brake rotor TOYOTA TERCEL 1985 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 562 of 885

BRAKE SYSTEM - TroubleshootingBR.3

TROU BLESHOOTING (Cont'd)

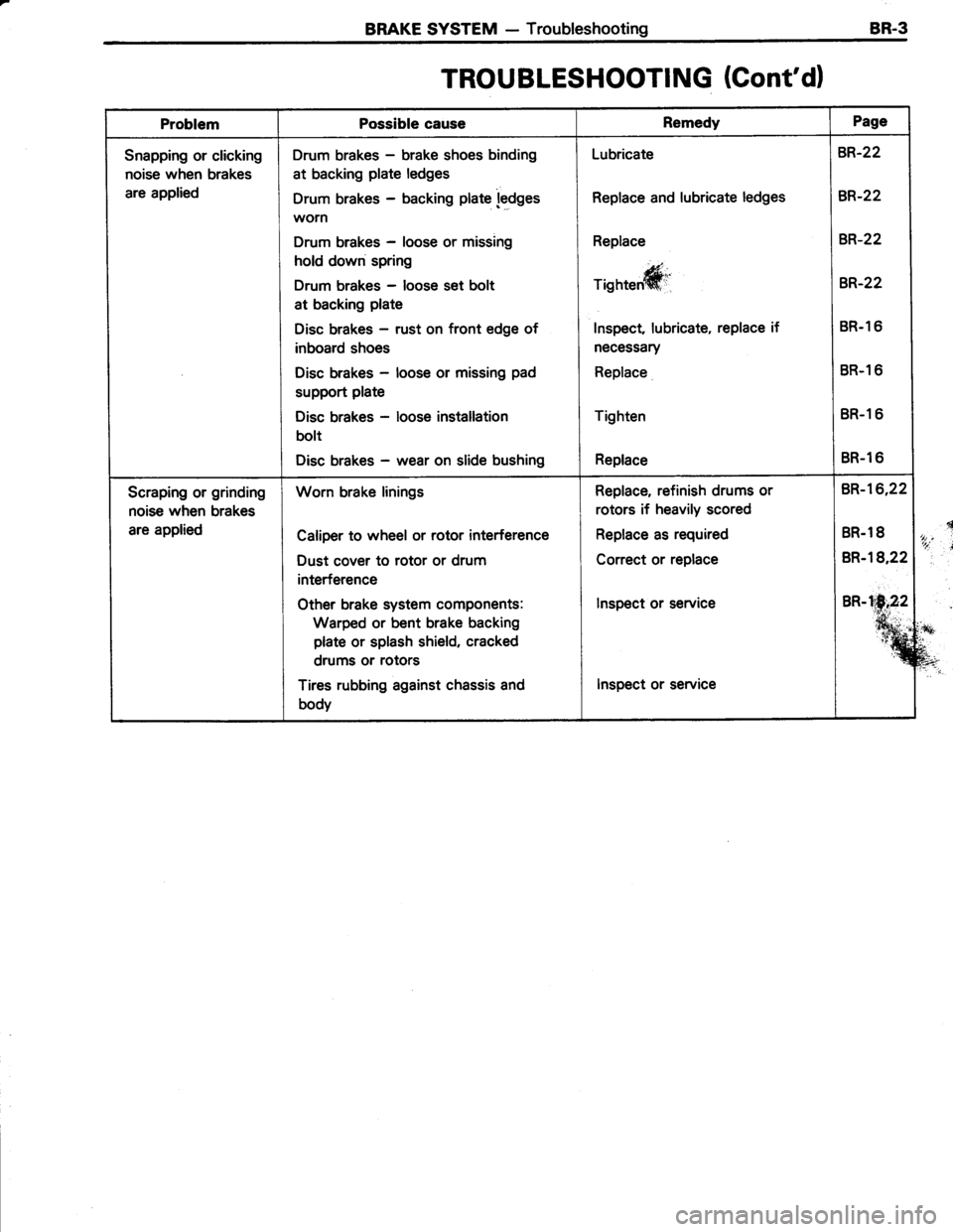

ProblemPossible causeRemedyPage

r+i

:?*

a?"t

Snapping or clicking

noise when brakes

are applied

Drum brakes - brake shoes binding

at backing plate ledges

Drum brakes - backing plate ledgesworn

Drum brakes - loose or missing

hold down spring

Drum brakes - loose set bolt

at backing plate

Disc brakes - rust on front edge of

inboard shoes

Disc brakes - loose or missing pad

support plate

Disc brakes - loose installation

bolt

Disc brakes - wear on slide bushing

Lubricate

Replace and lubricate ledges

Replace

E,

Tisnteffit'

