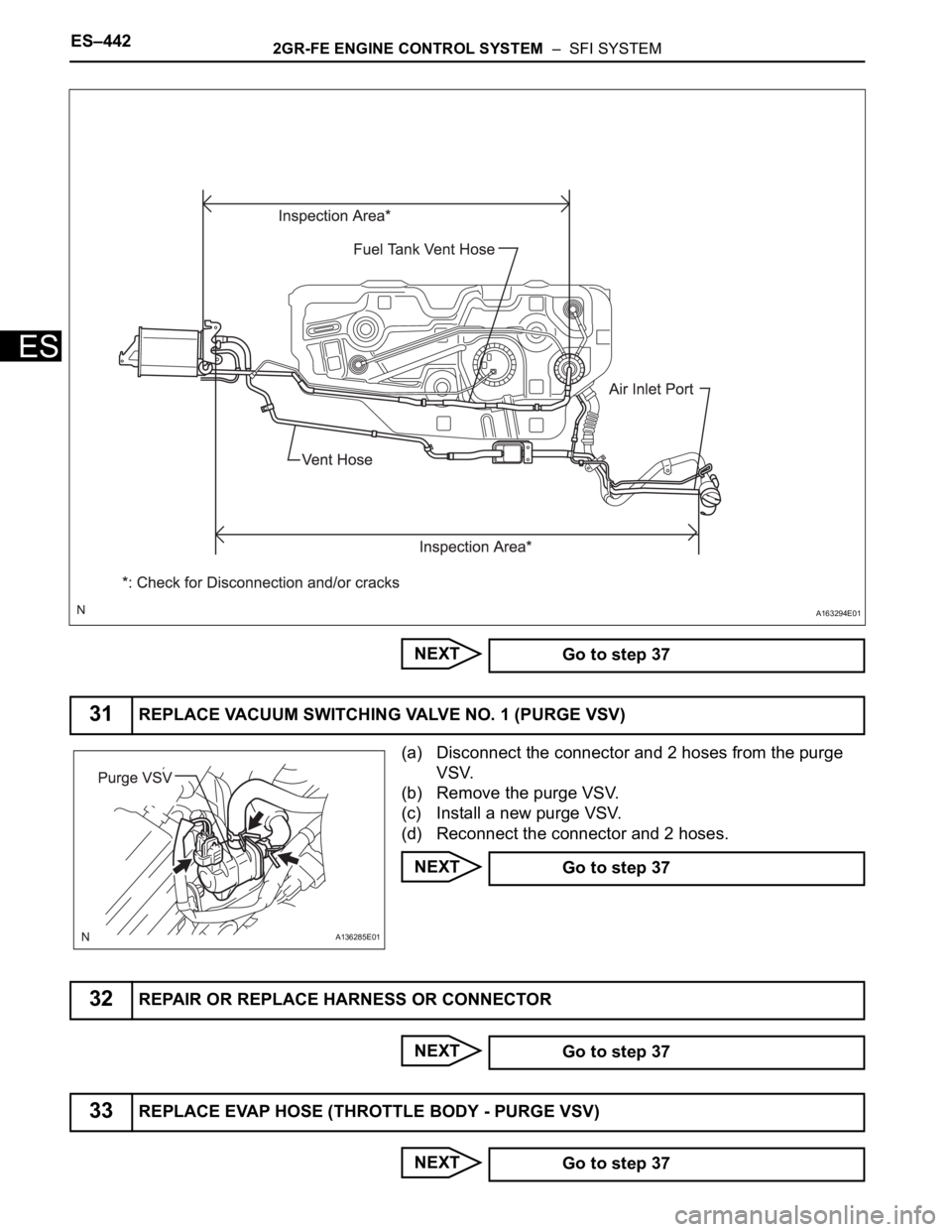

(a) Replace the charcoal canister assembly (See page EC-

8).

