suspension TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 33 of 3000

EM–342GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

45. REMOVE PROPELLER WITH CENTER BEARING

SHAFT ASSEMBLY (See page PR-3)

46. DISCONNECT FRONT STABILIZER LINK ASSEMBLY

LH (See page DS-5)

47. DISCONNECT FRONT STABILIZER LINK ASSEMBLY

RH

HINT:

Use the same procedures described for the LH side.

48. REMOVE FRONT AXLE HUB NUT LH (See page DS-

5)

49. REMOVE FRONT AXLE HUB NUT RH

HINT:

Use the same procedures described for the LH side.

50. DISCONNECT FRONT SPEED SENSOR LH (See page

DS-5)

51. DISCONNECT FRONT SPEED SENSOR RH

HINT:

Use the same procedures described for the LH side.

52. DISCONNECT TIE ROD ASSEMBLY LH (See page

DS-6)

53. DISCONNECT TIE ROD ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

54. SEPARATE FRONT SUSPENSION LOWER NO. 1

ARM LH (See page DS-6)

55. SEPARATE FRONT SUSPENSION LOWER NO. 1

ARM RH

HINT:

Use the same procedures described for the LH side.

56. SEPARATE FRONT AXLE ASSEMBLY LH (See page

DS-6)

57. SEPARATE FRONT AXLE ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

58. DISCONNECT STEERING INTERMEDIATE SHAFT

SUB-ASSEMBLY

59. DISCONNECT DISCHARGE HOSE SUB-ASSEMBLY

(See page AC-227)

60. DISCONNECT SUCTION HOSE SUB-ASSEMBLY (See

page AC-227)

61. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set the engine lifter.

Page 34 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–35

EM

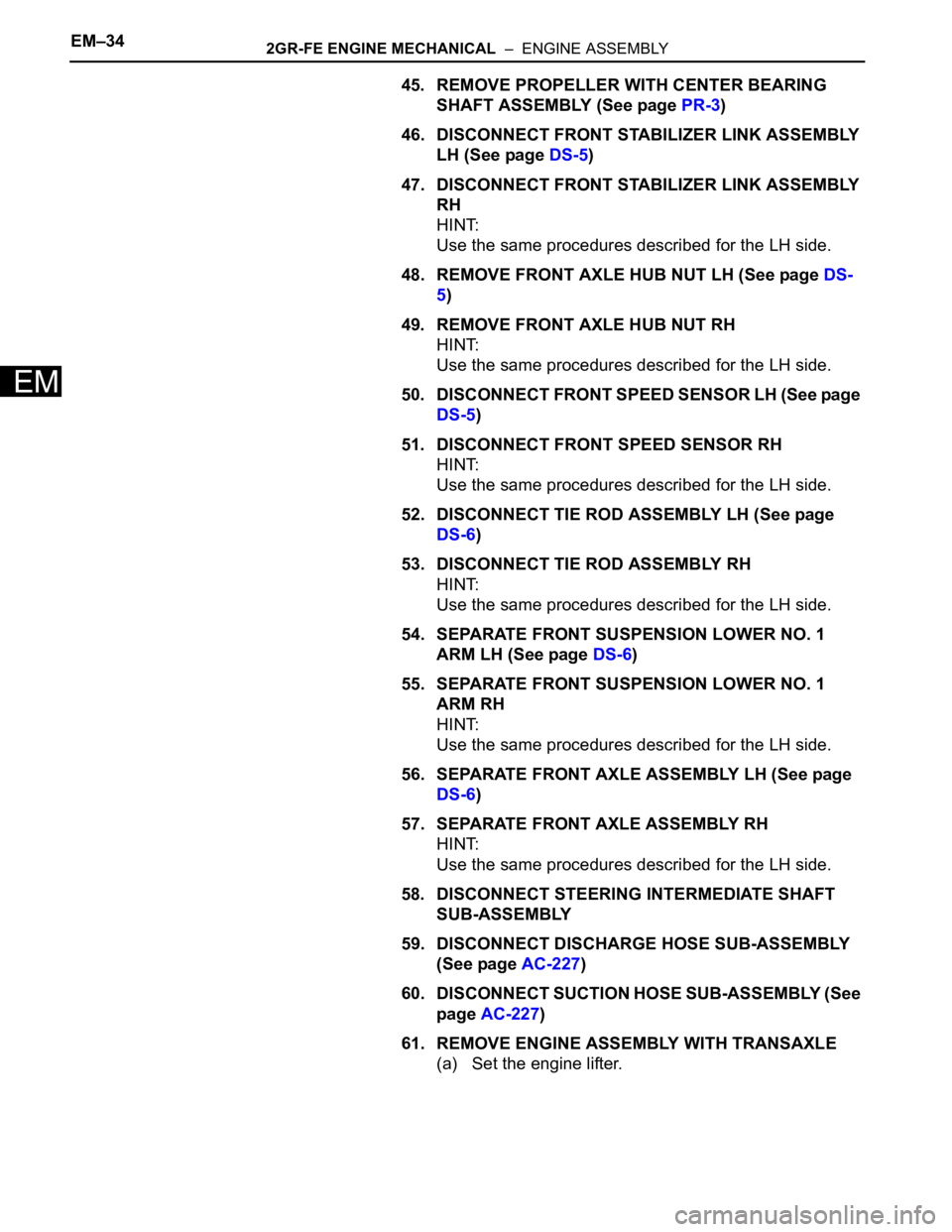

(b) Remove the 6 bolts, 2 nuts, and frame side rail

plates RH and LH.

