airbag TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 50 of 3000

IN–38INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

HINT:

• In troubleshooting, confirm that the problem symptoms

have been accurately identified. Preconceptions should be

discarded in order to make an accurate judgment. To

clearly understand what the problem symptoms are, it is

extremely important to ask the customer about the

problem and the conditions at the time the malfunction

occurred.

• Gather as much information as possible for reference.

Past problems that seem unrelated may also help in some

cases.

• The following 5 items are important points in the problem

analysis:

3. SYMPTOM CONFIRMATION AND DIAGNOSTIC

TROUBLE CODE

HINT:

The diagnostic system in the SIENNA has various

functions.

• The first function is the Diagnostic Trouble Code

(DTC) check. A DTC is a code stored in the ECU

memory whenever a malfunction in the signal circuits

to the ECU occurs. In a DTC check, a previous

malfunction's DTC can be checked by a technician

during troubleshooting.

• Another function is the Input Signal Check, which

checks if the signals from various switches are sent to

the ECU correctly.

By using these functions, the problem areas can be

narrowed down and troubleshooting is more effective.

Diagnostic functions are incorporated in the following

system in the SIENNA.

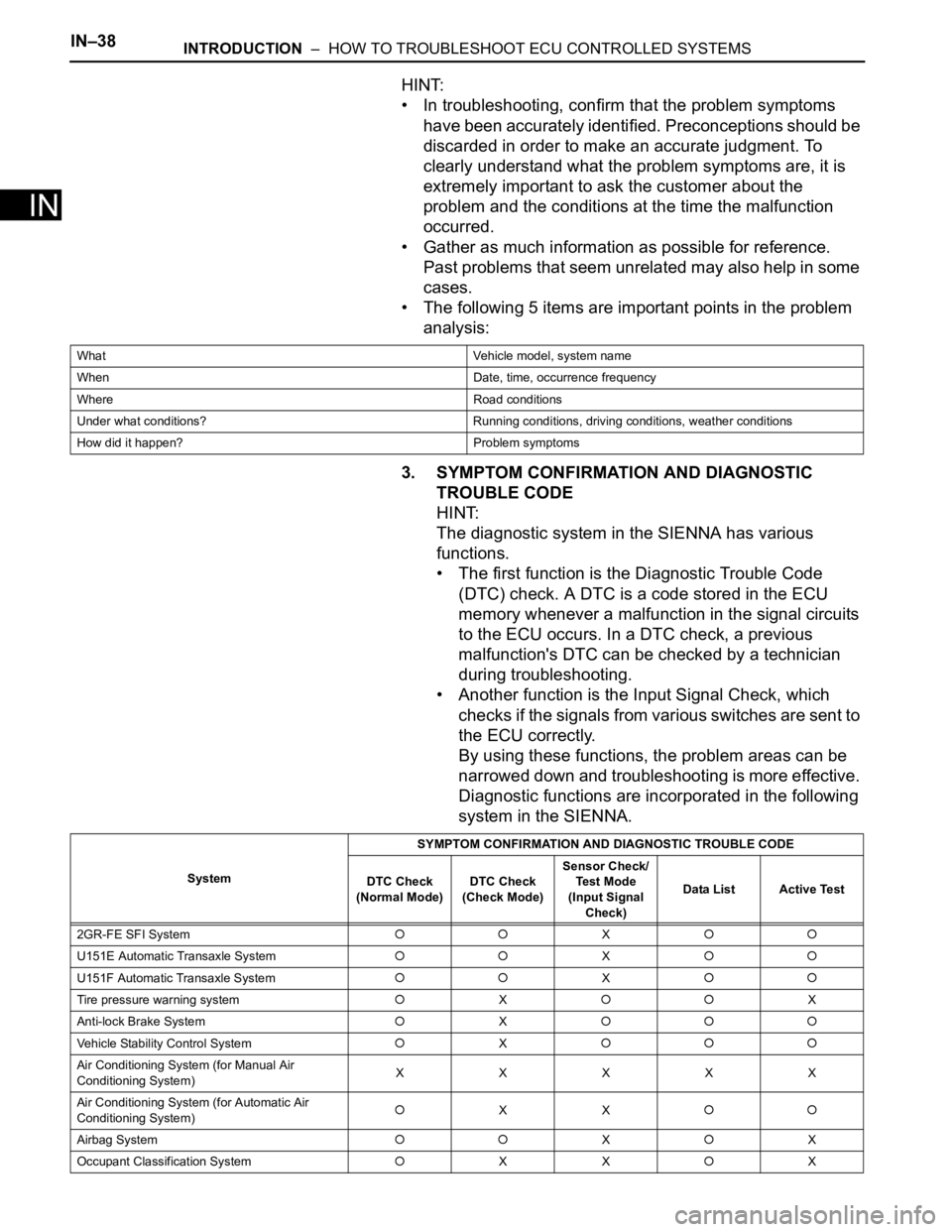

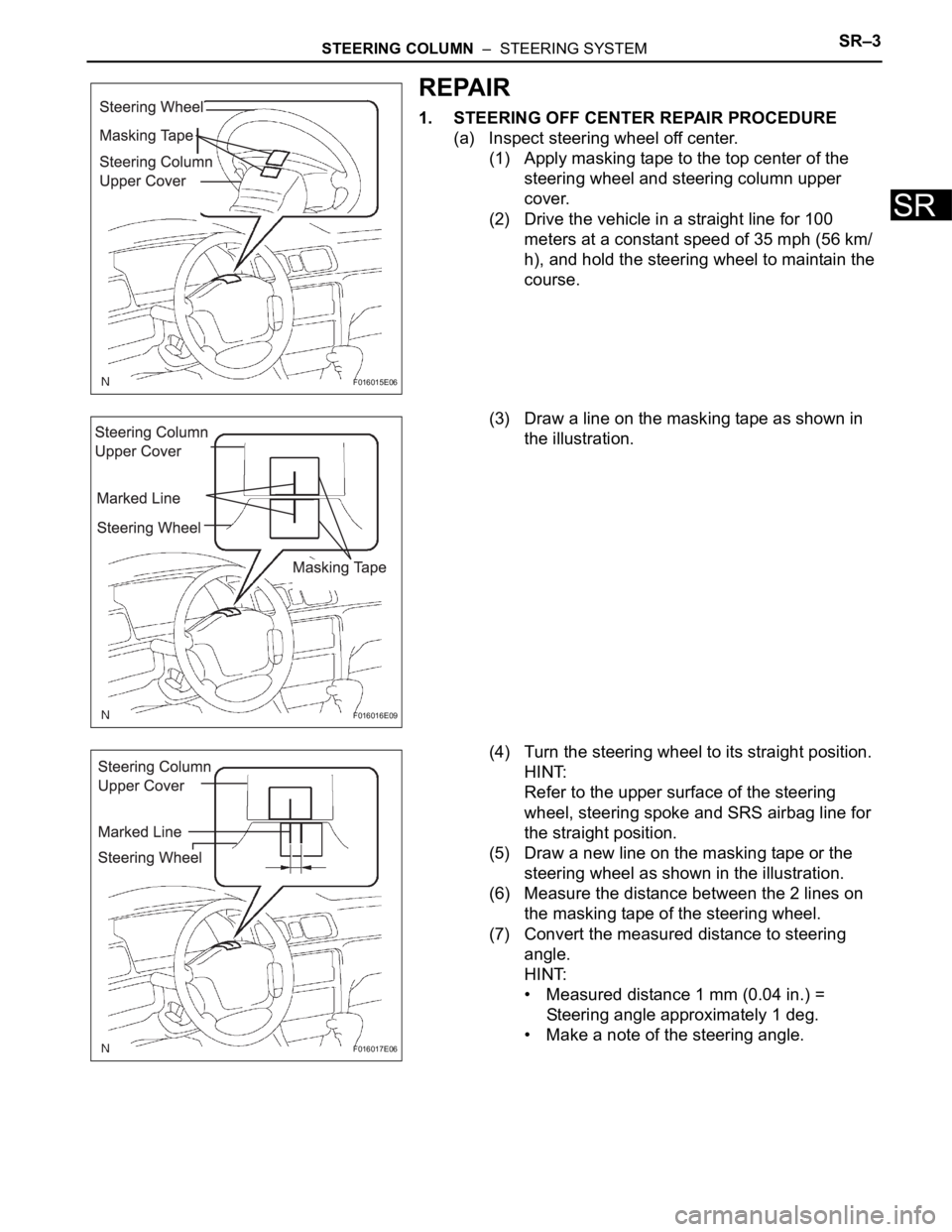

What Vehicle model, system name

When Date, time, occurrence frequency

Where Road conditions

Under what conditions? Running conditions, driving conditions, weather conditions

How did it happen? Problem symptoms

SystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