Inspect lubricate, replace if

necessary

Replace

Tighten

Replace

BR-22

BR-22

BR-22

BR-22

BR.1 6

BR-1 6

BR-1 6

BR-1 6

Scraping or grinding

noise when brakes

are applied

Worn brake linings

Caliper to wheel or rotor interference

Dust cover to rotor or drum

interference

other brake system components:

Warped or bent brake backing

plate or splash shield, cracked

drums or rotors

Tires rubbing against chassis and

body

Replace, refinish drums or

rotors if heavily scored

Replace as required

Correct or replace

lnspect or service

Inspect or service

BR-16,22

BR.1 8

BR-l8,22

BR-h1N,22

%

Page 563 of 885

BR-4 BRAKE SYSTEM - Troubleshooting

TROU BLESHOOTI NG (Cont'd)

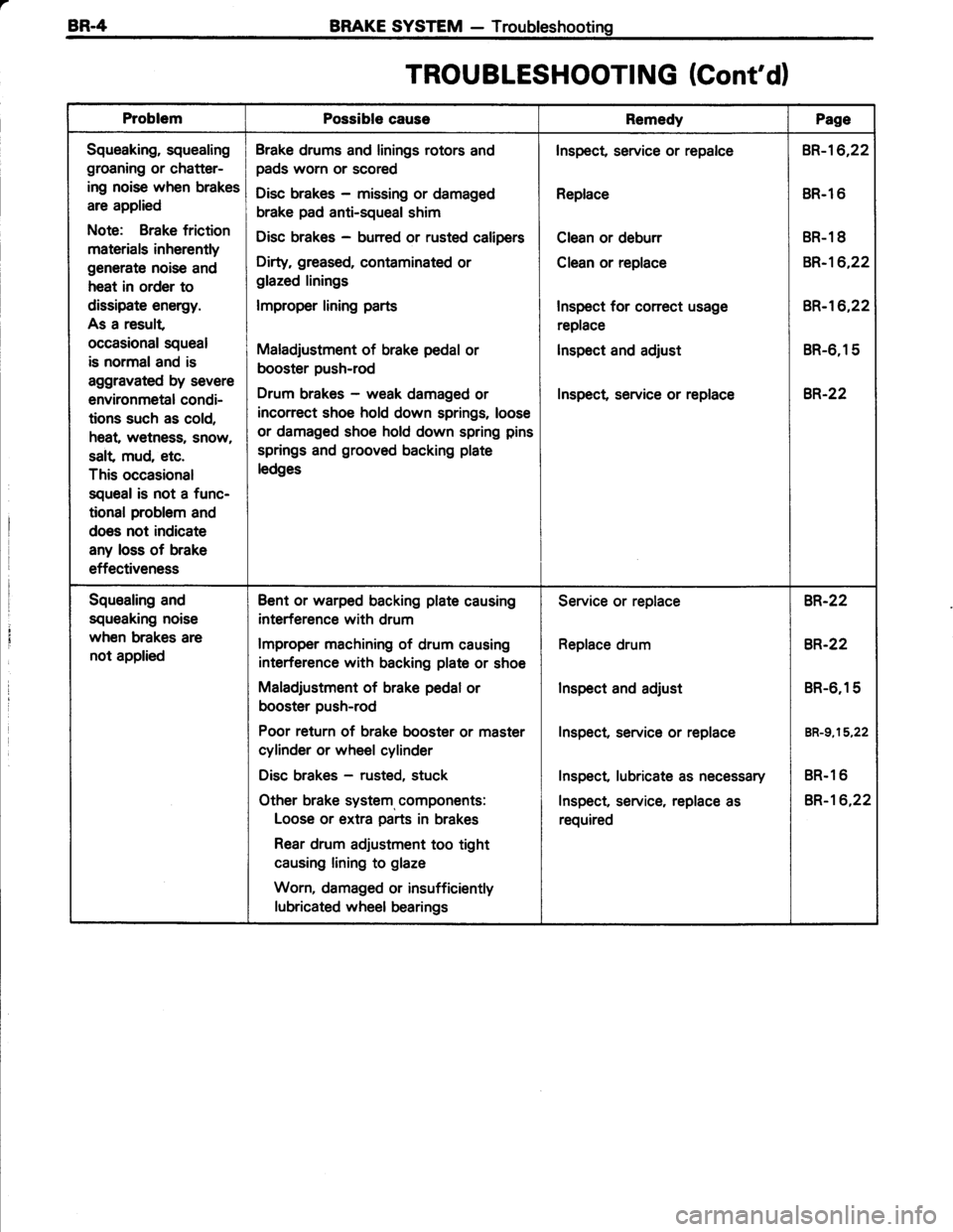

ProblemPossible causeRemedyPage

Squeaking, squealing

groaning or chatter-

ing noise when brakes

are applied

Note: Brake friction

materials inherently

generate noise and

heat in order to

dissipate energy.

