parking brake TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1 of 3000

INTRODUCTION – REPAIR INSTRUCTIONIN–25

IN

VEHICLE LIFT AND SUPPORT

LOCATIONS

1. NOTICE ABOUT VEHICLE CONDITION WHEN

JACKING UP VEHICLE

(a) The vehicle must be unloaded before jacking up/

lifting up the vehicle. Never jack up/lift up a heavily

loaded vehicle.

(b) When removing heavy parts such as the engine and

transmission, the center of gravity of the vehicle

may shift. To stabilize the vehicle, place a balance

weight in a location where it will not roll or shift, or

use a transmission jack to hold the jacking support.

2. NOTICE FOR USING 4 POST LIFT

(a) Follow the safety procedures outlined in the lift

instruction manual.

(b) Use precautionary measures to prevent the free

wheel beam from damaging tires or wheels.

(c) Use wheel chocks to secure the vehicle.

3. NOTICE FOR USING JACK AND SAFETY STAND

(a) Work on a level surface. Use wheel chocks at all

times.

(b) Set the jack and rigid racks to the specified

locations of the vehicle accurately.

(c) When jacking up the vehicle, first release the

parking brake and move the shift lever to N.

(d) When jacking up the entire vehicle:

(1) When jacking up the front wheels first, make

sure wheel chocks are behind the rear wheels.

(2) When jacking up the rear wheels first, make sure

wheel chocks are in front of the front wheels.

(e) When jacking up only the front or rear wheels of the

vehicle:

(1) Before jacking up the front wheels, place wheel

chocks on both sides of the rear wheels.

(2) Before jacking up the rear wheels, place wheel

chocks on both sides of the front wheels.

(f) When lowering a vehicle that only has its front or

rear wheels jacked up:

(1) Before lowering the front wheels, make sure

wheel chocks are in front of the rear wheels.

(2) Before lowering the rear wheels, make sure

wheel chocks are behind the front wheels.

