tire type TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 174 of 3000

TW–4TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

TW

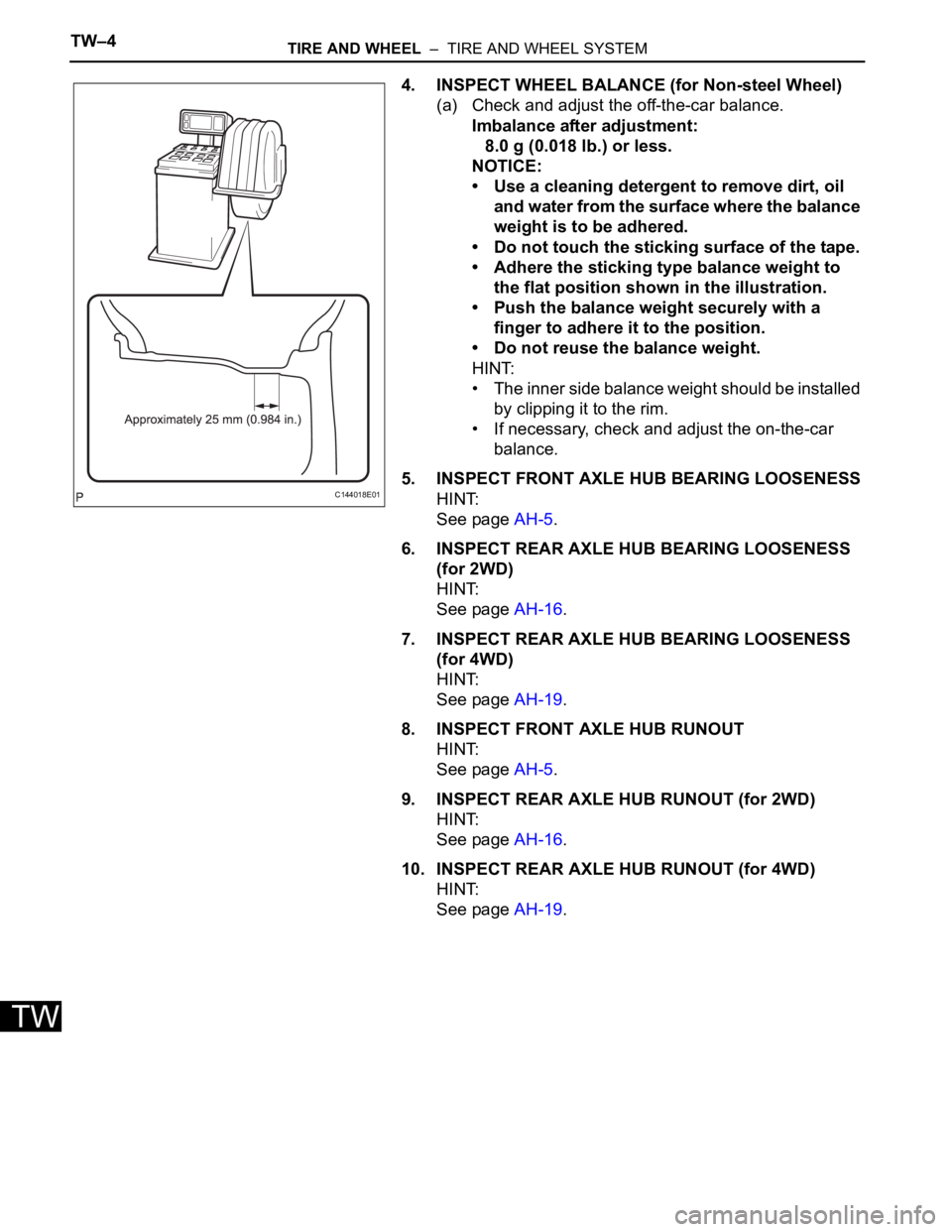

4. INSPECT WHEEL BALANCE (for Non-steel Wheel)

(a) Check and adjust the off-the-car balance.

Imbalance after adjustment:

8.0 g (0.018 lb.) or less.

NOTICE:

• Use a cleaning detergent to remove dirt, oil

and water from the surface where the balance

weight is to be adhered.

• Do not touch the sticking surface of the tape.

• Adhere the sticking type balance weight to

the flat position shown in the illustration.

• Push the balance weight securely with a

finger to adhere it to the position.

• Do not reuse the balance weight.

HINT:

• The inner side balance weight should be installed

by clipping it to the rim.

• If necessary, check and adjust the on-the-car

balance.