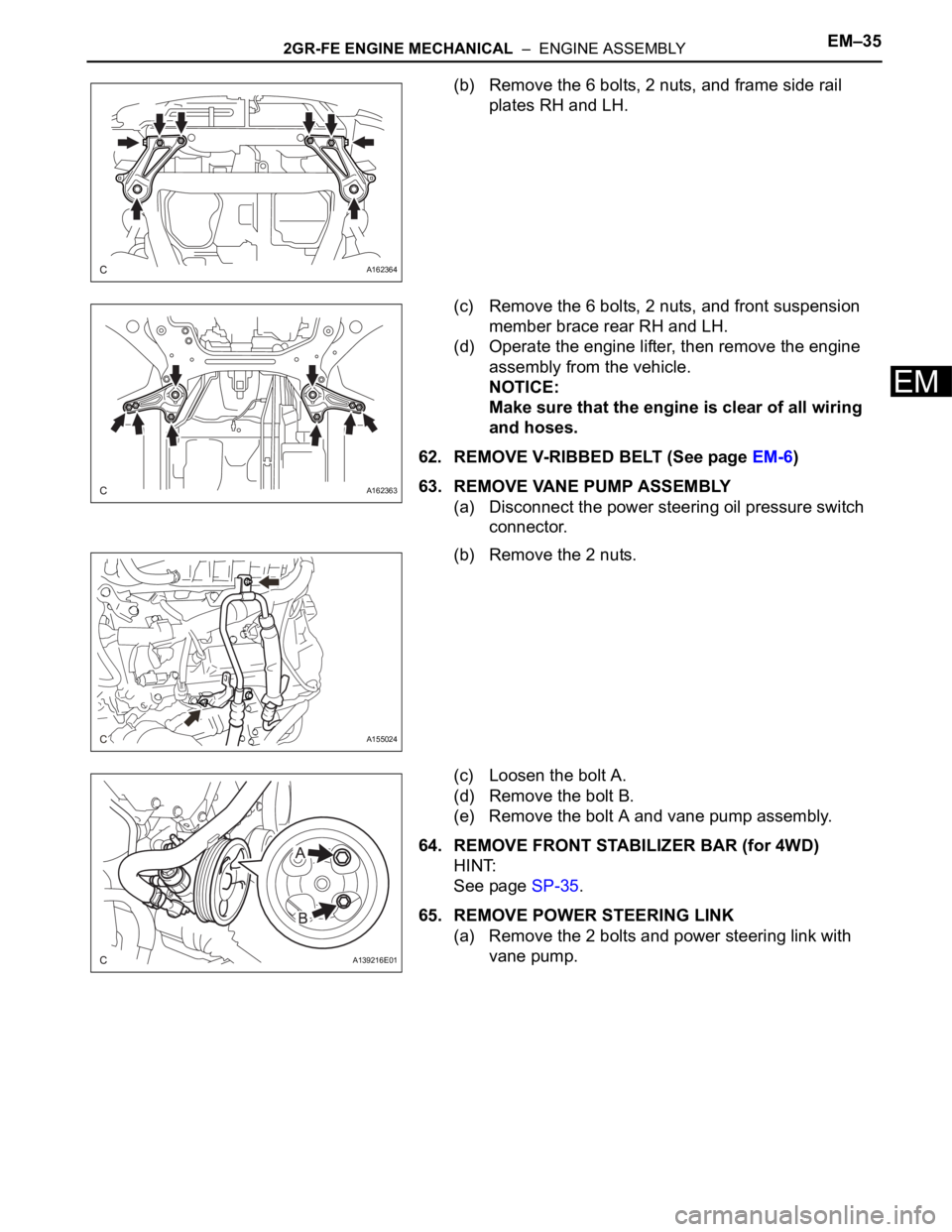

(c) Remove the 6 bolts, 2 nuts, and front suspension

member brace rear RH and LH.

(d) Operate the engine lifter, then remove the engine

assembly from the vehicle.

NOTICE:

Make sure that the engine is clear of all wiring

and hoses.

62. REMOVE V-RIBBED BELT (See page EM-6)

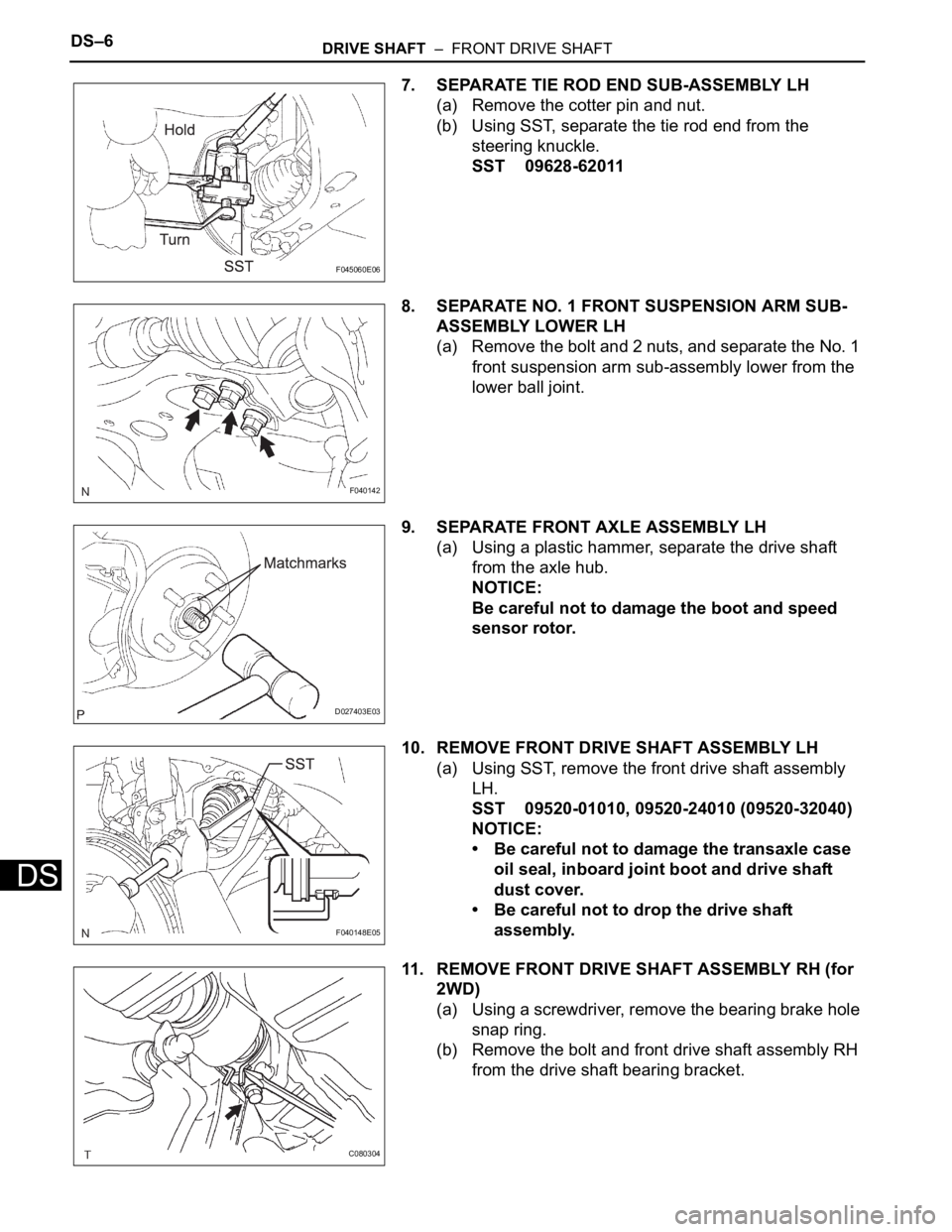

63. REMOVE VANE PUMP ASSEMBLY

(a) Disconnect the power steering oil pressure switch

connector.

