wheel torque TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 16 of 3000

SS–30SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSAXLE

SS

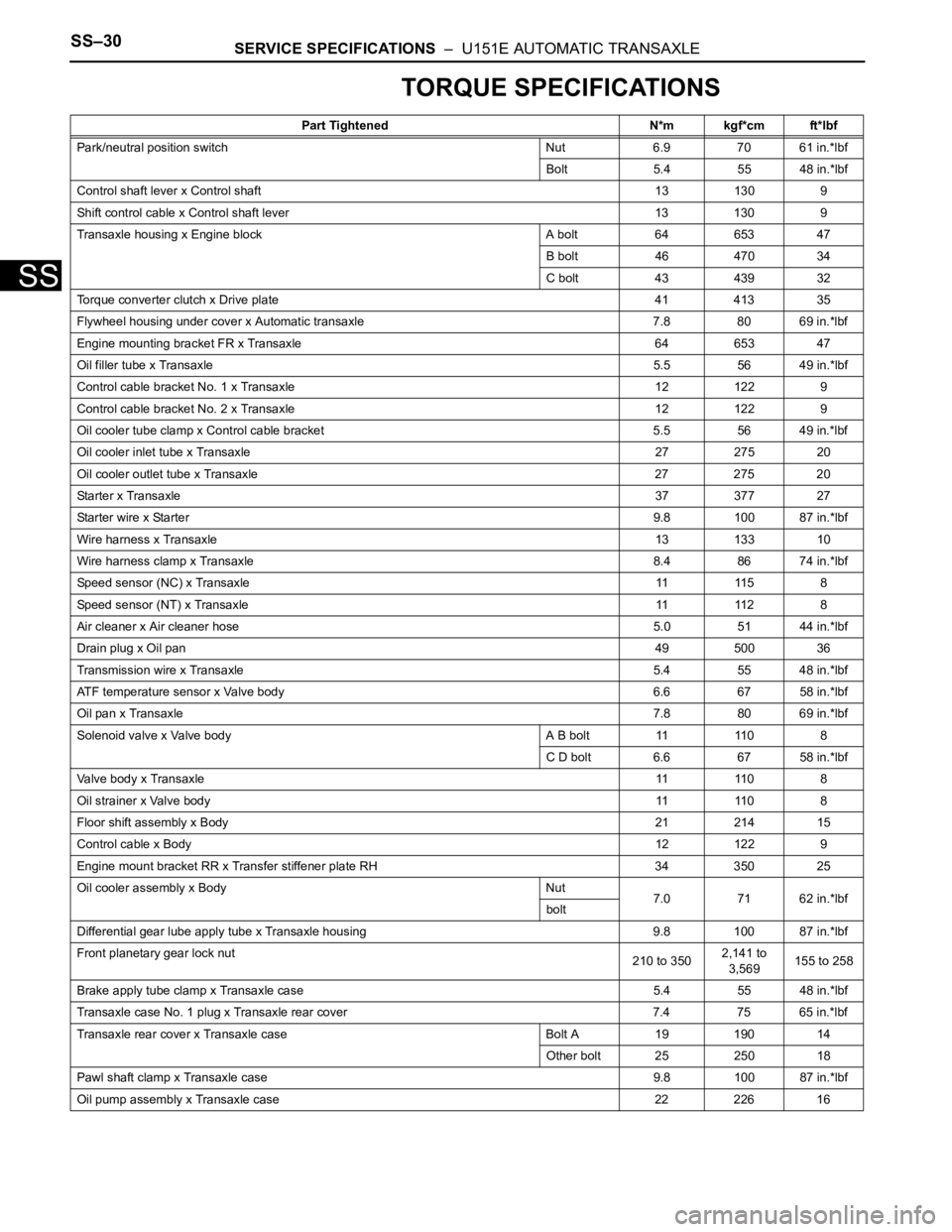

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 130 9

Shift control cable x Control shaft lever 13 130 9

Transaxle housing x Engine block A bolt 64 653 47

B bolt 46 470 34

C bolt 43 439 32

Torque converter clutch x Drive plate 41 413 35

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Engine mounting bracket FR x Transaxle 64 653 47

Oil filler tube x Transaxle5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler tube clamp x Control cable bracket 5.5 56 49 in.*lbf

Oil cooler inlet tube x Transaxle27 275 20

Oil cooler outlet tube x Transaxle 27 275 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 87 in.*lbf

Wire harness x Transaxle13 133 10

Wire harness clamp x Transaxle8.4 86 74 in.*lbf

Speed sensor (NC) x Transaxle11 11 5 8

Speed sensor (NT) x Transaxle11 11 2 8

Air cleaner x Air cleaner hose5.0 51 44 in.*lbf

Drain plug x Oil pan49 500 36

Transmission wire x Transaxle5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body A B bolt 11 110 8

C D bolt 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 0 8

Oil strainer x Valve body11 11 0 8

Floor shift assembly x Body21 214 15

Control cable x Body12 122 9

Engine mount bracket RR x Transfer stiffener plate RH 34 350 25

Oil cooler assembly x Body Nut

7.0 71 62 in.*lbf

bolt

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut

210 to 3502,141 to

3,569155 to 258

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 190 14

Other bolt 25 250 18

Pawl shaft clamp x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Page 92 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–165

