fuel type TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 353 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–27

ES

Contents:

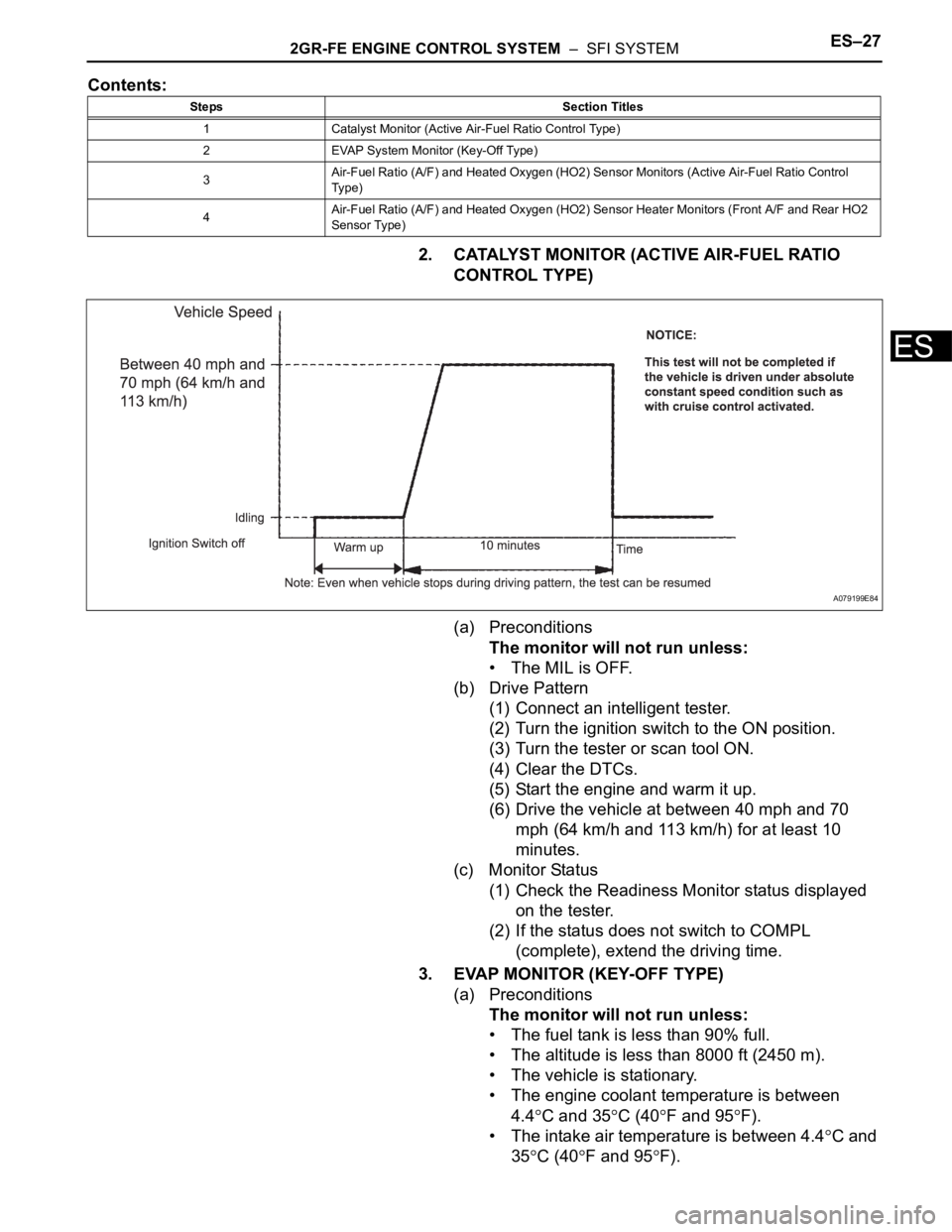

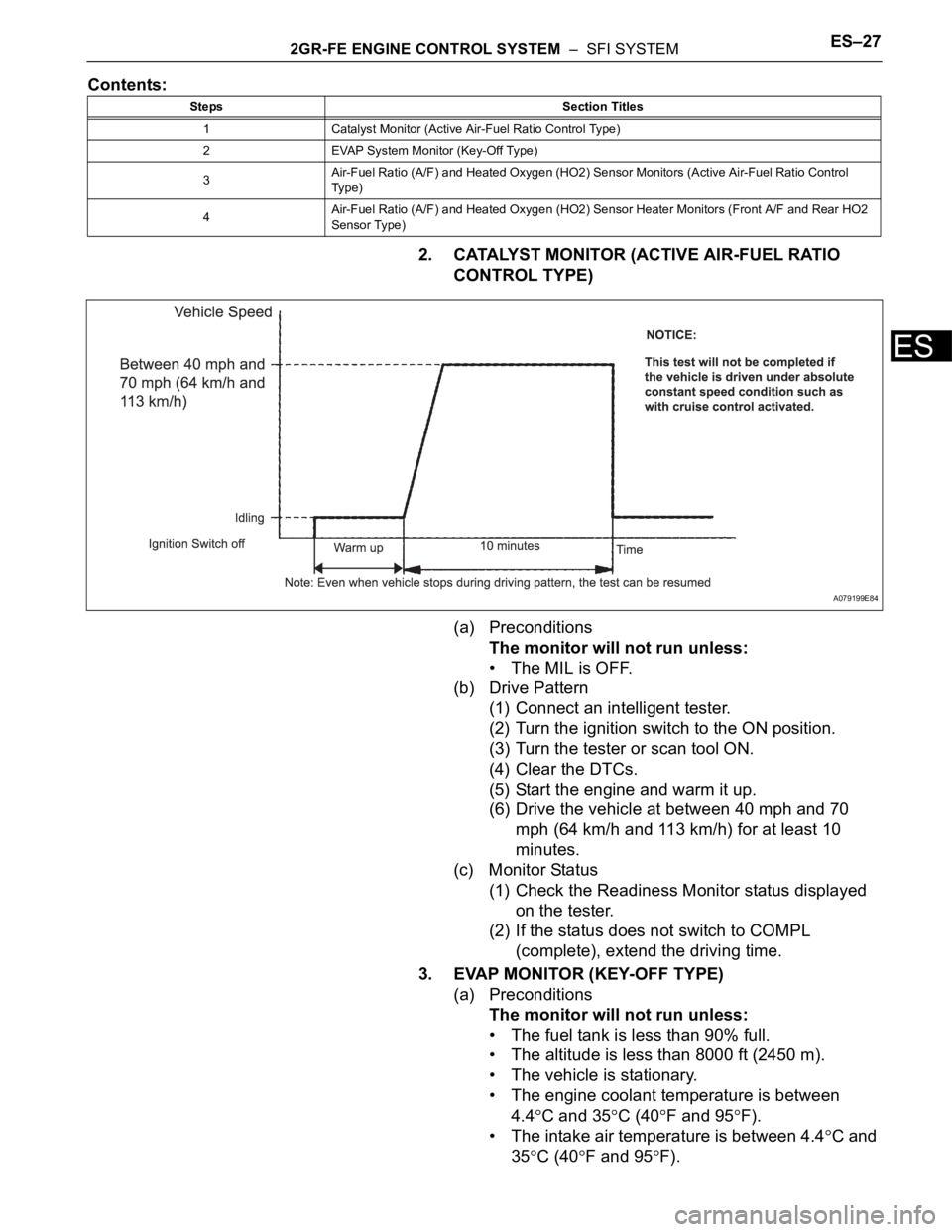

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Clear the DTCs.

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), extend the driving time.

3. EVAP MONITOR (KEY-OFF TYPE)

(a) Preconditions

The monitor will not run unless:

• The fuel tank is less than 90% full.

• The altitude is less than 8000 ft (2450 m).

• The vehicle is stationary.

• The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

• The intake air temperature is between 4.4

C and

35

C (40F and 95F).

Steps Section Titles

1 Catalyst Monitor (Active Air-Fuel Ratio Control Type)

2 EVAP System Monitor (Key-Off Type)

3Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Monitors (Active Air-Fuel Ratio Control

Ty p e )

4Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Heater Monitors (Front A/F and Rear HO2

Sensor Type)