(b) Remove the 2 nuts.

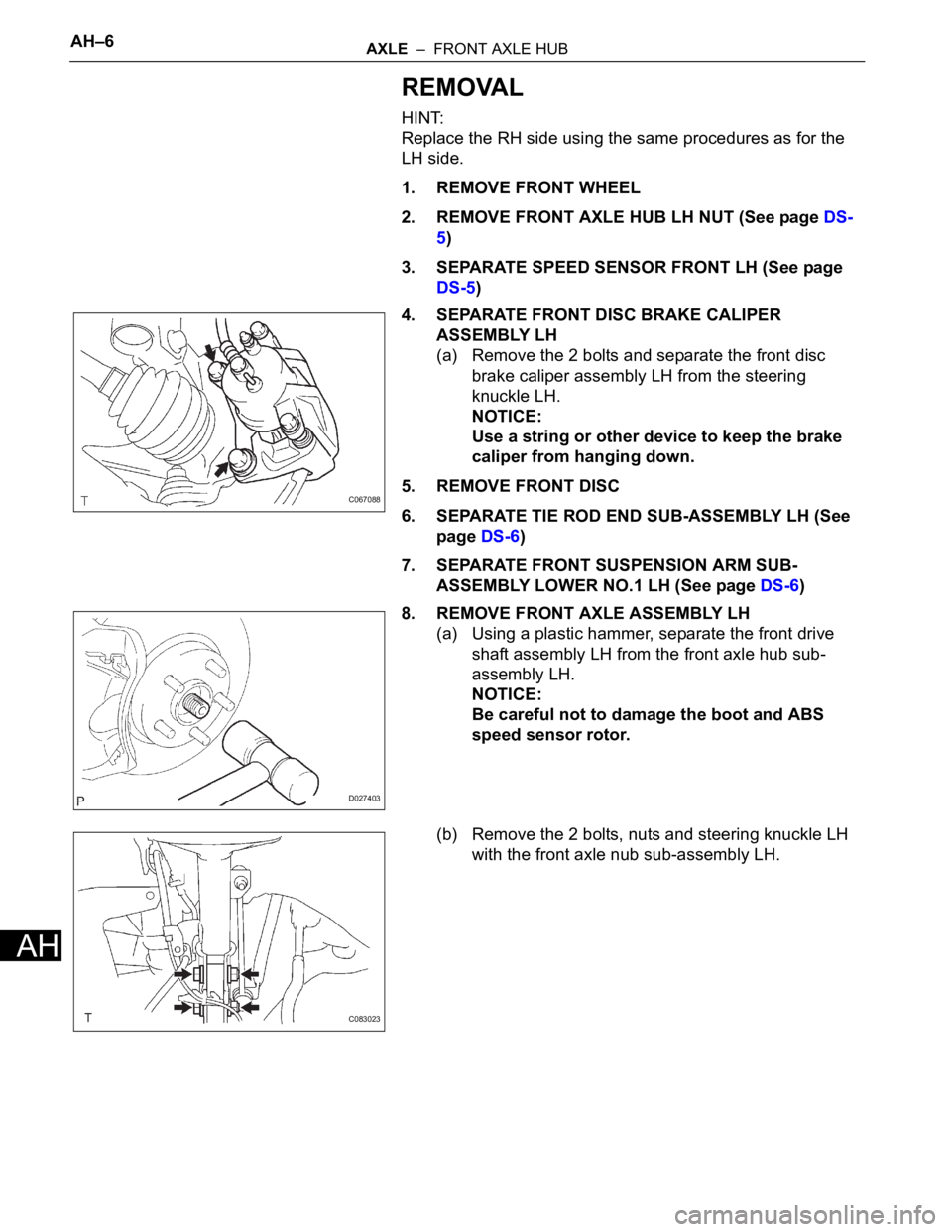

(c) Loosen the bolt A.

(d) Remove the bolt B.

(e) Remove the bolt A and vane pump assembly.

64. REMOVE FRONT STABILIZER BAR (for 4WD)

HINT:

See page SP-35.

65. REMOVE POWER STEERING LINK

(a) Remove the 2 bolts and power steering link with

vane pump.

A162364

A162363

A155024

A139216E01

Page 111 of 3000

DS–6DRIVE SHAFT – FRONT DRIVE SHAFT

DS

7. SEPARATE TIE ROD END SUB-ASSEMBLY LH

(a) Remove the cotter pin and nut.

(b) Using SST, separate the tie rod end from the

steering knuckle.

SST 09628-62011

8. SEPARATE NO. 1 FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER LH

(a) Remove the bolt and 2 nuts, and separate the No. 1

front suspension arm sub-assembly lower from the

lower ball joint.

9. SEPARATE FRONT AXLE ASSEMBLY LH

(a) Using a plastic hammer, separate the drive shaft

from the axle hub.

NOTICE:

Be careful not to damage the boot and speed

sensor rotor.

10. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

(a) Using SST, remove the front drive shaft assembly

LH.

SST 09520-01010, 09520-24010 (09520-32040)

NOTICE:

• Be careful not to damage the transaxle case

oil seal, inboard joint boot and drive shaft

dust cover.

• Be careful not to drop the drive shaft

assembly.

11. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH (for

2WD)

(a) Using a screwdriver, remove the bearing brake hole

snap ring.

(b) Remove the bolt and front drive shaft assembly RH

from the drive shaft bearing bracket.