2GR-FE SFI System

X

U151E Automatic Transaxle SystemX

U151F Automatic Transaxle SystemX

Tire pressure warning systemXX

Anti-lock Brake System

X

Vehicle Stability Control SystemX

Air Conditioning System (for Manual Air

Conditioning System)XXXXX

Air Conditioning System (for Automatic Air

Conditioning System)

XX

Airbag SystemXX

Occupant Classification System

XXX

Page 68 of 3000

IN–38INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

HINT:

• In troubleshooting, confirm that the problem symptoms

have been accurately identified. Preconceptions should be

discarded in order to make an accurate judgment. To

clearly understand what the problem symptoms are, it is

extremely important to ask the customer about the

problem and the conditions at the time the malfunction

occurred.

• Gather as much information as possible for reference.

Past problems that seem unrelated may also help in some

cases.

• The following 5 items are important points in the problem

analysis:

3. SYMPTOM CONFIRMATION AND DIAGNOSTIC

TROUBLE CODE

HINT:

The diagnostic system in the SIENNA has various

functions.

• The first function is the Diagnostic Trouble Code

(DTC) check. A DTC is a code stored in the ECU

memory whenever a malfunction in the signal circuits

to the ECU occurs. In a DTC check, a previous

malfunction's DTC can be checked by a technician

during troubleshooting.

• Another function is the Input Signal Check, which

checks if the signals from various switches are sent to

the ECU correctly.

By using these functions, the problem areas can be

narrowed down and troubleshooting is more effective.

Diagnostic functions are incorporated in the following

system in the SIENNA.

