tire pressure TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 50 of 3000

IN–38INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

HINT:

• In troubleshooting, confirm that the problem symptoms

have been accurately identified. Preconceptions should be

discarded in order to make an accurate judgment. To

clearly understand what the problem symptoms are, it is

extremely important to ask the customer about the

problem and the conditions at the time the malfunction

occurred.

• Gather as much information as possible for reference.

Past problems that seem unrelated may also help in some

cases.

• The following 5 items are important points in the problem

analysis:

3. SYMPTOM CONFIRMATION AND DIAGNOSTIC

TROUBLE CODE

HINT:

The diagnostic system in the SIENNA has various

functions.

• The first function is the Diagnostic Trouble Code

(DTC) check. A DTC is a code stored in the ECU

memory whenever a malfunction in the signal circuits

to the ECU occurs. In a DTC check, a previous

malfunction's DTC can be checked by a technician

during troubleshooting.

• Another function is the Input Signal Check, which

checks if the signals from various switches are sent to

the ECU correctly.

By using these functions, the problem areas can be

narrowed down and troubleshooting is more effective.

Diagnostic functions are incorporated in the following

system in the SIENNA.

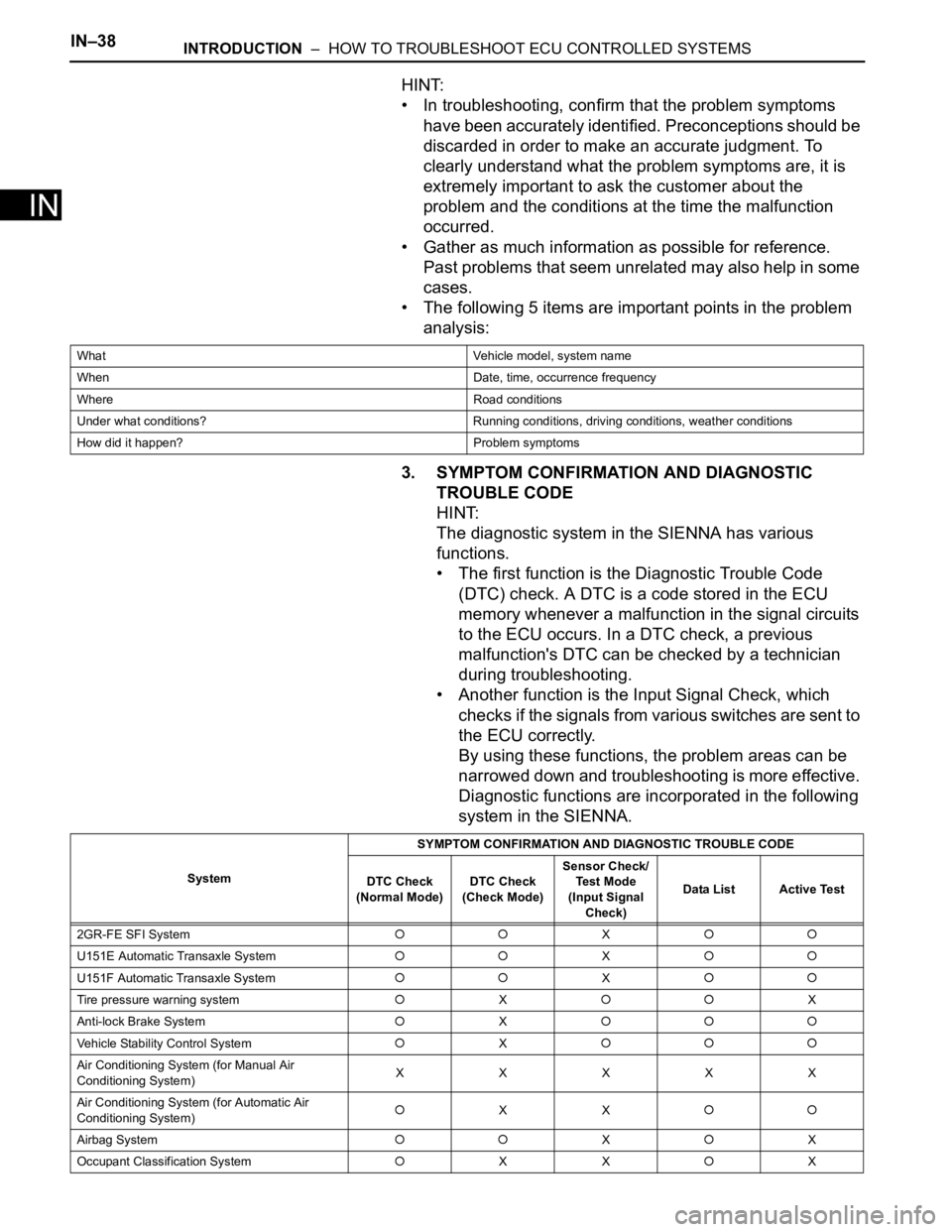

What Vehicle model, system name

When Date, time, occurrence frequency

Where Road conditions

Under what conditions? Running conditions, driving conditions, weather conditions

