height TOYOTA TERCEL 1985 Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 476 of 885

PR-z PROPELLER SHAFT - Precautions, Troubleshooting, Propeller Shaft

PRECAUTIONS

1. As the universal ioint is a non-disassembly type' the

propeller shaft or intermediate shaft must be replaced

as an assembly in the event of universalioint trouble.

2. Be careful not to grip the propeller shaft tube too tight-

ly in the vise as this will cause deformation.

TROUBLESHOOTING

ProblemPossible causeRemedyPage

NoiseSleeve yoke spline worn

Center bearing worn

Spider bearing worn or stuck

Replace intermediate shaft

Replace center bearing

Replace intermediate shaft or

propeller shaft

PR-3

PR-3

PR-3

VibrationPropeller shaft runout

Propeller shaft unbalance

Transmission extension housing rear

bushing worn

Sleeve yoke spline stuck

Center bearing height imProPer

Replace propeller shaft

Balance propeller shaft

Replace bushing

Replace intermediate shaft

Adjust bearing height

PR-3

PR-3

TA.4O

PR-3

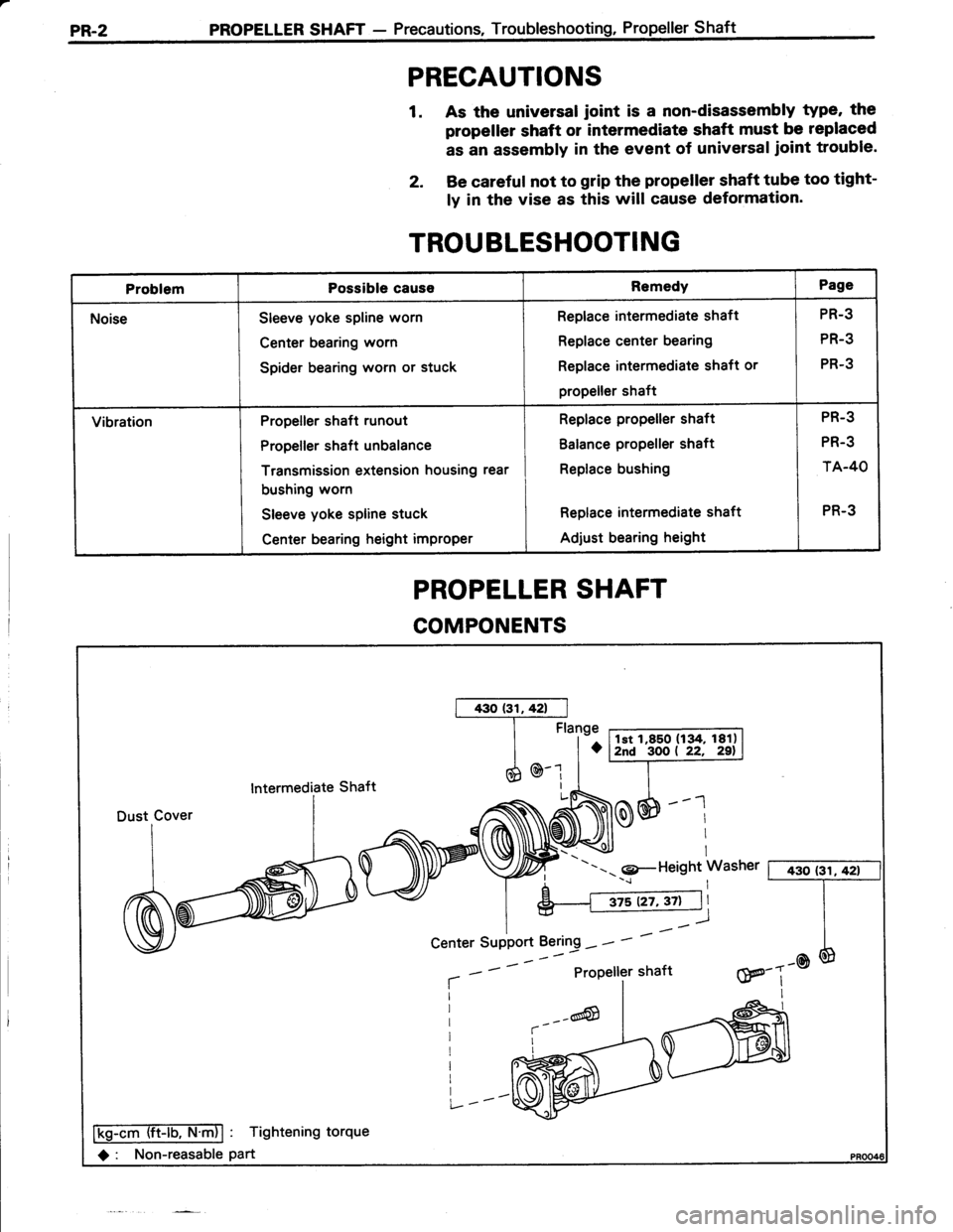

PROPELLER SHAFT

COMPONENTS

lntermediate Shaft

---- 9-Height Washer [ 430 (3il42t

aProPeller shaftw---@III

Ffiffiiib-ntnl : Tightening torque

O : Non-reasable part

Center SuPPort Bering - -

Page 480 of 885

PR-6 PROPELLER SHAFT - Propeiler Shaft

SST

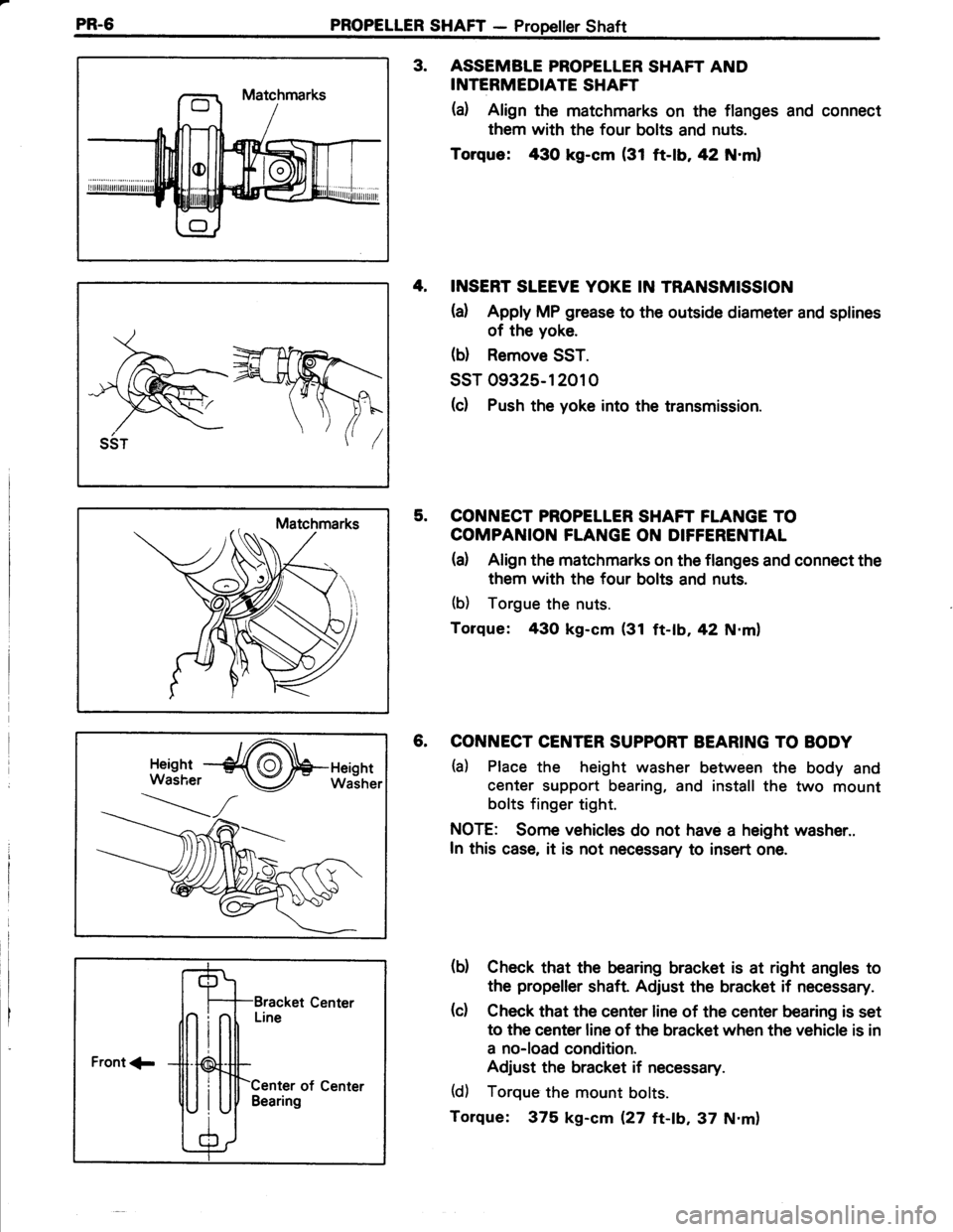

3. ASSEMBTE PROPELLER SHAFT AND

INTERMEDIATE SHAFT

(a) Align the matchmarks on the flanges and connect

them with the four bolts and nuts.

Torque: 430 kg-cm (31 ft-|b,42 N.ml

4, INSERT SLEEVE YOKE IN TRANSMISSION

{a) Apply MP grease to the outsade diameter and splines

of the yoke.

(b) Remove SST.

ssT 09325-12010

(c) Push the yoke into the transmission.

5. CONNECT PROPELLER SHAFT FLANGE TO

COMPANION FLANGE ON DIFFERENTIAL

(a) Align the matchmarks on the flanges and connect the

them with the four bolts and nuts.

(b) Torgue the nuts.

Torque: 43O kg-cm (31 ft-tb,42 N.m)

6. CONNECT CENTER SUPPORT BEARING TO BODY

ta) Place the height washer between the body and

center support bearing, and install the two mount

bolts finger tight.

NOTE: Some vehicles do not have a height washer..

In this case, it is not necessary to insert one.

(b) Check that the bearing bracket is at right angles to

the propeller shaft Adjust the bracket if necessary.

(c) Check that the center line of the center bearing is set

to the center line of the bracket when the vehicle is in

a no-load condition.

Adjust the bracket if necessary.

(d) Torque the mount bolts.

Torque: 375 kg-cm Q7 tt-ab,37 N.m)