As a result

occasional squeal

is normaland is

aggravated by severe

environmetal condi-

tions such as cold,

heat, wetness, snow,

salt mud, etc.

This occasional

squeal is not a func-

tional problem and

does not indicate

any loss of brake

effectiveness

Brake drums and linings rotors and

pads worn or scored

Disc brakes - missing or damaged

brake pad anti-squeal shim

Disc brakes - burred or rusted calipers

Dirty, greased, contaminated or

glazed linings

lmproper lining parts

Maladjustment of brake pedal or

booster push-rod

Drum brakes - weak damaged or

incorrect shoe hold down springs, loose

or damaged shoe hold down spring pins

springs and grooved backing plate

ledges

Inspect, service or repalce

Replace

Clean or deburr

Clean or replace

Inspect for conect usage

replace

lnspect and adjust

Inspect service or replace

BR-16,22

BR.l 6

BR-1 8

BR-16,22

BR-'�t6,22

BR-6,15

8R.22

Squealing and

squeaking noise

when brakes are

not applied

Bent or warped backing plate causing

interference with drum

lmproper machining of drum causing

interference with backing plate or shoe

Maladjustment of brake pedal or

booster push-rod

Poor return of brake booster or master

cylinder or wheel cylinder

Disc brakes - rusted, stuck

Other brake system, components:

