roof TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 51 of 3000

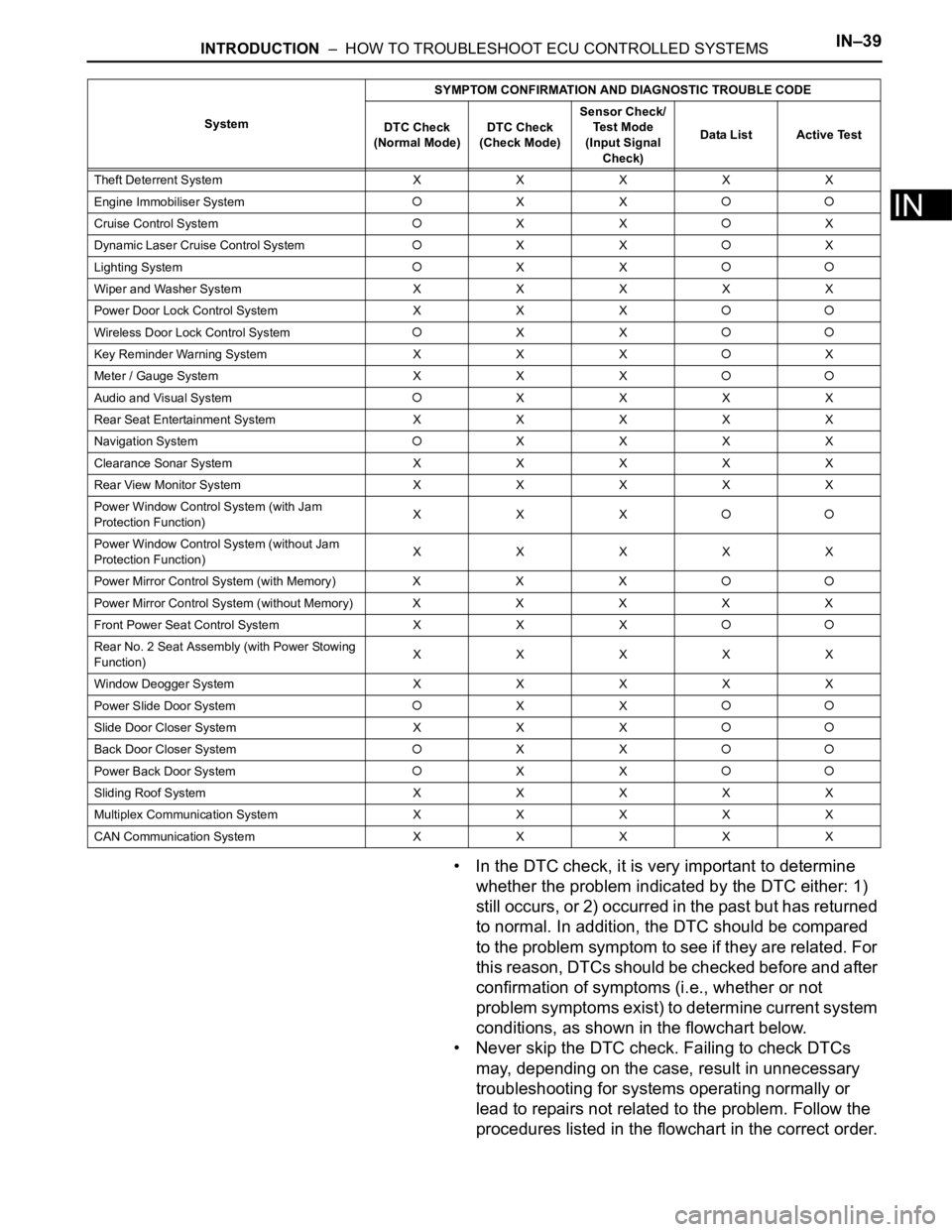

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–39

IN

• In the DTC check, it is very important to determine

whether the problem indicated by the DTC either: 1)

still occurs, or 2) occurred in the past but has returned

to normal. In addition, the DTC should be compared

to the problem symptom to see if they are related. For

this reason, DTCs should be checked before and after

confirmation of symptoms (i.e., whether or not

problem symptoms exist) to determine current system

conditions, as shown in the flowchart below.