A079199E84

Page 355 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–29

ES

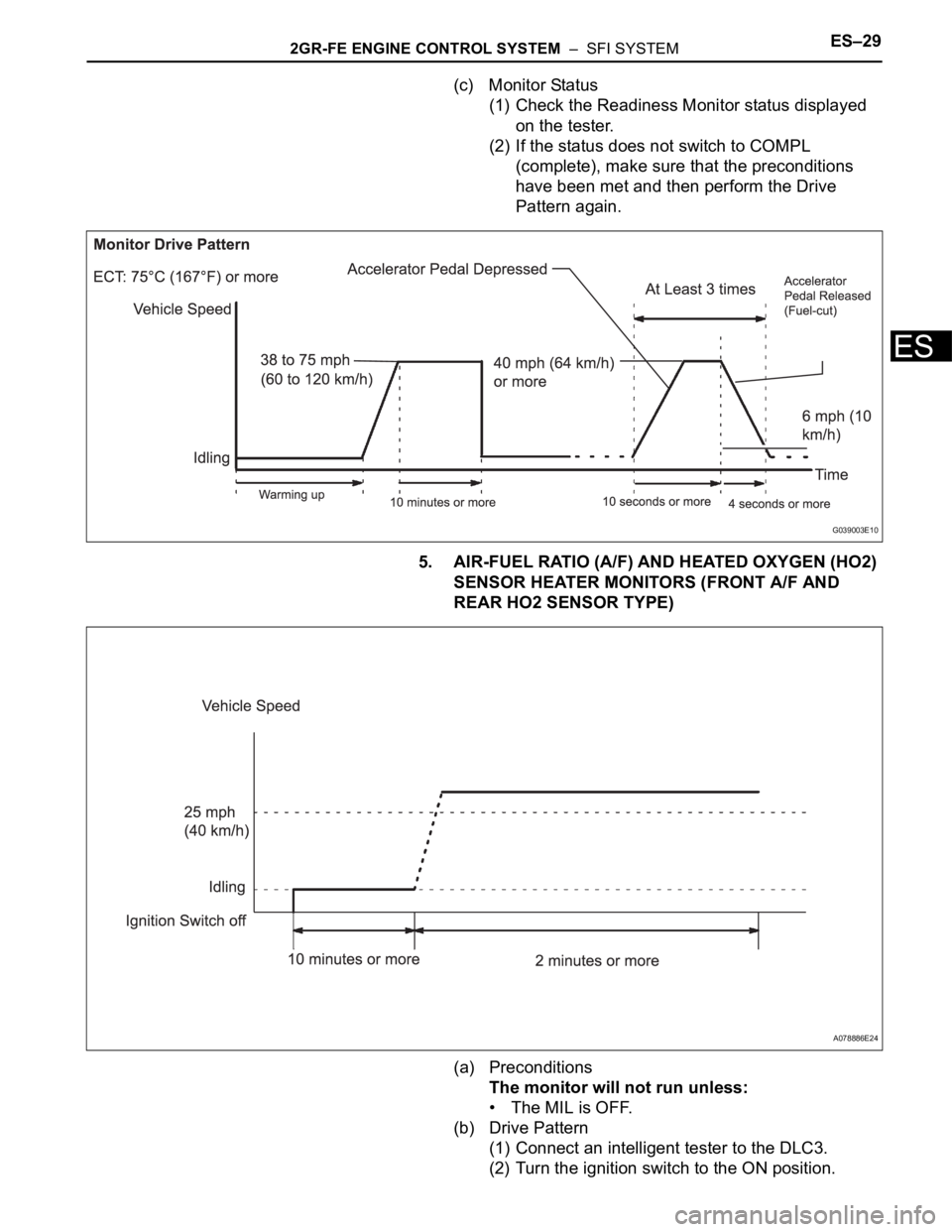

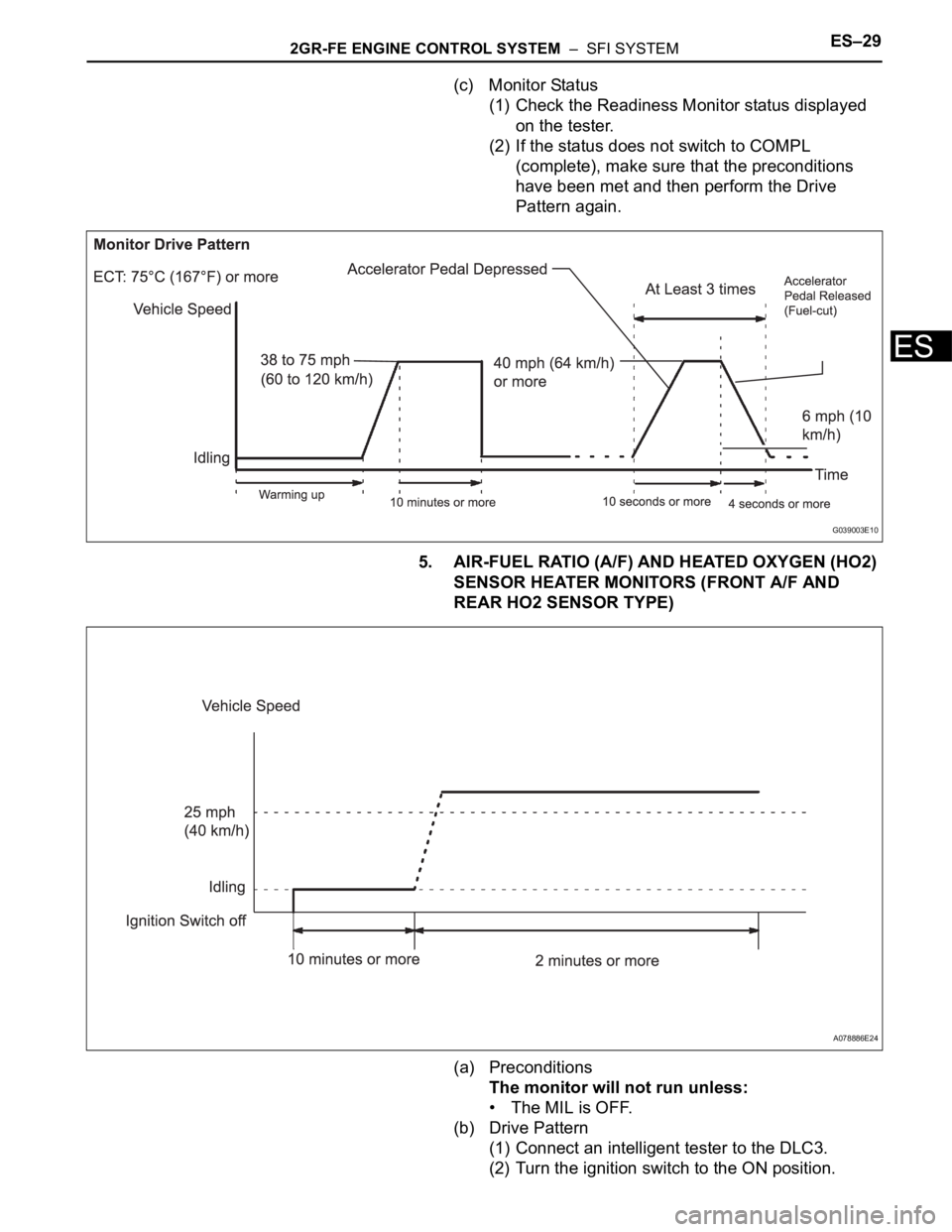

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met and then perform the Drive

Pattern again.

5. AIR-FUEL RATIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONITORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

G039003E10

A078886E24

Page 459 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–153

ES

HINT:

These DTCs relate to the Throttle Position (TP) sensor.

DESCRIPTION

HINT:

This ETC (Electrical Throttle Control System) does not use a throttle cable.

The Throttle Position (TP) sensor is mounted on the throttle body, and detects the opening angle of the

throttle valve. This sensor is a non-contact type, and uses Hall-effect elements, in order to yield accurate

signals, even in extreme driving conditions, such as at high speeds as well as very low speeds.

The TP sensor has two sensor circuits which each transmits a signal, VTA1 and VTA2. VTA1 is used to

detect the throttle valve angle and VTA2 is used to detect malfunctions in VTA1. The sensor signal

voltages vary between 0 V and 5 V in proportion to the throttle valve opening angle, and are transmitted to

the VTA terminals of the ECM.

As the valve closes, the sensor output voltage decreases and as the valve opens, the sensor output

voltage increases. The ECM calculates the throttle valve opening angle according to these signals and

controls the throttle actuator in response to driver inputs. These signals are also used in calculations such

as air-fuel ratio correction, power increase correction and fuel-cut control.

