heater TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 7 of 3000

PP–6PREPARATION – 2GR-FE ENGINE MECHANICAL

PP

EQUIPMENT

Abrasive compound

Brush

Caliper gauge

Carbide cutter (30

)

Carbide cutter (45

)

Carbide cutter (60

)

Carbide cutter (75

)

Connecting rod aligner

Cylinder gauge

Dial indicator

Dye penetrant

Engine tune-up tester

Groove cleaning tool

Heater

Micrometer

Piston ring compressor

Piston ring expander

Plastigage

Precision straight edge

Press

Reamer (5.5 mm)

Ridge reamer

Soft brush

Solvent

Spring tester

Steel square

Thermometer

To r q u e w r e n c h

Torx socket wrench

Valve seat cutter

Valve guide bushing brush

V-block

Vernier calipers

Wire brush

Bar

Chain Block

CO/HC meter

Compression gauge

Dial indicator with magnetic base

Engine Sling Device

Feeler gauge

Radiator cap tester

Slide calipers

Tachometer

Timing light

Wooden block

Deep socket wrench

Screwdriver

Hammer

Page 29 of 3000

EM–302GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

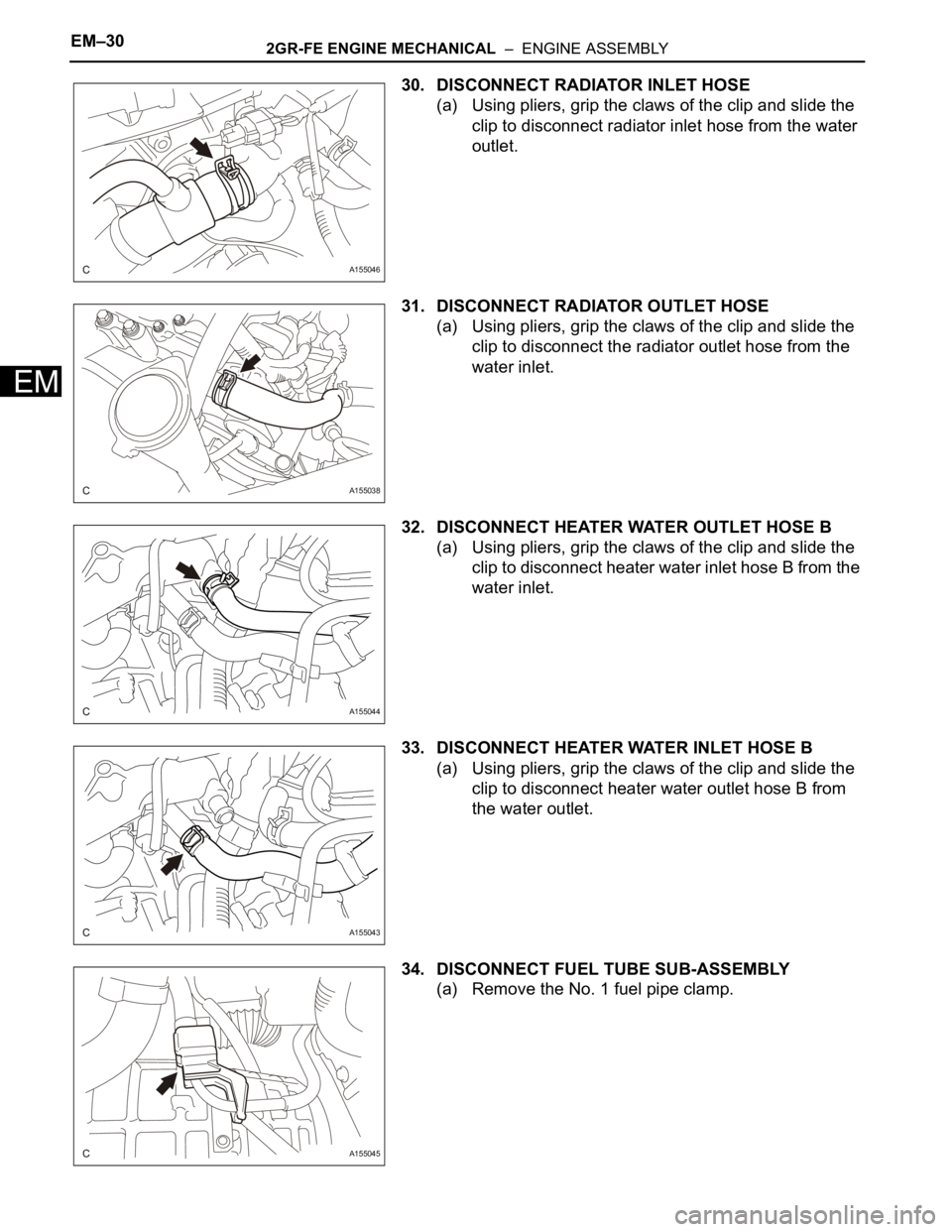

30. DISCONNECT RADIATOR INLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect radiator inlet hose from the water

outlet.

31. DISCONNECT RADIATOR OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect the radiator outlet hose from the

water inlet.

32. DISCONNECT HEATER WATER OUTLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect heater water inlet hose B from the

water inlet.

33. DISCONNECT HEATER WATER INLET HOSE B

(a) Using pliers, grip the claws of the clip and slide the

clip to disconnect heater water outlet hose B from

the water outlet.

34. DISCONNECT FUEL TUBE SUB-ASSEMBLY

(a) Remove the No. 1 fuel pipe clamp.

A155046

A155038

A155044

A155043

A155045

Page 55 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–43

IN

(d) HIGH ELECTRICAL LOAD METHOD: When a

malfunction seems to occur when electrical load is

excessive.

(1) Turn on the heater blower, headlight, rear

window defogger and all other electrical loads.

Check if the malfunction reoccurs.

5. DIAGNOSTIC TROUBLE CODE CHART

Look for output Diagnostic Trouble Codes (DTCs) (from the

DTC checks) in the appropriate section's Diagnostic Trouble

Code Chart. Use the chart to determine the trouble area and

the proper inspection procedure. A description of each of the

chart's columns is shown in the table below.