Page 180 of 3000

BC–4BRAKE CONTROL – ANTI-LOCK BRAKE SYSTEM

BC

TEST MODE PROCEDURE

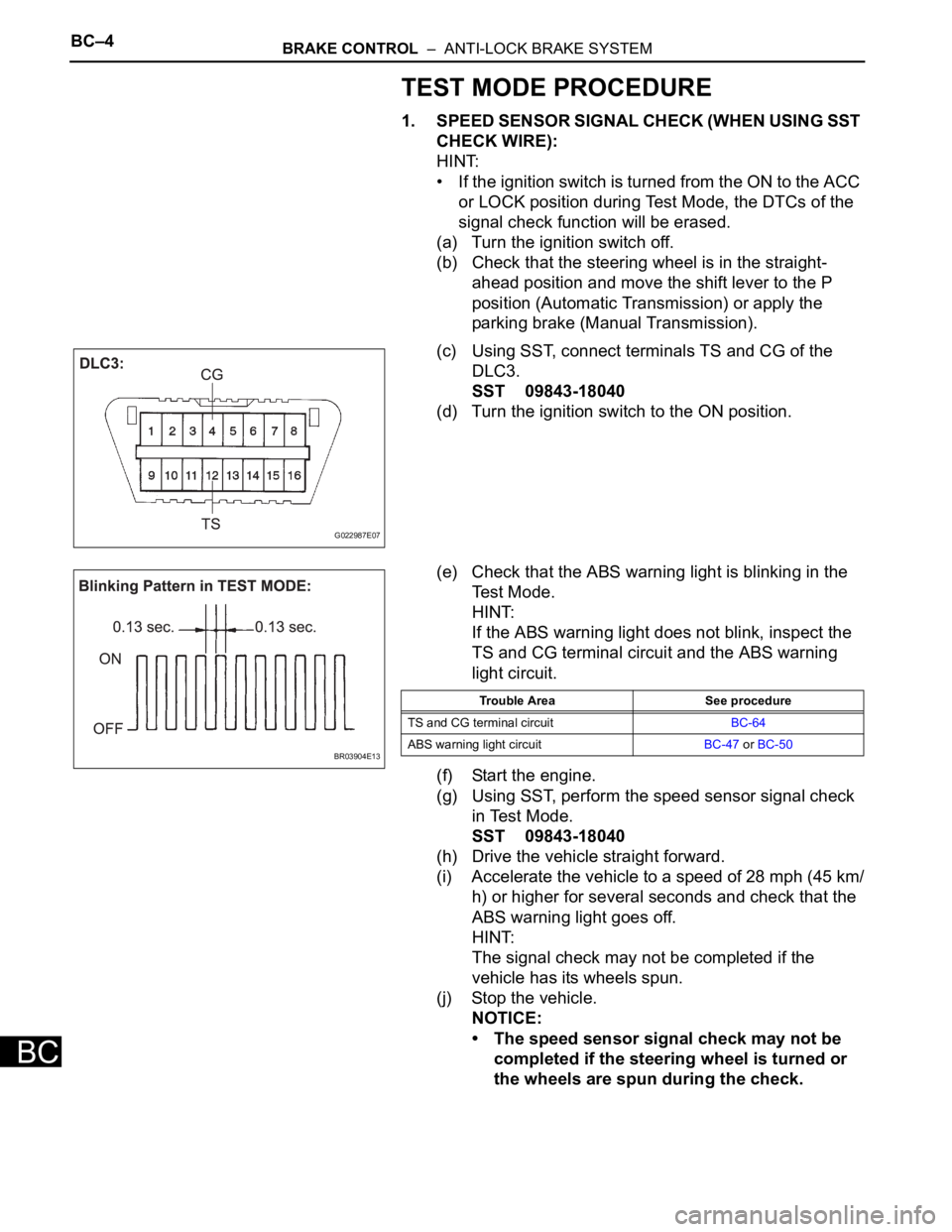

1. SPEED SENSOR SIGNAL CHECK (WHEN USING SST

CHECK WIRE):

HINT:

• If the ignition switch is turned from the ON to the ACC

or LOCK position during Test Mode, the DTCs of the

signal check function will be erased.

(a) Turn the ignition switch off.

(b) Check that the steering wheel is in the straight-

ahead position and move the shift lever to the P

position (Automatic Transmission) or apply the

parking brake (Manual Transmission).

(c) Using SST, connect terminals TS and CG of the

DLC3.

SST 09843-18040

(d) Turn the ignition switch to the ON position.

(e) Check that the ABS warning light is blinking in the

Test Mode.

HINT:

If the ABS warning light does not blink, inspect the

TS and CG terminal circuit and the ABS warning

light circuit.

(f) Start the engine.

(g) Using SST, perform the speed sensor signal check

in Test Mode.

SST 09843-18040

(h) Drive the vehicle straight forward.

(i) Accelerate the vehicle to a speed of 28 mph (45 km/

h) or higher for several seconds and check that the

ABS warning light goes off.

HINT:

The signal check may not be completed if the

vehicle has its wheels spun.

(j) Stop the vehicle.

NOTICE:

• The speed sensor signal check may not be

completed if the steering wheel is turned or

the wheels are spun during the check.

G022987E07

BR03904E13

Trouble Area See procedure

TS and CG terminal circuitBC-64

ABS warning light circuitBC-47 or BC-50

Page 187 of 3000

PARKING BRAKE – PARKING BRAKE PEDALPB–5

PB

REMOVAL

1. DISCONNECT BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH (See page IP-6)

5. REMOVE REAR DOOR SCUFF PLATE RH

6. REMOVE REAR DOOR SCUFF PLATE LH

7. REMOVE FRONT SEAT ASSEMBLY LH

HINT:

• Manual Seat Type (See page SE-48)

• Power Seat Type (See page SE-58)

• Fold Flat Type (See page SE-40)

8. REMOVE REAR SEAT NO.1 ASSEMBLY

HINT:

• Captain Seat Type (See page SE-68)

• Center Seat Type (See page SE-77)