DTC P0120Throttle / Pedal Position Sensor / Switch "A"

Circuit

DTC P0122Throttle / Pedal Position Sensor / Switch "A"

Circuit Low Input

DTC P0123Throttle / Pedal Position Sensor / Switch "A"

Circuit High Input

DTC P0220Throttle / Pedal Position Sensor / Switch "B"

Circuit

DTC P0222Throttle / Pedal Position Sensor / Switch "B"

Circuit Low Input

DTC P0223Throttle / Pedal Position Sensor / Switch "B"

Circuit High Input

DTC P2135Throttle / Pedal Position Sensor / Switch "A" /

"B" Voltage Correlation

Page 656 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–363

ES

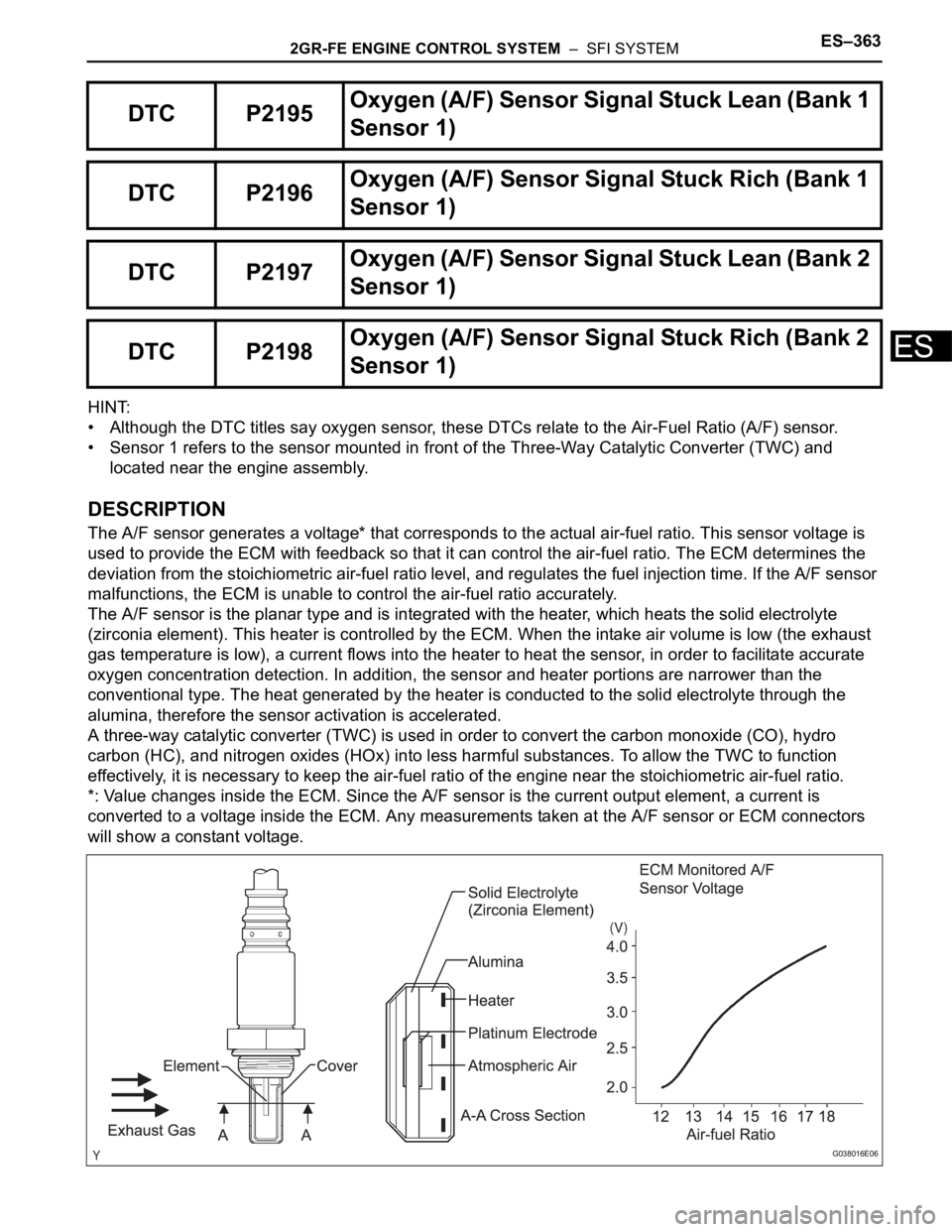

HINT:

• Although the DTC titles say oxygen sensor, these DTCs relate to the Air-Fuel Ratio (A/F) sensor.

• Sensor 1 refers to the sensor mounted in front of the Three-Way Catalytic Converter (TWC) and

located near the engine assembly.

DESCRIPTION

The A/F sensor generates a voltage* that corresponds to the actual air-fuel ratio. This sensor voltage is

used to provide the ECM with feedback so that it can control the air-fuel ratio. The ECM determines the

deviation from the stoichiometric air-fuel ratio level, and regulates the fuel injection time. If the A/F sensor

malfunctions, the ECM is unable to control the air-fuel ratio accurately.

The A/F sensor is the planar type and is integrated with the heater, which heats the solid electrolyte

(zirconia element). This heater is controlled by the ECM. When the intake air volume is low (the exhaust

gas temperature is low), a current flows into the heater to heat the sensor, in order to facilitate accurate

oxygen concentration detection. In addition, the sensor and heater portions are narrower than the

conventional type. The heat generated by the heater is conducted to the solid electrolyte through the

alumina, therefore the sensor activation is accelerated.

A three-way catalytic converter (TWC) is used in order to convert the carbon monoxide (CO), hydro

carbon (HC), and nitrogen oxides (HOx) into less harmful substances. To allow the TWC to function

effectively, it is necessary to keep the air-fuel ratio of the engine near the stoichiometric air-fuel ratio.