• Never skip the DTC check. Failing to check DTCs

may, depending on the case, result in unnecessary

troubleshooting for systems operating normally or

lead to repairs not related to the problem. Follow the

procedures listed in the flowchart in the correct order.

Theft Deterrent System XXXXX

Engine Immobiliser System

XX

Cruise Control SystemXXX

Dynamic Laser Cruise Control System

XXX

Lighting System

XX

Wiper and Washer SystemXXXXX

Power Door Lock Control System X X X

Wireless Door Lock Control SystemXX

Key Reminder Warning System X X XX

Meter / Gauge System X X X

Audio and Visual SystemXXXX

Rear Seat Entertainment System XXXXX

Navigation System

XXXX

Clearance Sonar SystemXXXXX

Rear View Monitor System XXXXX

Power Window Control System (with Jam

Protection Function)XXX

Power Window Control System (without Jam

Protection Function)XXXXX

Power Mirror Control System (with Memory) X X X

Power Mirror Control System (without Memory)XXXXX

Front Power Seat Control System X X X

Rear No. 2 Seat Assembly (with Power Stowing

Function)XXXXX

Window Deogger SystemXXXXX

Power Slide Door System

XX

Slide Door Closer System X X X

Back Door Closer SystemXX

Power Back Door SystemXX

Sliding Roof System XXXXX

Multiplex Communication System XXXXX

CAN Communication System XXXXXSystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

Page 61 of 3000

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–31

IN

ELECTRONIC CIRCUIT INSPECTION

PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF

ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance

measurements should be made at an ambient

temperature of 20

C (68F). Resistance

measurements may be inaccurate if measured

at high temperatures, i.e. immediately after the

vehicle has been running. Measurements should

be made after the engine has cooled down.