9. REMOVE REAR FLOOR SEAT LOCK COVER

10. REMOVE REAR FLOOR SEAT LOCK COVER

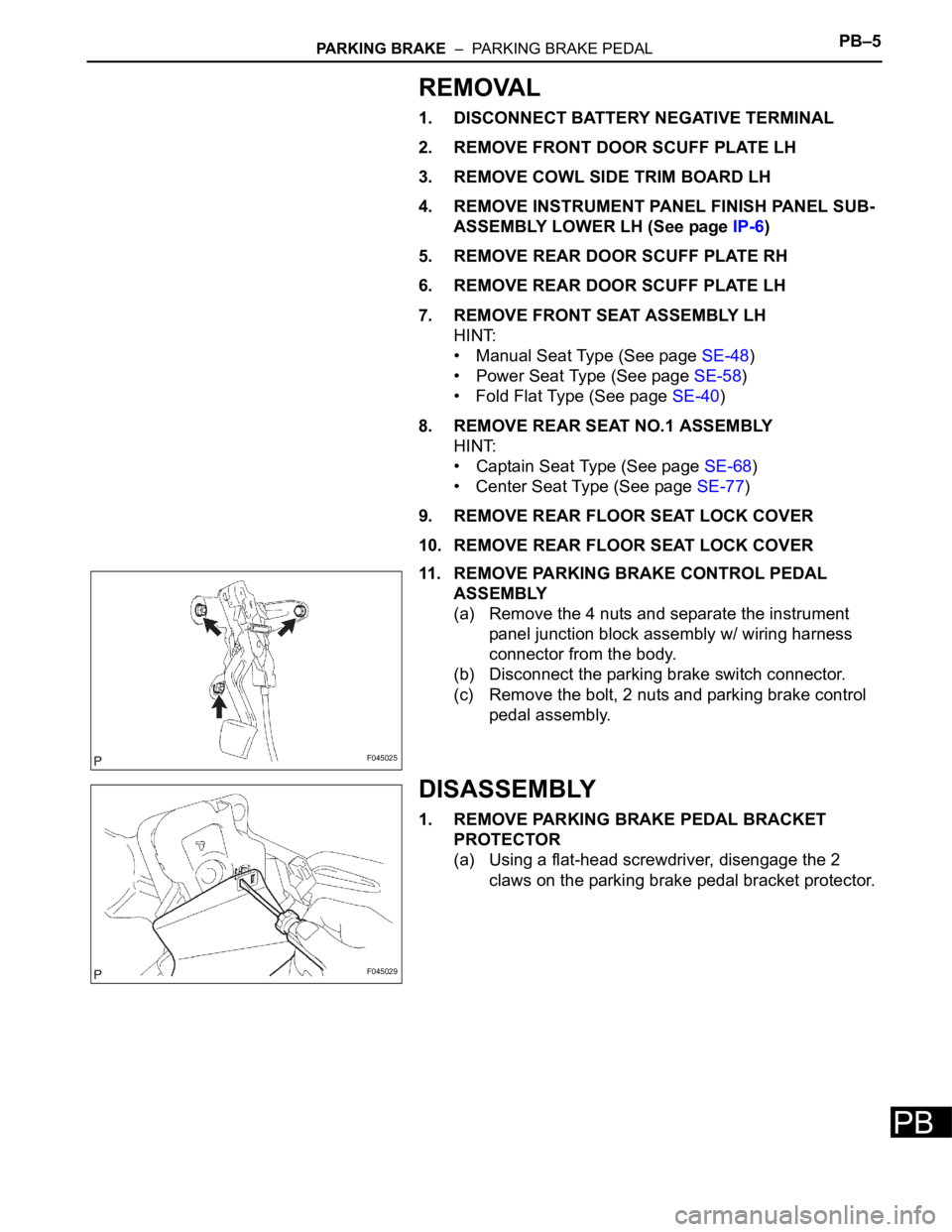

11. REMOVE PARKING BRAKE CONTROL PEDAL

ASSEMBLY

(a) Remove the 4 nuts and separate the instrument

panel junction block assembly w/ wiring harness

connector from the body.

(b) Disconnect the parking brake switch connector.

(c) Remove the bolt, 2 nuts and parking brake control

pedal assembly.

DISASSEMBLY

1. REMOVE PARKING BRAKE PEDAL BRACKET

PROTECTOR

(a) Using a flat-head screwdriver, disengage the 2

claws on the parking brake pedal bracket protector.