NOTICE:

When replacing the canister, check the canister

pump module interior and related pipes for water,

fuel and other liquids. If liquids are present, check

for disconnections and/or cracks in the following: 1)

the pipe from the air inlet port to the canister pump

module; 2) the canister filter; 3) the fuel tank vent

hose.

A137044E01

Go to step 37

30REPLACE CHARCOAL CANISTER ASSEMBLY

Page 728 of 3000

ES–4422GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NEXT

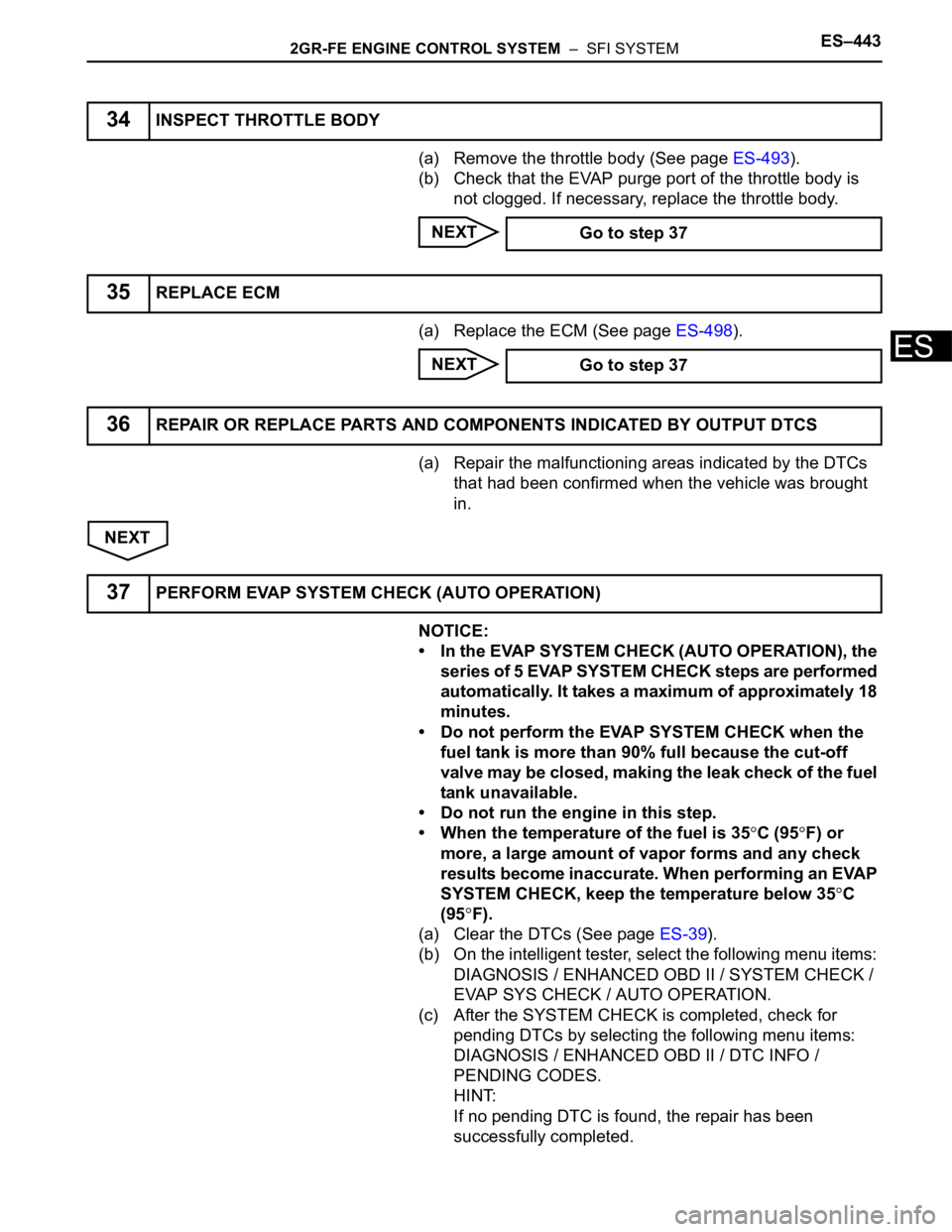

(a) Disconnect the connector and 2 hoses from the purge

VSV.

