checking oil TOYOTA SUPRA 1995 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1995, Model line: SUPRA, Model: TOYOTA SUPRA 1995Pages: 2543, PDF Size: 53.25 MB

Page 1101 of 2543

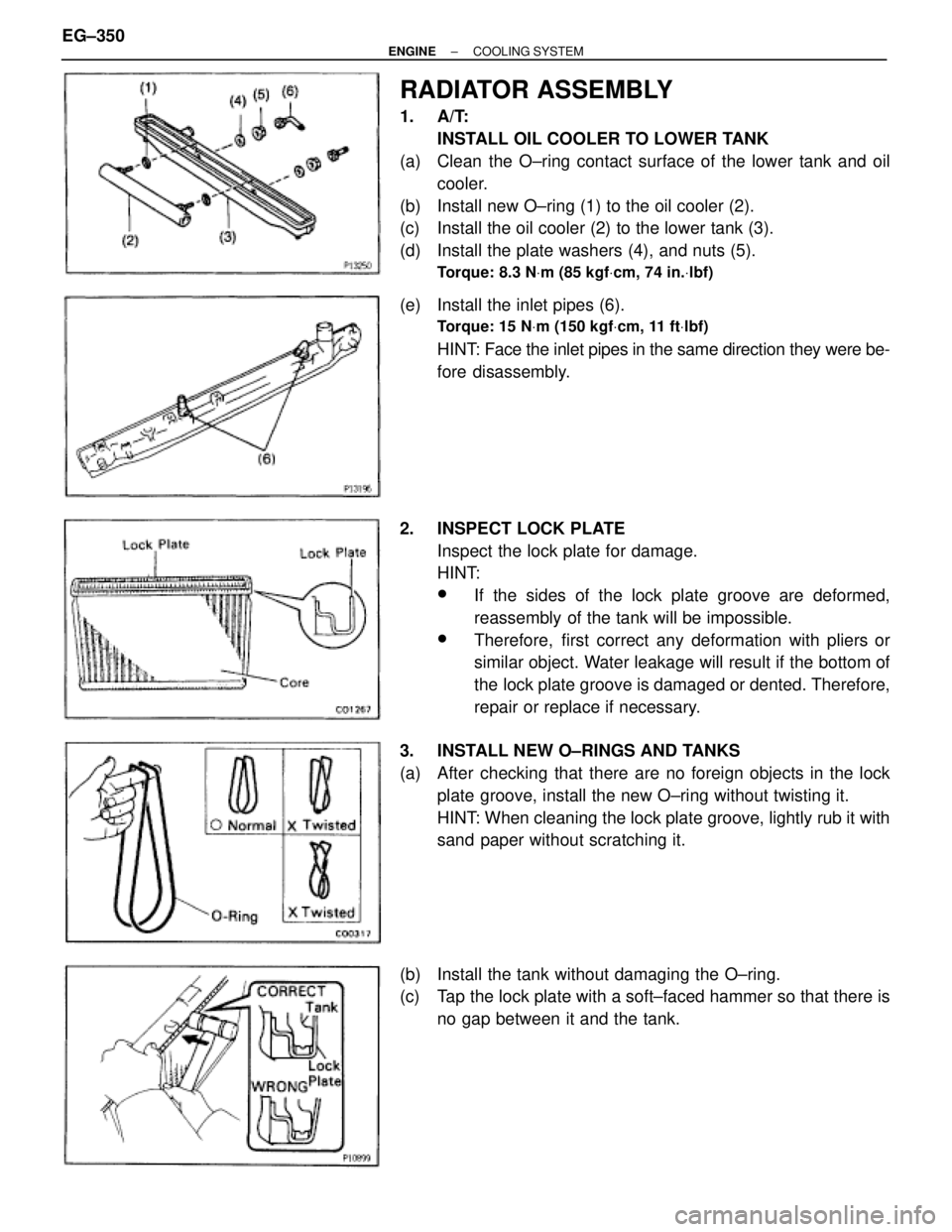

RADIATOR ASSEMBLY

1. A/T:

INSTALL OIL COOLER TO LOWER TANK

(a) Clean the O±ring contact surface of the lower tank and oil

cooler.