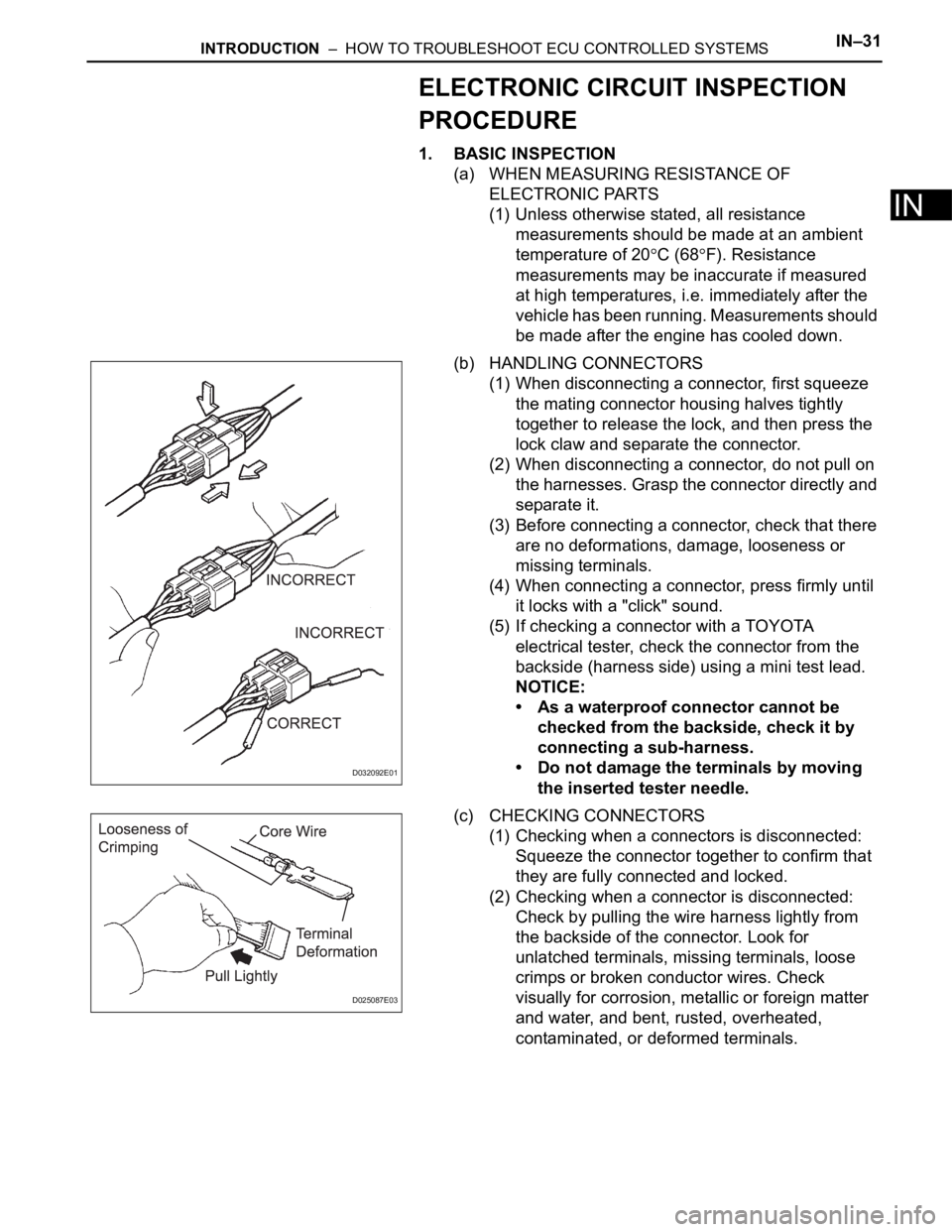

(b) HANDLING CONNECTORS

(1) When disconnecting a connector, first squeeze

the mating connector housing halves tightly

together to release the lock, and then press the

lock claw and separate the connector.

(2) When disconnecting a connector, do not pull on

the harnesses. Grasp the connector directly and

separate it.

(3) Before connecting a connector, check that there

are no deformations, damage, looseness or

missing terminals.

(4) When connecting a connector, press firmly until

it locks with a "click" sound.

(5) If checking a connector with a TOYOTA

electrical tester, check the connector from the

backside (harness side) using a mini test lead.

NOTICE:

• As a waterproof connector cannot be

checked from the backside, check it by

connecting a sub-harness.

• Do not damage the terminals by moving

the inserted tester needle.

(c) CHECKING CONNECTORS

(1) Checking when a connectors is disconnected:

Squeeze the connector together to confirm that

they are fully connected and locked.

(2) Checking when a connector is disconnected:

Check by pulling the wire harness lightly from

the backside of the connector. Look for

unlatched terminals, missing terminals, loose

crimps or broken conductor wires. Check

visually for corrosion, metallic or foreign matter

and water, and bent, rusted, overheated,

contaminated, or deformed terminals.