F045025

F045029

Page 188 of 3000

PB–6PARKING BRAKE – PARKING BRAKE PEDAL

PB

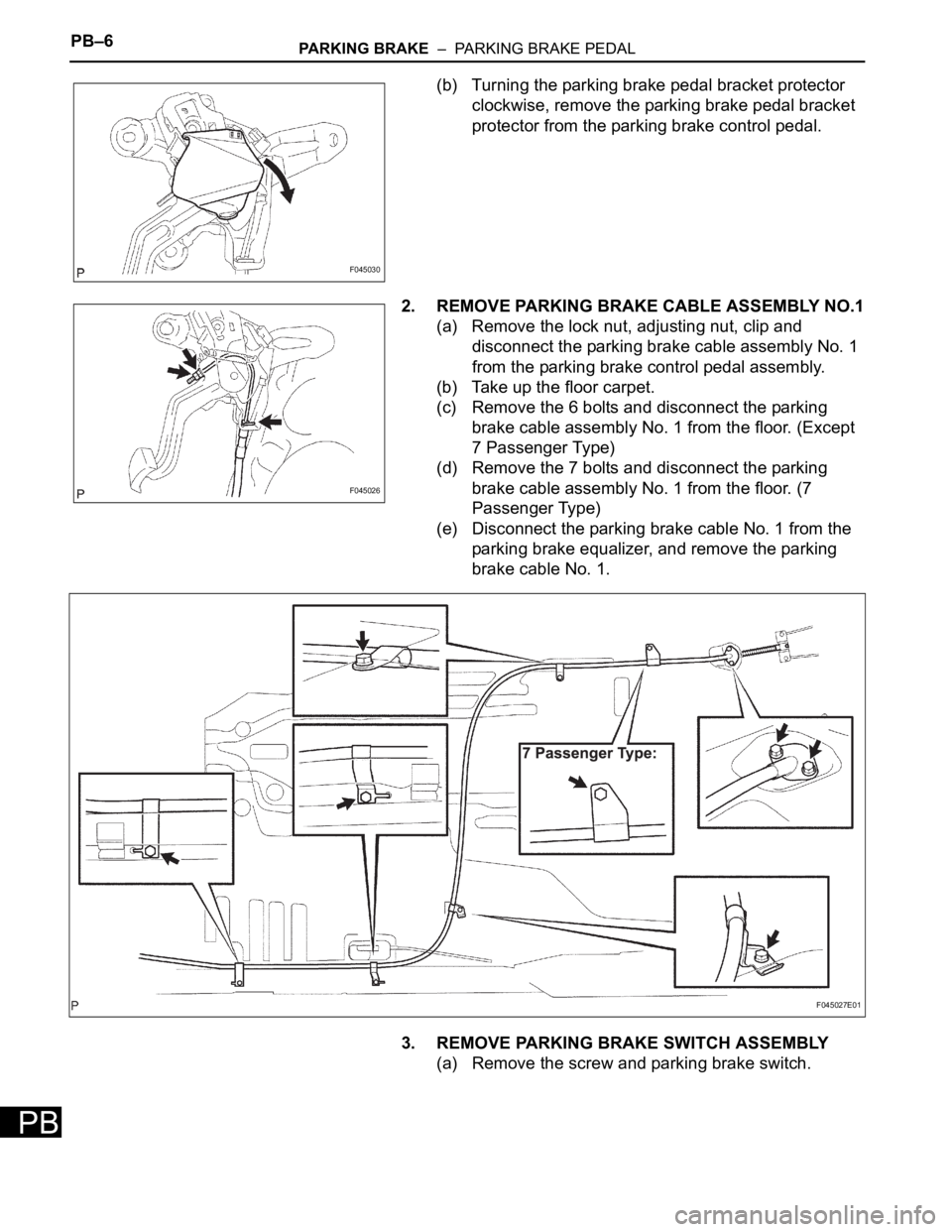

(b) Turning the parking brake pedal bracket protector

clockwise, remove the parking brake pedal bracket

protector from the parking brake control pedal.

2. REMOVE PARKING BRAKE CABLE ASSEMBLY NO.1

(a) Remove the lock nut, adjusting nut, clip and

disconnect the parking brake cable assembly No. 1

from the parking brake control pedal assembly.

(b) Take up the floor carpet.

(c) Remove the 6 bolts and disconnect the parking

brake cable assembly No. 1 from the floor. (Except

7 Passenger Type)

(d) Remove the 7 bolts and disconnect the parking

brake cable assembly No. 1 from the floor. (7

Passenger Type)

(e) Disconnect the parking brake cable No. 1 from the

parking brake equalizer, and remove the parking

brake cable No. 1.

3. REMOVE PARKING BRAKE SWITCH ASSEMBLY

(a) Remove the screw and parking brake switch.

F045030

F045026

F045027E01

Page 643 of 3000

ES–3502GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(f) Securely apply the parking brake and move the gear

selector lever to the D position (Procedure "A").

(g) While depressing the brake pedal securely, fully depress

the accelerator pedal for 5 seconds (Procedure "B").

(h) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / DTC INFO /

CURRENT CODES.

(i) Read the DTCs.

HINT:

The voltage output of the throttle position sensor can be

checked during procedure "B" using the intelligent tester.

Variations in the voltage output indicate that the throttle

actuator is in operation. To check the voltage output

using the intelligent tester, select the following menu

items: DIAGNOSIS / ENHANCED OBD II / DATA LIST /

PRIMARY / THROTTLE POS #1.

OK:

No DTC output.

NG

OKREPLACE THROTTLE BODY (See page ES-

493)

CHECK FOR INTERMITTENT PROBLEMS

Page 1389 of 3000

AX–12U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(d) 2 position test:

Shift into the 2 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2 up-shift takes place and

that the shift point conforms to the automatic

shift schedule (See page SS-24).