5. INSPECT FRONT AXLE HUB BEARING LOOSENESS

HINT:

See page AH-5.

6. INSPECT REAR AXLE HUB BEARING LOOSENESS

(for 2WD)

HINT:

See page AH-16.

7. INSPECT REAR AXLE HUB BEARING LOOSENESS

(for 4WD)

HINT:

See page AH-19.

8. INSPECT FRONT AXLE HUB RUNOUT

HINT:

See page AH-5.

9. INSPECT REAR AXLE HUB RUNOUT (for 2WD)

HINT:

See page AH-16.

10. INSPECT REAR AXLE HUB RUNOUT (for 4WD)

HINT:

See page AH-19.

C144018E01

Page 2252 of 3000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–17

TW

3. WHEN TIRE PRESSURE WARNING LIGHT IS LIT

(a) When the tire pressure warning light does not go off,

or when it comes on during driving, check tire

pressure. If the tire pressure warning light comes on

within several hours after adjusting the tire

pressure, the tire may have a slow air leak.

(b) Under the following conditions, the system may not

function properly.

• Facilities or devices that use similar radio

frequencies are located in the vicinity of the

vehicle.

• A radio device of similar frequency is used in the

vehicle.

• A large amount of snow or ice is stuck to the

vehicle, especially onto the wheels and around

the wheel houses.

• The ID of the tire pressure warning valve and

transmitter has not been registered with the

ECU.

• A film or window tint that may interfere with radio

waves is attached on the glass.

• The battery of the sensor has been depleted.

• The tires without tire pressure warning valve and

transmitter are used.

• Tire chains are used.

• The use of non-genuine wheels may result in the

system failure or air-leak.

• Depending on the tire type, the system may not

function properly even though the specified

wheels are used.

(c) After removing and installing the ECU or a sensor,

check for a diagnostic trouble code and verify that it

is a normal code.