*: Value changes inside the ECM. Since the A/F sensor is the current output element, a current is

converted to a voltage inside the ECM. Any measurements taken at the A/F sensor or ECM connectors

will show a constant voltage.

DTC P2195Oxyg en ( A/ F) S en so r S ig n al Stu ck Lea n (Ban k 1

Sensor 1)

DTC P2196Oxygen (A/F) Sensor Signal Stuck Rich (Bank 1

Sensor 1)

DTC P2197Oxyg en ( A/ F) S en so r S ig n al Stu ck Lea n (Ban k 2

Sensor 1)

DTC P2198Oxygen (A/F) Sensor Signal Stuck Rich (Bank 2

Sensor 1)

G038016E06

Page 803 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–27

ES

Contents:

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Clear the DTCs.

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), extend the driving time.

3. EVAP MONITOR (KEY-OFF TYPE)

(a) Preconditions

The monitor will not run unless:

• The fuel tank is less than 90% full.

• The altitude is less than 8000 ft (2450 m).

• The vehicle is stationary.

• The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

• The intake air temperature is between 4.4

C and

35

C (40F and 95F).

Steps Section Titles

1 Catalyst Monitor (Active Air-Fuel Ratio Control Type)

2 EVAP System Monitor (Key-Off Type)

3Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Monitors (Active Air-Fuel Ratio Control

Ty p e )

4Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Heater Monitors (Front A/F and Rear HO2

Sensor Type)

A079199E84

Page 805 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–29

ES

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), make sure that the preconditions

have been met and then perform the Drive

Pattern again.

5. AIR-FUEL RATIO (A/F) AND HEATED OXYGEN (HO2)

SENSOR HEATER MONITORS (FRONT A/F AND

REAR HO2 SENSOR TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

G039003E10

A078886E24

Page 1123 of 3000

FU–22GR-FE FUEL – FUEL SYSTEM

FU

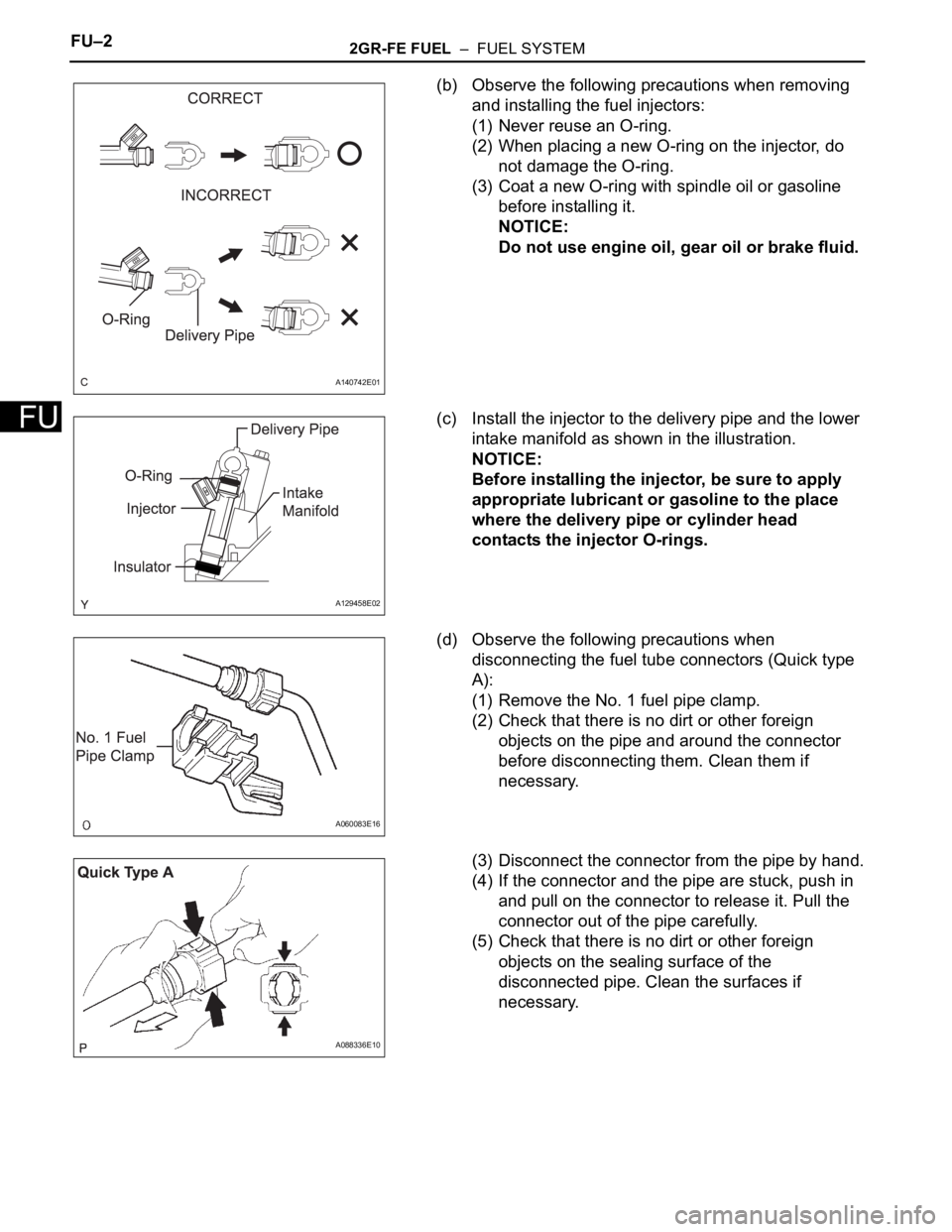

(b) Observe the following precautions when removing

and installing the fuel injectors:

(1) Never reuse an O-ring.