AX

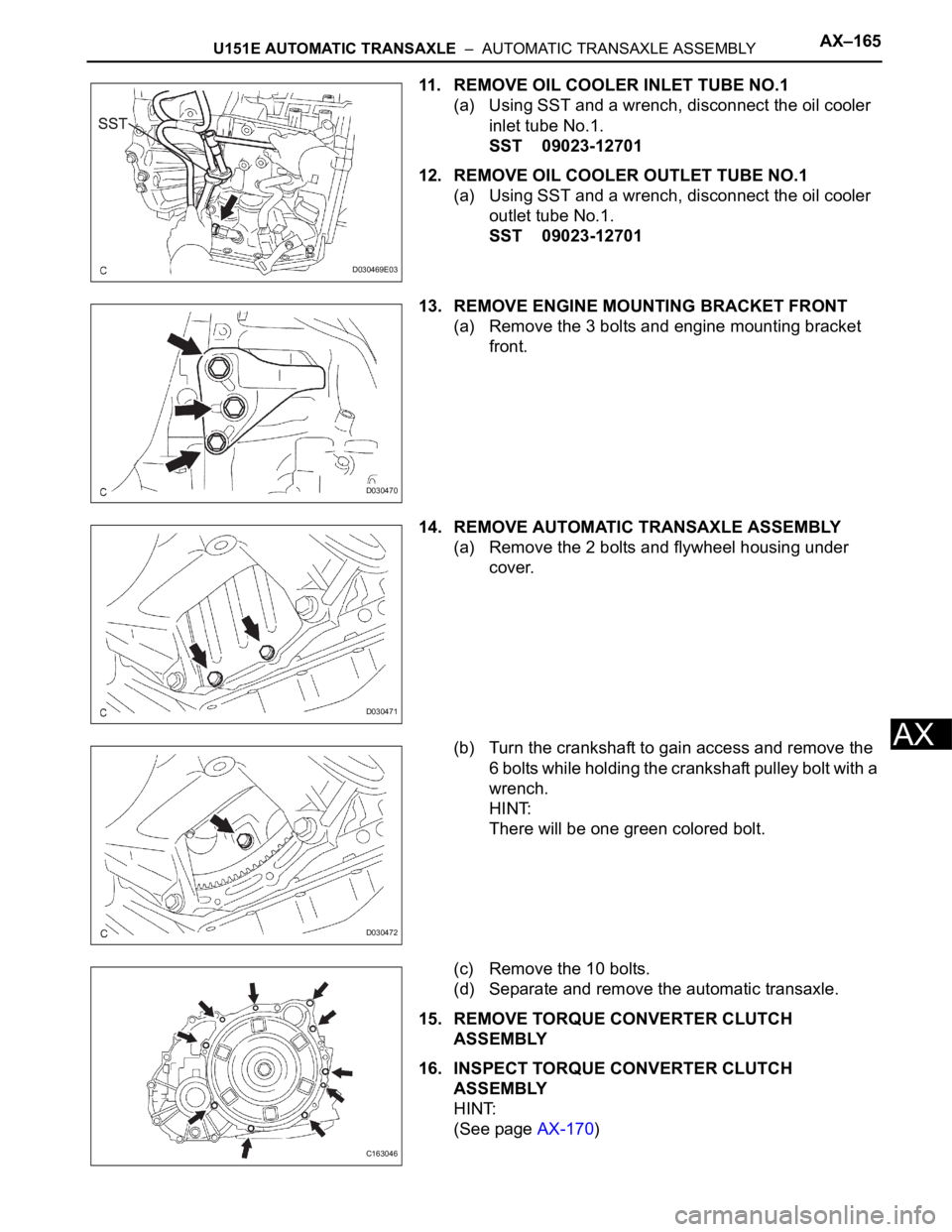

11. REMOVE OIL COOLER INLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler

inlet tube No.1.

SST 09023-12701

12. REMOVE OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler

outlet tube No.1.

SST 09023-12701

13. REMOVE ENGINE MOUNTING BRACKET FRONT

(a) Remove the 3 bolts and engine mounting bracket

front.

14. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

(a) Remove the 2 bolts and flywheel housing under

cover.

(b) Turn the crankshaft to gain access and remove the

6 bolts while holding the crankshaft pulley bolt with a

wrench.

HINT:

There will be one green colored bolt.

(c) Remove the 10 bolts.

(d) Separate and remove the automatic transaxle.