How did it happen? Problem symptoms

SystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

2GR-FE SFI System

X

U151E Automatic Transaxle SystemX

U151F Automatic Transaxle SystemX

Tire pressure warning systemXX

Anti-lock Brake System

X

Vehicle Stability Control SystemX

Air Conditioning System (for Manual Air

Conditioning System)XXXXX

Air Conditioning System (for Automatic Air

Conditioning System)

XX

Airbag SystemXX

Occupant Classification System

XXX

Page 68 of 3000

IN–38INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

HINT:

• In troubleshooting, confirm that the problem symptoms

have been accurately identified. Preconceptions should be

discarded in order to make an accurate judgment. To

clearly understand what the problem symptoms are, it is

extremely important to ask the customer about the

problem and the conditions at the time the malfunction

occurred.

• Gather as much information as possible for reference.

Past problems that seem unrelated may also help in some

cases.

• The following 5 items are important points in the problem

analysis:

3. SYMPTOM CONFIRMATION AND DIAGNOSTIC

TROUBLE CODE

HINT:

The diagnostic system in the SIENNA has various

functions.

• The first function is the Diagnostic Trouble Code

(DTC) check. A DTC is a code stored in the ECU

memory whenever a malfunction in the signal circuits

to the ECU occurs. In a DTC check, a previous

malfunction's DTC can be checked by a technician

during troubleshooting.

• Another function is the Input Signal Check, which

checks if the signals from various switches are sent to

the ECU correctly.

By using these functions, the problem areas can be

narrowed down and troubleshooting is more effective.

Diagnostic functions are incorporated in the following

system in the SIENNA.

What Vehicle model, system name

When Date, time, occurrence frequency

Where Road conditions

Under what conditions? Running conditions, driving conditions, weather conditions

How did it happen? Problem symptoms

SystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

2GR-FE SFI System

X

U151E Automatic Transaxle SystemX

U151F Automatic Transaxle SystemX

Tire pressure warning systemXX

Anti-lock Brake System

X

Vehicle Stability Control SystemX

Air Conditioning System (for Manual Air

Conditioning System)XXXXX

Air Conditioning System (for Automatic Air

Conditioning System)