6. PROBLEM SYMPTOMS TABLE

When a "Normal" code is output during a DTC check but

the problem still occurs, use the Problem Symptoms

Table. The suspected areas (circuits or parts) for each

problem symptoms are in the table. The suspected areas

are listed in order of probability. A description of each of

the chart's columns is shown in the table below.

HINT:

In some cases, the problem is not detected by the

diagnostic system even though a problem symptom

occurs. It is possible that the problem is occurring

outside the detection range of the diagnostic system, or

that the problem occurs in a completely different system.

7. CIRCUIT INSPECTION

A description of the main areas of each circuit inspection

is shown in the table below.

B107149

Item Description

DTC No. Indicates the diagnostic trouble code

Detection Item Indicates the system or details of the problem

Trouble Area Indicates the suspect areas of the problem

See Page Indicates the page where the inspection procedures for each circuit is

to be found, or gives instruction for checking and repairs.

Item Description

Problem Symptom -

Circuit Inspection, Inspection Order Indicates the order in which the circuits need to be checked

Circuit or Part Name Indicates the circuit or part which needs to be checked

See Page Indicates the page where the flowchart for each circuit is located

Item Description

Circuit Description The major role, operation of the circuit and its component parts are

explained.

Diagnostic Trouble Code No. and Detection item Indicates the diagnostic trouble codes, diagnostic trouble code

settings and suspected areas for a problem

Wiring diagram This shows a wiring diagram of the circuit.

Use this diagram together with ELECTRICAL WIRING DIAGRAM to

thoroughly understand the circuit.

Wire colors are indicated by an alphabetical code. B = Black, L = Blue,

R = Red, BR = Brown, LG = Light Green, V = Violet, G = Green, O =

Orange, W = White, GR = Gray, P = Pink, Y = Yellow, SB = Sky Blue

The first letter indicates the basic wire color and the second letter

indicates the color of the stripe.

Page 57 of 3000

IN–50INTRODUCTION – TERMS

IN

GLOSSARY OF SAE AND TOYOTA

TERMS

This glossary lists all SAE-J1930 terms and abbreviations

used in this manual in compliance with SAE

recommendations, as well as their TOYOTA equivalents.