HINT:

There is no 3rd up-shift and lock-up in the 2

position.

(2) Check engine braking.

While running in the 2 position and 2nd gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(e) L position test:

Shift into the L position and fully depress the

accelerator pedal and check the following points.

(1) Check no up-shift.

While running in the L position, check that there

is no up-shift to 2nd gear.

HINT:

There is no lock-up in the L position.

(2) Check engine braking.

While running in the L position, release the

accelerator pedal and check the engine braking

effect.

(3) Check for abnormal noise during acceleration

and deceleration.

(f) R position test:

Shift into the R position and fully depress the

accelerator pedal and check for slipping.

CAUTION:

Before conducting this test ensure that the test

area is free from people and obstruction.

(g) P position test:

Stop the vehicle on the grade (more than 5

) and

after shifting into the P position, release the parking

brake. Then, check that the parking lock pawl holds

the vehicle in place.

(h) Uphill/downhill control function test:

(1) Check that the gear does not up-shift to the 4th

or 5th gear while the vehicle is driving uphill.

(2) Check that the gear automatically down-shifts

from 5th to 4th or from the 4th to 3rd gear when

brake is applied while the vehicle is driving

downhill.

Page 1390 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–13

AX

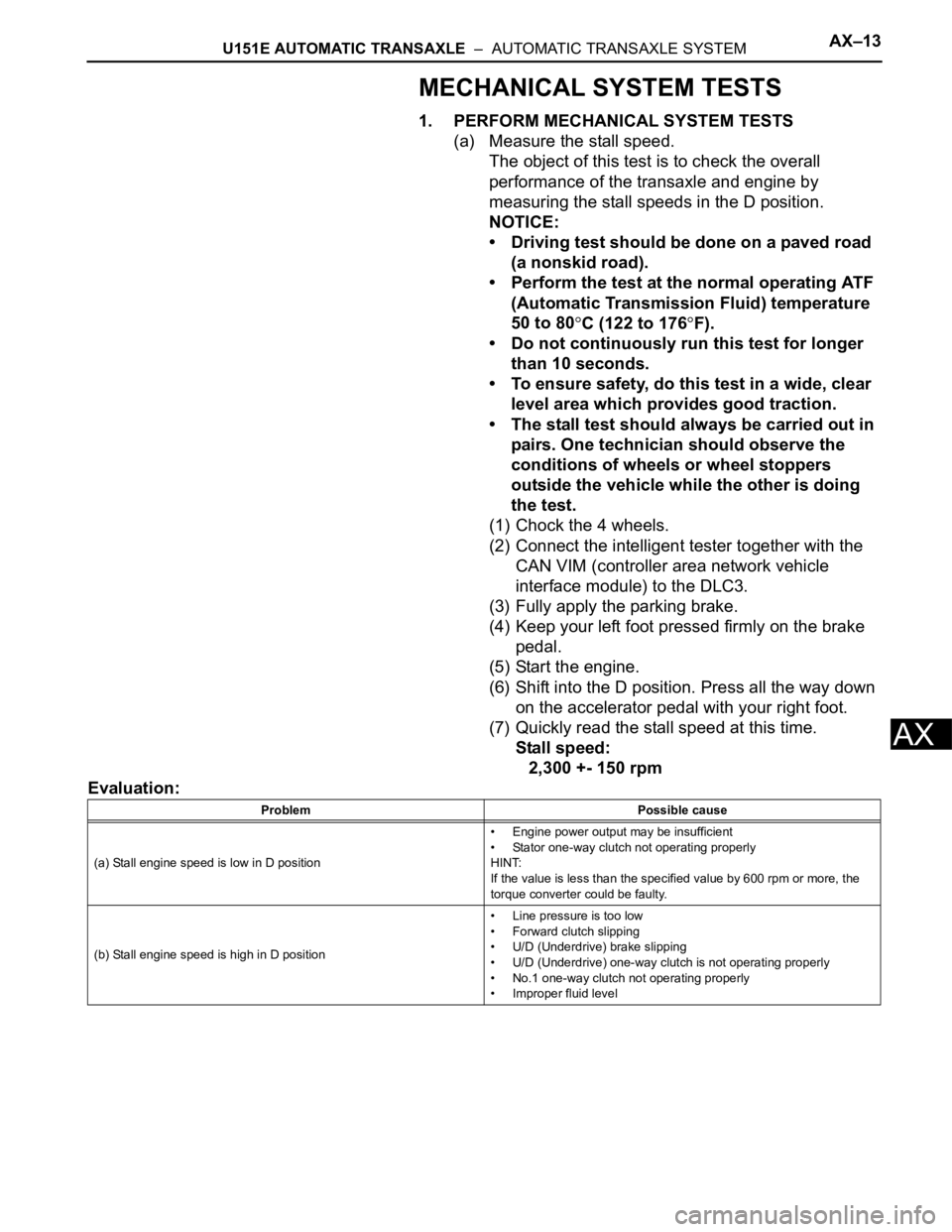

MECHANICAL SYSTEM TESTS

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D position.