D032092E01

D025087E03

Page 69 of 3000

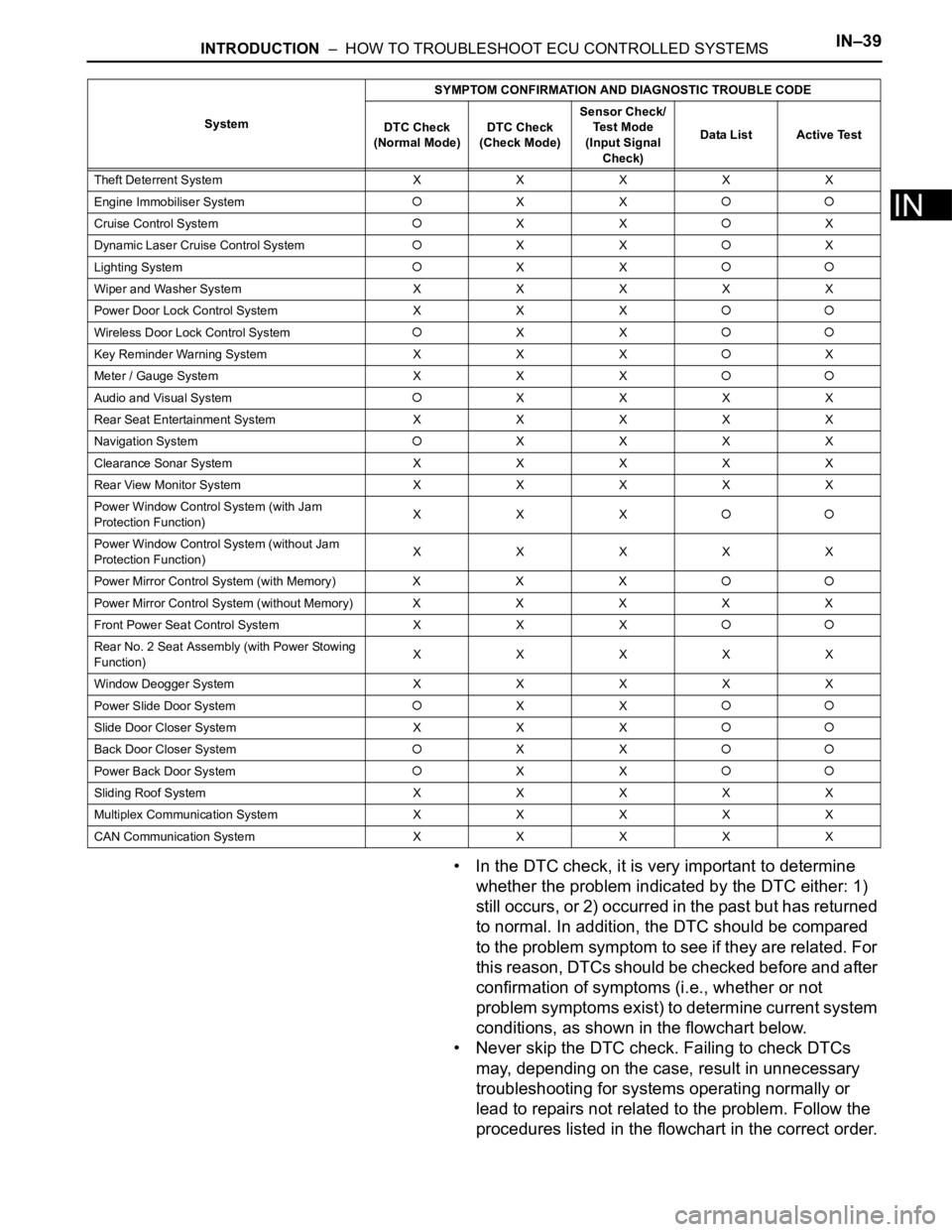

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–39

IN

• In the DTC check, it is very important to determine

whether the problem indicated by the DTC either: 1)

still occurs, or 2) occurred in the past but has returned

to normal. In addition, the DTC should be compared

to the problem symptom to see if they are related. For

this reason, DTCs should be checked before and after

confirmation of symptoms (i.e., whether or not

problem symptoms exist) to determine current system

conditions, as shown in the flowchart below.

• Never skip the DTC check. Failing to check DTCs

may, depending on the case, result in unnecessary

troubleshooting for systems operating normally or

lead to repairs not related to the problem. Follow the

procedures listed in the flowchart in the correct order.