Loose or extra parts in brakes

Rear drum adjustment too tight

causing lining to glaze

Worn, damaged or insufficiently

lubricated wheel bearings

Service or replace

Replace drum

Inspect and adjust

Inspect, service or replace

Inspect lubricate as necessary

Inspect, service, replace as

required

BR-22

8R.22

BR-6,15

BR-g,15,22

BR.1 6

BR-16,22

Page 564 of 885

BRAKE SYSTEM - TroubleshootingBR-5

TROUBLESHOOTING (Cont'dl

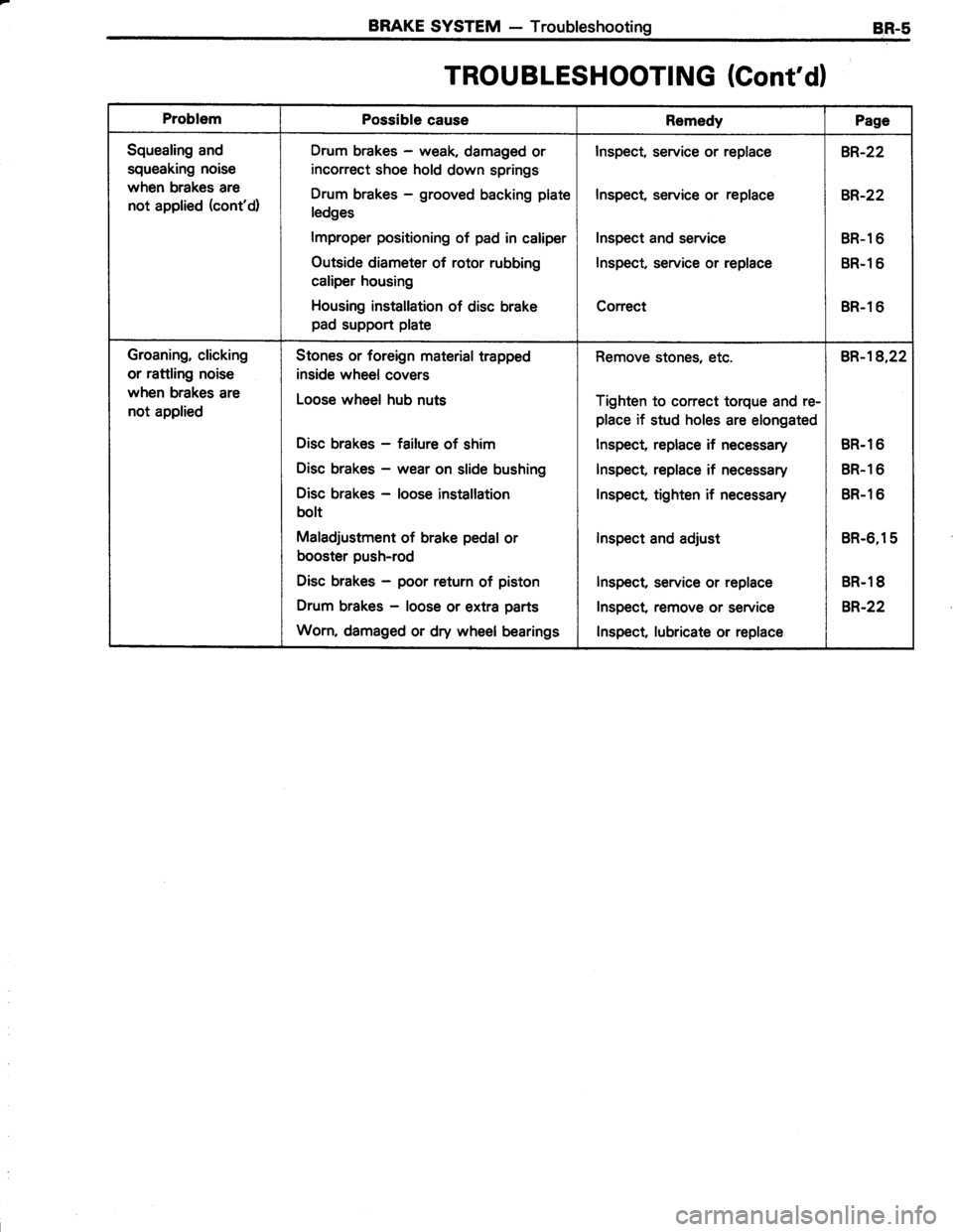

ProblemPossible causeRemedyPage

Squealing and

squeaking noise

when brakes are

not applied (cont'd)

Drum brakes - weak, damaged or

incorrect shoe hold down springs

Drum brakes - grooved backing plate

ledges

lmproper positioning of pad in caliper

Outside diameter of rotor rubbing

caliper housing

Housing installation of disc brake

pad support plate

Inspect, service or replace

Inspect, service or replace

Inspect and service

Inspect, service or replace

Correct

BR-22

BR-22

BR-l 6

BR-l 6

BR-1 6

Groaning, clicking

or rattling noise

when brakes are

not applied

Stones or foreign material trapped

inside wheel covers

Loose wheel hub nuts

Disc brakes - failure of shim

Disc brakes - wear on slide bushing

Disc brakes - loose installation

bolt

Maladjustment of brake pedal or

booster push-rod

Disc brakes - poor return of piston

Drum brakes - loose or extra parts

Worn, damaged or dry wheel bearings

Remove stones, etc.