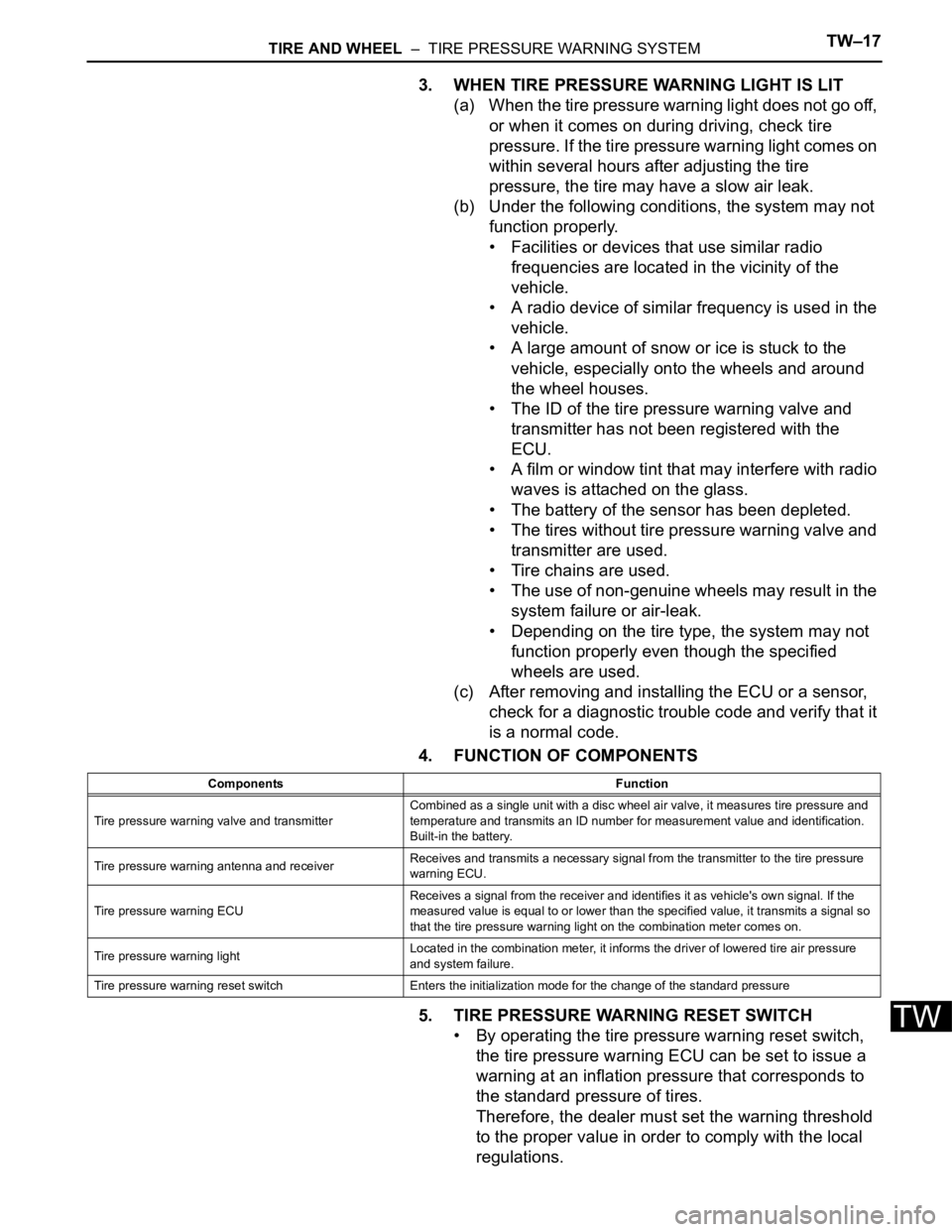

4. FUNCTION OF COMPONENTS

5. TIRE PRESSURE WARNING RESET SWITCH

• By operating the tire pressure warning reset switch,

the tire pressure warning ECU can be set to issue a

warning at an inflation pressure that corresponds to

the standard pressure of tires.

Therefore, the dealer must set the warning threshold

to the proper value in order to comply with the local

regulations.

Components Function

Tire pressure warning valve and transmitterCombined as a single unit with a disc wheel air valve, it measures tire pressure and

temperature and transmits an ID number for measurement value and identification.

Built-in the battery.

Tire pressure warning antenna and receiverReceives and transmits a necessary signal from the transmitter to the tire pressure

warning ECU.

Tire pressure warning ECUReceives a signal from the receiver and identifies it as vehicle's own signal. If the

measured value is equal to or lower than the specified value, it transmits a signal so

that the tire pressure warning light on the combination meter comes on.

Tire pressure warning lightLocated in the combination meter, it informs the driver of lowered tire air pressure

and system failure.

Tire pressure warning reset switch Enters the initialization mode for the change of the standard pressure