(2) When placing a new O-ring on the injector, do

not damage the O-ring.

(3) Coat a new O-ring with spindle oil or gasoline

before installing it.

NOTICE:

Do not use engine oil, gear oil or brake fluid.

(c) Install the injector to the delivery pipe and the lower

intake manifold as shown in the illustration.

NOTICE:

Before installing the injector, be sure to apply

appropriate lubricant or gasoline to the place

where the delivery pipe or cylinder head

contacts the injector O-rings.

(d) Observe the following precautions when

disconnecting the fuel tube connectors (Quick type

A):

(1) Remove the No. 1 fuel pipe clamp.

(2) Check that there is no dirt or other foreign

objects on the pipe and around the connector

before disconnecting them. Clean them if

necessary.

(3) Disconnect the connector from the pipe by hand.

(4) If the connector and the pipe are stuck, push in

and pull on the connector to release it. Pull the

connector out of the pipe carefully.

(5) Check that there is no dirt or other foreign

objects on the sealing surface of the

disconnected pipe. Clean the surfaces if

necessary.

A140742E01

A129458E02

A060083E16

A088336E10

Page 1124 of 3000

2GR-FE FUEL – FUEL SYSTEMFU–3

FU

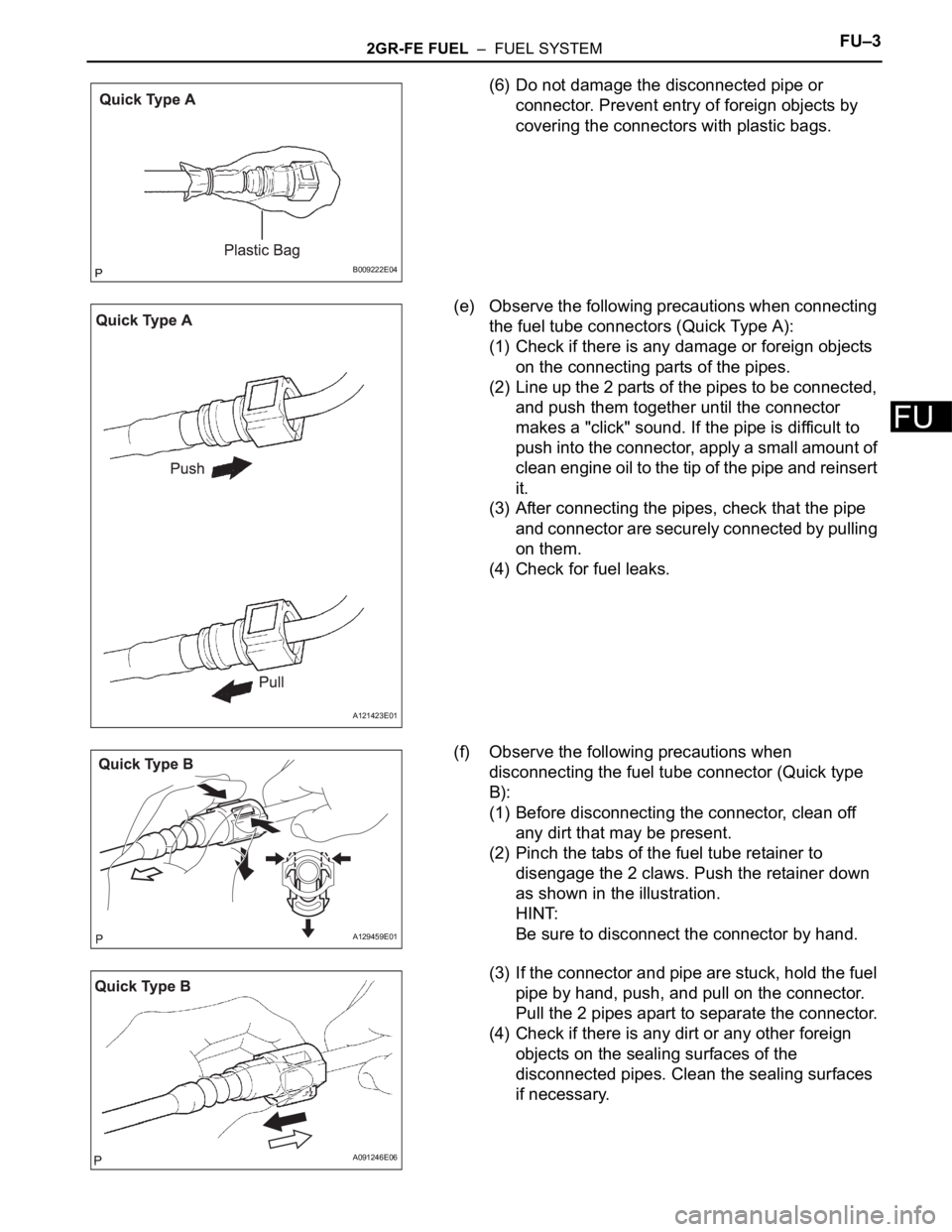

(6) Do not damage the disconnected pipe or

connector. Prevent entry of foreign objects by

covering the connectors with plastic bags.

(e) Observe the following precautions when connecting

the fuel tube connectors (Quick Type A):

(1) Check if there is any damage or foreign objects

on the connecting parts of the pipes.

(2) Line up the 2 parts of the pipes to be connected,

and push them together until the connector

makes a "click" sound. If the pipe is difficult to

push into the connector, apply a small amount of

clean engine oil to the tip of the pipe and reinsert

it.

(3) After connecting the pipes, check that the pipe

and connector are securely connected by pulling

on them.

(4) Check for fuel leaks.

(f) Observe the following precautions when

disconnecting the fuel tube connector (Quick type

B):

(1) Before disconnecting the connector, clean off

any dirt that may be present.