XX

Airbag SystemXX

Occupant Classification System

XXX

Page 173 of 3000

TIRE AND WHEEL – TIRE AND WHEEL SYSTEMTW–3

TW

INSPECTION

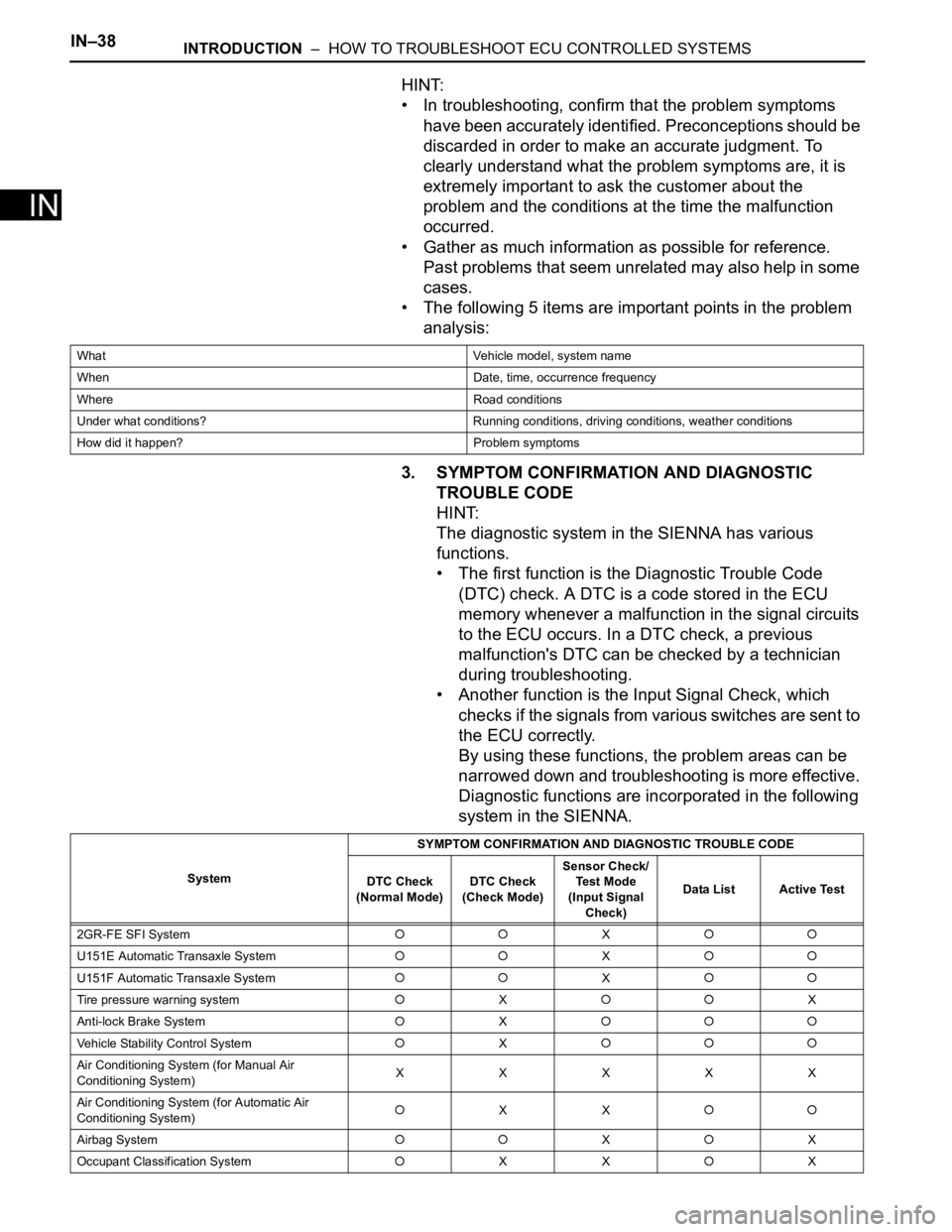

1. INSPECT TIRES

(a) Check the tires for wear and proper inflation

pressure.

Cold tire inflation pressure

(b) Using a dial indicator, check the runout of the tires.

Tire runout:

1.4 mm (0.055 in.) or less

2. ROTATE TIRES

HINT:

Rotate the tires as shown in the illustration.

3. INSPECT WHEEL BALANCE (for Steel Wheel)

(a) Check and adjust the off-the-car balance.

Imbalance after adjustment:

8.0 g (0.018 lb.) or less.

HINT:

If necessary, check and adjust the on-the-car

balance.

Tire size

Front kPa (kgf*cm2, psi) Rear kPa (kgf*cm2, psi)

P215/65R16 96T

P225/60R17 98T240 (2.4, 35) 240 (2.4, 35)

C137874

C140312E01

C144019

Page 175 of 3000

TIRE AND WHEEL – TIRE AND WHEEL SYSTEMTW–5

TW

REPAIR

1. INTRODUCTION

(a) This section introduces ways to determine whether

the run-flat tire is repairable or not. Repair must be

performed by following the appropriate procedures.

If a flat tire occurs, it is possible to drive a maximum

of 160 km (100 miles) at a speed below 90 km/h (55

mph) due to the reinforced sidewalls. However, if

the customer continues to drive with low tire

pressure (less than about 100 kPa (1.0 kgf/cm

2,

14.5 psi) and tire pressure warning light is on), the

inside of the sidewall will gradually deteriorate and

the run-flat performance may be reduced.

Therefore, the tires may require replacement.

However, there are some cases where it is possible

to repair a run-flat tire using the same repair method

as for normal tires. Use the following flowchart to

determine if a run-flat tire is repairable.

NOTICE:

When performing repairs, follow the Rubber

Manufacturers Association (RMA) repair

procedures.

2. REPAIR PROCEDURE (CUSTOMER INTERVIEW)

(a) The tire pressure warning system can help

determine the history of the tire's use. The driving

conditions the tire was subjected to while the tire

pressure warning light was on should be obtained

from the customer. Also, make sure to ask the

following questions.

(1) Was the vehicle driven at a speed over 90 km/h

(55 mph) with the tire pressure warning light

on?

(2) Was the vehicle driven over 160 km (100 miles)

with the tire pressure warning light on?

A "Yes" response to either of the above will

greatly reduce the chance of tire repairability.

3. TECHNICIAN TIRE INSPECTION

(a) After the customer interview, it is necessary to

conduct a thorough inspection of the tire after it has

been removed from the wheel. As it is difficult to

identify a tire with low pressure visually, check the

pressure of each tire to determine the tire(s) causing

the low-pressure warning. If the tire is found to be

repairable, follow the RMA repair procedures.

NOTICE:

The deflated tire may be extremely hot, which

may cause injury, so allow the tire to cool prior

to handling.