Tighten to correct torque and re-

place if stud holes are elongated

lnspect, replace if necessary

Inspect, replace if necessary

Inspect, tighten if necessary

lnspect and adjust

Inspect, service or replace

Inspect remove or service

lnspect lubricate or replace

BR-18,22

BR.1 6

BR.1 6

BR-1 6

BR-6,15

BR.1 8

B,R.22

Page 575 of 885

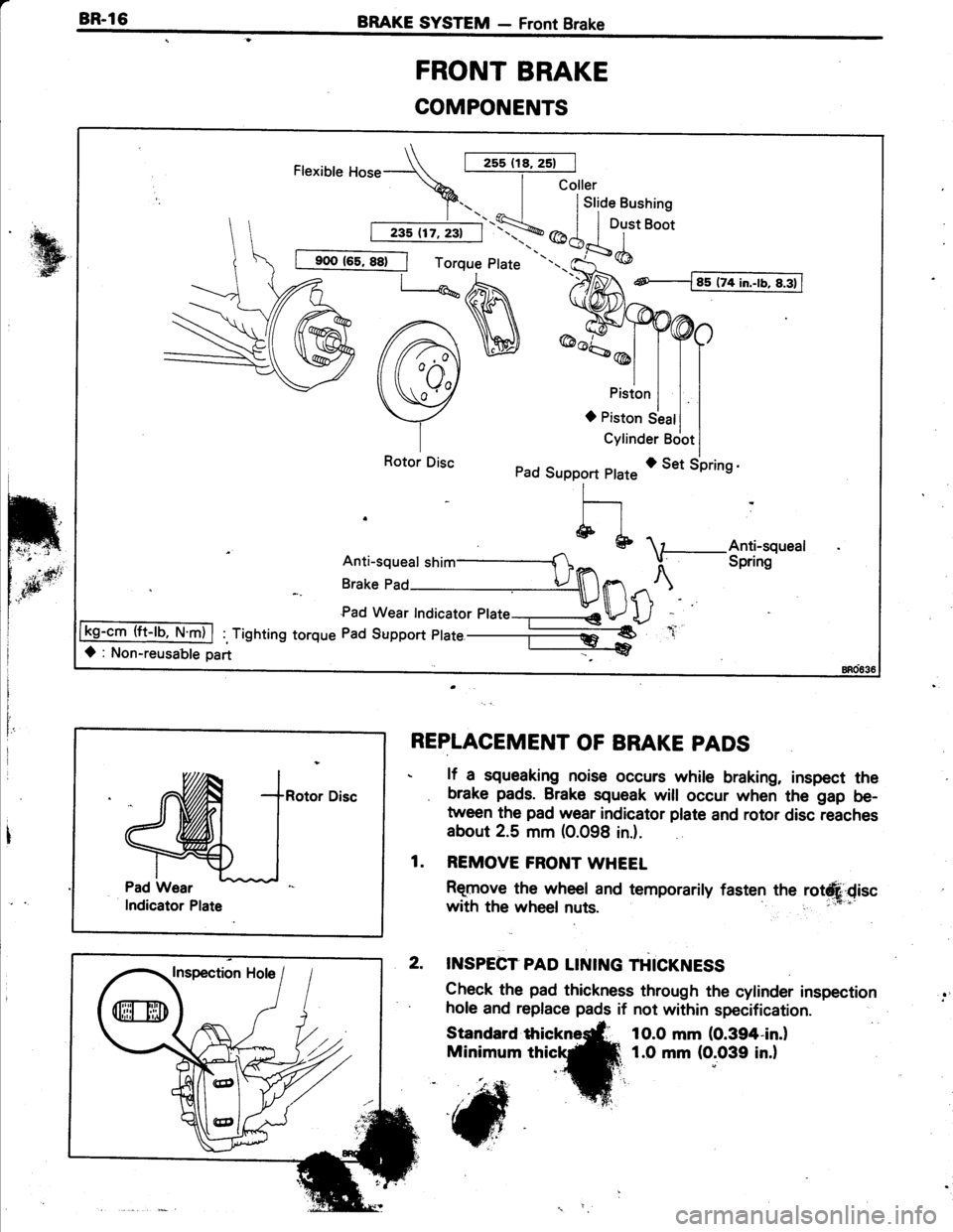

BR-l6BRAKE SYSTEM - Front Brake

FRONT BRAKE

COMPONENTS

I

IREPLACEMENT OF BRAKE PADS

. lf a squeaking noise occurs while braking, inspect the

. brake pads. Brake squeak will occur when the gap be-

tween the pad wear indicator plate and rotor disc reaches

about 2.5 mm (0.098 in.).

1. REMOVE FRONT WHEET

Rqmove the wheel and temporarily fasten the rotdfu discwith the wheel nuts. ;:E "'

2. INSPECT PAD LINING THICKNESS

Check the pad thickness through the cylinder inspection' hole and replace pads if not within specification.

Standard

Minimum

1O.0 mm (0.394-in.l

1.0 mm (0.039 in.)

\_ [-5s ntzst IFlexible Hose--\\>.;lco

Ja-- |I 'r fa-l

235 117,231

900 165,88)j Torque Plate

Leh

A\H)

Rotor Disc

Anti-squeal shim __Anti-squeal

I Spring

-cm (ft-lb, N.m)