SAE

ABBREVIATIONSSAE TERMSTOYOTA TERMS

( )-ABBREVIATIONS

A/C Air Conditioning Air Conditioner

ACL Air Cleaner Air Cleaner, A/CL

AIR Secondary Air Injection Air Injection (AI)

AP Accelerator Pedal -

B+ Battery Positive Voltage +B, Battery Voltage

BARO Barometric Pressure HAC

CAC Charge Air Cooler Intercooler

CARB Carburetor Carburetor

CFI Continuous Fuel Injection -

CKP Crankshaft Position Crank Angle

CL Closed Loop Closed Loop

CMP Camshaft Position Cam Angle

CPP Clutch Pedal Position -

CTOX Continuous Trap Oxidizer -

CTP Closed Throttle Position LL ON, Idle ON

DFI Direct Fuel Injection Direct Injection (DI./INJ)

DI Distributor Ignition -

DLC3 Data Link Connector 3 OBD II Diagnostic Connector

DTC Diagnostic Trouble Code Diagnostic Trouble Code

DTM Diagnostic Test Mode -

ECL Engine Coolant Level -

ECM Engine Control Module Engine Electronic Control Unit (ECU)

ECT Engine Coolant Temperature Coolant Temperature, Water Temperature (THW)

EEPROM Electrically Erasable Programmable Read Only MemoryElectrically Erasable Programmable Read Only

Memory (EEPROM), Erasable Programmable Read

Only Memory (EPROM)

EFE Early Fuel Evaporation Cold Mixture Heater (CMH), Heat Control Valve (HCV)

EGR Exhaust Gas Recirculation Exhaust Gas Recirculation (EGR)

EI Electronic Ignition Distributorless Ignition (DLI)

EM Engine Modification Engine Modification (EM)

EPROM Erasable Programmable Read Only Memory Programmable Read Only Memory (PROM)

EVAP Evaporative Emission Evaporative Emission Control (EVAP)

FC Fan Control -

FEEPROMFlash Electrically Erasable Programmable Read Only

Memory-

FEPROM Flash Erasable Programmable Read Only Memory -

FF Flexible Fuel -

FP Fuel Pump Fuel Pump

GEN Generator Alternator

GND Ground Ground (GND)

HO2S Heated Oxygen SensorHeated Oxygen Sensor (HO

2S)

IAC Idle Air Control Idle Speed Control (ISC)

IAT Intake Air Temperature Intake or Inlet Air Temperature

ICM Ignition Control Module -

Page 73 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–43

IN

(d) HIGH ELECTRICAL LOAD METHOD: When a

malfunction seems to occur when electrical load is

excessive.

(1) Turn on the heater blower, headlight, rear

window defogger and all other electrical loads.

Check if the malfunction reoccurs.

5. DIAGNOSTIC TROUBLE CODE CHART

Look for output Diagnostic Trouble Codes (DTCs) (from the

DTC checks) in the appropriate section's Diagnostic Trouble

Code Chart. Use the chart to determine the trouble area and

the proper inspection procedure. A description of each of the

chart's columns is shown in the table below.

6. PROBLEM SYMPTOMS TABLE

When a "Normal" code is output during a DTC check but

the problem still occurs, use the Problem Symptoms

Table. The suspected areas (circuits or parts) for each

problem symptoms are in the table. The suspected areas

are listed in order of probability. A description of each of

the chart's columns is shown in the table below.

HINT:

In some cases, the problem is not detected by the

diagnostic system even though a problem symptom

occurs. It is possible that the problem is occurring

outside the detection range of the diagnostic system, or

that the problem occurs in a completely different system.

7. CIRCUIT INSPECTION

A description of the main areas of each circuit inspection

is shown in the table below.

B107149

Item Description

DTC No. Indicates the diagnostic trouble code

Detection Item Indicates the system or details of the problem

Trouble Area Indicates the suspect areas of the problem

See Page Indicates the page where the inspection procedures for each circuit is

to be found, or gives instruction for checking and repairs.

Item Description

Problem Symptom -

Circuit Inspection, Inspection Order Indicates the order in which the circuits need to be checked

Circuit or Part Name Indicates the circuit or part which needs to be checked

See Page Indicates the page where the flowchart for each circuit is located

Item Description

Circuit Description The major role, operation of the circuit and its component parts are

explained.

Diagnostic Trouble Code No. and Detection item Indicates the diagnostic trouble codes, diagnostic trouble code

settings and suspected areas for a problem

Wiring diagram This shows a wiring diagram of the circuit.

Use this diagram together with ELECTRICAL WIRING DIAGRAM to

thoroughly understand the circuit.