15. REMOVE TORQUE CONVERTER CLUTCH

ASSEMBLY

16. INSPECT TORQUE CONVERTER CLUTCH

ASSEMBLY

HINT:

(See page AX-170)

D030469E03

D030470

D030471

D030472

C163046

Page 94 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–167

AX

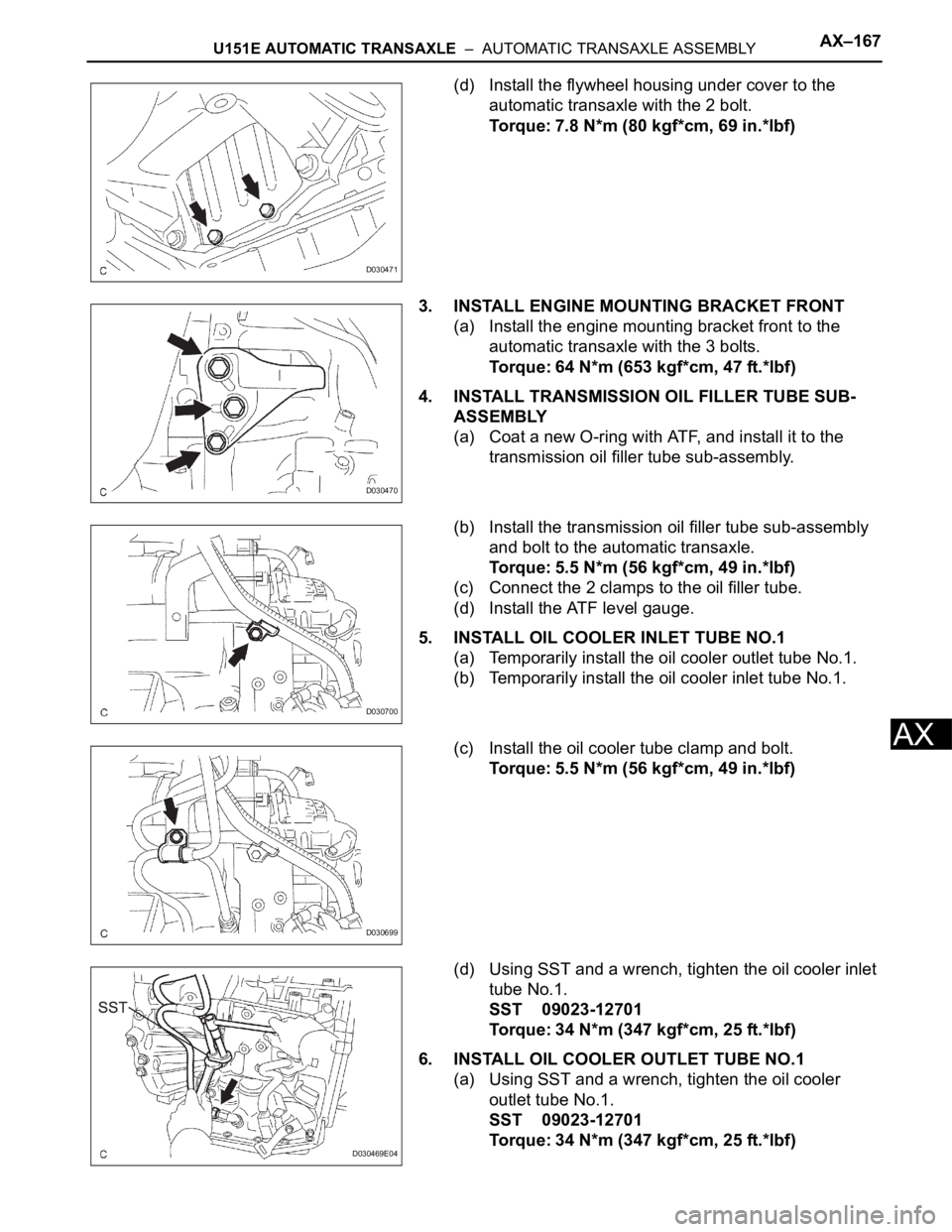

(d) Install the flywheel housing under cover to the

automatic transaxle with the 2 bolt.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

3. INSTALL ENGINE MOUNTING BRACKET FRONT

(a) Install the engine mounting bracket front to the

automatic transaxle with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

4. INSTALL TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Coat a new O-ring with ATF, and install it to the

transmission oil filler tube sub-assembly.

(b) Install the transmission oil filler tube sub-assembly

and bolt to the automatic transaxle.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(c) Connect the 2 clamps to the oil filler tube.

(d) Install the ATF level gauge.

5. INSTALL OIL COOLER INLET TUBE NO.1

(a) Temporarily install the oil cooler outlet tube No.1.

(b) Temporarily install the oil cooler inlet tube No.1.

(c) Install the oil cooler tube clamp and bolt.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(d) Using SST and a wrench, tighten the oil cooler inlet

tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

6. INSTALL OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, tighten the oil cooler

outlet tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

D030471

D030470

D030700

D030699

D030469E04

Page 104 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–169

AX

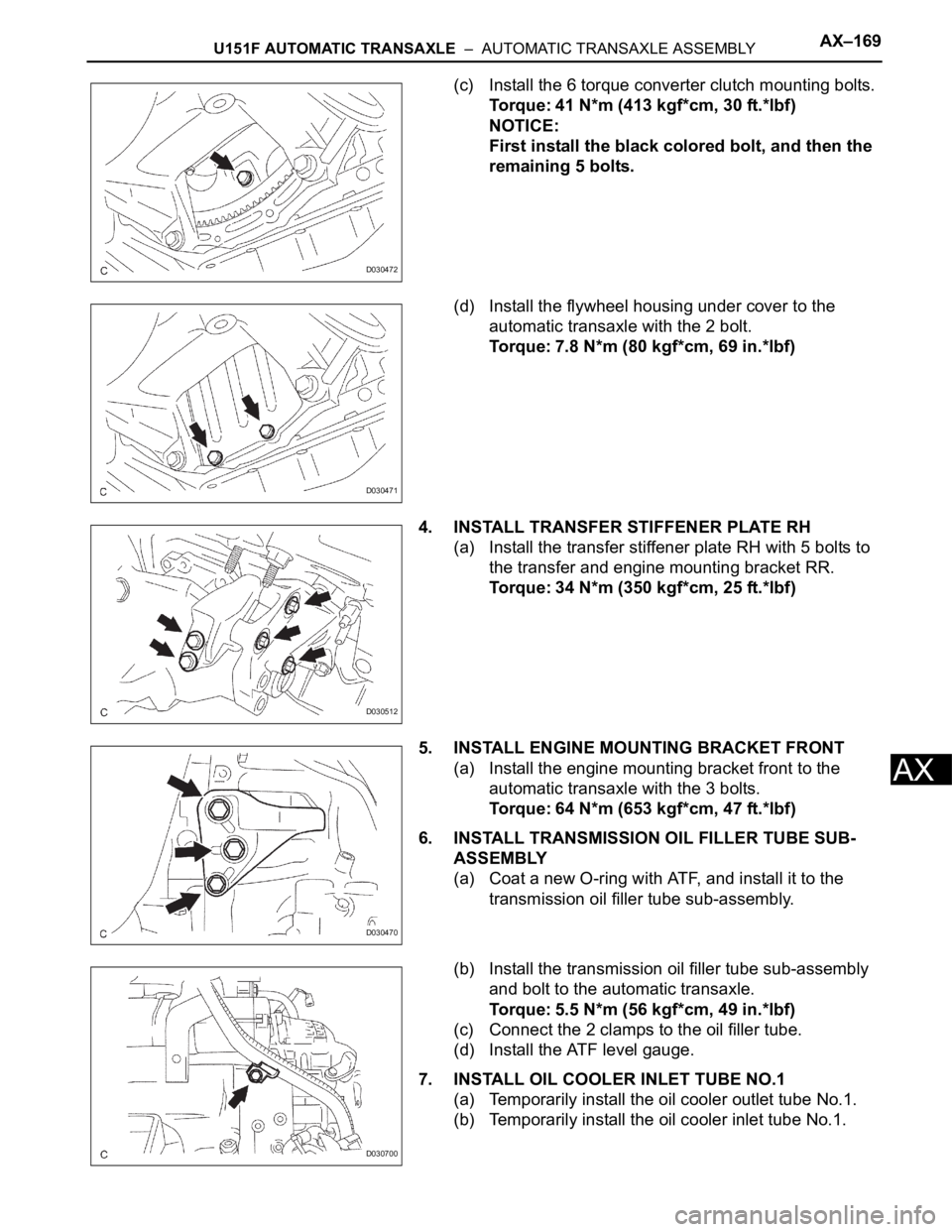

(c) Install the 6 torque converter clutch mounting bolts.

Torque: 41 N*m (413 kgf*cm, 30 ft.*lbf)

NOTICE:

First install the black colored bolt, and then the

remaining 5 bolts.

(d) Install the flywheel housing under cover to the

automatic transaxle with the 2 bolt.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

4. INSTALL TRANSFER STIFFENER PLATE RH

(a) Install the transfer stiffener plate RH with 5 bolts to

the transfer and engine mounting bracket RR.

Torque: 34 N*m (350 kgf*cm, 25 ft.*lbf)

5. INSTALL ENGINE MOUNTING BRACKET FRONT

(a) Install the engine mounting bracket front to the

automatic transaxle with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

6. INSTALL TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Coat a new O-ring with ATF, and install it to the

transmission oil filler tube sub-assembly.

(b) Install the transmission oil filler tube sub-assembly

and bolt to the automatic transaxle.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(c) Connect the 2 clamps to the oil filler tube.

(d) Install the ATF level gauge.

7. INSTALL OIL COOLER INLET TUBE NO.1

(a) Temporarily install the oil cooler outlet tube No.1.

(b) Temporarily install the oil cooler inlet tube No.1.

D030472

D030471

D030512

D030470

D030700

Page 108 of 3000

TF–10TRANSFER – TRANSFER ASSEMBLY

TF

6. INSTALL NO. 1 TRANSFER CASE PLUG

(a) Add oil up to 0 to 5 mm below the lower side of the

plug hole.

Oil quantity:

0.9 L (0.95 US qts, 0.71 lmp. qts)

HINT:

When adding oil, pour it slowly.