Page 176 of 3000

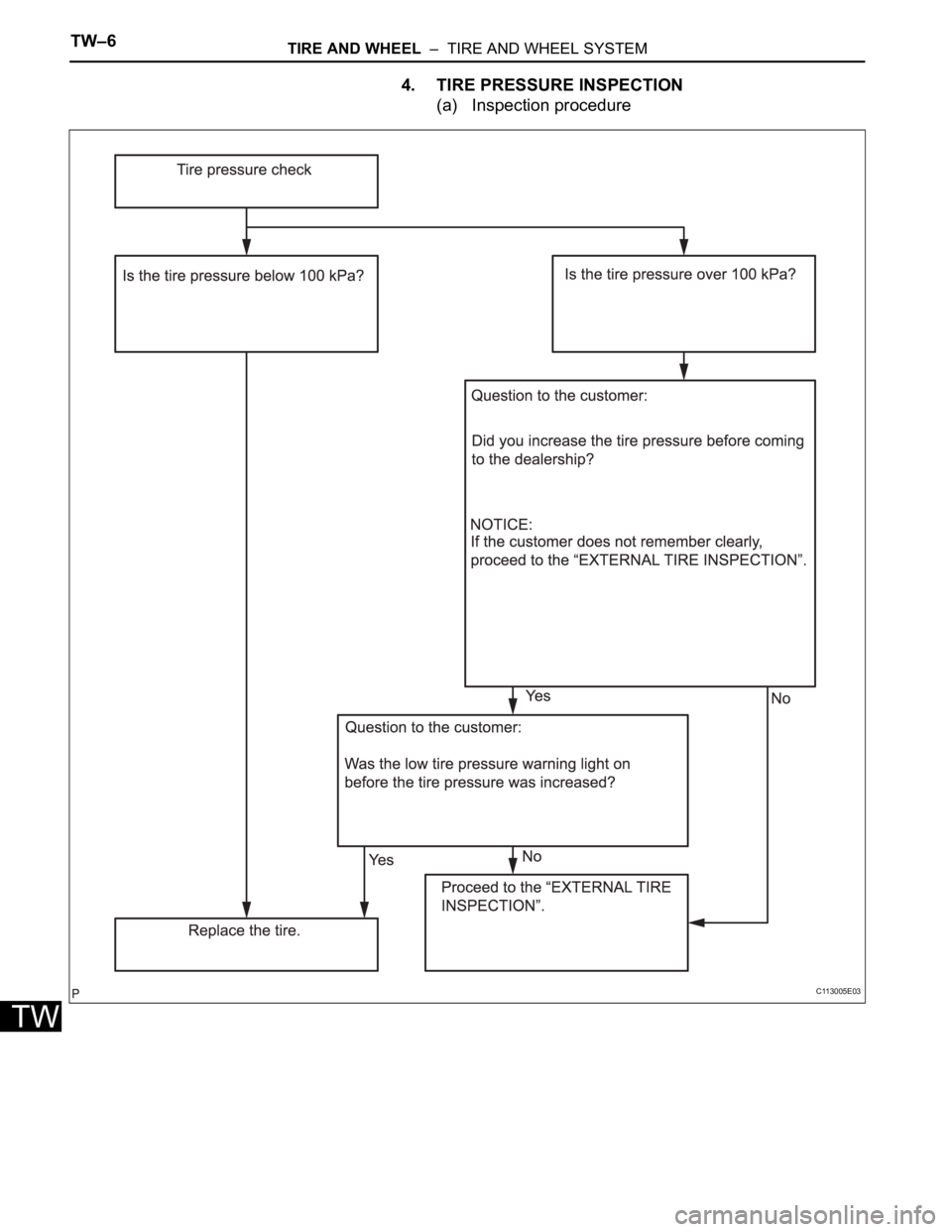

TW–6TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

TW

4. TIRE PRESSURE INSPECTION

(a) Inspection procedure

C113005E03

Page 218 of 3000

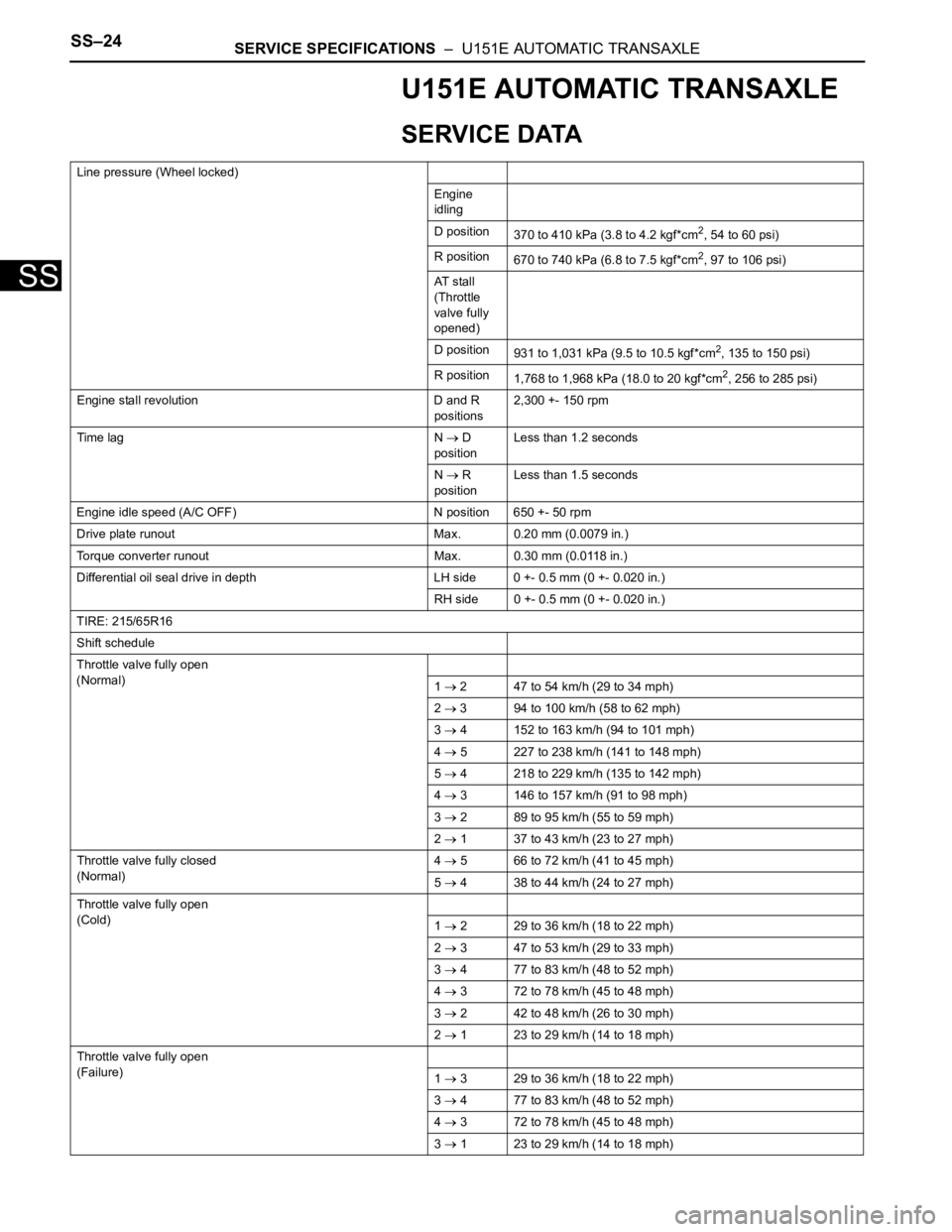

SS–24SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

U151E AUTOMATIC TRANSAXLE

SERVICE DATA

Line pressure (Wheel locked)

Engine

idling

D position

370 to 410 kPa (3.8 to 4.2 kgf*cm

2, 54 to 60 psi)

R position

670 to 740 kPa (6.8 to 7.5 kgf*cm

2, 97 to 106 psi)

AT s t a l l

(Throttle

valve fully

opened)

D position

931 to 1,031 kPa (9.5 to 10.5 kgf*cm

2, 135 to 150 psi)

R position

1,768 to 1,968 kPa (18.0 to 20 kgf*cm

2, 256 to 285 psi)

Engine stall revolution D and R

positions2,300 +- 150 rpm

Time lag N

D

positionLess than 1.2 seconds

N

R

positionLess than 1.5 seconds

Engine idle speed (A/C OFF) N position 650 +- 50 rpm

Drive plate runout Max. 0.20 mm (0.0079 in.)

Torque converter runout Max. 0.30 mm (0.0118 in.)