NOTICE:

• Driving test should be done on a paved road

(a nonskid road).

• Perform the test at the normal operating ATF

(Automatic Transmission Fluid) temperature

50 to 80

C (122 to 176F).

• Do not continuously run this test for longer

than 10 seconds.

• To ensure safety, do this test in a wide, clear

level area which provides good traction.

• The stall test should always be carried out in

pairs. One technician should observe the

conditions of wheels or wheel stoppers

outside the vehicle while the other is doing

the test.

(1) Chock the 4 wheels.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Keep your left foot pressed firmly on the brake

pedal.

(5) Start the engine.

(6) Shift into the D position. Press all the way down

on the accelerator pedal with your right foot.

(7) Quickly read the stall speed at this time.

Stall speed:

2,300 +- 150 rpm

Evaluation:

Problem Possible cause

(a) Stall engine speed is low in D position• Engine power output may be insufficient

• Stator one-way clutch not operating properly

HINT:

If the value is less than the specified value by 600 rpm or more, the

torque converter could be faulty.

(b) Stall engine speed is high in D position• Line pressure is too low

• Forward clutch slipping

• U/D (Underdrive) brake slipping

• U/D (Underdrive) one-way clutch is not operating properly

• No.1 one-way clutch not operating properly

• Improper fluid level

Page 1391 of 3000

AX–14U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

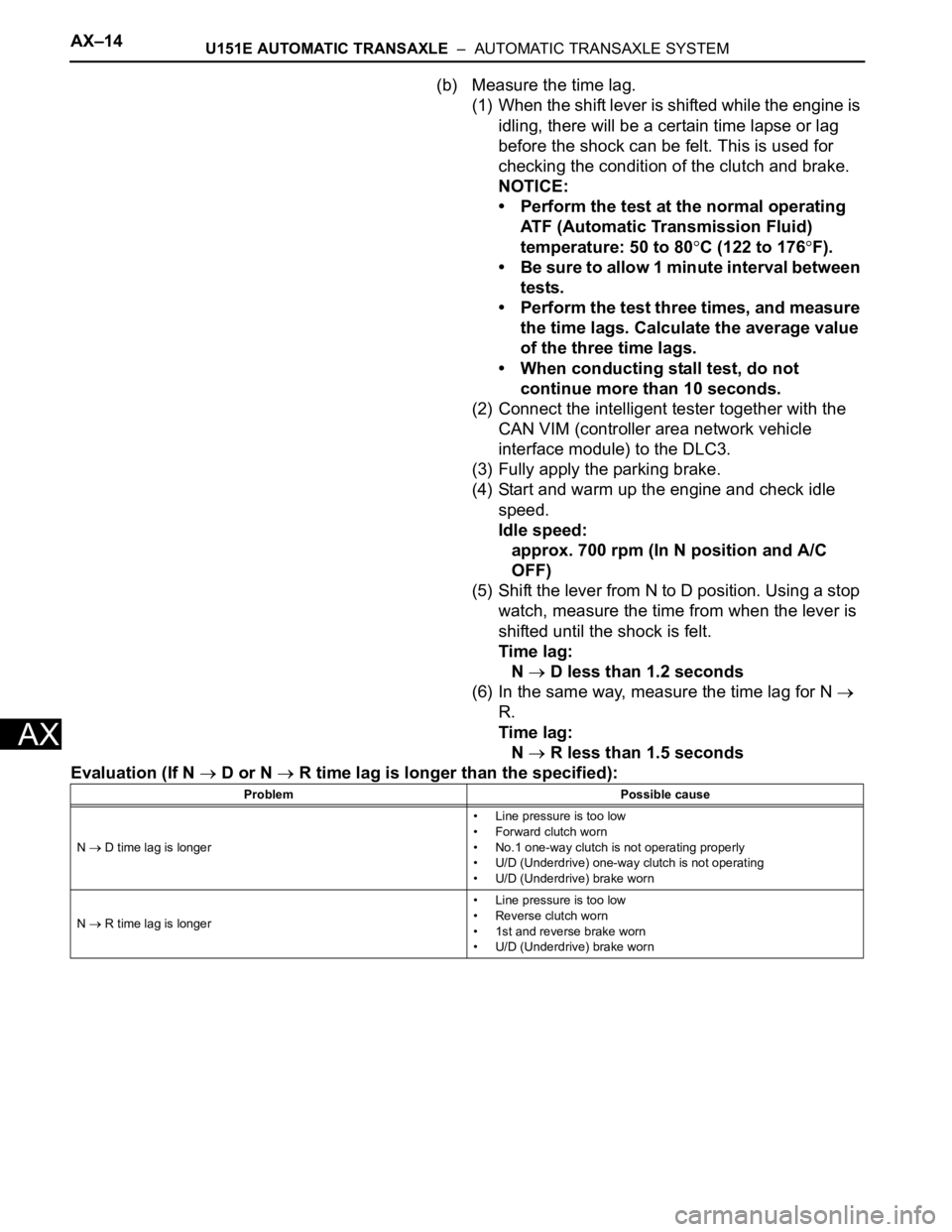

(b) Measure the time lag.

(1) When the shift lever is shifted while the engine is

idling, there will be a certain time lapse or lag

before the shock can be felt. This is used for

checking the condition of the clutch and brake.

NOTICE:

• Perform the test at the normal operating

ATF (Automatic Transmission Fluid)

temperature: 50 to 80

C (122 to 176F).

• Be sure to allow 1 minute interval between

tests.

• Perform the test three times, and measure

the time lags. Calculate the average value

of the three time lags.

• When conducting stall test, do not

continue more than 10 seconds.

(2) Connect the intelligent tester together with the

CAN VIM (controller area network vehicle

interface module) to the DLC3.

(3) Fully apply the parking brake.

(4) Start and warm up the engine and check idle

speed.

Idle speed:

approx. 700 rpm (In N position and A/C

OFF)

(5) Shift the lever from N to D position. Using a stop