Theft Deterrent System XXXXX

Engine Immobiliser System

XX

Cruise Control SystemXXX

Dynamic Laser Cruise Control System

XXX

Lighting System

XX

Wiper and Washer SystemXXXXX

Power Door Lock Control System X X X

Wireless Door Lock Control SystemXX

Key Reminder Warning System X X XX

Meter / Gauge System X X X

Audio and Visual SystemXXXX

Rear Seat Entertainment System XXXXX

Navigation System

XXXX

Clearance Sonar SystemXXXXX

Rear View Monitor System XXXXX

Power Window Control System (with Jam

Protection Function)XXX

Power Window Control System (without Jam

Protection Function)XXXXX

Power Mirror Control System (with Memory) X X X

Power Mirror Control System (without Memory)XXXXX

Front Power Seat Control System X X X

Rear No. 2 Seat Assembly (with Power Stowing

Function)XXXXX

Window Deogger SystemXXXXX

Power Slide Door System

XX

Slide Door Closer System X X X

Back Door Closer SystemXX

Power Back Door SystemXX

Sliding Roof System XXXXX

Multiplex Communication System XXXXX

CAN Communication System XXXXXSystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

Page 845 of 3000

SLIDING ROOF – SLIDING ROOF SYSTEMRF–3

RF

INITIALIZATION

1. RESET SLIDING ROOF MOTOR

(a) If the AUTO operation function does not operate,

reset the sliding roof motor using any of the

following methods.

(1) Press the sliding roof switch on the TILT UP side

and hold it until the sliding roof motor stops.

Then release the switch and leave it untouched

for 10 seconds or more.

(2) Press the sliding roof switch on the TILT UP side

again for 10 seconds or more and hold it until the

sliding roof stops at the fully open and up

position.

(3) Release the switch, press it again within 5

seconds and hold it until a series of movements

indicated below has done:

Fully closing

Fully opening Fully closing

HINT:

If the battery terminal is disconnected or after

the jam protection function has operated, the

sliding roof ECU may not detect a position of the

roof glass. If the AUTO operation function is still

disabled even if the sliding roof motor has been

reset, the Hall IC (built in the sliding roof motor

assembly) for detecting the roof glass position

may be malfunctioning.