8ao?36

Page 576 of 885

l'-

BRAKE SYSTEM - Front Brake

,ritl t'i'.ihffi:ir ''$,8R.17

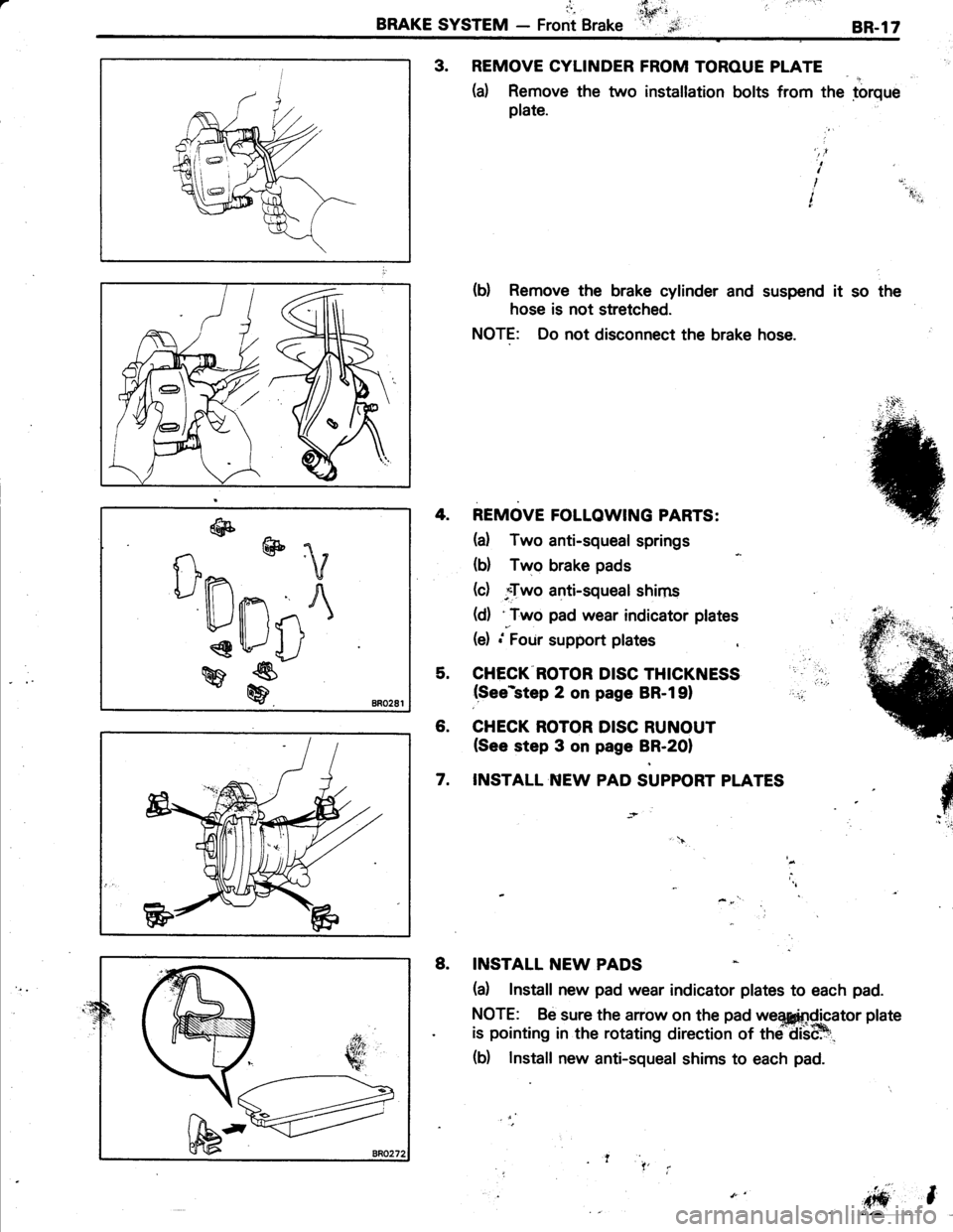

3. REMOVE CYLINDER FROM TOROUE PLATE

(a) Remove the two installation bolts from the torque

plate.

(b) Remove the brake cylinder and suspend it so the

hose is not stretched.

NOTE: Do not disconnect the brake hose.

't'l'|

I

,t'r

REMOVE FOLLOWING PARTS:

(a) Two anti-squeal springs

(b) Two brake pads

(d ."Two anti-squeal shims

(d) 'Two pad wear indicator plates

(e) .'FoUr support plates

CHECK ROTOR DISC THICKNESS(See*step 2 on page BR-l91

CHECK ROTOR DISC RUNOUT(See step 3 on page BR-2OI

INSTALL NEW PAD SUPPORT PLATES

4.

5.

6.

7.

$

INSTALL NEW PADS

(a) Install new pad wear indicator plates to each pad.

NOTE: Be sure the arrow on the pad we*fiQicator plate

is pointing in the rotating direction of thd diiHt_

(b) Install new anti-squeal shims to each pad.

iffi

8.

@

n @

ilPnn

- )\

tPlll i{1q

4J

w

# BRo281

l'l

Page 578 of 885

BRAKE SVSTEM - Front Brake8R.19

2. REMOVE CYLINDER BOOT SET RING AND CYLINDER

BOOT

Using a screwdriver, remove the set ring and boot.

3. REMOVE PISTON FROM CYLINDER

(a) Put a piece of cloth or such between the piston and

cylinder.

(d Use compressed air to remove the piston from the

cylinder.

WARNING: Do not place your fingers in front of the

piston when using compressed air.

- REMOVE PISTON SEAL FROM BRAKE CYLINDER

Using a screwdriver, remove the piston seal.