watch, measure the time from when the lever is

shifted until the shock is felt.

Time lag:

N

D less than 1.2 seconds

(6) In the same way, measure the time lag for N

R.

Time lag:

N

R less than 1.5 seconds

Evaluation (If N

D or N R time lag is longer than the specified):

Problem Possible cause

N

D time lag is longer• Line pressure is too low

• Forward clutch worn

• No.1 one-way clutch is not operating properly

• U/D (Underdrive) one-way clutch is not operating

• U/D (Underdrive) brake worn

N

R time lag is longer• Line pressure is too low

• Reverse clutch worn

• 1st and reverse brake worn

• U/D (Underdrive) brake worn

Page 1498 of 3000

AX–12U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(d) 2 position test:

Shift into the 2 position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that the 1

2 up-shift takes place and

that the shift point conforms to the automatic

shift schedule (See page SS-24).

HINT:

There is no 3rd up-shift and lock-up in the 2

position.

(2) Check engine braking.

While running in the 2 position and 2nd gear,

release the accelerator pedal and check the

engine braking effect.

(3) Check for abnormal noise during acceleration

and deceleration, and for shock at up-shift and

down-shift.

(e) L position test:

Shift into the L position and fully depress the

accelerator pedal and check the following points.

(1) Check no up-shift.

While running in the L position, check that there

is no up-shift to 2nd gear.

HINT:

There is no lock-up in the L position.

(2) Check engine braking.

While running in the L position, release the

accelerator pedal and check the engine braking

effect.

(3) Check for abnormal noise during acceleration

and deceleration.

(f) R position test:

Shift into the R position and fully depress the

accelerator pedal and check for slipping.

CAUTION:

Before conducting this test ensure that the test

area is free from people and obstruction.

(g) P position test:

Stop the vehicle on the grade (more than 5

) and

after shifting into the P position, release the parking

brake. Then, check that the parking lock pawl holds

the vehicle in place.

(h) Uphill/downhill control function test:

(1) Check that the gear does not up-shift to the 4th

or 5th gear while the vehicle is driving uphill.

(2) Check that the gear automatically down-shifts

from 5th to 4th or from the 4th to 3rd gear when

brake is applied while the vehicle is driving

downhill.