Page 846 of 3000

RF–4SLIDING ROOF – SLIDING ROOF SYSTEM

RF

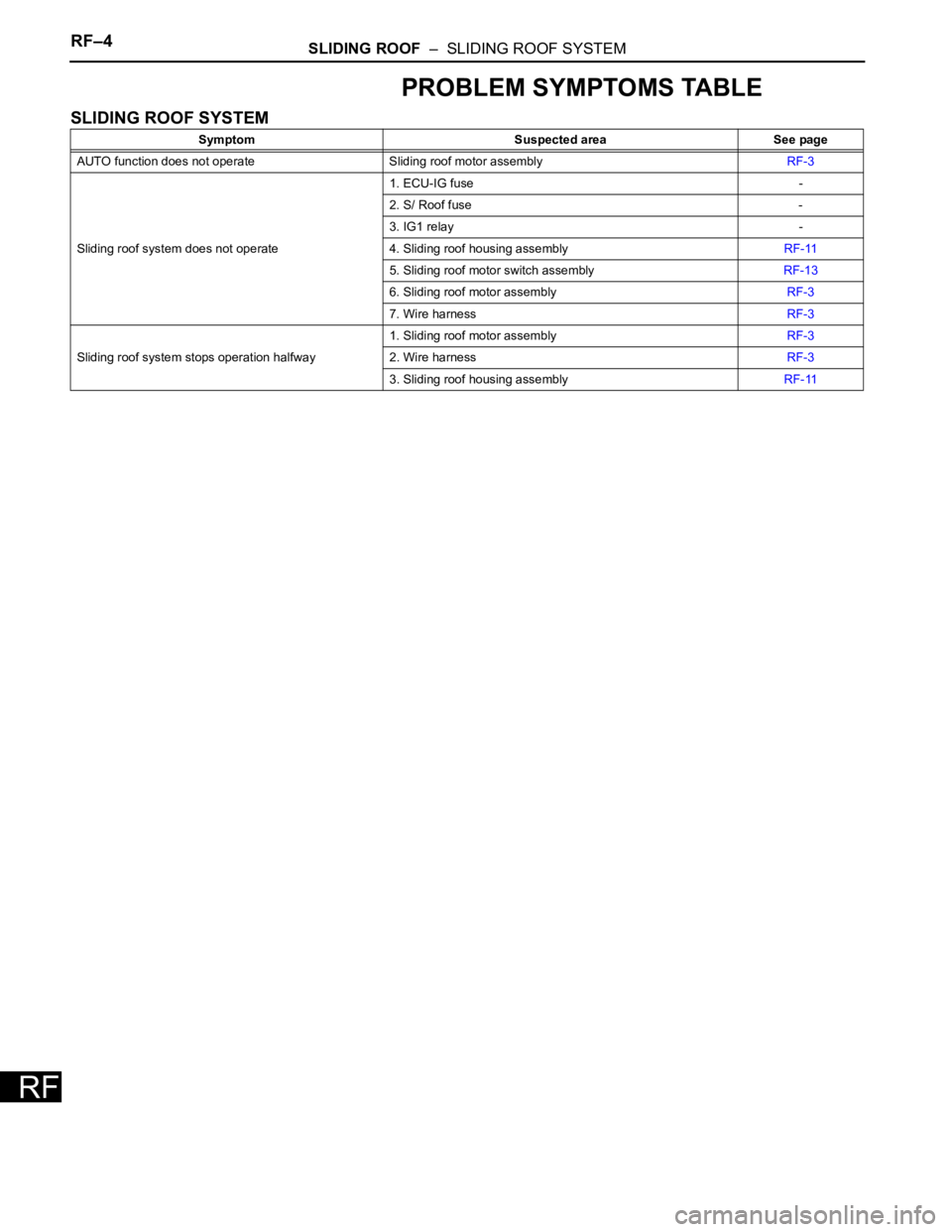

PROBLEM SYMPTOMS TABLE

SLIDING ROOF SYSTEM

Symptom Suspected area See page

AUTO function does not operate Sliding roof motor assemblyRF-3

Sliding roof system does not operate1. ECU-IG fuse -

2. S/ Roof fuse -

3. IG1 relay -

4. Sliding roof housing assemblyRF-11

5. Sliding roof motor switch assemblyRF-13

6. Sliding roof motor assemblyRF-3

7. Wire harnessRF-3

Sliding roof system stops operation halfway1. Sliding roof motor assemblyRF-3

2. Wire harnessRF-3

3. Sliding roof housing assemblyRF-11

Page 2331 of 3000

TW–82TIRE AND WHEEL – TIRE PRESSURE WARNING RECEIVER (w/ Antenna)