(2) Pinch the tabs of the fuel tube retainer to

disengage the 2 claws. Push the retainer down

as shown in the illustration.

HINT:

Be sure to disconnect the connector by hand.

(3) If the connector and pipe are stuck, hold the fuel

pipe by hand, push, and pull on the connector.

Pull the 2 pipes apart to separate the connector.

(4) Check if there is any dirt or any other foreign

objects on the sealing surfaces of the

disconnected pipes. Clean the sealing surfaces

if necessary.

B009222E04

A121423E01

A129459E01

A091246E06

Page 1125 of 3000

FU–42GR-FE FUEL – FUEL SYSTEM

FU

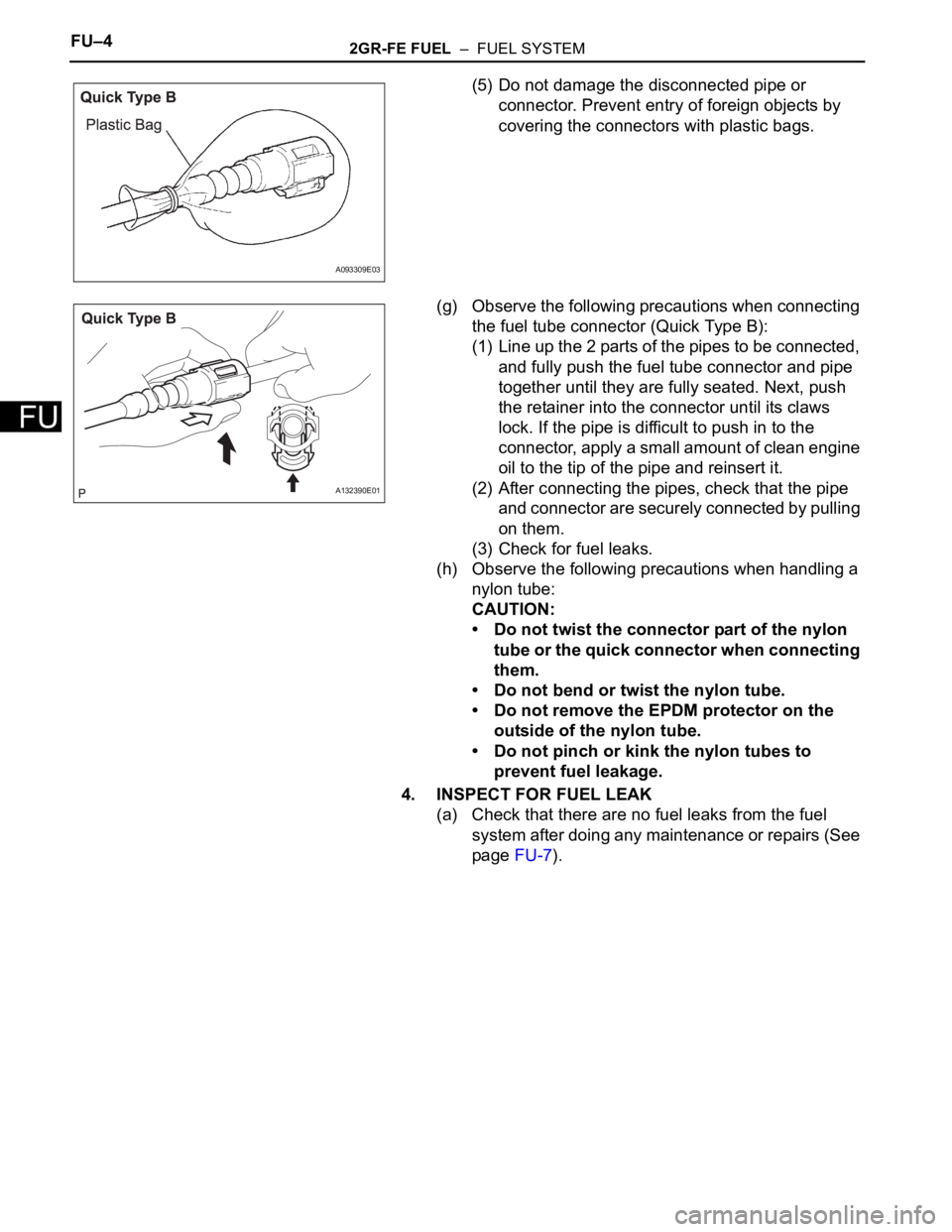

(5) Do not damage the disconnected pipe or

connector. Prevent entry of foreign objects by

covering the connectors with plastic bags.

(g) Observe the following precautions when connecting

the fuel tube connector (Quick Type B):

(1) Line up the 2 parts of the pipes to be connected,

and fully push the fuel tube connector and pipe

together until they are fully seated. Next, push

the retainer into the connector until its claws

lock. If the pipe is difficult to push in to the

connector, apply a small amount of clean engine

oil to the tip of the pipe and reinsert it.

(2) After connecting the pipes, check that the pipe

and connector are securely connected by pulling

on them.

(3) Check for fuel leaks.

(h) Observe the following precautions when handling a

nylon tube:

CAUTION:

• Do not twist the connector part of the nylon

tube or the quick connector when connecting

them.

• Do not bend or twist the nylon tube.

• Do not remove the EPDM protector on the

outside of the nylon tube.

• Do not pinch or kink the nylon tubes to

prevent fuel leakage.

4. INSPECT FOR FUEL LEAK

(a) Check that there are no fuel leaks from the fuel

system after doing any maintenance or repairs (See

page FU-7).