F045060E06

F040142

D027403E03

F040148E05

C080304

Page 163 of 3000

AH–6AXLE – FRONT AXLE HUB

AH

REMOVAL

HINT:

Replace the RH side using the same procedures as for the

LH side.

1. REMOVE FRONT WHEEL

2. REMOVE FRONT AXLE HUB LH NUT (See page DS-

5)

3. SEPARATE SPEED SENSOR FRONT LH (See page

DS-5)

4. SEPARATE FRONT DISC BRAKE CALIPER

ASSEMBLY LH

(a) Remove the 2 bolts and separate the front disc

brake caliper assembly LH from the steering

knuckle LH.

NOTICE:

Use a string or other device to keep the brake

caliper from hanging down.

5. REMOVE FRONT DISC

6. SEPARATE TIE ROD END SUB-ASSEMBLY LH (See

page DS-6)

7. SEPARATE FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-6)

8. REMOVE FRONT AXLE ASSEMBLY LH

(a) Using a plastic hammer, separate the front drive

shaft assembly LH from the front axle hub sub-

assembly LH.

NOTICE:

Be careful not to damage the boot and ABS

speed sensor rotor.

(b) Remove the 2 bolts, nuts and steering knuckle LH

with the front axle nub sub-assembly LH.

C067088

D027403

C083023

Page 166 of 3000

AXLE – FRONT AXLE HUBAH–9

AH

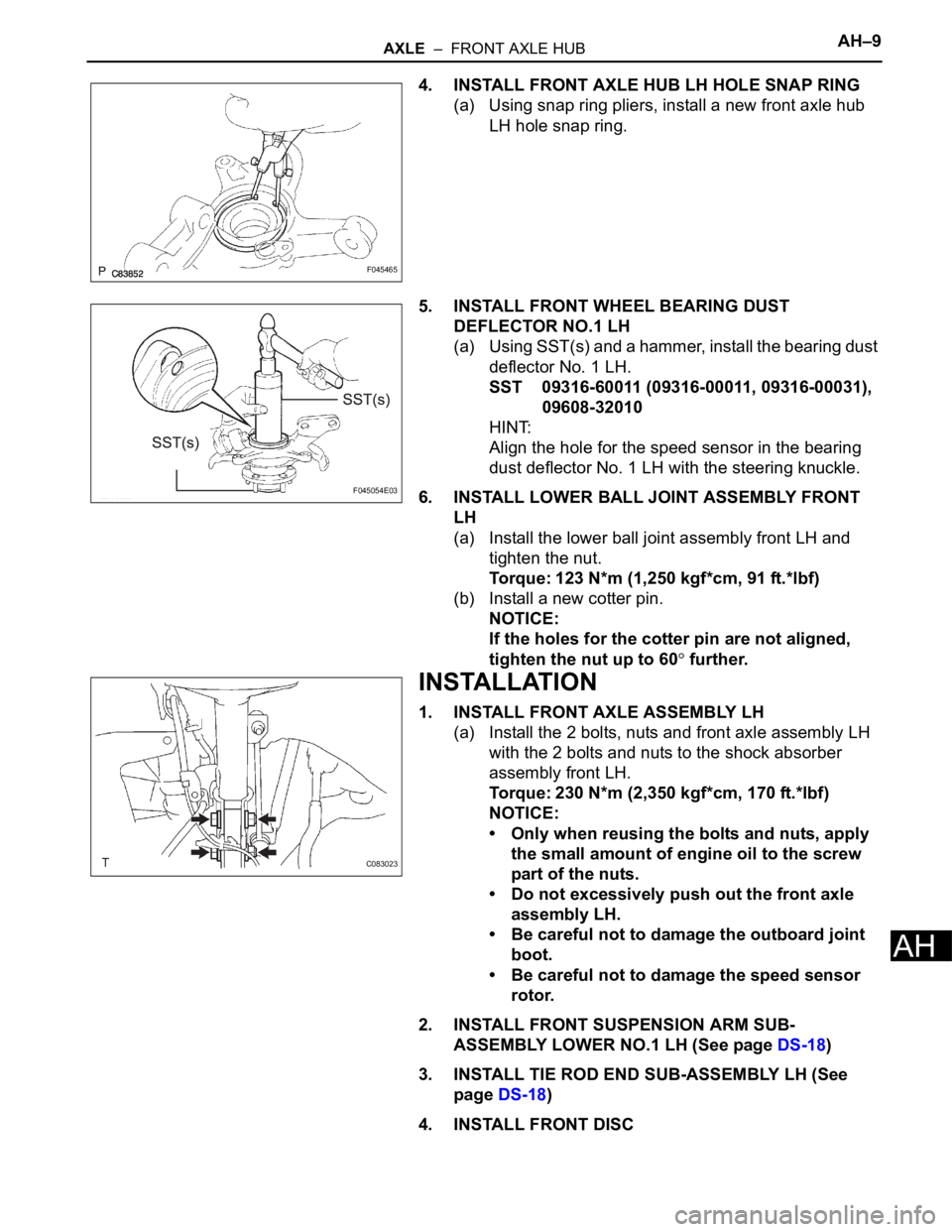

4. INSTALL FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, install a new front axle hub

LH hole snap ring.