(b) Install new O±ring (1) to the oil cooler (2).

(c) Install the oil cooler (2) to the lower tank (3).

(d) Install the plate washers (4), and nuts (5).

Torque: 8.3 NVm (85 kgfVcm, 74 in.Vlbf)

(e) Install the inlet pipes (6).

Torque: 15 NVm (150 kgfVcm, 11 ftVlbf)

HINT: Face the inlet pipes in the same direction they were be-

fore disassembly.

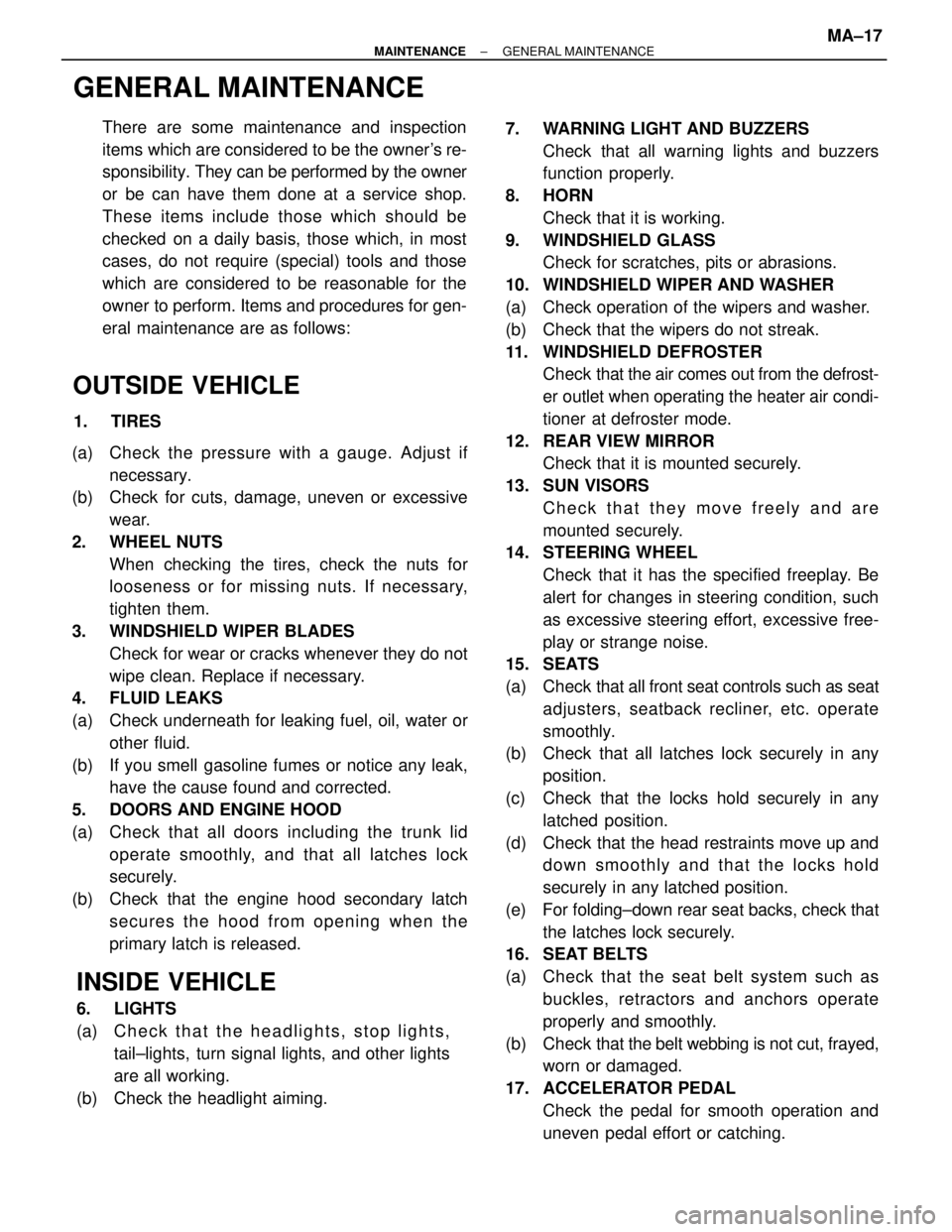

2. INSPECT LOCK PLATE

Inspect the lock plate for damage.