INSPECTION AND REPAIR OF FRONT BRAKE

COMPONENTS

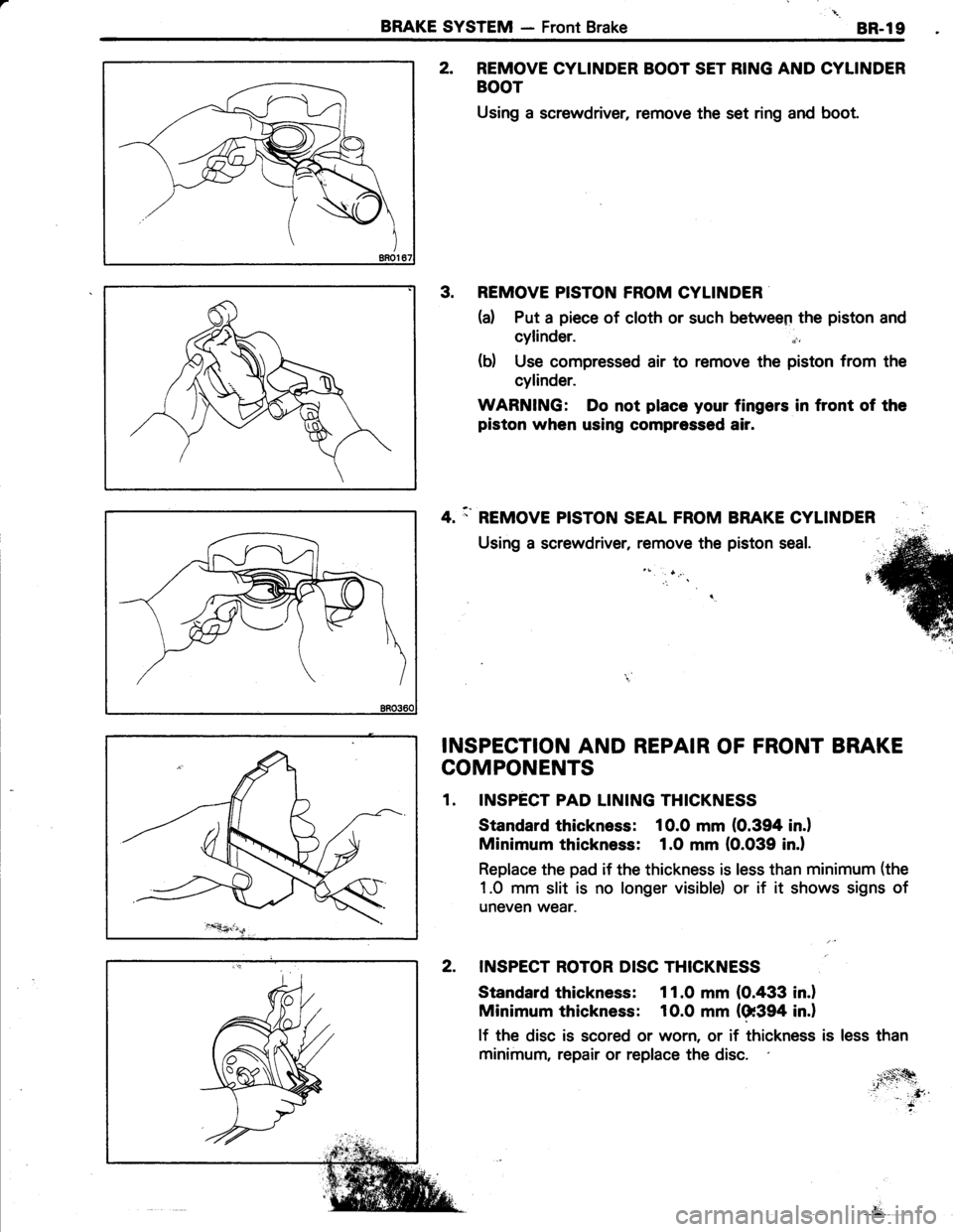

1. TNSPECT PAD LINING THICKNESS

Standard thickness: 10.O mm (0.394 in.)

Minimum thickness: 1.0 mm (0.039 in.l

Replace the pad if the thickness is less than minimum (the

1.0 mm slit is no longer visible) or if it shows signs of

uneven wear.

INSPECT ROTOR DISC THICKNESS

Standard thickness: 1 1.0 mm (0.433 in.l

Minimum thickness: 10.0 mm {0r39a in.}

lf the disc is scored or worn, or if thickness is less than

minimum, repair or replace the disc.

4.