(b) Install the No. 1 transfer case plug with a new No. 1

gasket.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

7. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4)

8. CHECK ABS SPEED SENSOR SIGNAL

HINT:

(See page BC-3)

Page 110 of 3000

DRIVE SHAFT – FRONT DRIVE SHAFTDS–5

DS

REMOVAL

1. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

2. DRAIN TRANSFER OIL (for 4WD)

HINT:

(See page TF-8)

3. REMOVE FRONT WHEEL

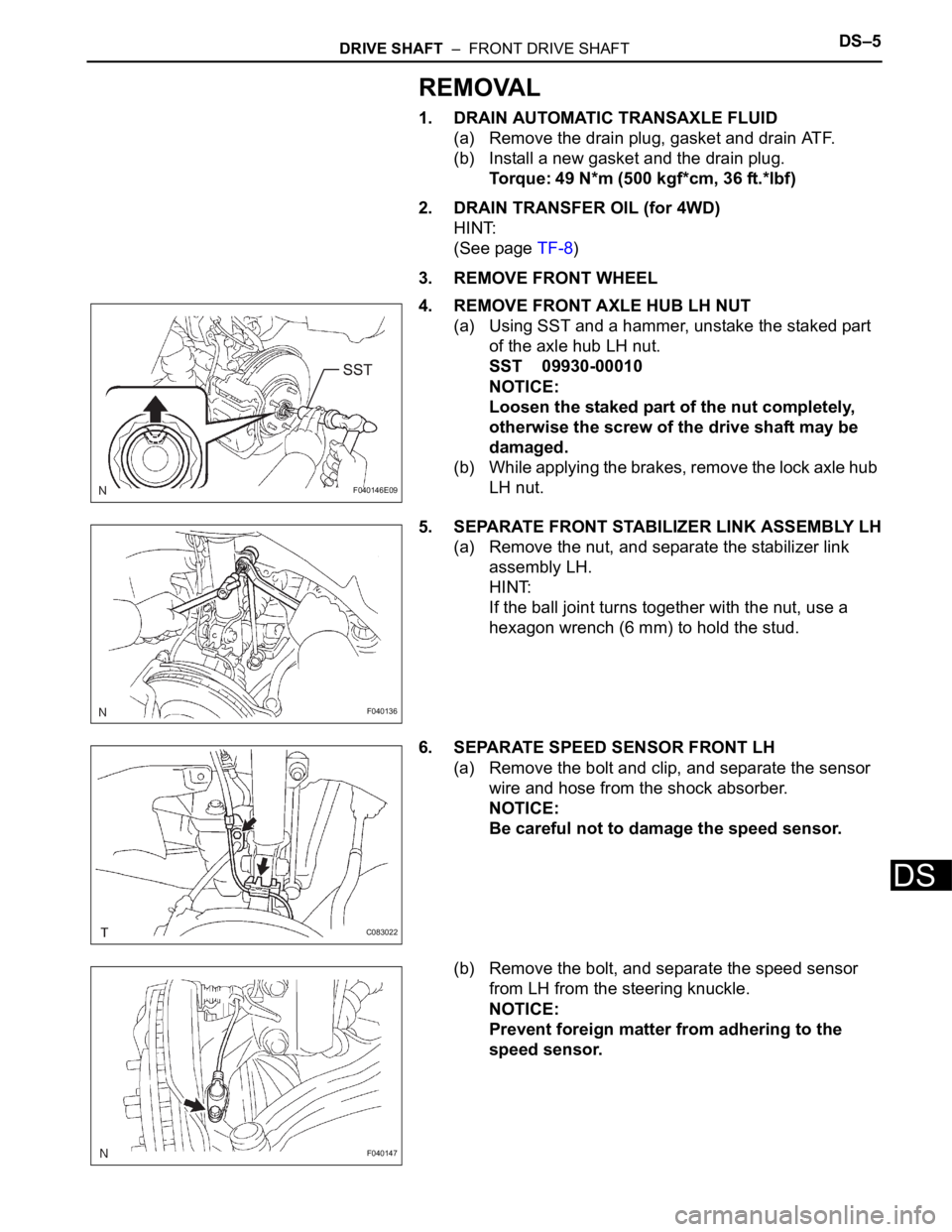

4. REMOVE FRONT AXLE HUB LH NUT

(a) Using SST and a hammer, unstake the staked part

of the axle hub LH nut.

SST 09930-00010

NOTICE:

Loosen the staked part of the nut completely,

otherwise the screw of the drive shaft may be

damaged.

(b) While applying the brakes, remove the lock axle hub

LH nut.

5. SEPARATE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the nut, and separate the stabilizer link

assembly LH.

HINT:

If the ball joint turns together with the nut, use a

hexagon wrench (6 mm) to hold the stud.

6. SEPARATE SPEED SENSOR FRONT LH

(a) Remove the bolt and clip, and separate the sensor

wire and hose from the shock absorber.

NOTICE:

Be careful not to damage the speed sensor.

(b) Remove the bolt, and separate the speed sensor

from LH from the steering knuckle.

NOTICE:

Prevent foreign matter from adhering to the

speed sensor.

F040146E09

F040136

C083022

F040147

Page 157 of 3000

PREPARATION – SUPPLEMENTAL RESTRAINT SYSTEMPP–67

PP

EQUIPMENT

Torque wrench

Feeler gauge

Bolt

Length: 35.0 mm (1.378 in.)