Differential oil seal drive in depth LH side 0 +- 0.5 mm (0 +- 0.020 in.)

RH side 0 +- 0.5 mm (0 +- 0.020 in.)

TIRE: 215/65R16

Shift schedule

Throttle valve fully open

(Normal)

1

2 47 to 54 km/h (29 to 34 mph)

2

3 94 to 100 km/h (58 to 62 mph)

3

4 152 to 163 km/h (94 to 101 mph)

4

5 227 to 238 km/h (141 to 148 mph)

5

4 218 to 229 km/h (135 to 142 mph)

4

3 146 to 157 km/h (91 to 98 mph)

3

2 89 to 95 km/h (55 to 59 mph)

2

1 37 to 43 km/h (23 to 27 mph)

Throttle valve fully closed

(Normal)4

5 66 to 72 km/h (41 to 45 mph)

5

4 38 to 44 km/h (24 to 27 mph)

Throttle valve fully open

(Cold)

1

2 29 to 36 km/h (18 to 22 mph)

2

3 47 to 53 km/h (29 to 33 mph)

3

4 77 to 83 km/h (48 to 52 mph)

4

3 72 to 78 km/h (45 to 48 mph)

3

2 42 to 48 km/h (26 to 30 mph)

2

1 23 to 29 km/h (14 to 18 mph)

Throttle valve fully open

(Failure)

1

3 29 to 36 km/h (18 to 22 mph)

3

4 77 to 83 km/h (48 to 52 mph)

4

3 72 to 78 km/h (45 to 48 mph)

3

1 23 to 29 km/h (14 to 18 mph)