What Vehicle model, system name

When Date, time, occurrence frequency

Where Road conditions

Under what conditions? Running conditions, driving conditions, weather conditions

How did it happen? Problem symptoms

SystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

2GR-FE SFI System

X

U151E Automatic Transaxle SystemX

U151F Automatic Transaxle SystemX

Tire pressure warning systemXX

Anti-lock Brake System

X

Vehicle Stability Control SystemX

Air Conditioning System (for Manual Air

Conditioning System)XXXXX

Air Conditioning System (for Automatic Air

Conditioning System)

XX

Airbag SystemXX

Occupant Classification System

XXX

Page 157 of 3000

PREPARATION – SUPPLEMENTAL RESTRAINT SYSTEMPP–67

PP

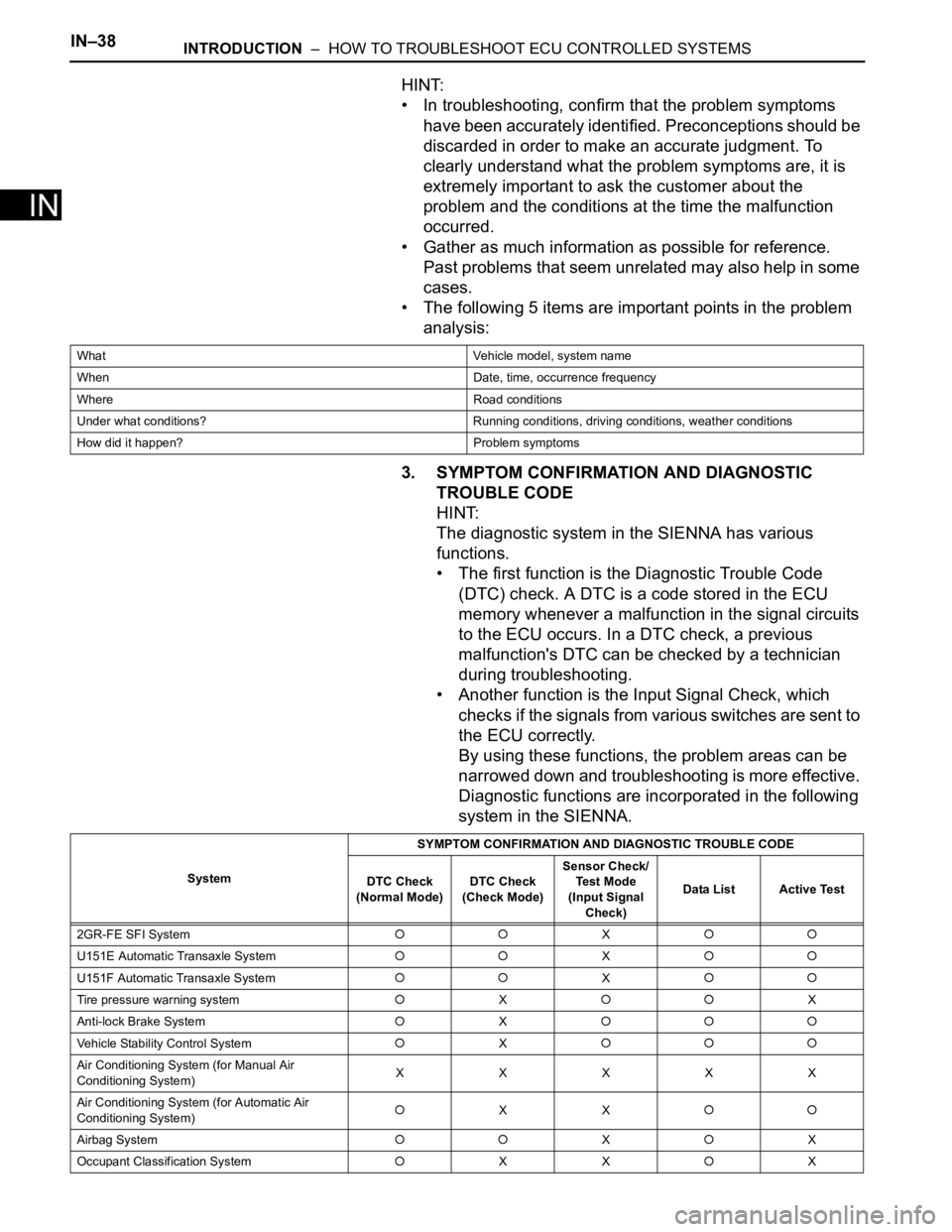

EQUIPMENT

Torque wrench

Feeler gauge

Bolt

Length: 35.0 mm (1.378 in.)

Diameter: 6.0mm (0.236 in.)

Pitch: 1.0 mm (0.039 in.)Airbag disposal

Tire

Width: 185mm (7.28 in.)

Inner diameter: 360mm (14.17 in.)Airbag disposal

Tire with disc wheel

Width: 185 mm (7.28 in.)