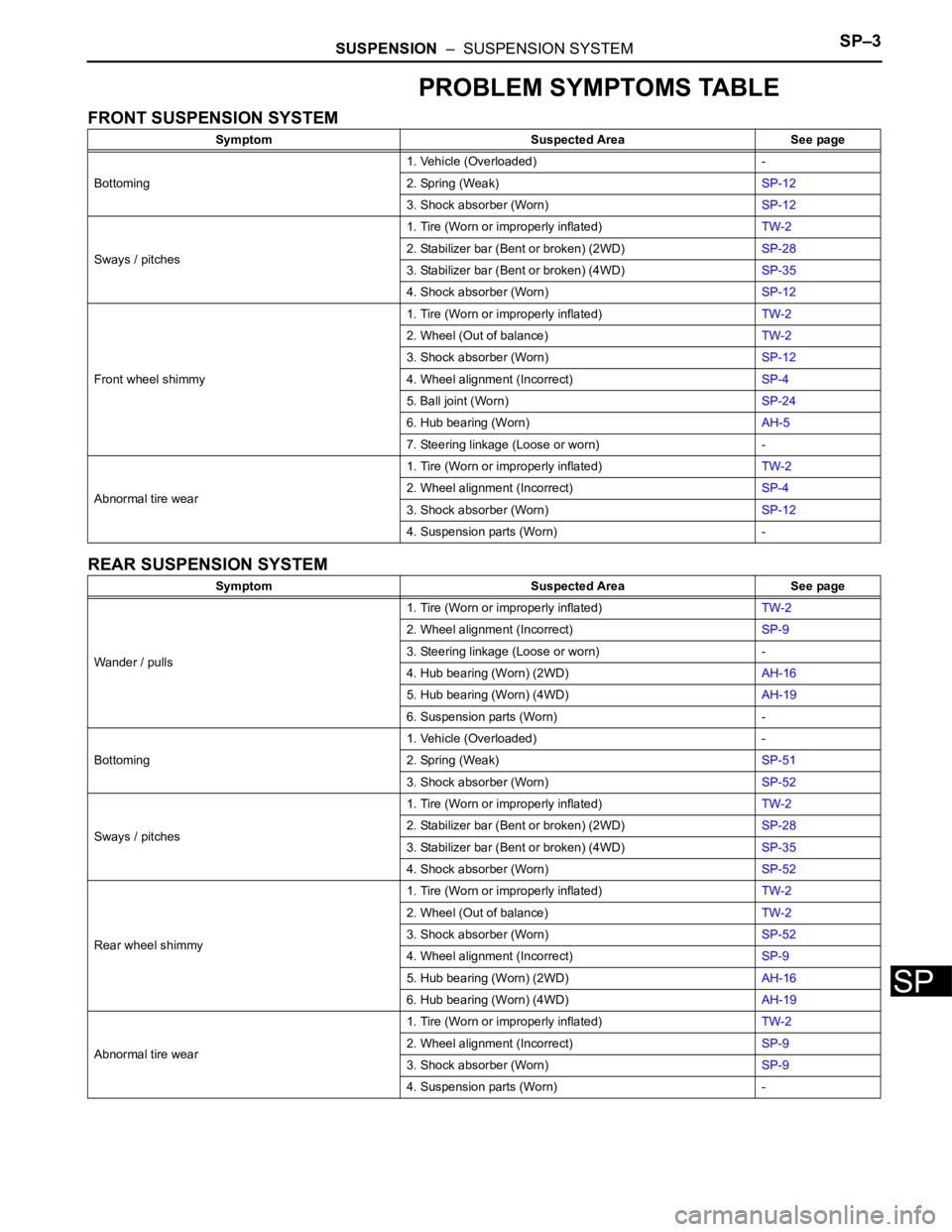

5. INSTALL FRONT WHEEL BEARING DUST

DEFLECTOR NO.1 LH

(a) Using SST(s) and a hammer, install the bearing dust

deflector No. 1 LH.

SST 09316-60011 (09316-00011, 09316-00031),

09608-32010

HINT:

Align the hole for the speed sensor in the bearing

dust deflector No. 1 LH with the steering knuckle.

6. INSTALL LOWER BALL JOINT ASSEMBLY FRONT

LH

(a) Install the lower ball joint assembly front LH and

tighten the nut.

Torque: 123 N*m (1,250 kgf*cm, 91 ft.*lbf)

(b) Install a new cotter pin.

NOTICE:

If the holes for the cotter pin are not aligned,

tighten the nut up to 60

further.