Page 2255 of 3000

TW–4TIRE AND WHEEL – TIRE AND WHEEL SYSTEM

TW

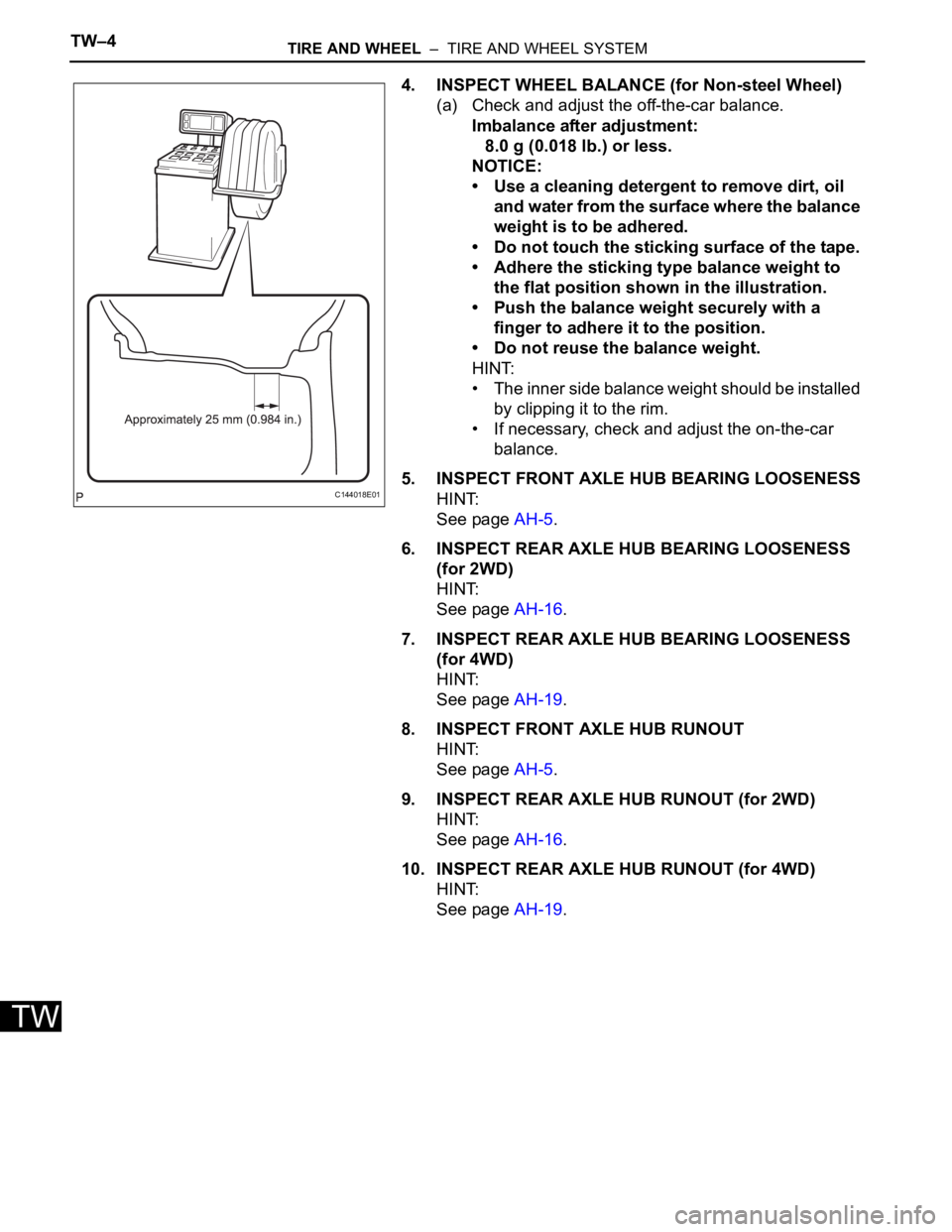

4. INSPECT WHEEL BALANCE (for Non-steel Wheel)

(a) Check and adjust the off-the-car balance.

Imbalance after adjustment:

8.0 g (0.018 lb.) or less.

NOTICE:

• Use a cleaning detergent to remove dirt, oil

and water from the surface where the balance

weight is to be adhered.

• Do not touch the sticking surface of the tape.

• Adhere the sticking type balance weight to

the flat position shown in the illustration.

• Push the balance weight securely with a

finger to adhere it to the position.

• Do not reuse the balance weight.

HINT:

• The inner side balance weight should be installed

by clipping it to the rim.

• If necessary, check and adjust the on-the-car

balance.

5. INSPECT FRONT AXLE HUB BEARING LOOSENESS

HINT:

See page AH-5.

6. INSPECT REAR AXLE HUB BEARING LOOSENESS

(for 2WD)

HINT:

See page AH-16.

7. INSPECT REAR AXLE HUB BEARING LOOSENESS

(for 4WD)

HINT:

See page AH-19.

8. INSPECT FRONT AXLE HUB RUNOUT

HINT:

See page AH-5.

9. INSPECT REAR AXLE HUB RUNOUT (for 2WD)

HINT:

See page AH-16.

10. INSPECT REAR AXLE HUB RUNOUT (for 4WD)

HINT:

See page AH-19.