Inner diameter: 360mm (14.17 in.)Airbag disposal

Plastic bag Airbag disposal

Page 189 of 3000

STEERING COLUMN – STEERING SYSTEMSR–3

SR

REPAIR

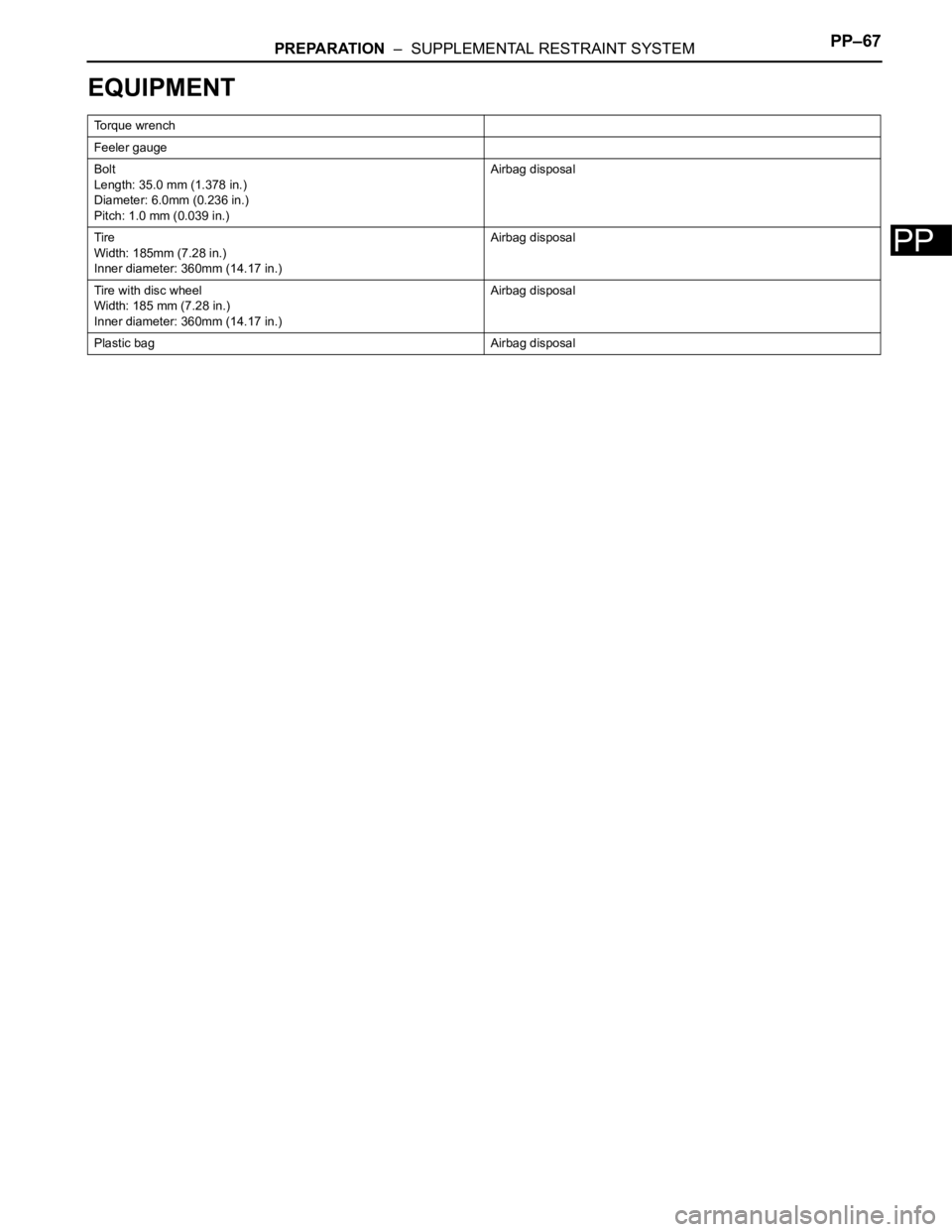

1. STEERING OFF CENTER REPAIR PROCEDURE

(a) Inspect steering wheel off center.

(1) Apply masking tape to the top center of the

steering wheel and steering column upper

cover.

(2) Drive the vehicle in a straight line for 100

meters at a constant speed of 35 mph (56 km/

h), and hold the steering wheel to maintain the

course.

(3) Draw a line on the masking tape as shown in

the illustration.

(4) Turn the steering wheel to its straight position.

HINT:

Refer to the upper surface of the steering

wheel, steering spoke and SRS airbag line for

the straight position.

(5) Draw a new line on the masking tape or the

steering wheel as shown in the illustration.

(6) Measure the distance between the 2 lines on

the masking tape of the steering wheel.

(7) Convert the measured distance to steering

angle.

HINT:

• Measured distance 1 mm (0.04 in.) =

Steering angle approximately 1 deg.

• Make a note of the steering angle.