Diameter: 6.0mm (0.236 in.)

Pitch: 1.0 mm (0.039 in.)Airbag disposal

Tire

Width: 185mm (7.28 in.)

Inner diameter: 360mm (14.17 in.)Airbag disposal

Tire with disc wheel

Width: 185 mm (7.28 in.)

Inner diameter: 360mm (14.17 in.)Airbag disposal

Plastic bag Airbag disposal

Page 166 of 3000

AXLE – FRONT AXLE HUBAH–9

AH

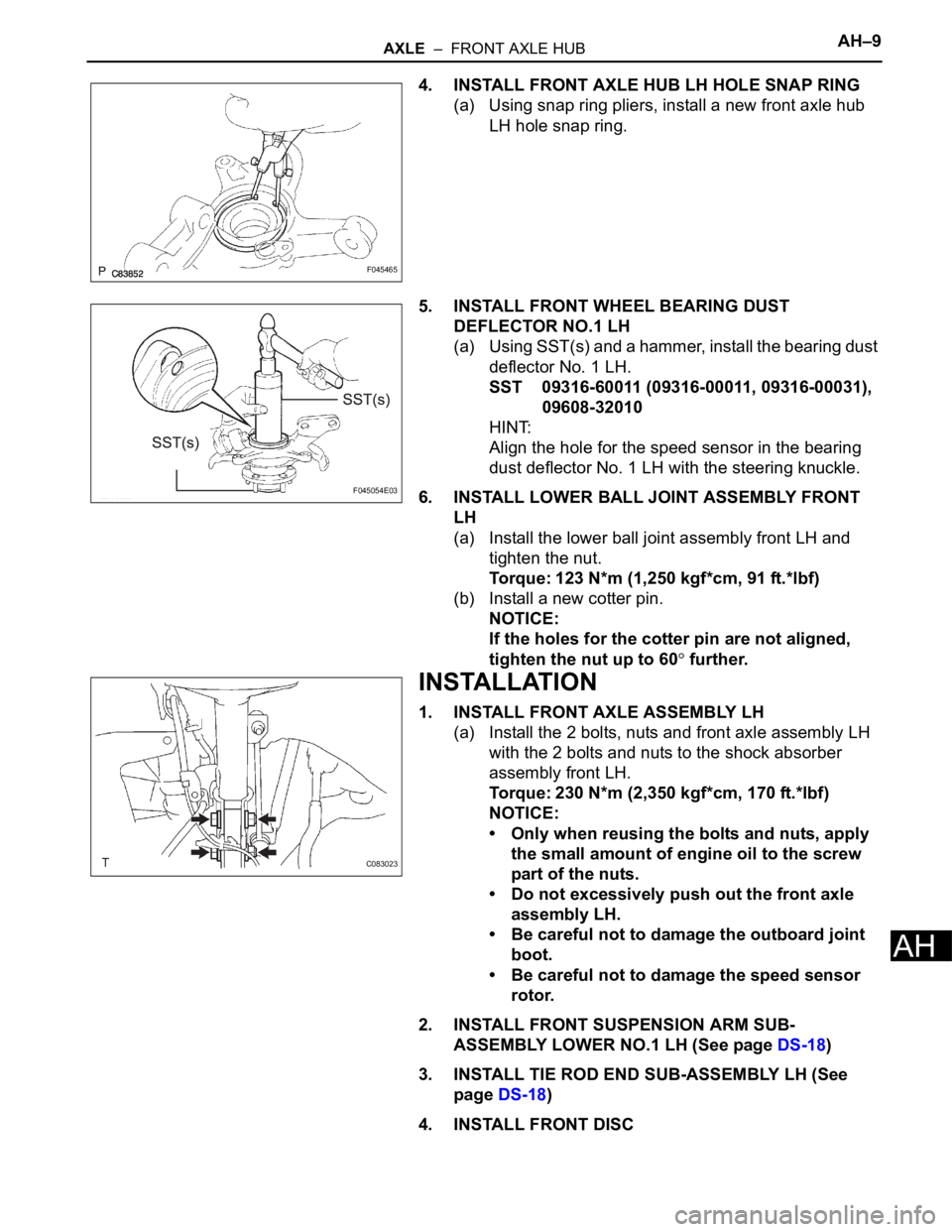

4. INSTALL FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, install a new front axle hub

LH hole snap ring.

5. INSTALL FRONT WHEEL BEARING DUST

DEFLECTOR NO.1 LH

(a) Using SST(s) and a hammer, install the bearing dust

deflector No. 1 LH.

SST 09316-60011 (09316-00011, 09316-00031),

09608-32010

HINT:

Align the hole for the speed sensor in the bearing

dust deflector No. 1 LH with the steering knuckle.

6. INSTALL LOWER BALL JOINT ASSEMBLY FRONT

LH

(a) Install the lower ball joint assembly front LH and

tighten the nut.

Torque: 123 N*m (1,250 kgf*cm, 91 ft.*lbf)

(b) Install a new cotter pin.

NOTICE:

If the holes for the cotter pin are not aligned,

tighten the nut up to 60

further.