Page 1499 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE FLUIDAX–123

AX

AUTOMATIC TRANSAXLE FLUID

ON-VEHICLE INSPECTION

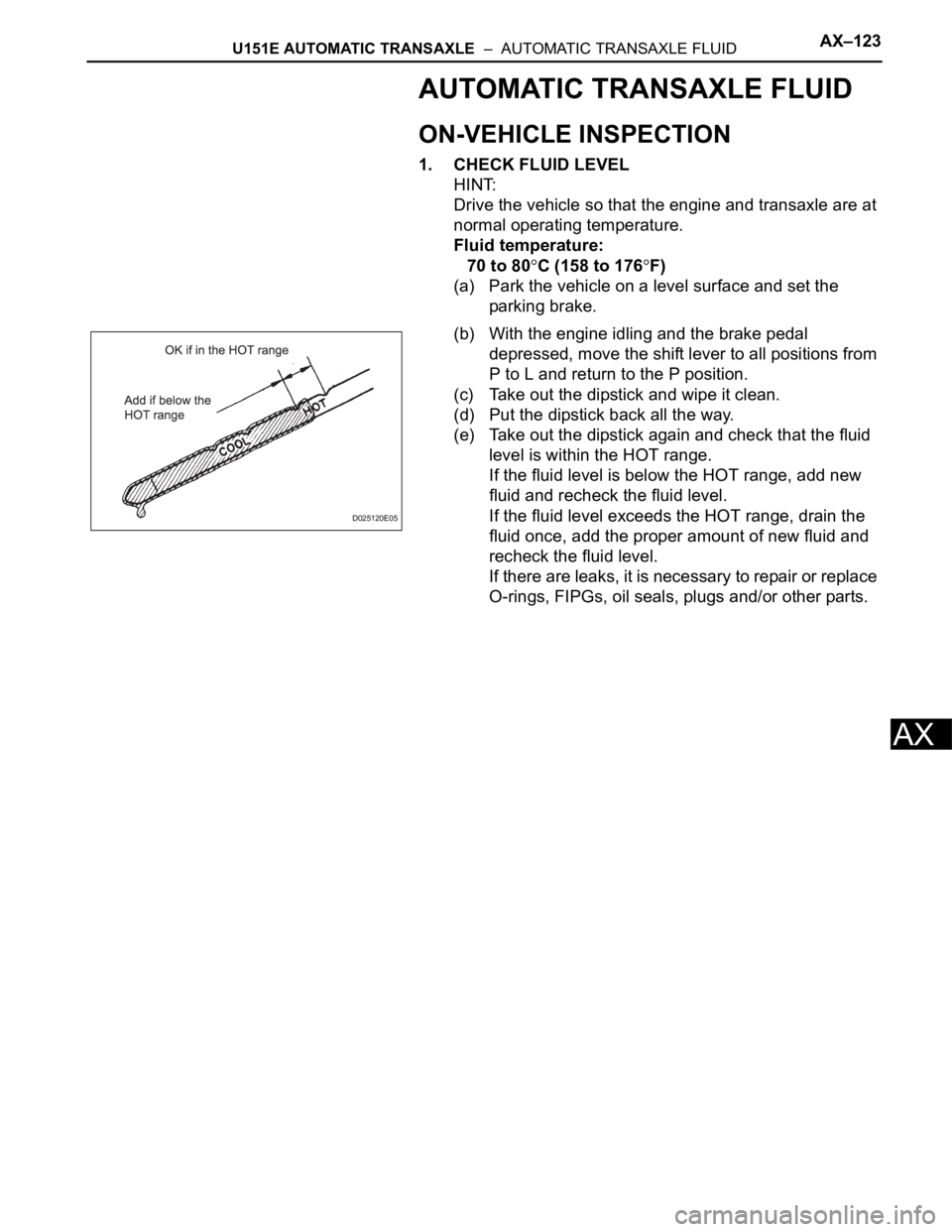

1. CHECK FLUID LEVEL

HINT:

Drive the vehicle so that the engine and transaxle are at

normal operating temperature.

Fluid temperature:

70 to 80

C (158 to 176F)

(a) Park the vehicle on a level surface and set the

parking brake.

(b) With the engine idling and the brake pedal

depressed, move the shift lever to all positions from

P to L and return to the P position.

(c) Take out the dipstick and wipe it clean.

(d) Put the dipstick back all the way.

(e) Take out the dipstick again and check that the fluid

level is within the HOT range.

If the fluid level is below the HOT range, add new

fluid and recheck the fluid level.

If the fluid level exceeds the HOT range, drain the

fluid once, add the proper amount of new fluid and

recheck the fluid level.

If there are leaks, it is necessary to repair or replace

O-rings, FIPGs, oil seals, plugs and/or other parts.

D025120E05