:t-$ixt:r- , . -rr,

*i,

Page 579 of 885

BR-2OBRAKE SYSTEM - Front Brake

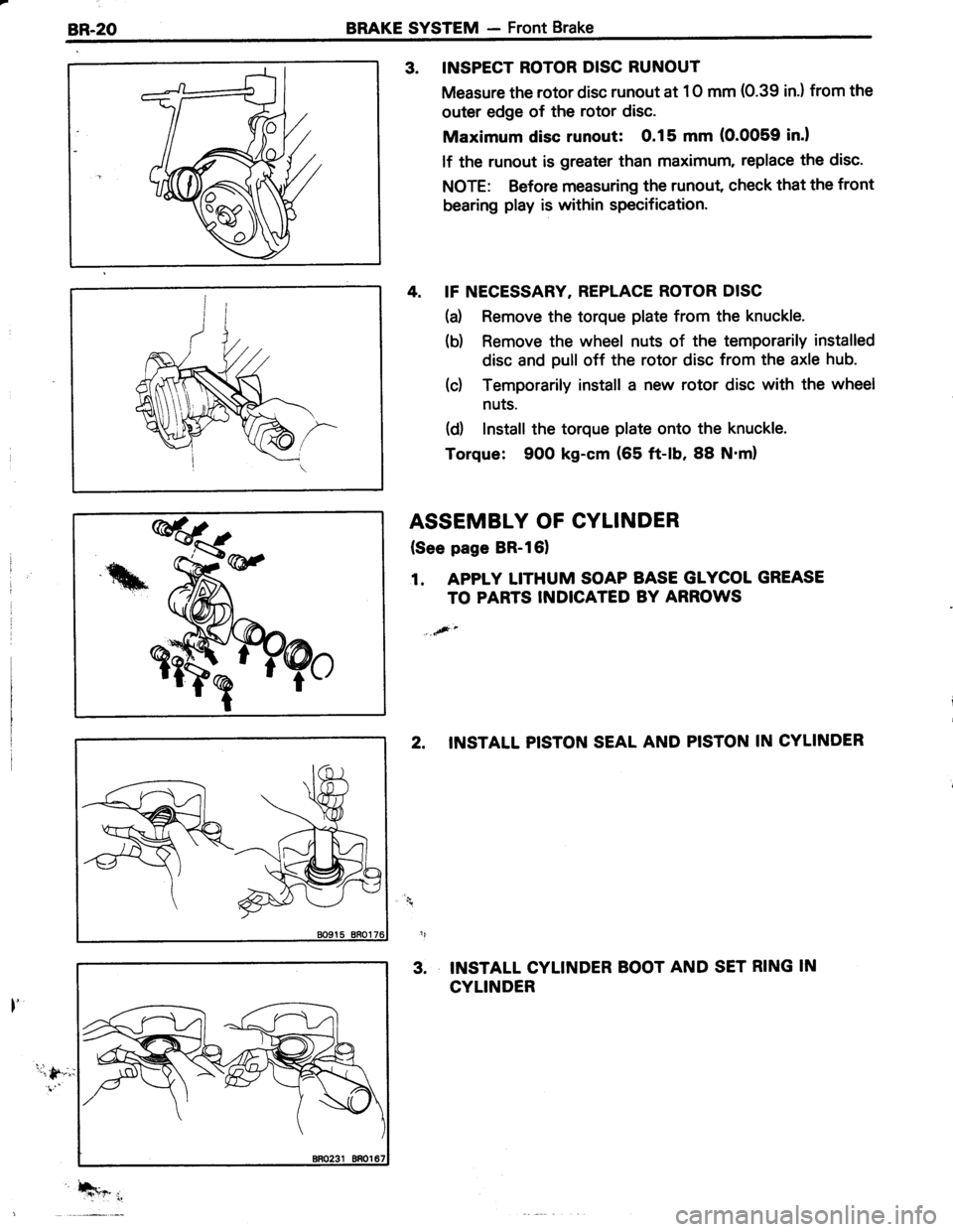

3. INSPECT ROTOR DISC RUNOUT

Measure the rotor disc runout at 1O mm (0.39 in.) from the

outer edge of the rotor disc.

Maximum disc runout: 0.15 mm (0.0059 in.l

lf the runout is greater than maximum, replace the disc.

NorE: Before measuring the runout check that the front

bearing play is within specification.

4. IF NECESSARY, REPLACE ROTOR DISC

(d Remove the torque plate from the knuckle.

(b) Remove the wheel nuts of the temporarily installed

disc and pull off the rotor disc from the axle hub.

(c) Temporarily install a new rotor disc with the wheel

nuts.

(d) Install the torque plate onto the knuckle.

Torque: 900 kg-cm (65 ft-lb, 88 N'm)

ASSEMBLY OF CYLINDER

(See page BR-161

1. APPLY LITHUM SOAP BASE GLYCOL GREASE

TO PARTS INDICATED BY ARROWS

2. INSTALL PISTON SEAL AND PISTON IN CYLINDER

INSTALL CYLINDER BOOT AND SET RING IN

CYLINDER

\

ti

3.

Q++, i,