INSTALLATION

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ft.*lbf)

NOTICE:

• Only when reusing the bolts and nuts, apply

the small amount of engine oil to the screw

part of the nuts.

• Do not excessively push out the front axle

assembly LH.

• Be careful not to damage the outboard joint

boot.

• Be careful not to damage the speed sensor

rotor.

2. INSTALL FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-18)

3. INSTALL TIE ROD END SUB-ASSEMBLY LH (See

page DS-18)

4. INSTALL FRONT DISC

F045465

F045054E03

C083023

Page 167 of 3000

AH–10AXLE – FRONT AXLE HUB

AH

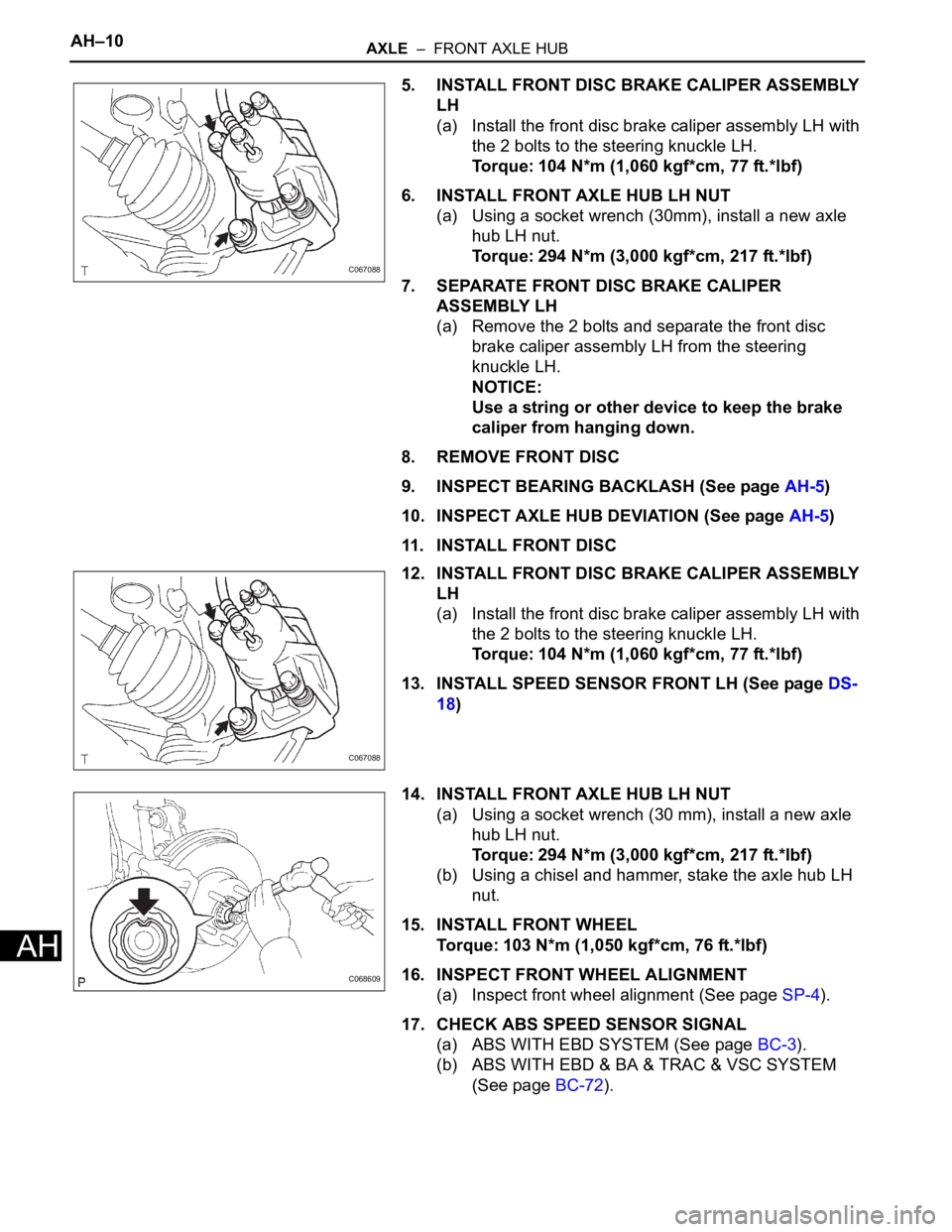

5. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

LH

(a) Install the front disc brake caliper assembly LH with

the 2 bolts to the steering knuckle LH.

Torque: 104 N*m (1,060 kgf*cm, 77 ft.*lbf)

6. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

7. SEPARATE FRONT DISC BRAKE CALIPER

ASSEMBLY LH

(a) Remove the 2 bolts and separate the front disc

brake caliper assembly LH from the steering

knuckle LH.

NOTICE:

Use a string or other device to keep the brake

caliper from hanging down.

8. REMOVE FRONT DISC

9. INSPECT BEARING BACKLASH (See page AH-5)

10. INSPECT AXLE HUB DEVIATION (See page AH-5)

11. INSTALL FRONT DISC

12. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

LH

(a) Install the front disc brake caliper assembly LH with

the 2 bolts to the steering knuckle LH.