INSTALLATION

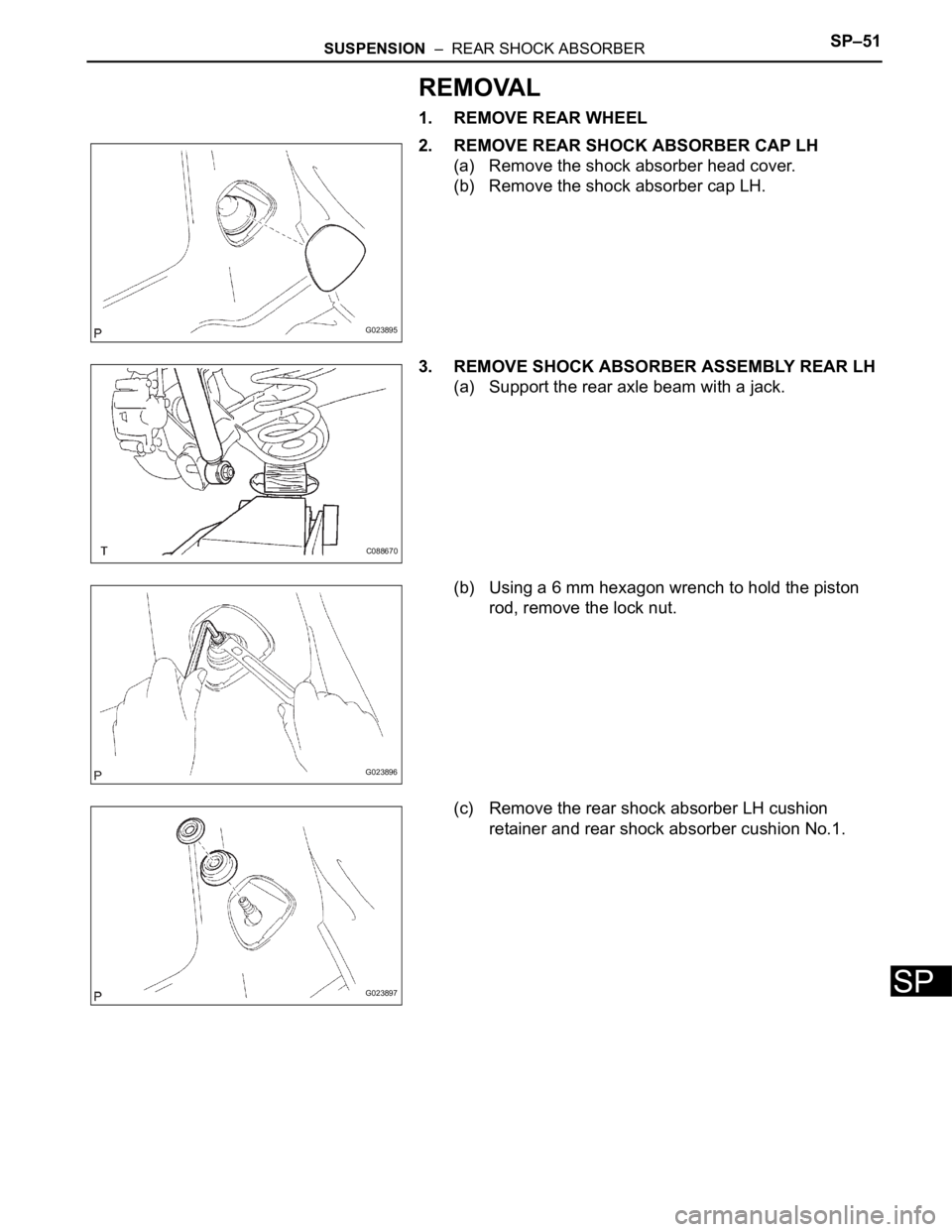

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ft.*lbf)

NOTICE:

• Only when reusing the bolts and nuts, apply

the small amount of engine oil to the screw

part of the nuts.

• Do not excessively push out the front axle

assembly LH.

• Be careful not to damage the outboard joint

boot.

• Be careful not to damage the speed sensor

rotor.

2. INSTALL FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-18)

3. INSTALL TIE ROD END SUB-ASSEMBLY LH (See

page DS-18)