F016015E06

F016016E09

F016017E06

Page 230 of 3000

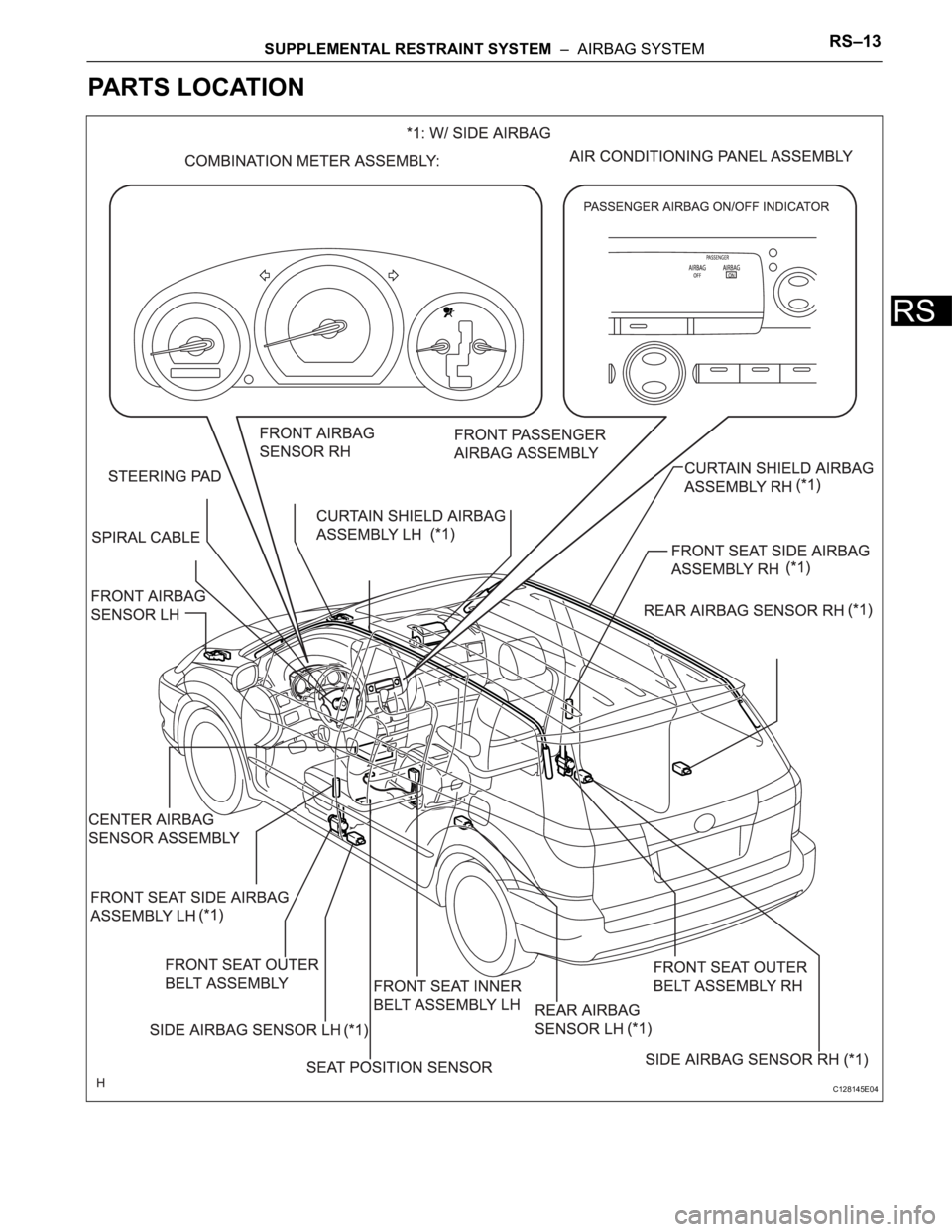

SUPPLEMENTAL RESTRAINT SYSTEM – AIRBAG SYSTEMRS–13

RS

PARTS LOCATION

C128145E04

Page 231 of 3000

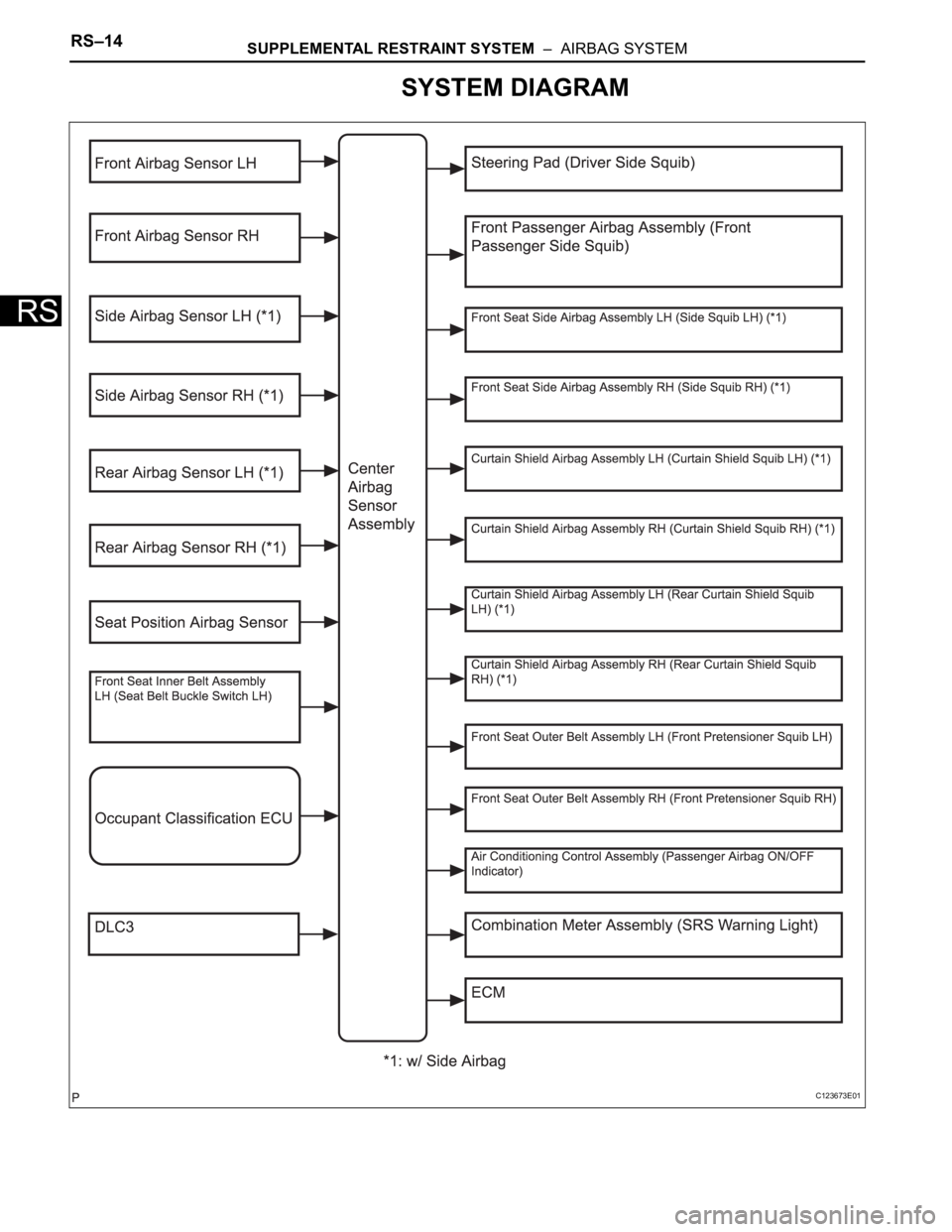

RS–14SUPPLEMENTAL RESTRAINT SYSTEM – AIRBAG SYSTEM

RS

SYSTEM DIAGRAM

C123673E01

Page 232 of 3000

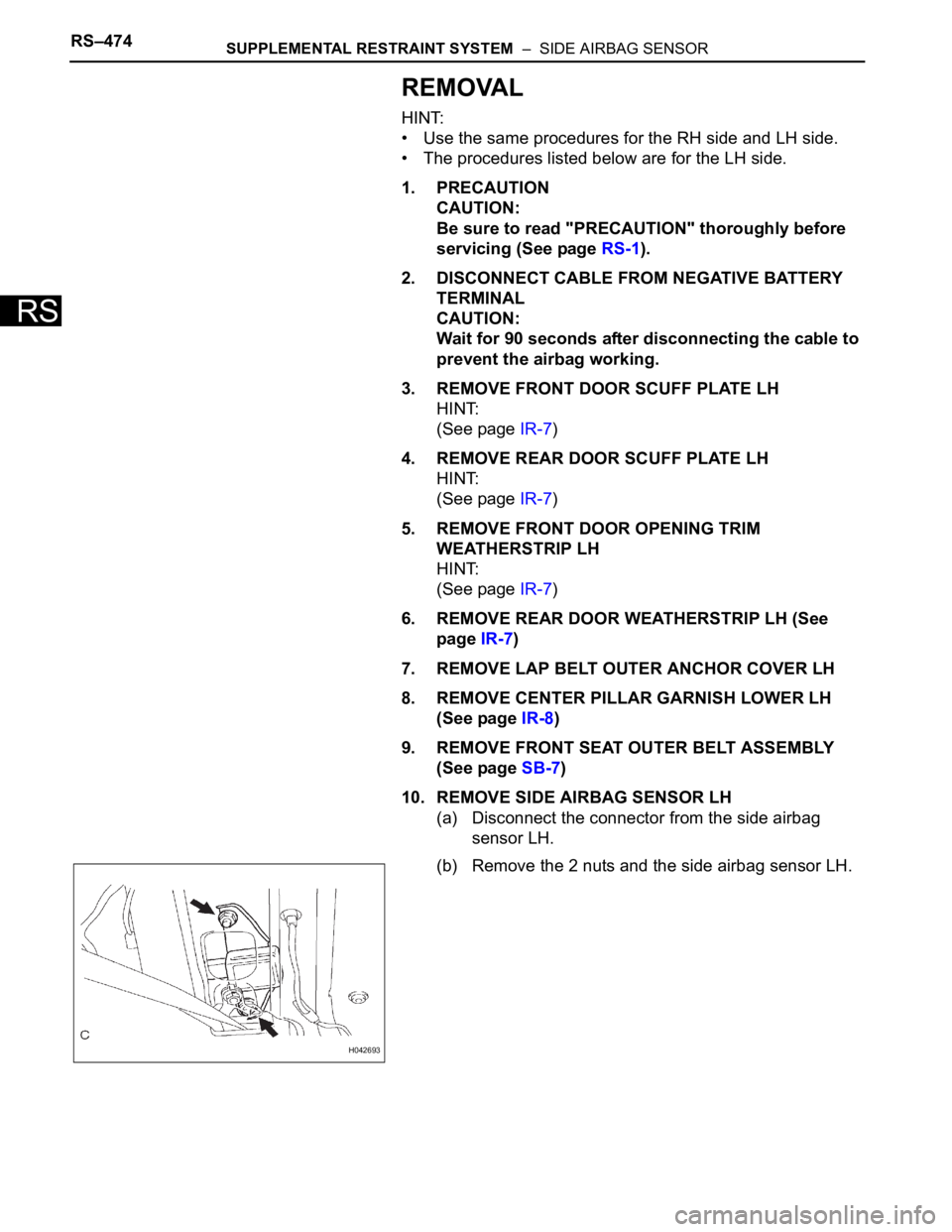

RS–474SUPPLEMENTAL RESTRAINT SYSTEM – SIDE AIRBAG SENSOR

RS

REMOVAL

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. PRECAUTION

CAUTION:

Be sure to read "PRECAUTION" thoroughly before

servicing (See page RS-1).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. REMOVE FRONT DOOR SCUFF PLATE LH

HINT:

(See page IR-7)

4. REMOVE REAR DOOR SCUFF PLATE LH

HINT:

(See page IR-7)

5. REMOVE FRONT DOOR OPENING TRIM

WEATHERSTRIP LH

HINT:

(See page IR-7)

6. REMOVE REAR DOOR WEATHERSTRIP LH (See

page IR-7)

7. REMOVE LAP BELT OUTER ANCHOR COVER LH

8. REMOVE CENTER PILLAR GARNISH LOWER LH

(See page IR-8)

9. REMOVE FRONT SEAT OUTER BELT ASSEMBLY

(See page SB-7)

10. REMOVE SIDE AIRBAG SENSOR LH

(a) Disconnect the connector from the side airbag

sensor LH.