Torque: 104 N*m (1,060 kgf*cm, 77 ft.*lbf)

13. INSTALL SPEED SENSOR FRONT LH (See page DS-

18)

14. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

(b) Using a chisel and hammer, stake the axle hub LH

nut.

15. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

16. INSPECT FRONT WHEEL ALIGNMENT

(a) Inspect front wheel alignment (See page SP-4).

17. CHECK ABS SPEED SENSOR SIGNAL

(a) ABS WITH EBD SYSTEM (See page BC-3).

(b) ABS WITH EBD & BA & TRAC & VSC SYSTEM

(See page BC-72).

C067088

C067088

C068609

Page 171 of 3000

SUSPENSION – REAR SHOCK ABSORBERSP–53

SP

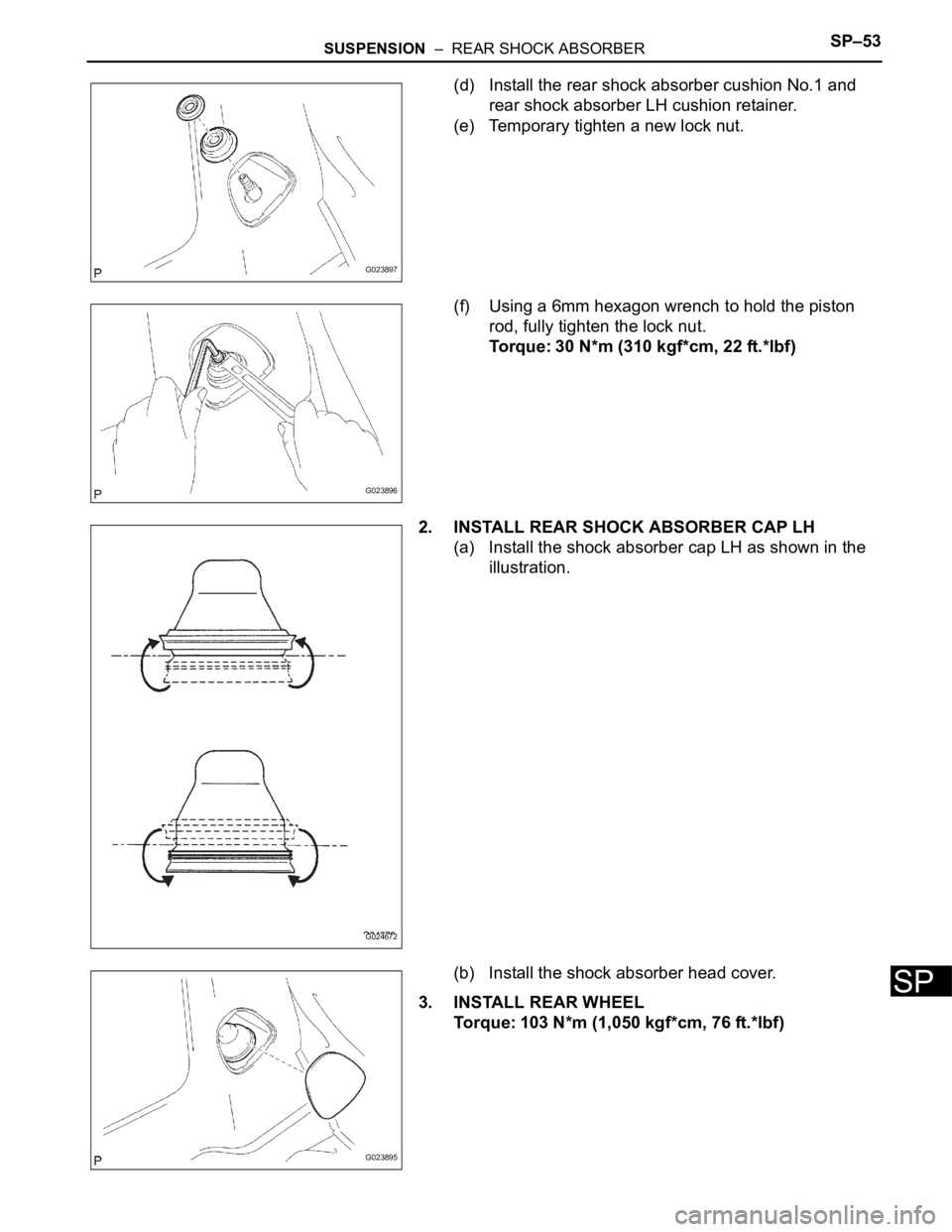

(d) Install the rear shock absorber cushion No.1 and

rear shock absorber LH cushion retainer.

(e) Temporary tighten a new lock nut.

(f) Using a 6mm hexagon wrench to hold the piston

rod, fully tighten the lock nut.

Torque: 30 N*m (310 kgf*cm, 22 ft.*lbf)

2. INSTALL REAR SHOCK ABSORBER CAP LH

(a) Install the shock absorber cap LH as shown in the

illustration.

(b) Install the shock absorber head cover.

3. INSTALL REAR WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

G023897

G023896

G024672

G023895