4. INSTALL FRONT DISC

F045465

F045054E03

C083023

Page 168 of 3000

SUSPENSION – SUSPENSION SYSTEMSP–3

SP

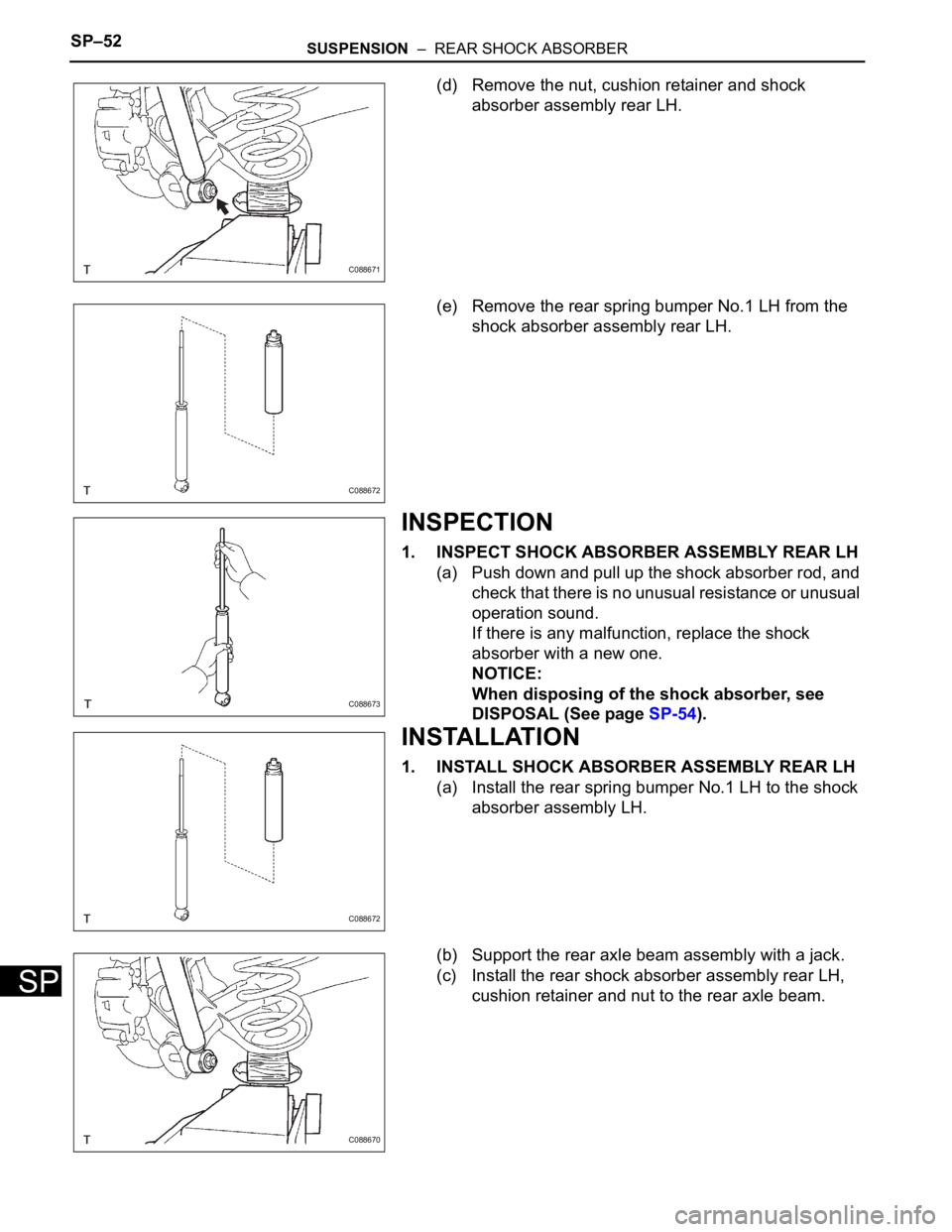

PROBLEM SYMPTOMS TABLE

FRONT SUSPENSION SYSTEM

REAR SUSPENSION SYSTEM

Symptom Suspected Area See page

Bottoming1. Vehicle (Overloaded) -

2. Spring (Weak)SP-12

3. Shock absorber (Worn)SP-12

Sways / pitches1. Tire (Worn or improperly inflated)TW-2

2. Stabilizer bar (Bent or broken) (2WD)SP-28

3. Stabilizer bar (Bent or broken) (4WD)SP-35

4. Shock absorber (Worn)SP-12

Front wheel shimmy1. Tire (Worn or improperly inflated)TW-2

2. Wheel (Out of balance)TW-2

3. Shock absorber (Worn)SP-12

4. Wheel alignment (Incorrect)SP-4

5. Ball joint (Worn)SP-24

6. Hub bearing (Worn)AH-5

7. Steering linkage (Loose or worn) -

Abnormal tire wear1. Tire (Worn or improperly inflated)TW-2

2. Wheel alignment (Incorrect)SP-4

3. Shock absorber (Worn)SP-12

4. Suspension parts (Worn) -

Symptom Suspected Area See page

Wander / pulls1. Tire (Worn or improperly inflated)TW-2

2. Wheel alignment (Incorrect)SP-9

3. Steering linkage (Loose or worn) -

4. Hub bearing (Worn) (2WD)AH-16

5. Hub bearing (Worn) (4WD)AH-19

6. Suspension parts (Worn) -

Bottoming1. Vehicle (Overloaded) -

2. Spring (Weak)SP-51

3. Shock absorber (Worn)SP-52

Sways / pitches1. Tire (Worn or improperly inflated)TW-2

2. Stabilizer bar (Bent or broken) (2WD)SP-28

3. Stabilizer bar (Bent or broken) (4WD)SP-35

4. Shock absorber (Worn)SP-52

Rear wheel shimmy1. Tire (Worn or improperly inflated)TW-2

2. Wheel (Out of balance)TW-2

3. Shock absorber (Worn)SP-52

4. Wheel alignment (Incorrect)SP-9

5. Hub bearing (Worn) (2WD)AH-16

6. Hub bearing (Worn) (4WD)AH-19

Abnormal tire wear1. Tire (Worn or improperly inflated)TW-2

2. Wheel alignment (Incorrect)SP-9

3. Shock absorber (Worn)SP-9

4. Suspension parts (Worn) -

Page 169 of 3000

SUSPENSION – REAR SHOCK ABSORBERSP–51

SP

REMOVAL

1. REMOVE REAR WHEEL

2. REMOVE REAR SHOCK ABSORBER CAP LH

(a) Remove the shock absorber head cover.

(b) Remove the shock absorber cap LH.

3. REMOVE SHOCK ABSORBER ASSEMBLY REAR LH

(a) Support the rear axle beam with a jack.

(b) Using a 6 mm hexagon wrench to hold the piston

rod, remove the lock nut.

(c) Remove the rear shock absorber LH cushion

retainer and rear shock absorber cushion No.1.

G023895

C088670

G023896

G023897

Page 170 of 3000

SP–52SUSPENSION – REAR SHOCK ABSORBER

SP

(d) Remove the nut, cushion retainer and shock

absorber assembly rear LH.

(e) Remove the rear spring bumper No.1 LH from the

shock absorber assembly rear LH.

INSPECTION

1. INSPECT SHOCK ABSORBER ASSEMBLY REAR LH

(a) Push down and pull up the shock absorber rod, and

check that there is no unusual resistance or unusual

operation sound.

If there is any malfunction, replace the shock

absorber with a new one.

NOTICE:

When disposing of the shock absorber, see

DISPOSAL (See page SP-54).

INSTALLATION

1. INSTALL SHOCK ABSORBER ASSEMBLY REAR LH

(a) Install the rear spring bumper No.1 LH to the shock

absorber assembly LH.

(b) Support the rear axle beam assembly with a jack.

(c) Install the rear shock absorber assembly rear LH,

cushion retainer and nut to the rear axle beam.

C088671

C088672

C088673

C088672

C088670

Page 171 of 3000

SUSPENSION – REAR SHOCK ABSORBERSP–53

SP

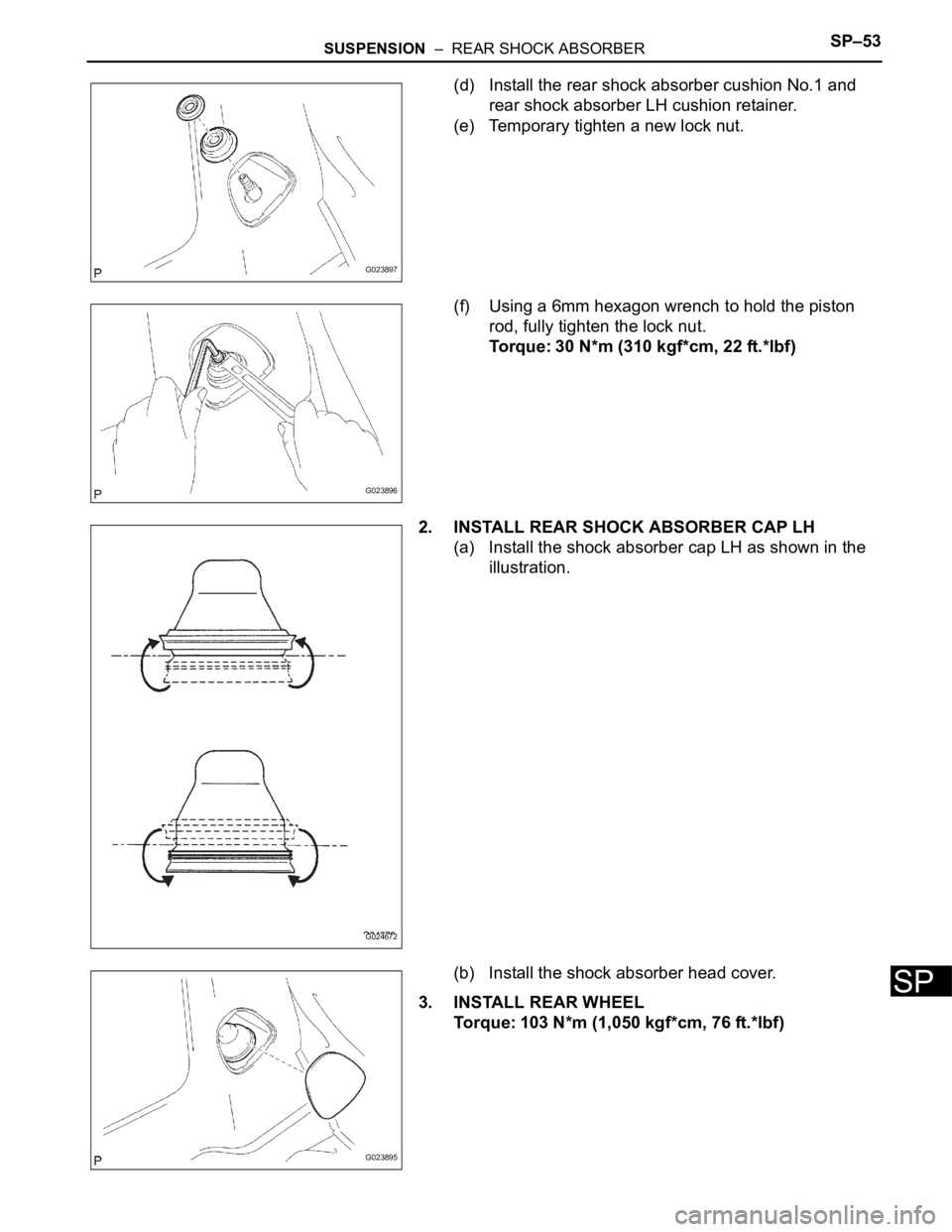

(d) Install the rear shock absorber cushion No.1 and

rear shock absorber LH cushion retainer.