Page 2109 of 3000

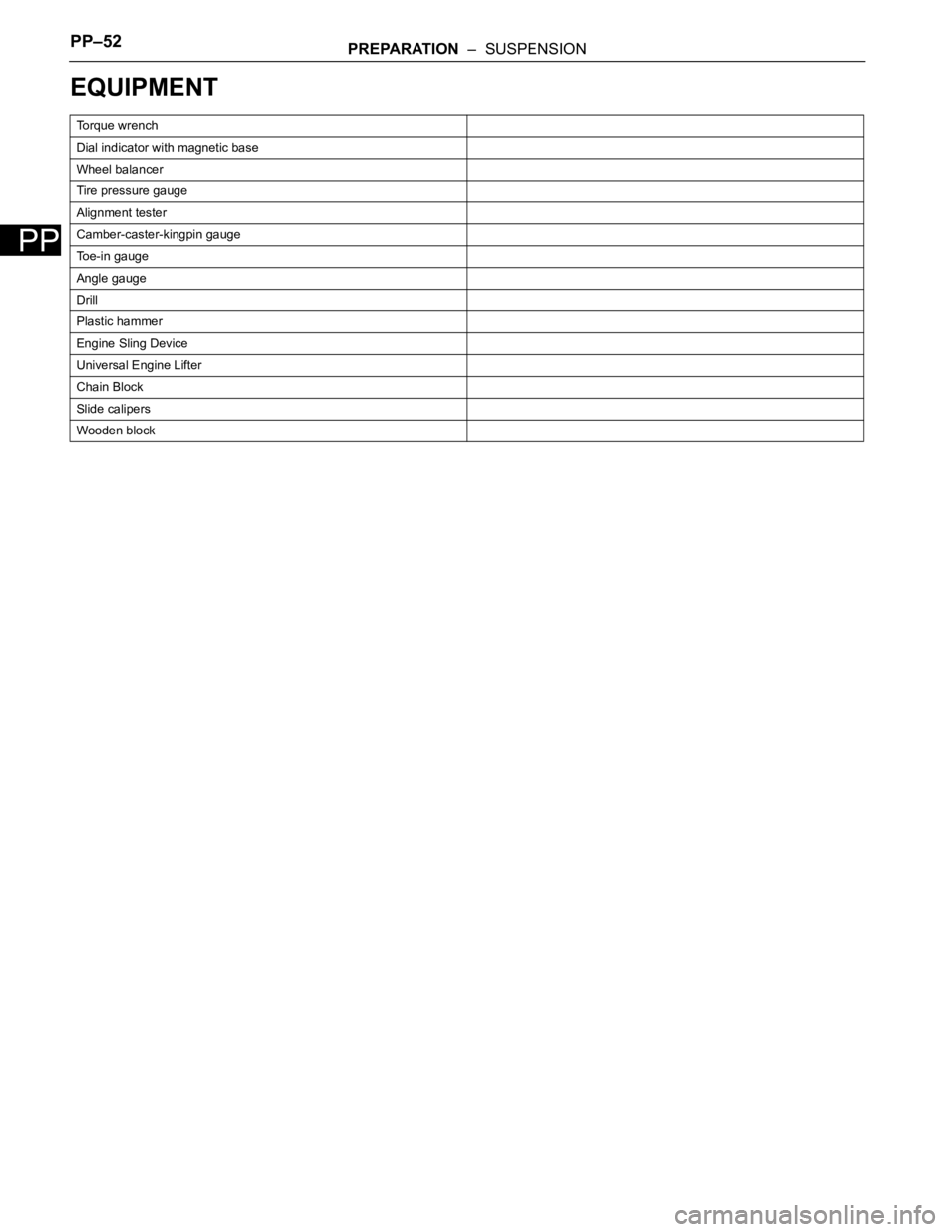

PP–52PREPARATION – SUSPENSION

PP

EQUIPMENT

To r q u e w r e n c h

Dial indicator with magnetic base

Wheel balancer

Tire pressure gauge

Alignment tester

Camber-caster-kingpin gauge

Toe-in gauge

Angle gauge

Drill

Plastic hammer

Engine Sling Device