Wire colors are indicated by an alphabetical code. B = Black, L = Blue,

R = Red, BR = Brown, LG = Light Green, V = Violet, G = Green, O =

Orange, W = White, GR = Gray, P = Pink, Y = Yellow, SB = Sky Blue

The first letter indicates the basic wire color and the second letter

indicates the color of the stripe.

Page 127 of 3000

PP–14PREPARATION – 2GR-FE COOLING

PP

EQUIPMENT

Ohmmeter -

Radiator cap tester -

Thermometer -

To r q u e w r e n c h -

Slide calipers -

Heater -

Ammeter (A) -

Page 283 of 3000

WS–66WINDSHIELD / WINDOWGLASS – WINDOW DEFOGGER SYSTEM

WS

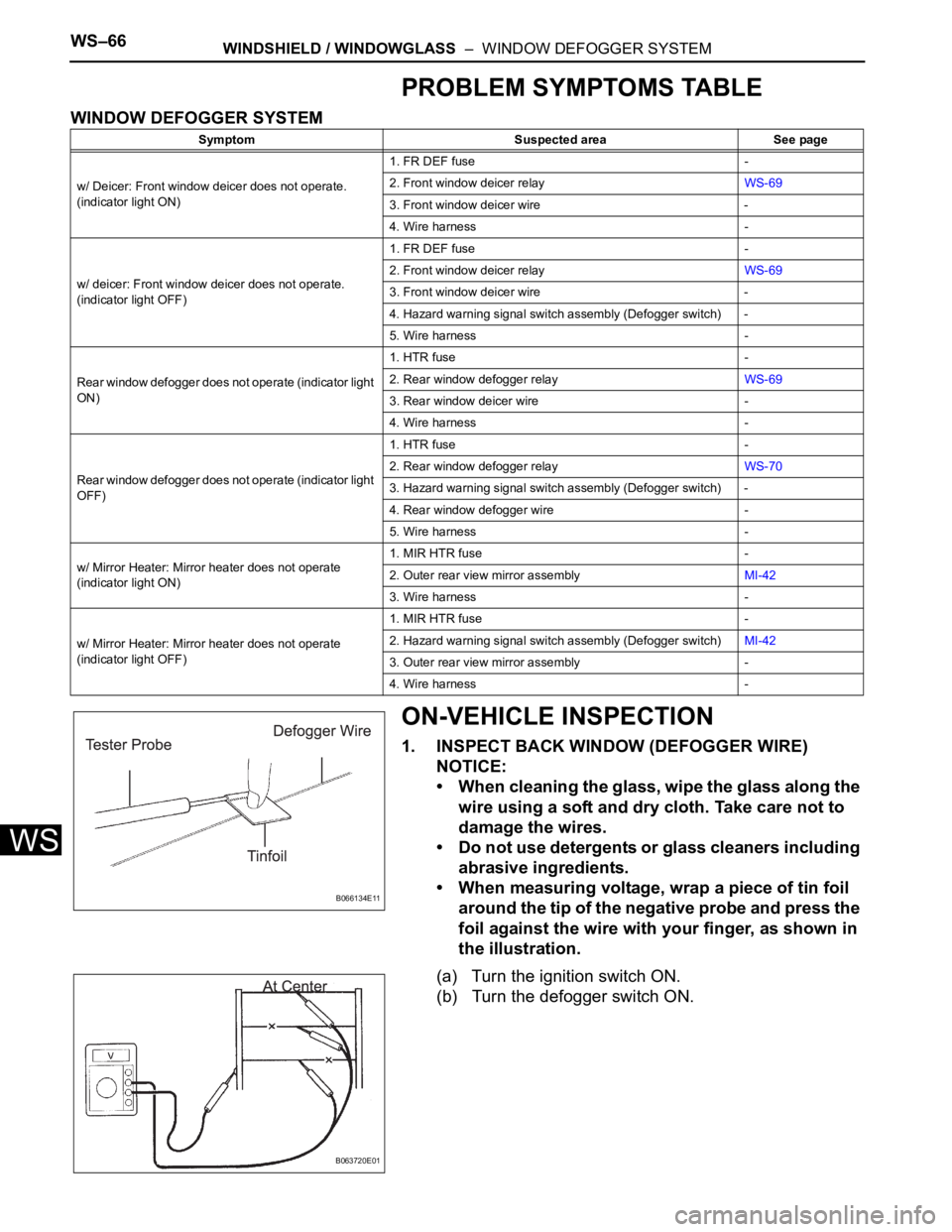

PROBLEM SYMPTOMS TABLE

WINDOW DEFOGGER SYSTEM

ON-VEHICLE INSPECTION

1. INSPECT BACK WINDOW (DEFOGGER WIRE)

NOTICE:

• When cleaning the glass, wipe the glass along the

wire using a soft and dry cloth. Take care not to

damage the wires.