(b) Remove the purge VSV.

(c) Install a new purge VSV.

(d) Reconnect the connector and 2 hoses.

NEXT

NEXT

NEXT

A163294E01

Go to step 37

31REPLACE VACUUM SWITCHING VALVE NO. 1 (PURGE VSV)

A136285E01

Go to step 37

32REPAIR OR REPLACE HARNESS OR CONNECTOR

Go to step 37

33REPLACE EVAP HOSE (THROTTLE BODY - PURGE VSV)

Go to step 37

Page 729 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–443

ES

(a) Remove the throttle body (See page ES-493).

(b) Check that the EVAP purge port of the throttle body is

not clogged. If necessary, replace the throttle body.

NEXT

(a) Replace the ECM (See page ES-498).

NEXT

(a) Repair the malfunctioning areas indicated by the DTCs

that had been confirmed when the vehicle was brought

in.

NEXT

NOTICE:

• In the EVAP SYSTEM CHECK (AUTO OPERATION), the

series of 5 EVAP SYSTEM CHECK steps are performed

automatically. It takes a maximum of approximately 18

minutes.

• Do not perform the EVAP SYSTEM CHECK when the

fuel tank is more than 90% full because the cut-off

valve may be closed, making the leak check of the fuel

tank unavailable.

• Do not run the engine in this step.

• When the temperature of the fuel is 35

C (95F) or

more, a large amount of vapor forms and any check

results become inaccurate. When performing an EVAP

SYSTEM CHECK, keep the temperature below 35

C

(95

F).

(a) Clear the DTCs (See page ES-39).

(b) On the intelligent tester, select the following menu items:

DIAGNOSIS / ENHANCED OBD II / SYSTEM CHECK /

EVAP SYS CHECK / AUTO OPERATION.

(c) After the SYSTEM CHECK is completed, check for

pending DTCs by selecting the following menu items:

DIAGNOSIS / ENHANCED OBD II / DTC INFO /

PENDING CODES.

HINT:

If no pending DTC is found, the repair has been

successfully completed.

34INSPECT THROTTLE BODY

Go to step 37

35REPLACE ECM

Go to step 37

36REPAIR OR REPLACE PARTS AND COMPONENTS INDICATED BY OUTPUT DTCS

37PERFORM EVAP SYSTEM CHECK (AUTO OPERATION)