(b) Remove the 2 nuts and the side airbag sensor LH.

H042693

Page 233 of 3000

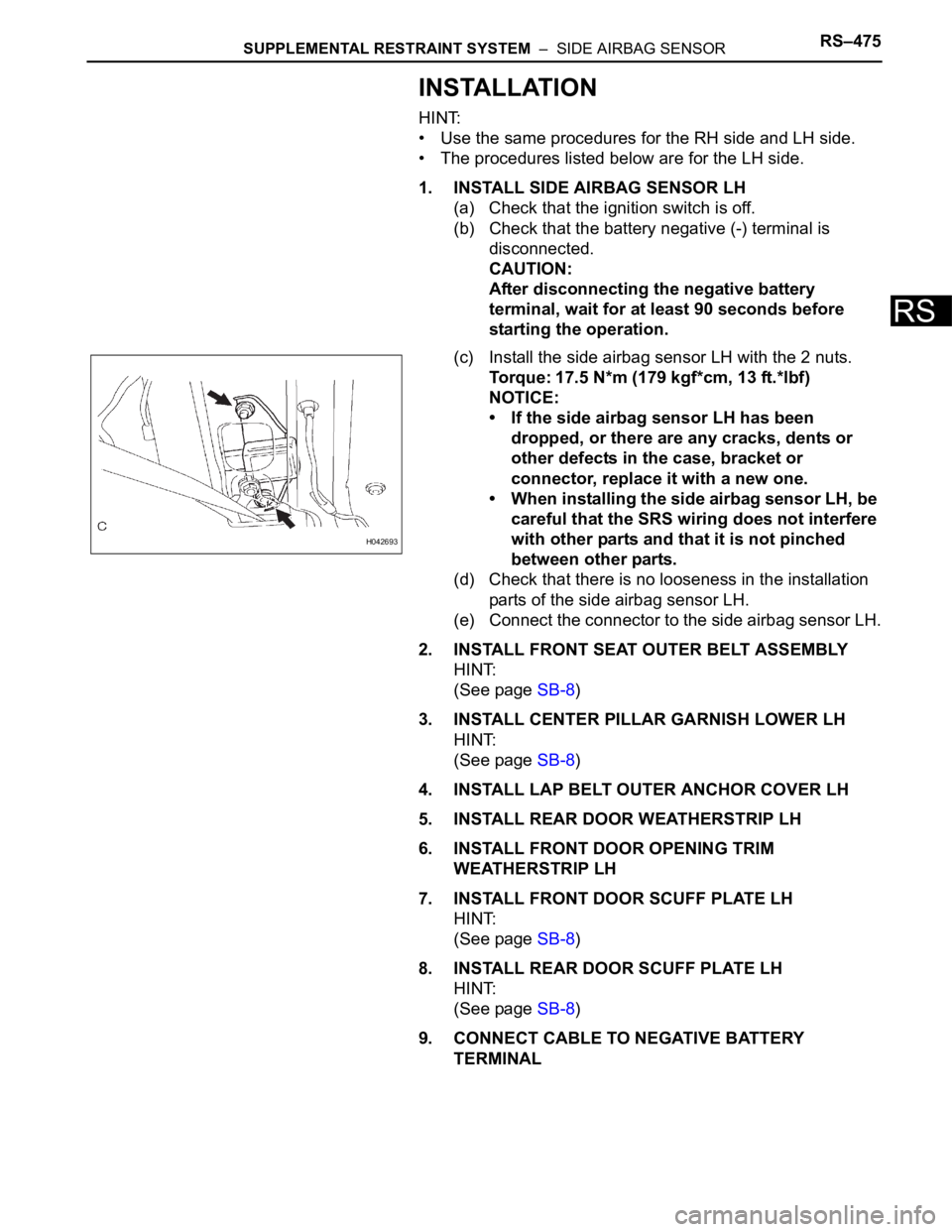

SUPPLEMENTAL RESTRAINT SYSTEM – SIDE AIRBAG SENSORRS–475

RS

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. INSTALL SIDE AIRBAG SENSOR LH

(a) Check that the ignition switch is off.

(b) Check that the battery negative (-) terminal is

disconnected.

CAUTION:

After disconnecting the negative battery

terminal, wait for at least 90 seconds before

starting the operation.

(c) Install the side airbag sensor LH with the 2 nuts.

Torque: 17.5 N*m (179 kgf*cm, 13 ft.*lbf)

NOTICE:

• If the side airbag sensor LH has been

dropped, or there are any cracks, dents or

other defects in the case, bracket or

connector, replace it with a new one.

• When installing the side airbag sensor LH, be

careful that the SRS wiring does not interfere

with other parts and that it is not pinched

between other parts.

(d) Check that there is no looseness in the installation

parts of the side airbag sensor LH.

(e) Connect the connector to the side airbag sensor LH.