• Do not use detergents or glass cleaners including

abrasive ingredients.

• When measuring voltage, wrap a piece of tin foil

around the tip of the negative probe and press the

foil against the wire with your finger, as shown in

the illustration.

(a) Turn the ignition switch ON.

(b) Turn the defogger switch ON.

Symptom Suspected area See page

w/ Deicer: Front window deicer does not operate.

(indicator light ON)1. FR DEF fuse -

2. Front window deicer relayWS-69

3. Front window deicer wire -

4. Wire harness -

w/ deicer: Front window deicer does not operate.

(indicator light OFF)1. FR DEF fuse -

2. Front window deicer relayWS-69

3. Front window deicer wire -

4. Hazard warning signal switch assembly (Defogger switch) -

5. Wire harness -

Rear window defogger does not operate (indicator light

ON)1. HTR fuse -

2. Rear window defogger relayWS-69

3. Rear window deicer wire -

4. Wire harness -

Rear window defogger does not operate (indicator light

OFF)1. HTR fuse -

2. Rear window defogger relayWS-70

3. Hazard warning signal switch assembly (Defogger switch) -

4. Rear window defogger wire -

5. Wire harness -

w/ Mirror Heater: Mirror heater does not operate

(indicator light ON)1. MIR HTR fuse -

2. Outer rear view mirror assemblyMI-42

3. Wire harness -

w/ Mirror Heater: Mirror heater does not operate

(indicator light OFF)1. MIR HTR fuse -

2. Hazard warning signal switch assembly (Defogger switch)MI-42

3. Outer rear view mirror assembly -

4. Wire harness -

B066134E11

B063720E01

Page 327 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–259

ES

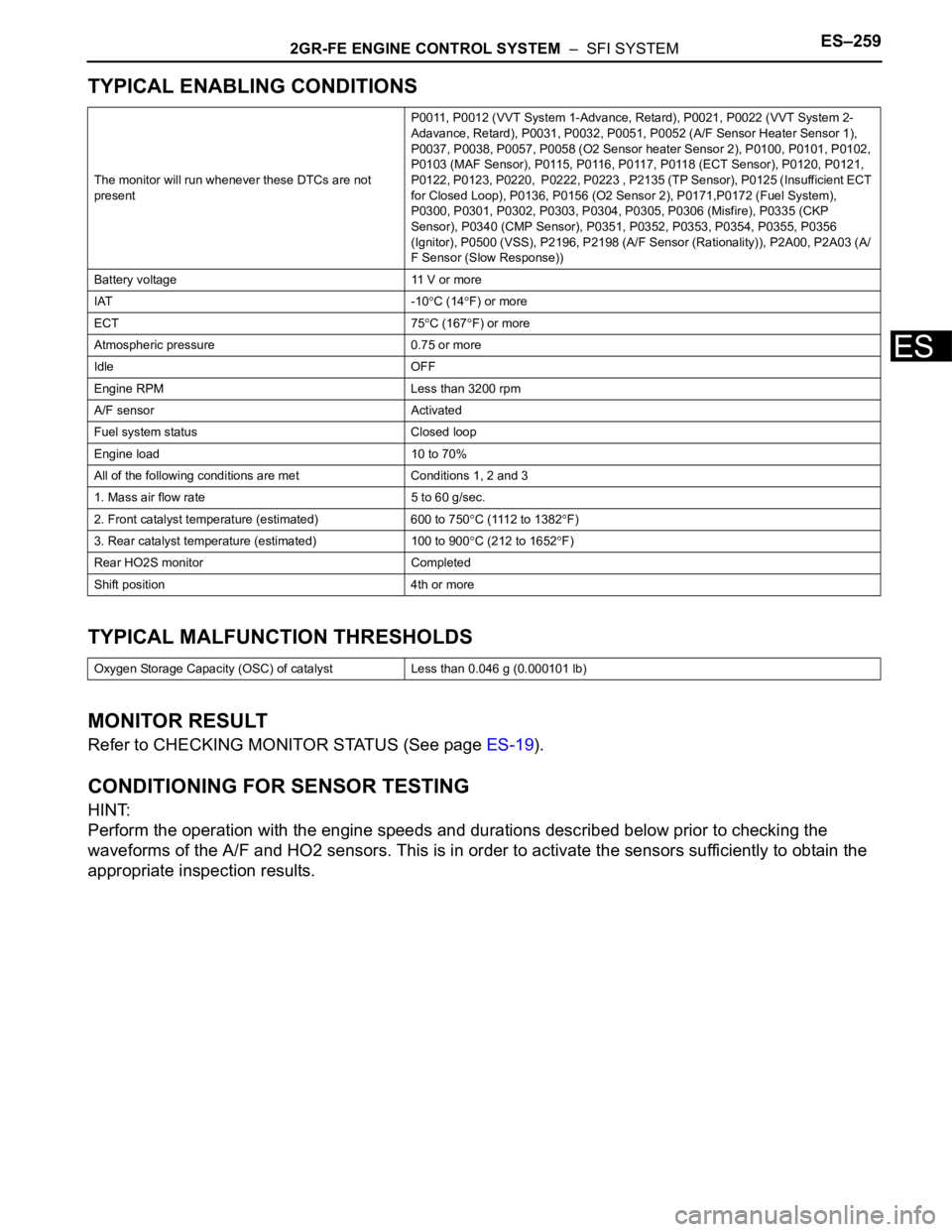

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

MONITOR RESULT