(e) Temporary tighten a new lock nut.

(f) Using a 6mm hexagon wrench to hold the piston

rod, fully tighten the lock nut.

Torque: 30 N*m (310 kgf*cm, 22 ft.*lbf)

2. INSTALL REAR SHOCK ABSORBER CAP LH

(a) Install the shock absorber cap LH as shown in the

illustration.

(b) Install the shock absorber head cover.

3. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

G023897

G023896

G024672

G023895

Page 172 of 3000

SP–54SUSPENSION – REAR SHOCK ABSORBER

SP

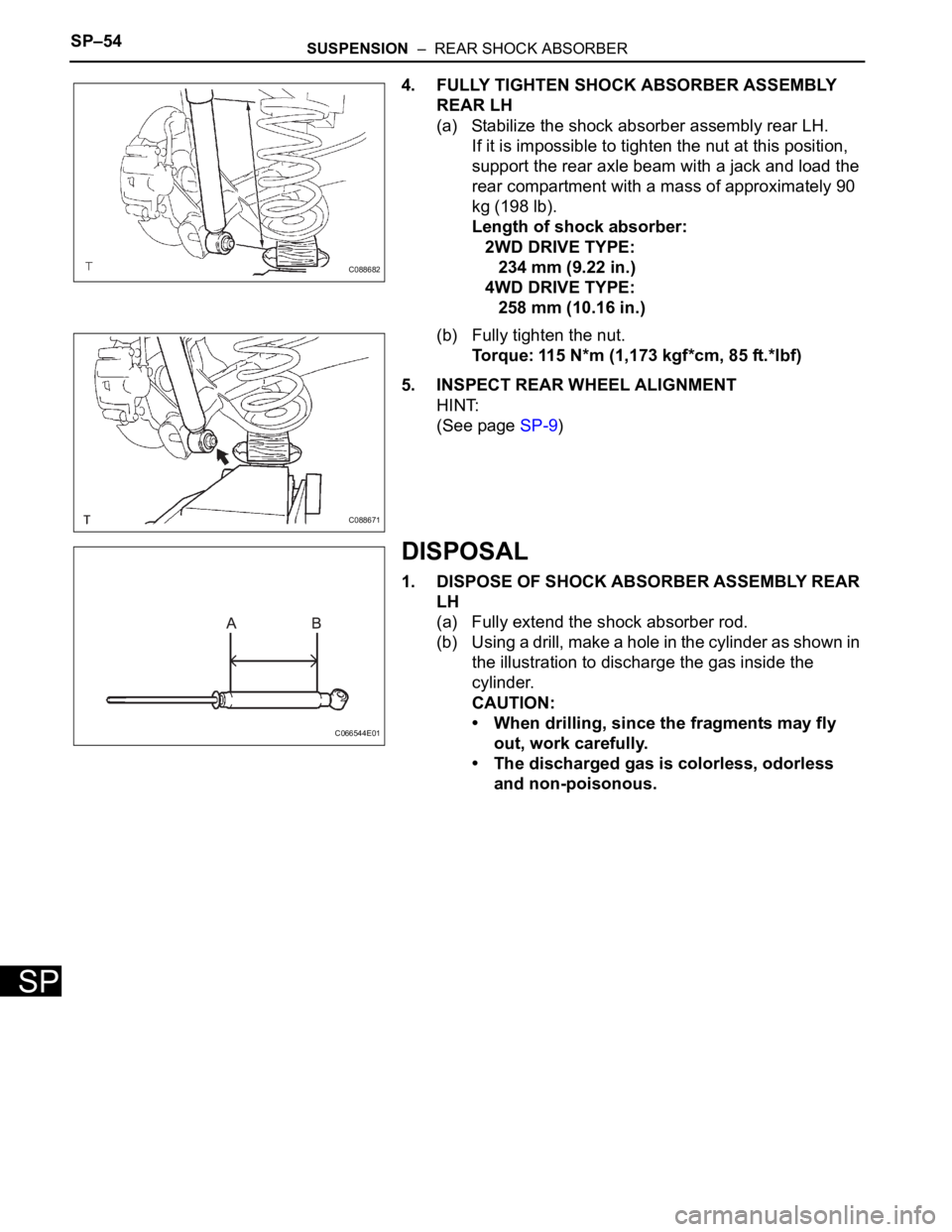

4. FULLY TIGHTEN SHOCK ABSORBER ASSEMBLY

REAR LH

(a) Stabilize the shock absorber assembly rear LH.

If it is impossible to tighten the nut at this position,

support the rear axle beam with a jack and load the

rear compartment with a mass of approximately 90

kg (198 lb).

Length of shock absorber:

2WD DRIVE TYPE:

234 mm (9.22 in.)

4WD DRIVE TYPE:

258 mm (10.16 in.)

(b) Fully tighten the nut.

Torque: 115 N*m (1,173 kgf*cm, 85 ft.*lbf)

5. INSPECT REAR WHEEL ALIGNMENT

HINT:

(See page SP-9)

DISPOSAL

1. DISPOSE OF SHOCK ABSORBER ASSEMBLY REAR

LH

(a) Fully extend the shock absorber rod.

(b) Using a drill, make a hole in the cylinder as shown in

the illustration to discharge the gas inside the

cylinder.

CAUTION:

• When drilling, since the fragments may fly

out, work carefully.

• The discharged gas is colorless, odorless

and non-poisonous.

C088682

C088671

C066544E01