Universal Engine Lifter

Chain Block

Slide calipers

Wooden block

Page 2248 of 3000

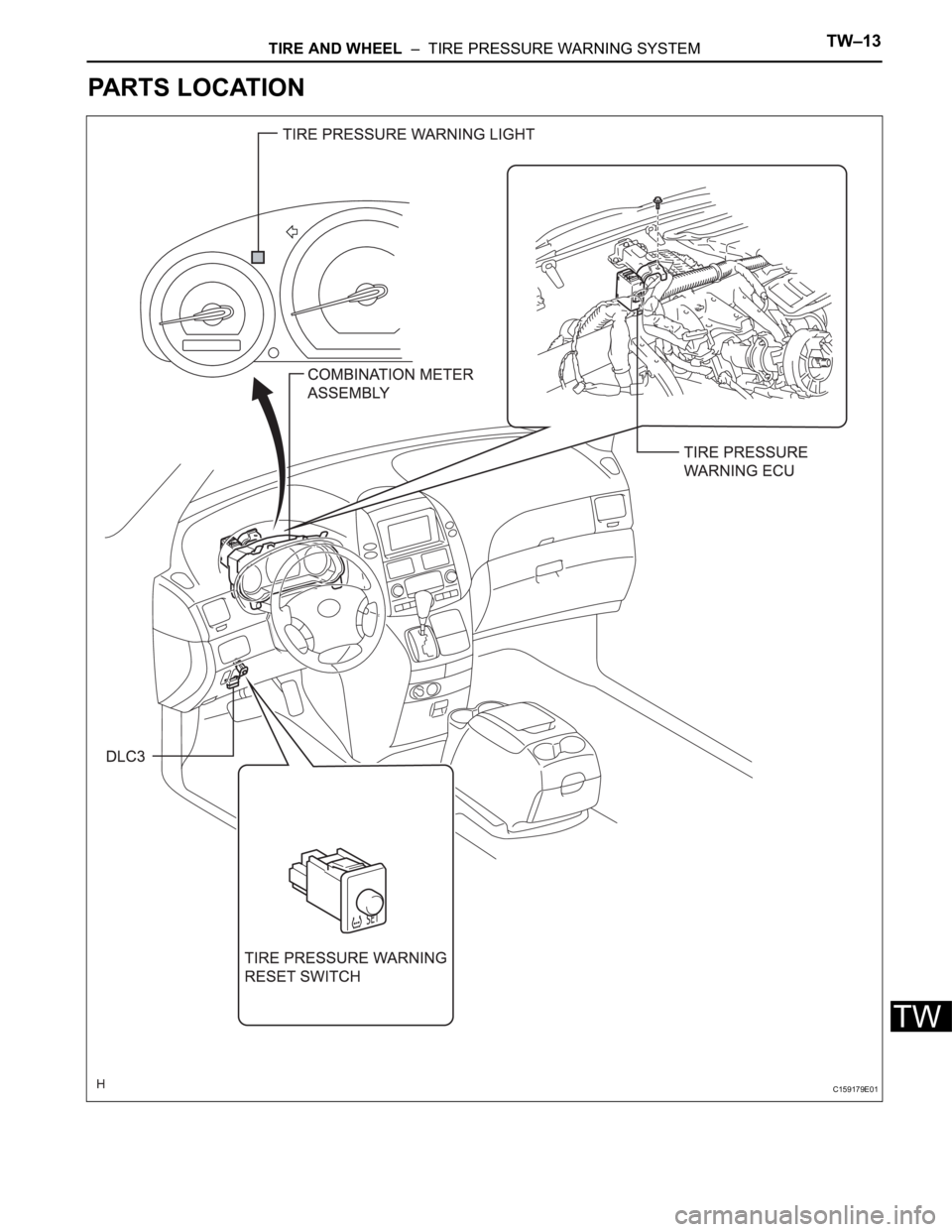

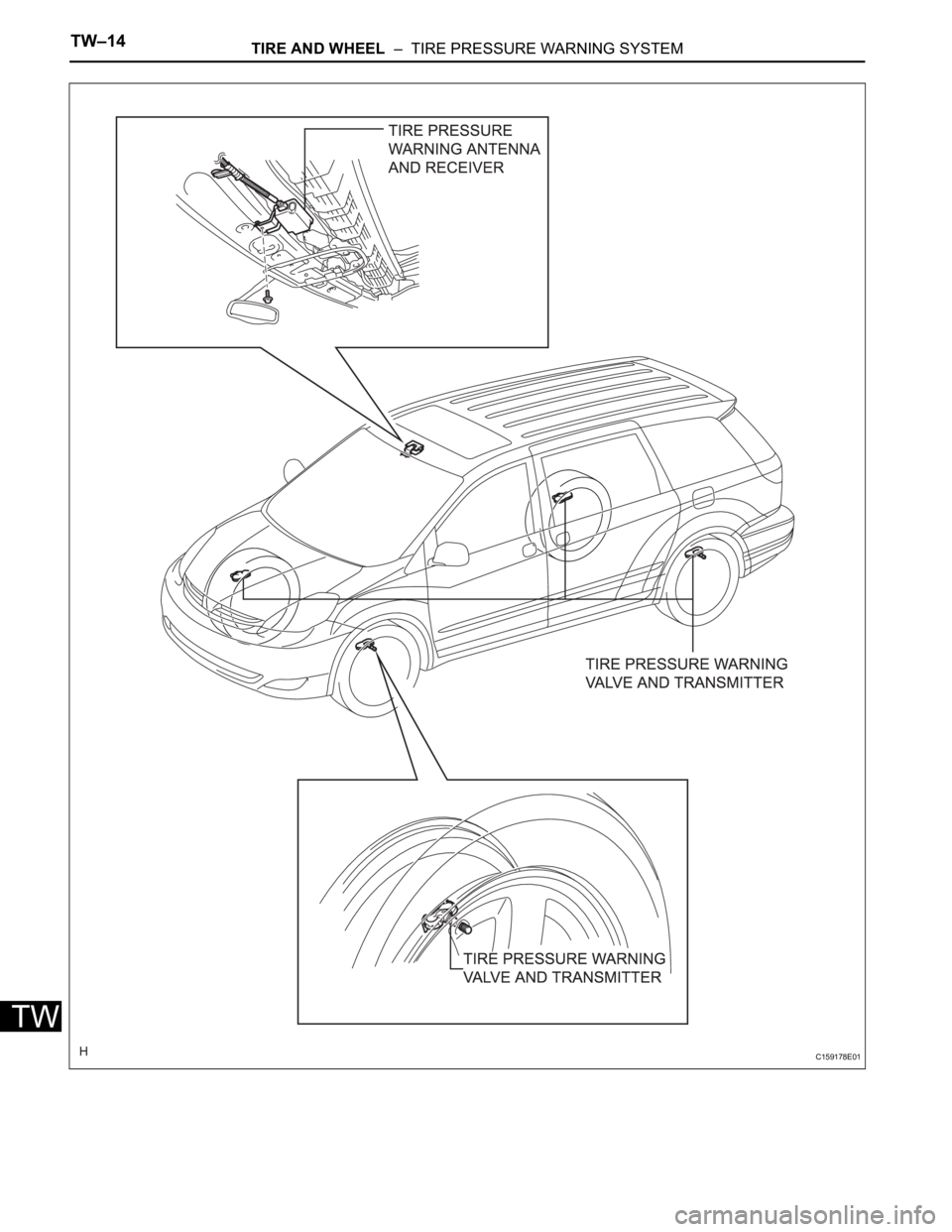

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–13

TW

PARTS LOCATION

C159179E01

Page 2249 of 3000

TW–14TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEM

TW

C159178E01

Page 2250 of 3000

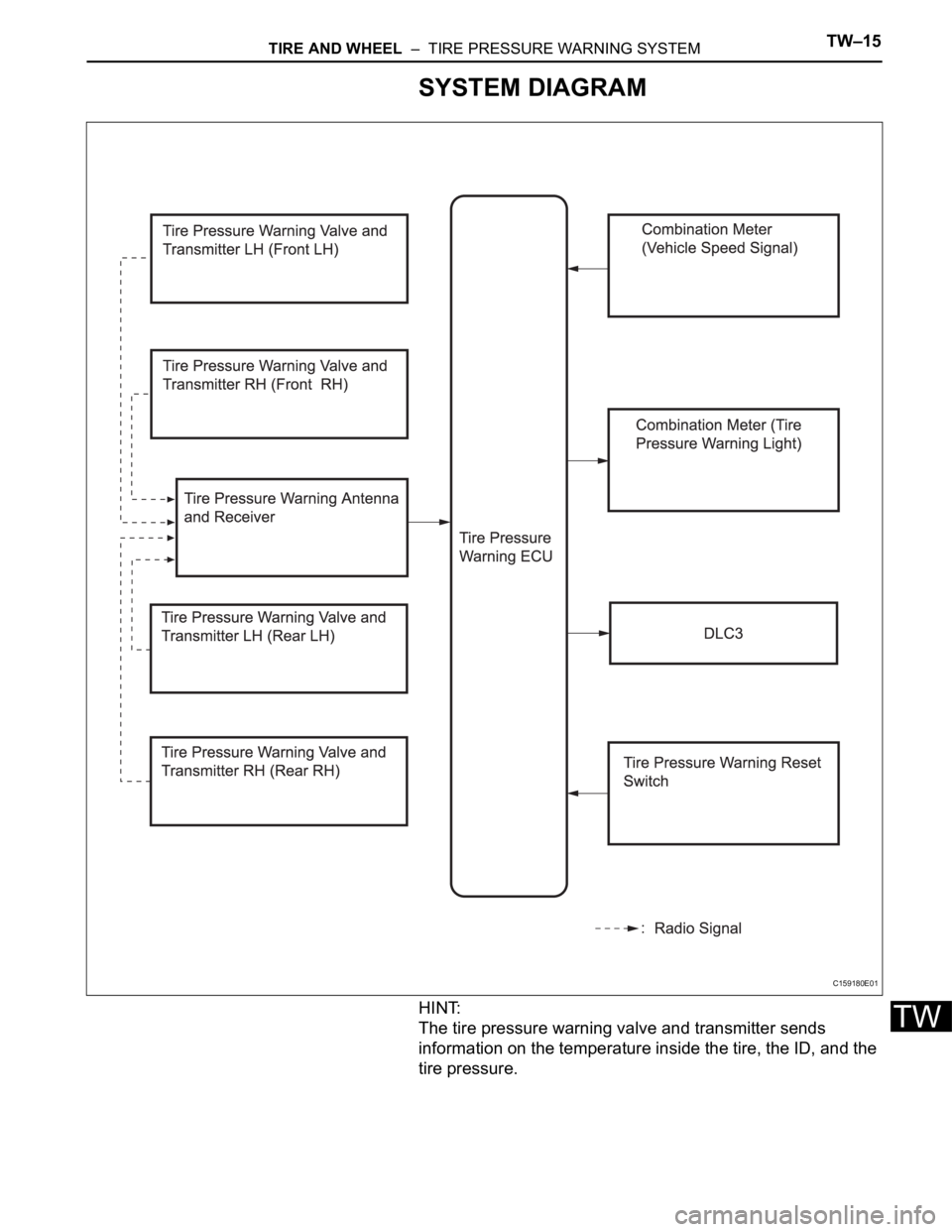

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–15

TW

SYSTEM DIAGRAM

HINT:

The tire pressure warning valve and transmitter sends

information on the temperature inside the tire, the ID, and the

tire pressure.

C159180E01