Refer to CHECKING MONITOR STATUS (See page ES-19).

CONDITIONING FOR SENSOR TESTING

HINT:

Perform the operation with the engine speeds and durations described below prior to checking the

waveforms of the A/F and HO2 sensors. This is in order to activate the sensors sufficiently to obtain the

appropriate inspection results.

The monitor will run whenever these DTCs are not

presentP0011, P0012 (VVT System 1-Advance, Retard), P0021, P0022 (VVT System 2-

Adavance, Retard), P0031, P0032, P0051, P0052 (A/F Sensor Heater Sensor 1),

P0037, P0038, P0057, P0058 (O2 Sensor heater Sensor 2), P0100, P0101, P0102,

P0103 (MAF Sensor), P0115, P0116, P0117, P0118 (ECT Sensor), P0120, P0121,

P0122, P0123, P0220, P0222, P0223 , P2135 (TP Sensor), P0125 (Insufficient ECT

for Closed Loop), P0136, P0156 (O2 Sensor 2), P0171,P0172 (Fuel System),

P0300, P0301, P0302, P0303, P0304, P0305, P0306 (Misfire), P0335 (CKP

Sensor), P0340 (CMP Sensor), P0351, P0352, P0353, P0354, P0355, P0356

(Ignitor), P0500 (VSS), P2196, P2198 (A/F Sensor (Rationality)), P2A00, P2A03 (A/

F Sensor (Slow Response))

Battery voltage 11 V or more

IAT -10

C (14F) or more

ECT 75

C (167F) or more

Atmospheric pressure 0.75 or more

Idle OFF

Engine RPM Less than 3200 rpm

A/F sensor Activated

Fuel system status Closed loop

Engine load 10 to 70%

All of the following conditions are met Conditions 1, 2 and 3

1. Mass air flow rate 5 to 60 g/sec.

2. Front catalyst temperature (estimated) 600 to 750

C (1112 to 1382F)

3. Rear catalyst temperature (estimated) 100 to 900

C (212 to 1652F)

Rear HO2S monitor Completed

Shift position 4th or more

Oxygen Storage Capacity (OSC) of catalyst Less than 0.046 g (0.000101 lb)