C144018E01

Page 2263 of 3000

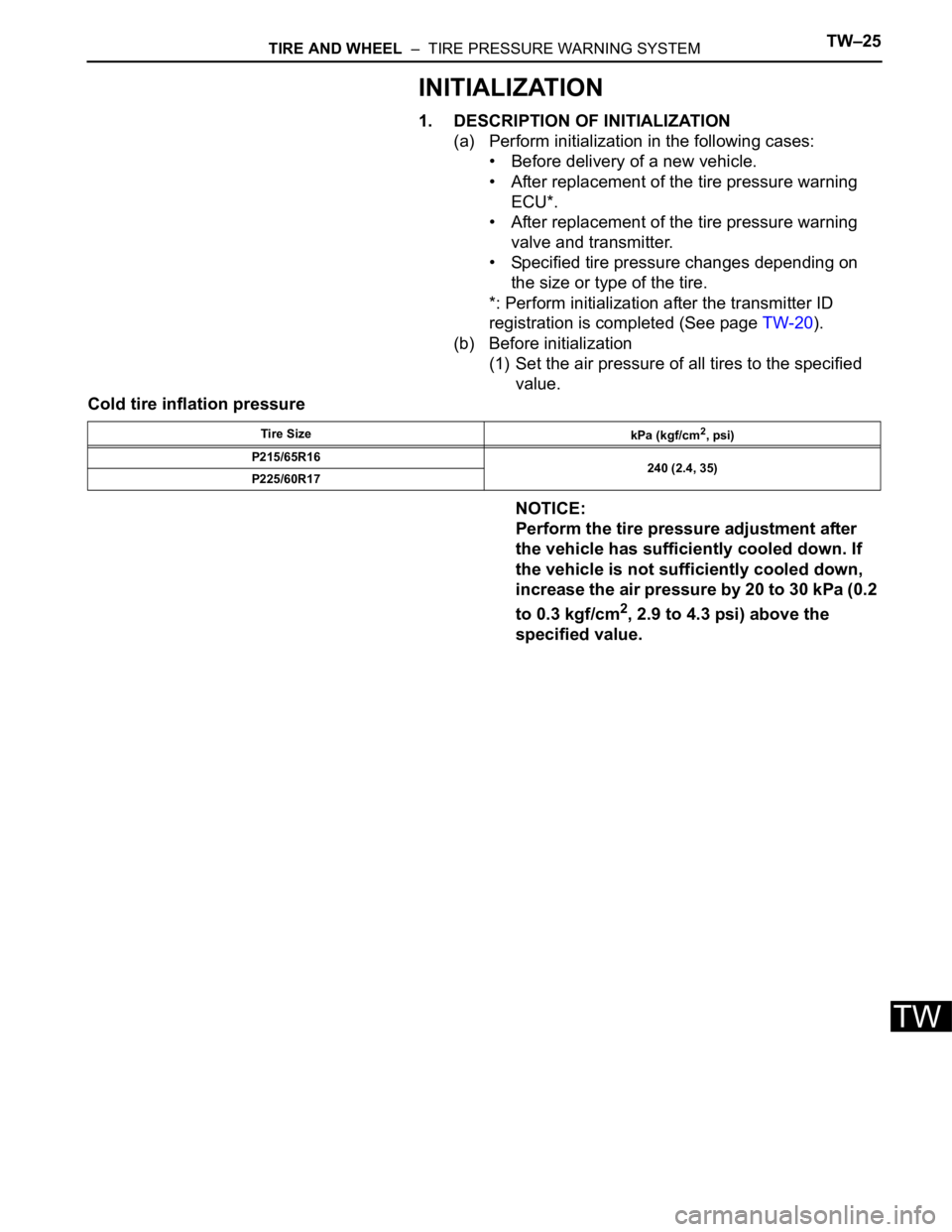

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–25

TW

INITIALIZATION

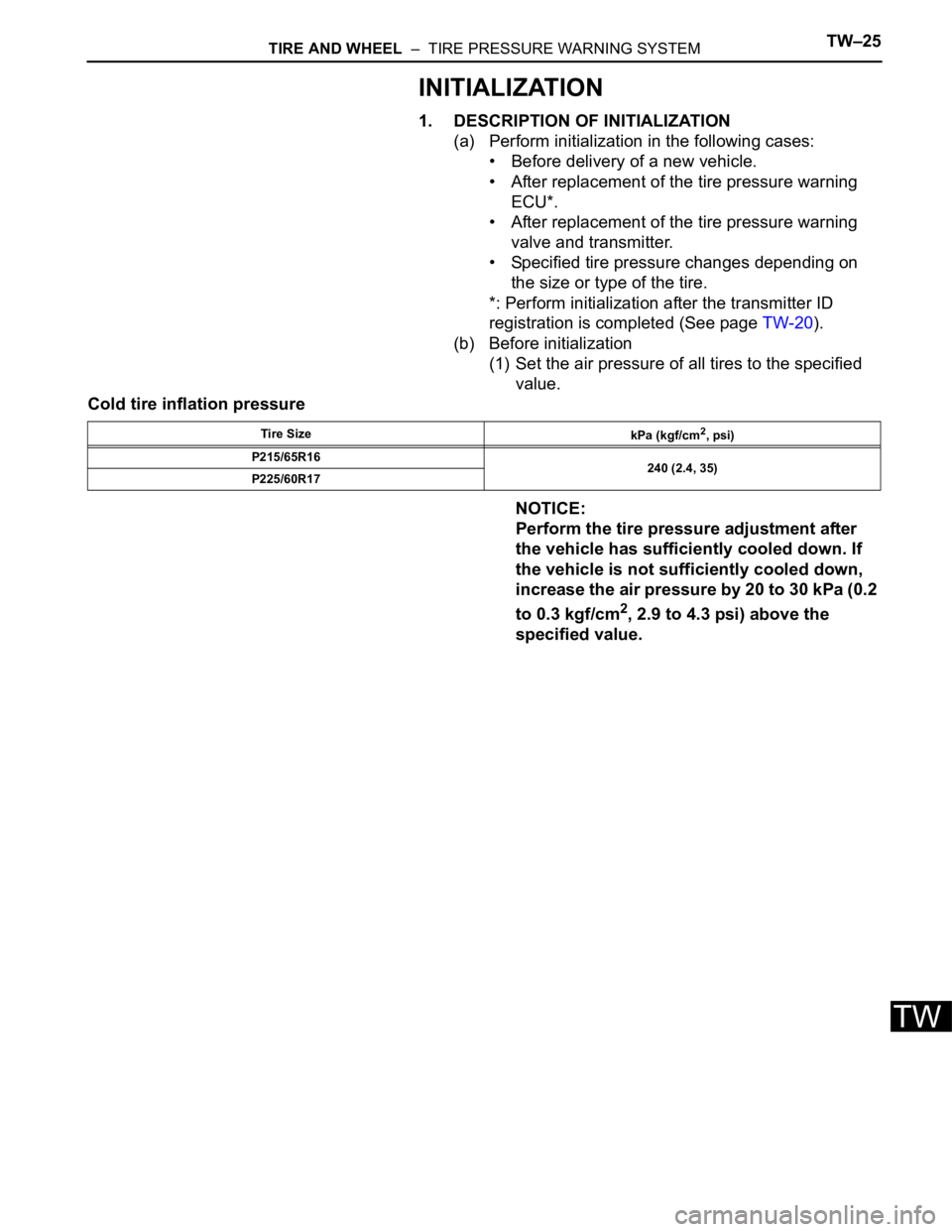

1. DESCRIPTION OF INITIALIZATION

(a) Perform initialization in the following cases:

• Before delivery of a new vehicle.

• After replacement of the tire pressure warning

ECU*.

• After replacement of the tire pressure warning

valve and transmitter.

• Specified tire pressure changes depending on

the size or type of the tire.

*: Perform initialization after the transmitter ID

registration is completed (See page TW-20).

(b) Before initialization

(1) Set the air pressure of all tires to the specified

value.

Cold tire inflation pressure

NOTICE:

Perform the tire pressure adjustment after

the vehicle has sufficiently cooled down. If

the vehicle is not sufficiently cooled down,

increase the air pressure by 20 to 30 kPa (0.2

to 0.3 kgf/cm

2, 2.9 to 4.3 psi) above the

specified value.

Tire Size

kPa (kgf/cm2, psi)

P215/65R16

240 (2.4, 35)

P225/60R17

Page 2332 of 3000

TIRE AND WHEEL – TIRE PRESSURE WARNING SYSTEMTW–25

TW

INITIALIZATION

1. DESCRIPTION OF INITIALIZATION

(a) Perform initialization in the following cases:

• Before delivery of a new vehicle.

• After replacement of the tire pressure warning

ECU*.

• After replacement of the tire pressure warning