HINT:

wIf the sides of the lock plate groove are deformed,

reassembly of the tank will be impossible.

wTherefore, first correct any deformation with pliers or

similar object. Water leakage will result if the bottom of

the lock plate groove is damaged or dented. Therefore,

repair or replace if necessary.

3. INSTALL NEW O±RINGS AND TANKS

(a) After checking that there are no foreign objects in the lock

plate groove, install the new O±ring without twisting it.

HINT: When cleaning the lock plate groove, lightly rub it with

sand paper without scratching it.

(b) Install the tank without damaging the O±ring.

(c) Tap the lock plate with a soft±faced hammer so that there is

no gap between it and the tank. EG±350

± ENGINECOOLING SYSTEM

Page 1250 of 2543

There are some maintenance and inspection

items which are considered to be the owner's re-

sponsibility. They can be performed by the owner

or be can have them done at a service shop.

These items include those which should be

checked on a daily basis, those which, in most

cases, do not require (special) tools and those

which are considered to be reasonable for the

owner to perform. Items and procedures for gen-

eral maintenance are as follows:

OUTSIDE VEHICLE

1. TIRES

(a) Check the pressure with a gauge. Adjust if

necessary.

(b) Check for cuts, damage, uneven or excessive

wear.

2. WHEEL NUTS

When checking the tires, check the nuts for

looseness or for missing nuts. If necessary,

tighten them.

3. WINDSHIELD WIPER BLADES

Check for wear or cracks whenever they do not

wipe clean. Replace if necessary.

4. FLUID LEAKS

(a) Check underneath for leaking fuel, oil, water or

other fluid.

(b) If you smell gasoline fumes or notice any leak,

have the cause found and corrected.

5. DOORS AND ENGINE HOOD

(a) Check that all doors including the trunk lid

operate smoothly, and that all latches lock

securely.

(b) Check that the engine hood secondary latch

secures the hood from opening when the

primary latch is released.

INSIDE VEHICLE

6. LIGHTS

(a) C h e c k t h a t t h e headlights, stop lights,

tail±lights, turn signal lights, and other lights

are all working.

(b) Check the headlight aiming.7. WARNING LIGHT AND BUZZERS

Check that all warning lights and buzzers

function properly.

8. HORN

Check that it is working.

9. WINDSHIELD GLASS

Check for scratches, pits or abrasions.

10. WINDSHIELD WIPER AND WASHER

(a) Check operation of the wipers and washer.

(b) Check that the wipers do not streak.

11. WINDSHIELD DEFROSTER

Check that the air comes out from the defrost-

er outlet when operating the heater air condi-

tioner at defroster mode.

12. REAR VIEW MIRROR

Check that it is mounted securely.

13. SUN VISORS

Check that they move freely and are

mounted securely.

14. STEERING WHEEL

Check that it has the specified freeplay. Be

alert for changes in steering condition, such

as excessive steering effort, excessive free-

play or strange noise.

15. SEATS

(a) Check that all front seat controls such as seat

adjusters, seatback recliner, etc. operate

smoothly.

(b) Check that all latches lock securely in any

position.

(c) Check that the locks hold securely in any

latched position.

(d) Check that the head restraints move up and

down smoothly and that the locks hold

securely in any latched position.

(e) For folding±down rear seat backs, check that

the latches lock securely.

16. SEAT BELTS

(a) Check that the seat belt system such as

buckles, retractors and anchors operate

properly and smoothly.

(b) Check that the belt webbing is not cut, frayed,

worn or damaged.