Page 330 of 3000

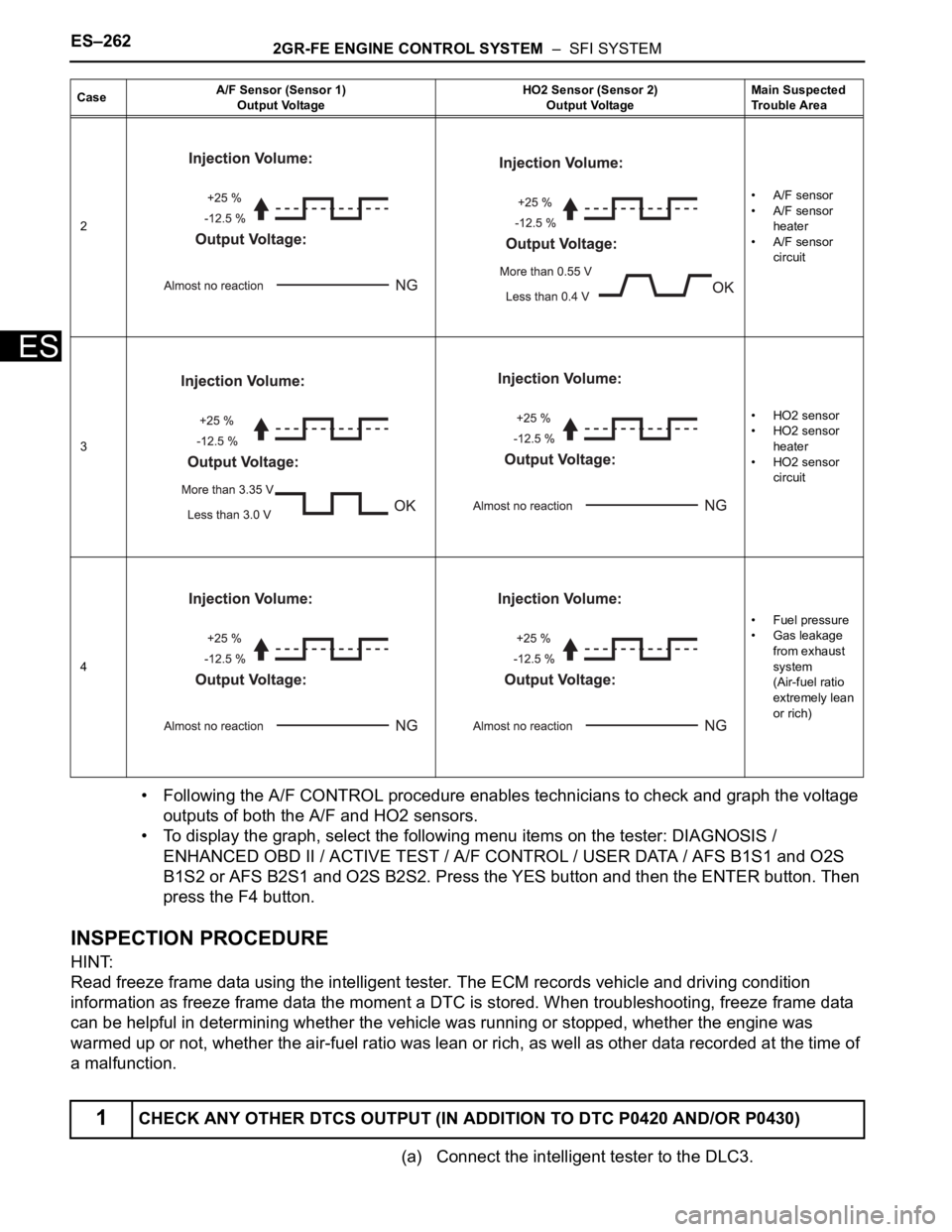

ES–2622GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Following the A/F CONTROL procedure enables technicians to check and graph the voltage

outputs of both the A/F and HO2 sensors.

• To display the graph, select the following menu items on the tester: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / A/F CONTROL / USER DATA / AFS B1S1 and O2S

B1S2 or AFS B2S1 and O2S B2S2. Press the YES button and then the ENTER button. Then

press the F4 button.

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Connect the intelligent tester to the DLC3.