Page 730 of 3000

ES–4442GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

NEXT

COMPLETED

Page 731 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–445

ES

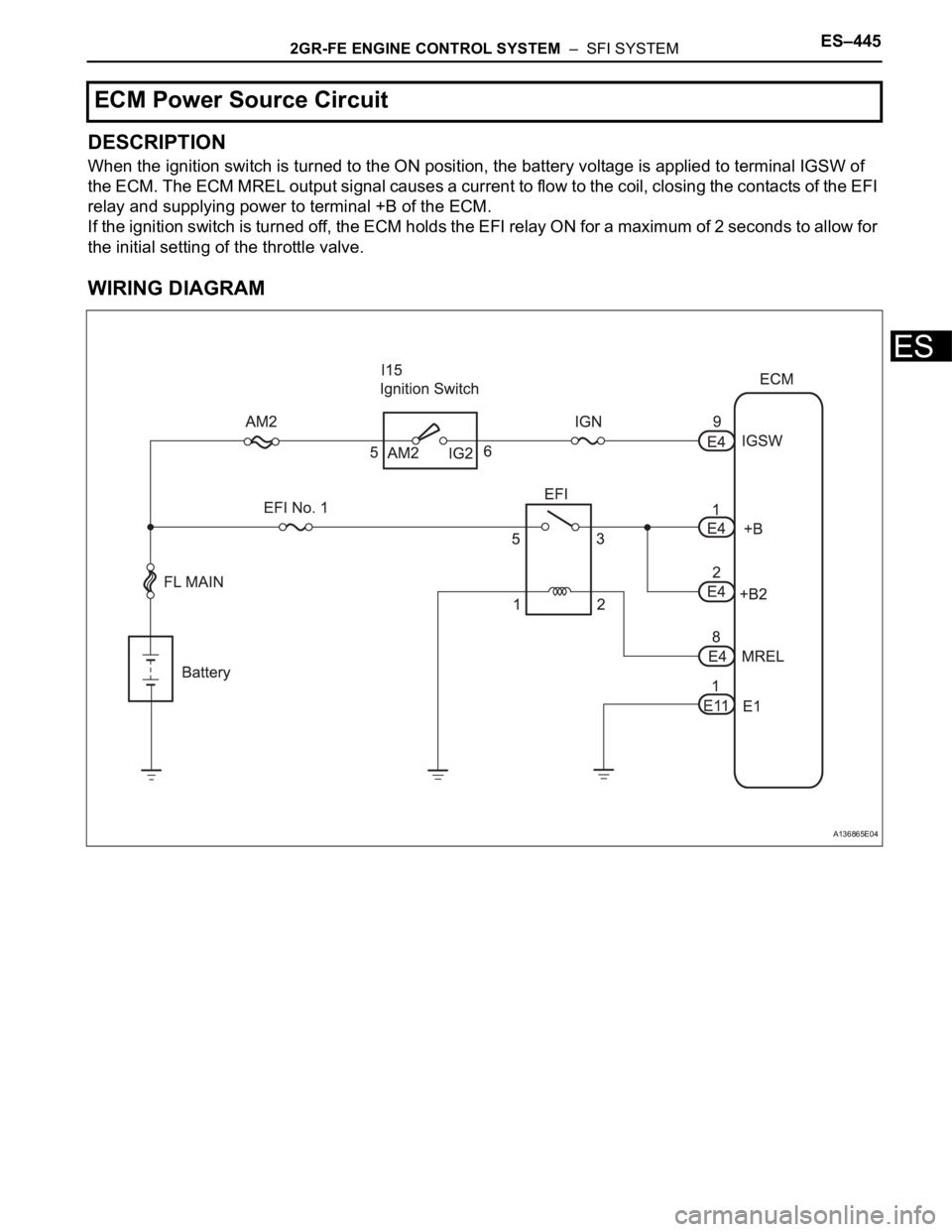

DESCRIPTION

When the ignition switch is turned to the ON position, the battery voltage is applied to terminal IGSW of

the ECM. The ECM MREL output signal causes a current to flow to the coil, closing the contacts of the EFI

relay and supplying power to terminal +B of the ECM.

If the ignition switch is turned off, the ECM holds the EFI relay ON for a maximum of 2 seconds to allow for

the initial setting of the throttle valve.