17. ACCELERATOR PEDAL

Check the pedal for smooth operation and

uneven pedal effort or catching.

GENERAL MAINTENANCE

± MAINTENANCEGENERAL MAINTENANCEMA±17

Page 1251 of 2543

18. BRAKE PEDAL

(a) Check that pedal for smooth operation.

(b) Check that the pedal has the proper reserve

distance and freeplay.

(c) Check the brake booster function.

19. BRAKES

At a safe place, check that the brakes do not

pull to one side when applied.

20. PARKING BRAKE

(a) Check that the pedal has the proper travel.

(b) On a safe incline, check that the vehicle is

held securely with only the parking brake

applied.

21. AUTOMATIC TRANSMISSION PARK

MECHANISM

(a) Check the lock release button of the selector

lever for proper and smooth operation.

(b) On a safe incline, check that the vehicle is

held securely with the selector lever in the ºPº

position and all brakes released.

UNDER HOOD

22. WINDSHIELD WASHER FLUID

Check that there is sufficient fluid in the tank.

23. ENGINE COOLANT LEVEL

Check that the coolant level is between the

LEVEL lines on the see±through reservoir at

normal temperature (20°C (68°F)).

24. RADIATOR AND HOSES

(a) Check that the front of the radiator is clean

and not blocked with leaves, dirt or bugs.

(b) Check the hoses for cracks, kinks, rot or

loose connections.

25. BATTERY ELECTROLYTE LEVEL

Check the indicator.

When the indicator color is blue, the condition

is satisfactory. A red color indicates that dis-

tilled water must be added, and white indi-

cates that charging is necessary.

26. BRAKE FLUID LEVEL

Check that the brake fluid level is near the up-

per level line on the see±through reservoir.27. ENGINE DRIVE BELT

Check drive belt for fraying, cracks, wear or

oil contamination.

28. ENGINE OIL LEVEL

Check that level on the dipstick with the en-

gine turned off.

29. POWER STEERING FLUID LEVEL

Check the level on the dipstick.

The level should be in the ºHOTº or ºCOLDº

range depending on the fluid temperature.

30. A U TO M AT I C TRANSMISSION FLUID

LEVEL

(a) Park the vehicle on a level surface.

(b) With the engine idling and the parking and

foot brake applied, shift the selector into all

positions from ºPº to ºLº, and then shift into ºPº

position.

(c) Turn and pull out the dipstick and wipe off the

fluid with a clean rag.

Re±insert the dipstick fully and check that the

fluid level is in the ºHOTº range.

(d) Perform this check with the fluid at normal

driving temperature (70±80°C (158±176°F)).

If the level is at the low side, add fluid.

NOTICE: Do not overfill.

HINT: Wait about 30 minutes before checking

the fluid level after extended driving at high

speeds in hot weather, driving in heavy traffic

or with a trailer.

31. EXHAUST SYSTEM

Visually inspect for cracks, holes or loose

supports.