2• A/F sensor

• A/F sensor

heater

• A/F sensor

circuit

3• HO2 sensor

• HO2 sensor

heater

• HO2 sensor

circuit

4•Fuel pressure

• Gas leakage

from exhaust

system

(Air-fuel ratio

extremely lean

or rich)

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0420 AND/OR P0430)

CaseA/F Sensor (Sensor 1)

Output VoltageHO2 Sensor (Sensor 2)

Output VoltageMain Suspected

Trouble Area

Page 351 of 3000

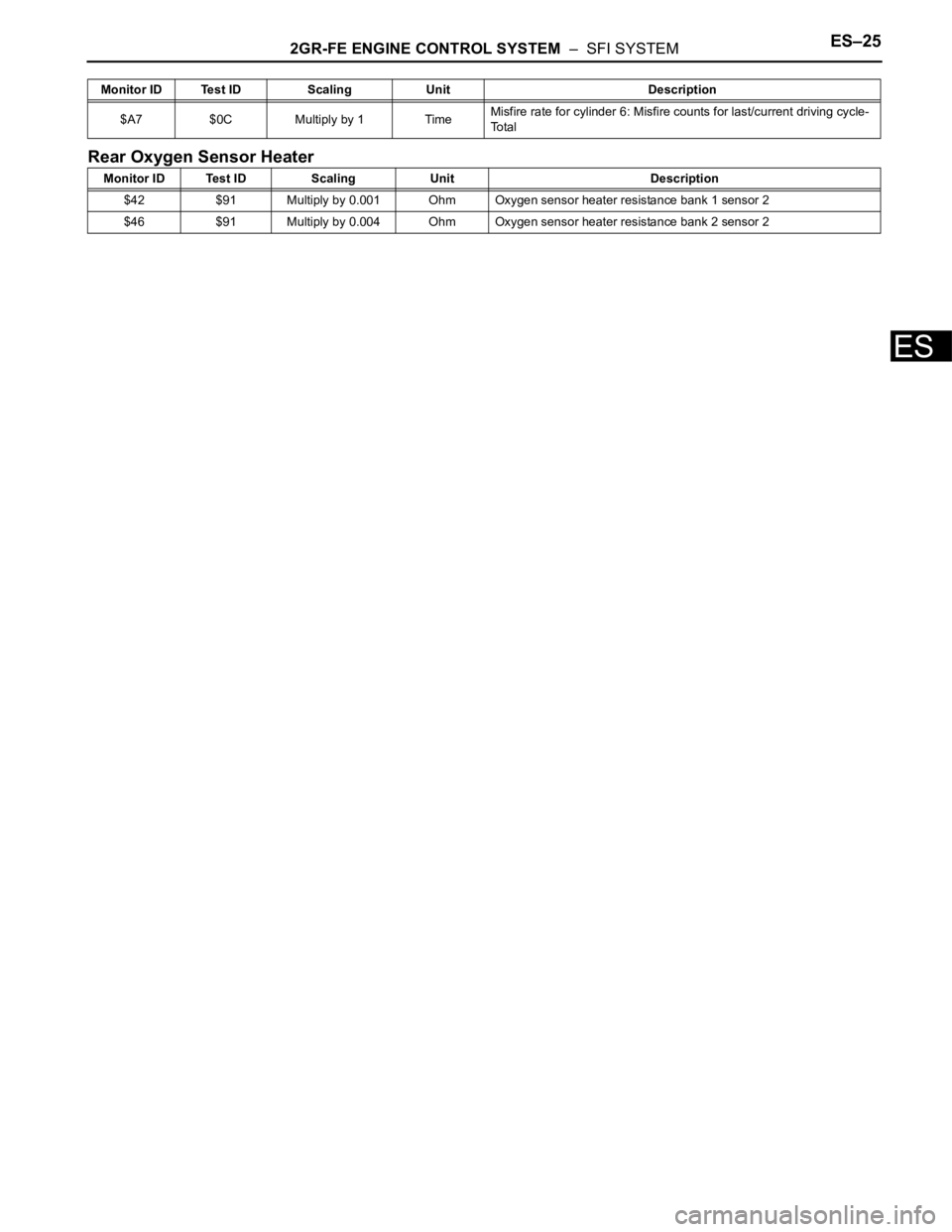

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–25

ES

Rear Oxygen Sensor Heater

$A7 $0C Multiply by 1 TimeMisfire rate for cylinder 6: Misfire counts for last/current driving cycle-

To t a l

Monitor ID Test ID Scaling Unit Description

$42 $91 Multiply by 0.001 Ohm Oxygen sensor heater resistance bank 1 sensor 2

$46 $91 Multiply by 0.004 Ohm Oxygen sensor heater resistance bank 2 sensor 2 Monitor ID Test ID Scaling Unit Description