A093309E03

A132390E01

Page 1192 of 3000

EC–182GR-FE EMISSION CONTROL – AIR FUEL RATIO SENSOR (for 2WD)

EC

ON-VEHICLE INSPECTION

HINT:

The type of ignition switch on this model differs according to

the specifications of the vehicle. For the expressions used in

this section, refer to the "EXPRESSIONS OF IGNITION

SWITCH" precaution (See page ES-1).

1. CHECK AIR FUEL RATIO COMPENSATION SYSTEM

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Select the following menu items: Data List / A/FS B1

S1 and O2S B1 S2.

(d) Warm up the A/F sensor with the engine speed at

2500 rpm for approximately 2 minutes.

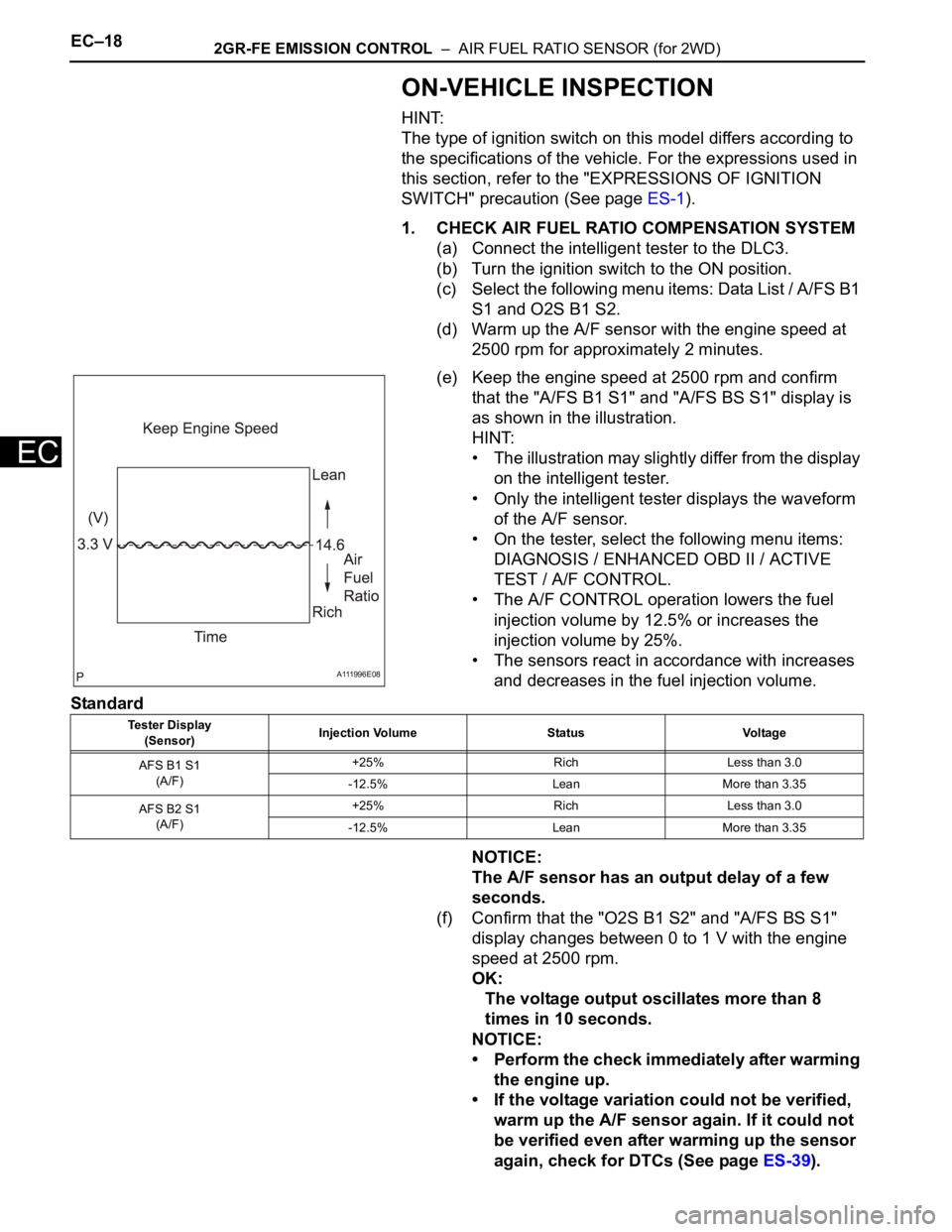

(e) Keep the engine speed at 2500 rpm and confirm

that the "A/FS B1 S1" and "A/FS BS S1" display is

as shown in the illustration.

HINT:

• The illustration may slightly differ from the display

on the intelligent tester.

• Only the intelligent tester displays the waveform

of the A/F sensor.

• On the tester, select the following menu items:

DIAGNOSIS / ENHANCED OBD II / ACTIVE

TEST / A/F CONTROL.

• The A/F CONTROL operation lowers the fuel

injection volume by 12.5% or increases the

injection volume by 25%.

• The sensors react in accordance with increases

and decreases in the fuel injection volume.

Standard

NOTICE:

The A/F sensor has an output delay of a few

seconds.

(f) Confirm that the "O2S B1 S2" and "A/FS BS S1"

display changes between 0 to 1 V with the engine

speed at 2500 rpm.

OK:

The voltage output oscillates more than 8

times in 10 seconds.

NOTICE:

• Perform the check immediately after warming

the engine up.

• If the voltage variation could not be verified,

warm up the A/F sensor again. If it could not

be verified even after warming up the sensor

again, check for DTCs (See page ES-39).

A111996E08

Tester Display

(Sensor)Injection Volume Status Voltage

AFS B1 S1

(A/F)+25% Rich Less than 3.0

-12.5% Lean More than 3.35

AFS B2 S1

(A/F)+25% Rich Less than 3.0

-12.5% Lean More than 3.35