TW

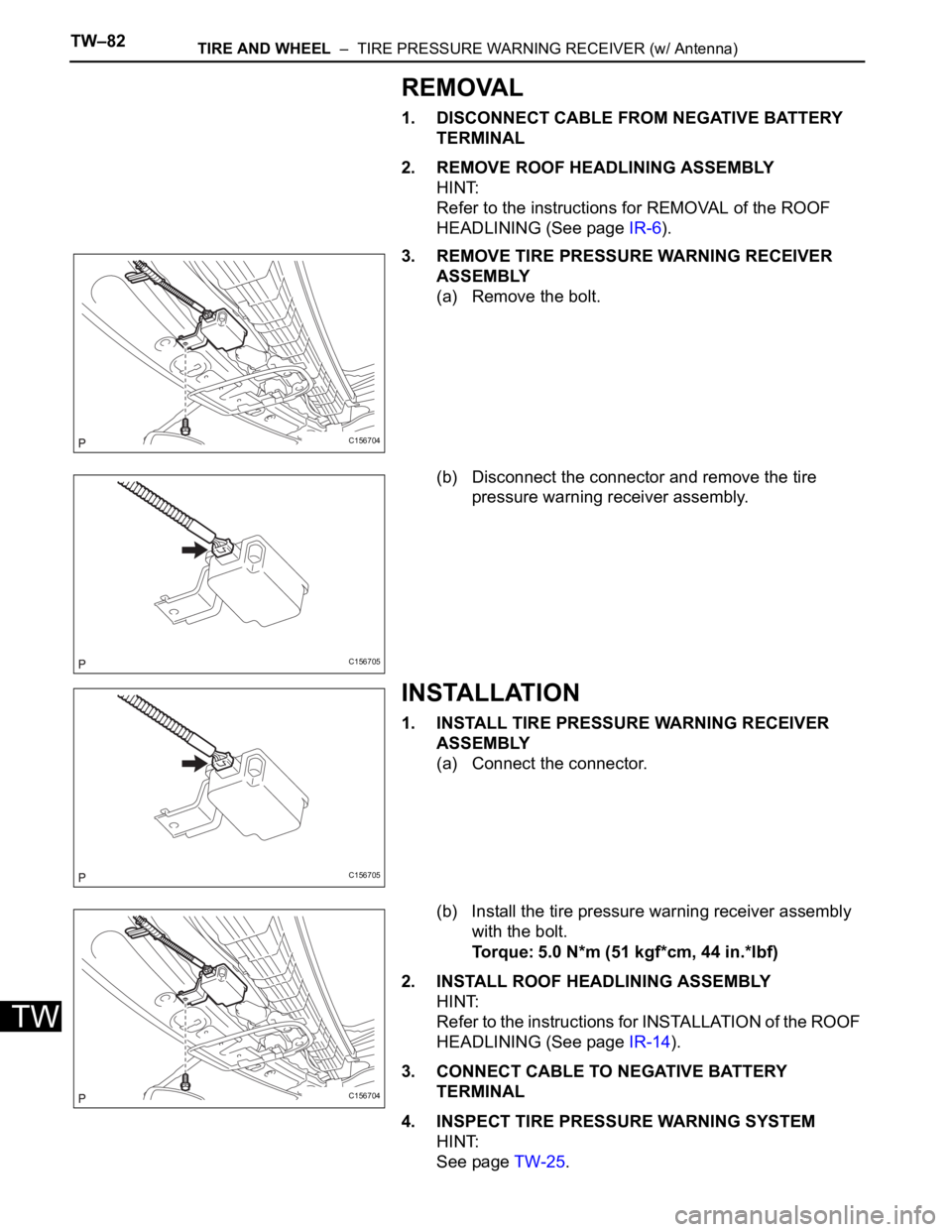

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE ROOF HEADLINING ASSEMBLY

HINT:

Refer to the instructions for REMOVAL of the ROOF

HEADLINING (See page IR-6).

3. REMOVE TIRE PRESSURE WARNING RECEIVER

ASSEMBLY

(a) Remove the bolt.

(b) Disconnect the connector and remove the tire

pressure warning receiver assembly.

INSTALLATION

1. INSTALL TIRE PRESSURE WARNING RECEIVER

ASSEMBLY

(a) Connect the connector.

(b) Install the tire pressure warning receiver assembly

with the bolt.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

2. INSTALL ROOF HEADLINING ASSEMBLY

HINT:

Refer to the instructions for INSTALLATION of the ROOF

HEADLINING (See page IR-14).

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

4. INSPECT TIRE PRESSURE WARNING SYSTEM

HINT:

See page TW-25.

C156704

C156705

C156705

C156704

Page 2942 of 3000

AC–204AIR CONDITIONING – BLOWER UNIT (for Rear Air Conditioning System)