If any change in the sound of the exhaust or

smell of the exhaust fumes is noticed, have

the cause located and correted. MA±18

± MAINTENANCEGENERAL MAINTENANCE

Page 1346 of 2543

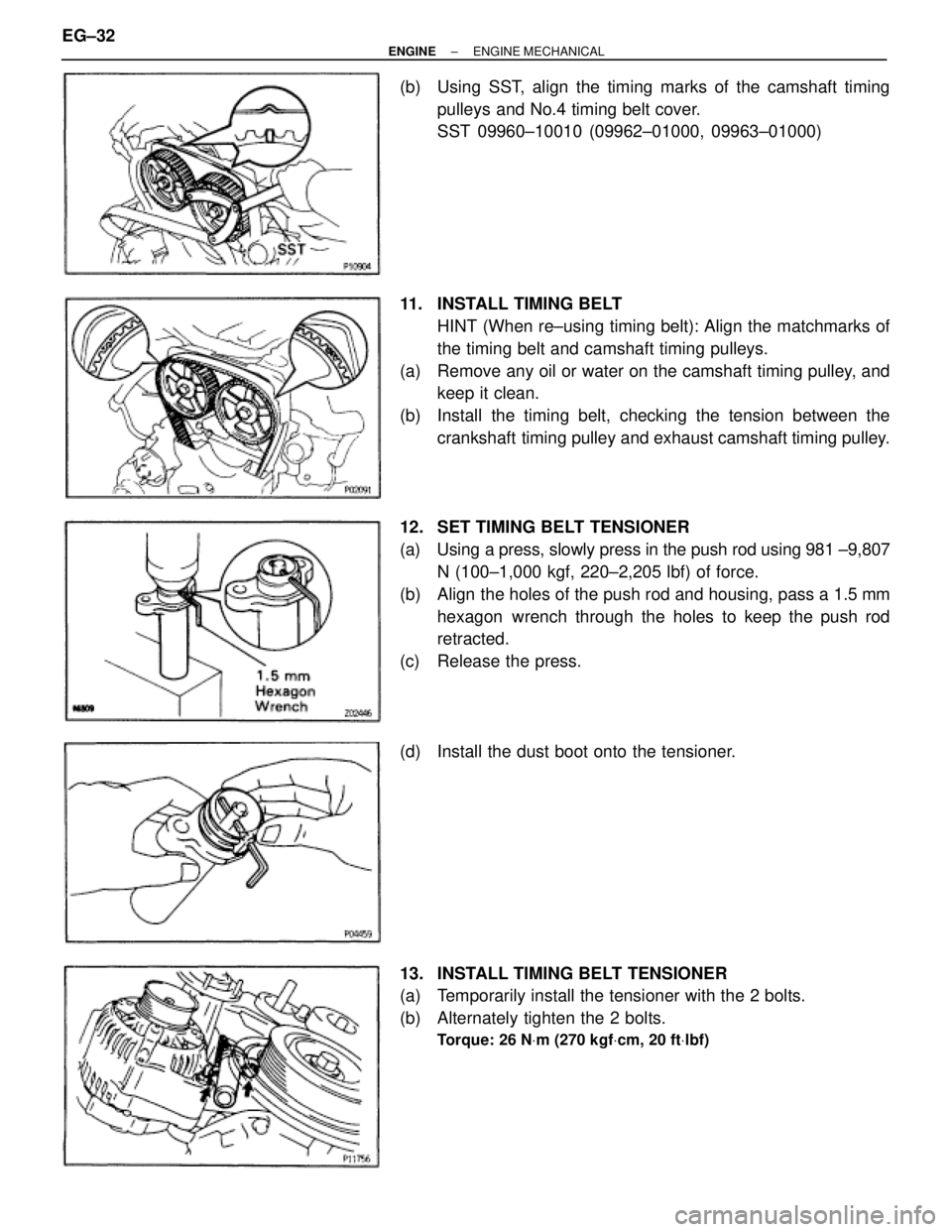

(b) Using SST, align the timing marks of the camshaft timing

pulleys and No.4 timing belt cover.

SST 09960±10010 (09962±01000, 09963±01000)

11. INSTALL TIMING BELT

HINT (When re±using timing belt): Align the matchmarks of

the timing belt and camshaft timing pulleys.

(a) Remove any oil or water on the camshaft timing pulley, and

keep it clean.

(b) Install the timing belt, checking the tension between the

crankshaft timing pulley and exhaust camshaft timing pulley.

12. SET TIMING BELT TENSIONER

(a) Using a press, slowly press in the push rod using 981 ±9,807

N (100±1,000 kgf, 220±2,205 lbf) of force.

(b) Align the holes of the push rod and housing, pass a 1.5 mm

hexagon wrench through the holes to keep the push rod

retracted.

(c) Release the press.

(d) Install the dust boot onto the tensioner.

13. INSTALL TIMING BELT TENSIONER

(a) Temporarily install the tensioner with the 2 bolts.

(b) Alternately tighten the 2 bolts.

Torque: 26 NVm (270 kgfVcm, 20 ftVlbf)

EG±32± ENGINEENGINE MECHANICAL