WIRING DIAGRAM

ECM Power Source Circuit

A136865E04

Page 732 of 3000

ES–4462GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

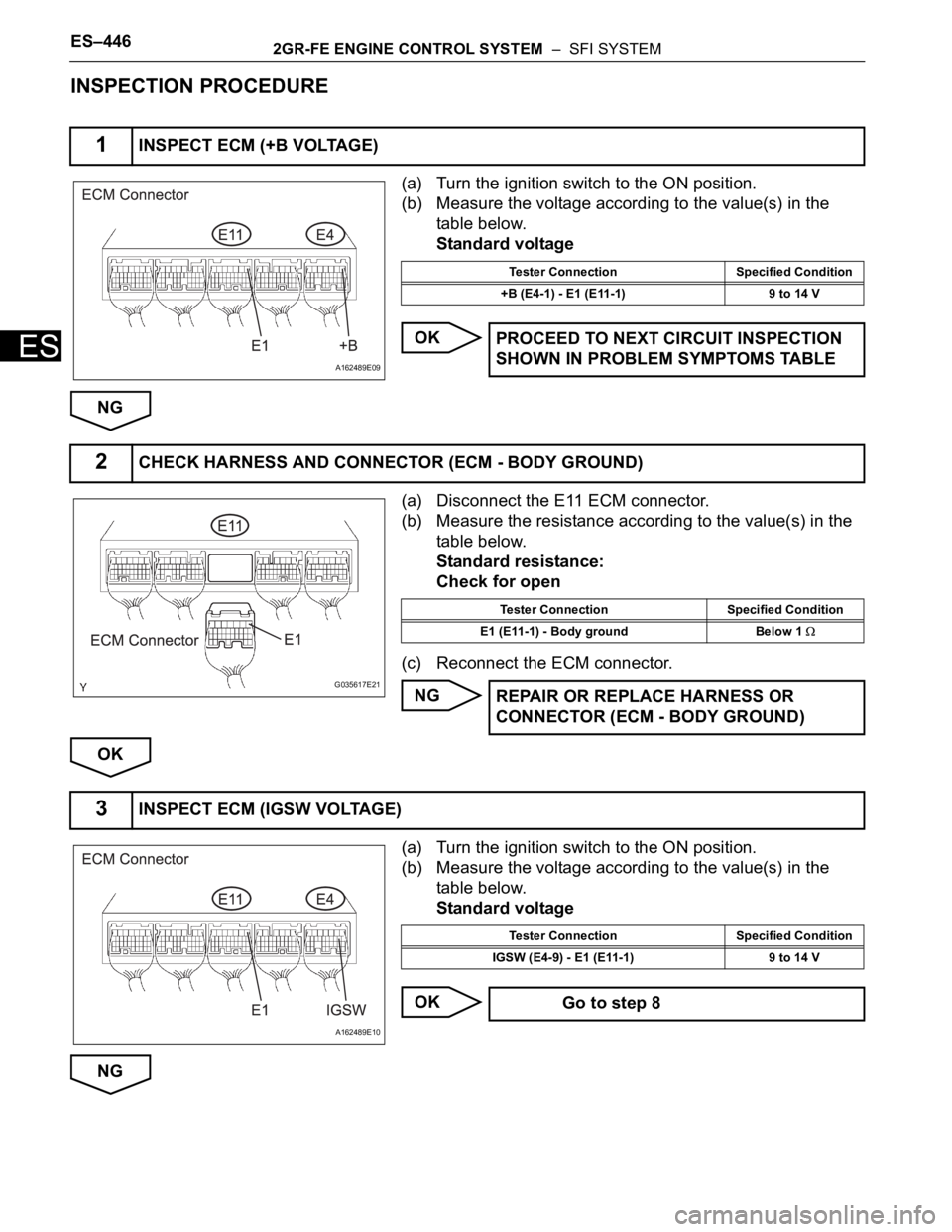

INSPECTION PROCEDURE

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

OK

NG

(a) Disconnect the E11 ECM connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Check for open

(c) Reconnect the ECM connector.

NG

OK

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

OK

NG

1INSPECT ECM (+B VOLTAGE)

A162489E09

Tester Connection Specified Condition

+B (E4-1) - E1 (E11-1) 9 to 14 V

PROCEED TO NEXT CIRCUIT INSPECTION

SHOWN IN PROBLEM SYMPTOMS TABLE

2CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND)

G035617E21

Tester Connection Specified Condition

E1 (E11-1) - Body ground Below 1

REPAIR OR REPLACE HARNESS OR

CONNECTOR (ECM - BODY GROUND)

3INSPECT ECM (IGSW VOLTAGE)

A162489E10

Tester Connection Specified Condition

IGSW (E4-9) - E1 (E11-1) 9 to 14 V

Go to step 8