2. INSTALL FRONT SEAT OUTER BELT ASSEMBLY

HINT:

(See page SB-8)

3. INSTALL CENTER PILLAR GARNISH LOWER LH

HINT:

(See page SB-8)

4. INSTALL LAP BELT OUTER ANCHOR COVER LH

5. INSTALL REAR DOOR WEATHERSTRIP LH

6. INSTALL FRONT DOOR OPENING TRIM

WEATHERSTRIP LH

7. INSTALL FRONT DOOR SCUFF PLATE LH

HINT:

(See page SB-8)

8. INSTALL REAR DOOR SCUFF PLATE LH

HINT:

(See page SB-8)

9. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

H042693

Page 234 of 3000

RS–476SUPPLEMENTAL RESTRAINT SYSTEM – SIDE AIRBAG SENSOR

RS

10. PERFORM INITIALIZATION

(a) Perform initialization.

HINT:

Some systems need initialization when

disconnecting the cable from the negative battery

terminal.

11. INSPECT SRS WARNING LIGHT

(a) Inspect the SRS warning light (See page RS-27).

Page 295 of 3000

INSTRUMENT PANEL – INSTRUMENT PANEL SAFETY PADIP–11

IP

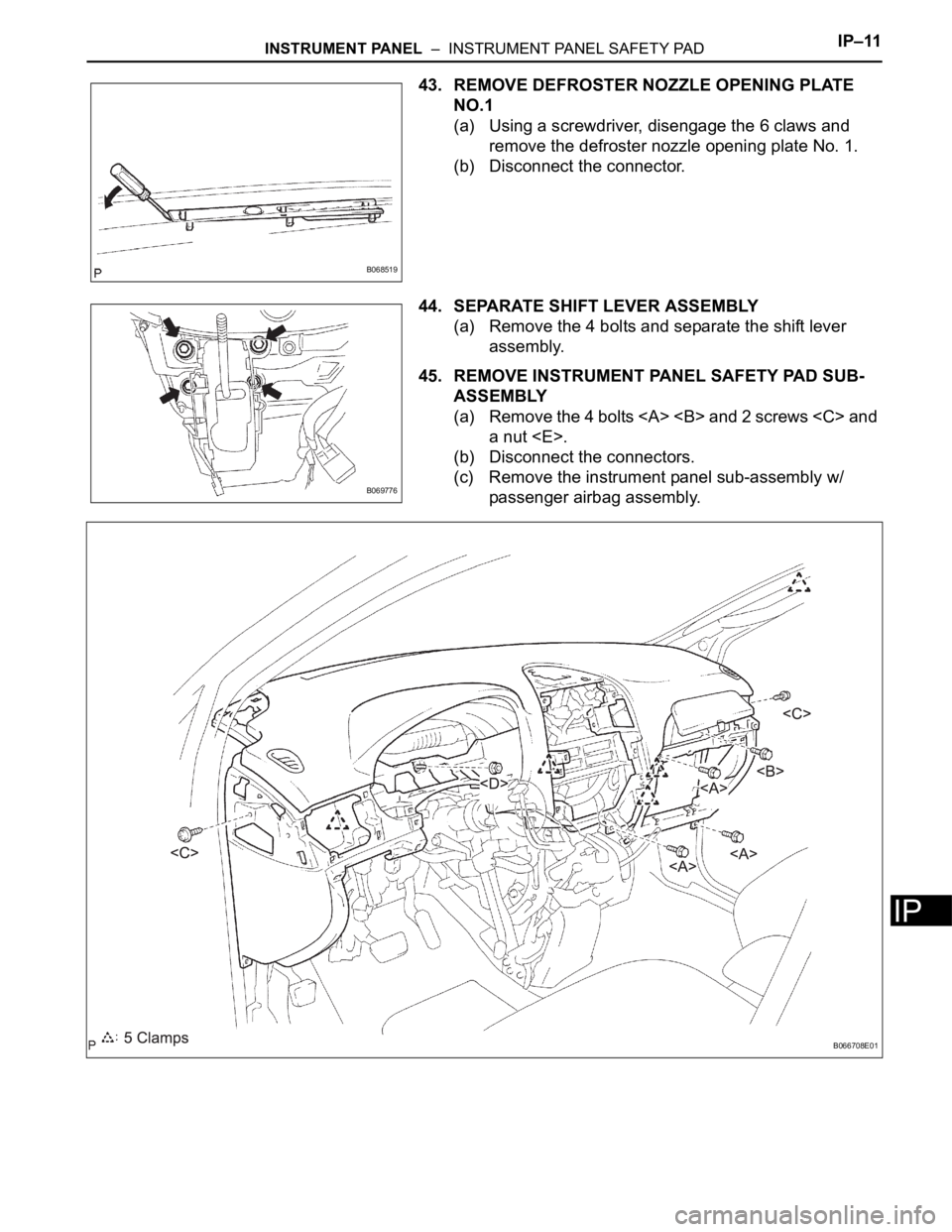

43. REMOVE DEFROSTER NOZZLE OPENING PLATE

NO.1

(a) Using a screwdriver, disengage the 6 claws and

remove the defroster nozzle opening plate No. 1.

(b) Disconnect the connector.

44. SEPARATE SHIFT LEVER ASSEMBLY

(a) Remove the 4 bolts and separate the shift lever

assembly.

45. REMOVE INSTRUMENT PANEL SAFETY PAD SUB-

ASSEMBLY

(a) Remove the 4 bolts and 2 screws

a nut

(b) Disconnect the connectors.

(c) Remove the instrument panel sub-assembly w/

passenger airbag assembly.

B068519

B069776

B066708E01