AC

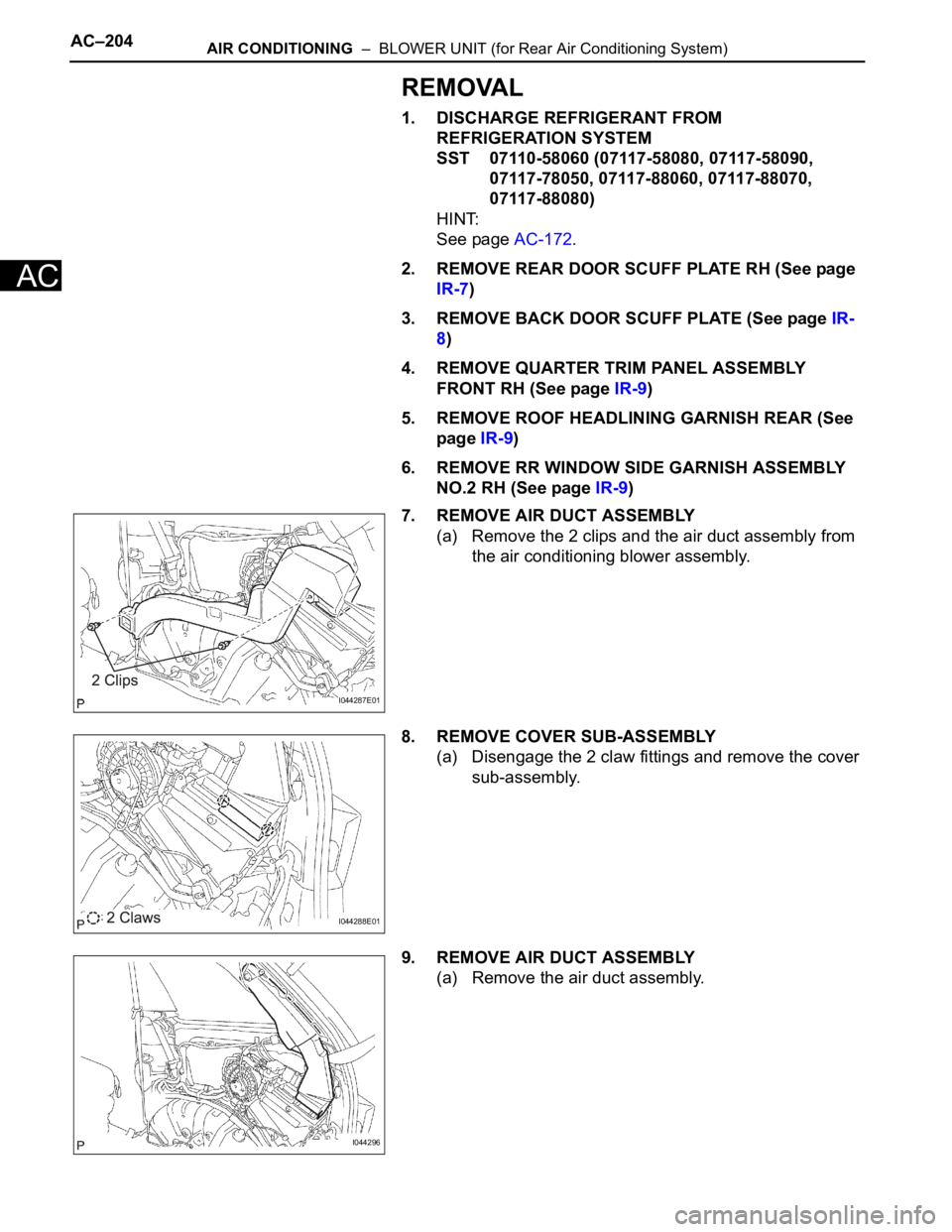

REMOVAL

1. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM

SST 07110-58060 (07117-58080, 07117-58090,

07117-78050, 07117-88060, 07117-88070,

07117-88080)

HINT:

See page AC-172.

2. REMOVE REAR DOOR SCUFF PLATE RH (See page

IR-7)

3. REMOVE BACK DOOR SCUFF PLATE (See page IR-

8)

4. REMOVE QUARTER TRIM PANEL ASSEMBLY

FRONT RH (See page IR-9)

5. REMOVE ROOF HEADLINING GARNISH REAR (See

page IR-9)

6. REMOVE RR WINDOW SIDE GARNISH ASSEMBLY

NO.2 RH (See page IR-9)

7. REMOVE AIR DUCT ASSEMBLY

(a) Remove the 2 clips and the air duct assembly from

the air conditioning blower assembly.

8. REMOVE COVER SUB-ASSEMBLY

(a) Disengage the 2 claw fittings and remove the cover

sub-assembly.

9. REMOVE AIR DUCT ASSEMBLY

(a) Remove the air duct assembly.

I044287E01

I044288E01

I044296