valve and transmitter.

• Specified tire pressure changes depending on

the size or type of the tire.

*: Perform initialization after the transmitter ID

registration is completed (See page TW-20).

(b) Before initialization

(1) Set the air pressure of all tires to the specified

value.

Cold tire inflation pressure

NOTICE:

Perform the tire pressure adjustment after

the vehicle has sufficiently cooled down. If

the vehicle is not sufficiently cooled down,

increase the air pressure by 20 to 30 kPa (0.2

to 0.3 kgf/cm

2, 2.9 to 4.3 psi) above the

specified value.

Tire Size

kPa (kgf/cm2, psi)

P215/65R16

240 (2.4, 35)

P225/60R17

Page 2716 of 3000

PS–6POWER STEERING – POWER STEERING SYSTEM

PS

(g) Turn the steering wheel 90 degrees to the right and

check steering effort (torque) while turning the

wheel. Check the opposite direction in the same

manner.

Torque: Steering effort (Reference)

6.0 N*m (61 kgf*cm, 53 in.*lbf)

HINT:

Check the tire type, pressure, and the road surface

before making your diagnosis.

(h) Disconnect the negative (-) battery cable from the

battery.

(i) Tighten the steering wheel set nut.

Torque: 50 N*m (510 kgf*cm, 37 ft.*lbf)

(j) Install the steering pad (See page RS-424).

(k) Connect the negative (-) battery cable to the battery.

(l) Clear the DTCs (See page RS-35).

(m) Inspect the airbag warning light (See page RS-27).

F041590