Front 1-

Center of CenterBearing

Page 483 of 885

FRONT AXLE AND SUSPENSION - Front Wheel AlignmentFA-3

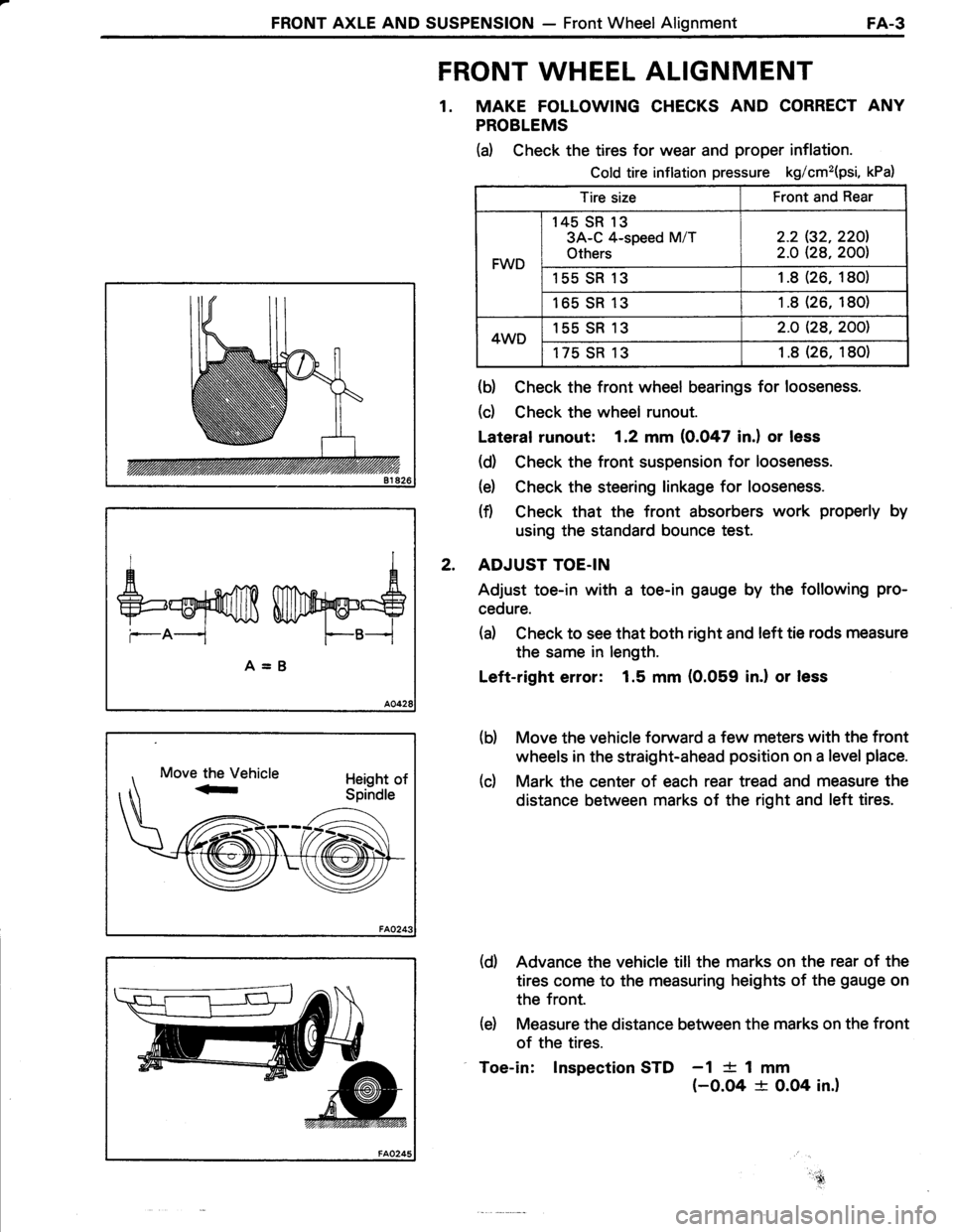

FRONT WHEEL ALIGNMENT

1. MAKE FOLLOWING CHECKS AND CORRECT ANY

PROBLEMS

(d Check the tires for wear and proper inflation.

Cold tire inflation pressure kg/cm2(psi, kPa)

Tire sizeFront and Rear

FWD

145 SR 13

3A-C 4-speed M/T

Others

2.2 (32.220l.

2.O Q8,2001

155 SR 131.8(26. 180)

165 SR131 .8 (26, 180)

4WD155 SR 132.O Q8,2001

175 SR 131 .8 (26. 180)

(b) Check the front wheel bearings for looseness.

(d Check the wheel runout.

Lateral runout: 1.2 mm (0.047 in.) or less

(d) Check the front suspension for looseness.

(e) Check the steering linkage for looseness.

(f) Check that the front absorbers work properly by

using the standard bounce test.

ADJUST TOE.IN

Adjust toe-in with a toe-in gauge by the following pro-

cedure.

(d Check to see that both right and left tie rods measure

the same in length.

Left-right error: 1.5 mm (0.059 in.l or less

Move the vehicle forward a few meters with the front

wheels in the straight-ahead position on a level place.

Mark the center of each rear tread and measure the

distance between marks of the right and left tires.

(d) Advance the vehicle till the marks on the rear of the

tires come to the measuring heights of the gauge on

the front.

(e) Measure the distance between the marks on the front

of the tires.

Toe-in: lnspection STD -1 {- 1 mm(-0.O4 + O.O4 in.)

AA

+=ruf,ffi Wry@=S

--A-- F--B--i

A=B

2.

(b)

(c)

!,.-!'ru,

Page 485 of 885

FRONT AXLE AND SUSPENSION - Front Wheel AlignmentFA-5

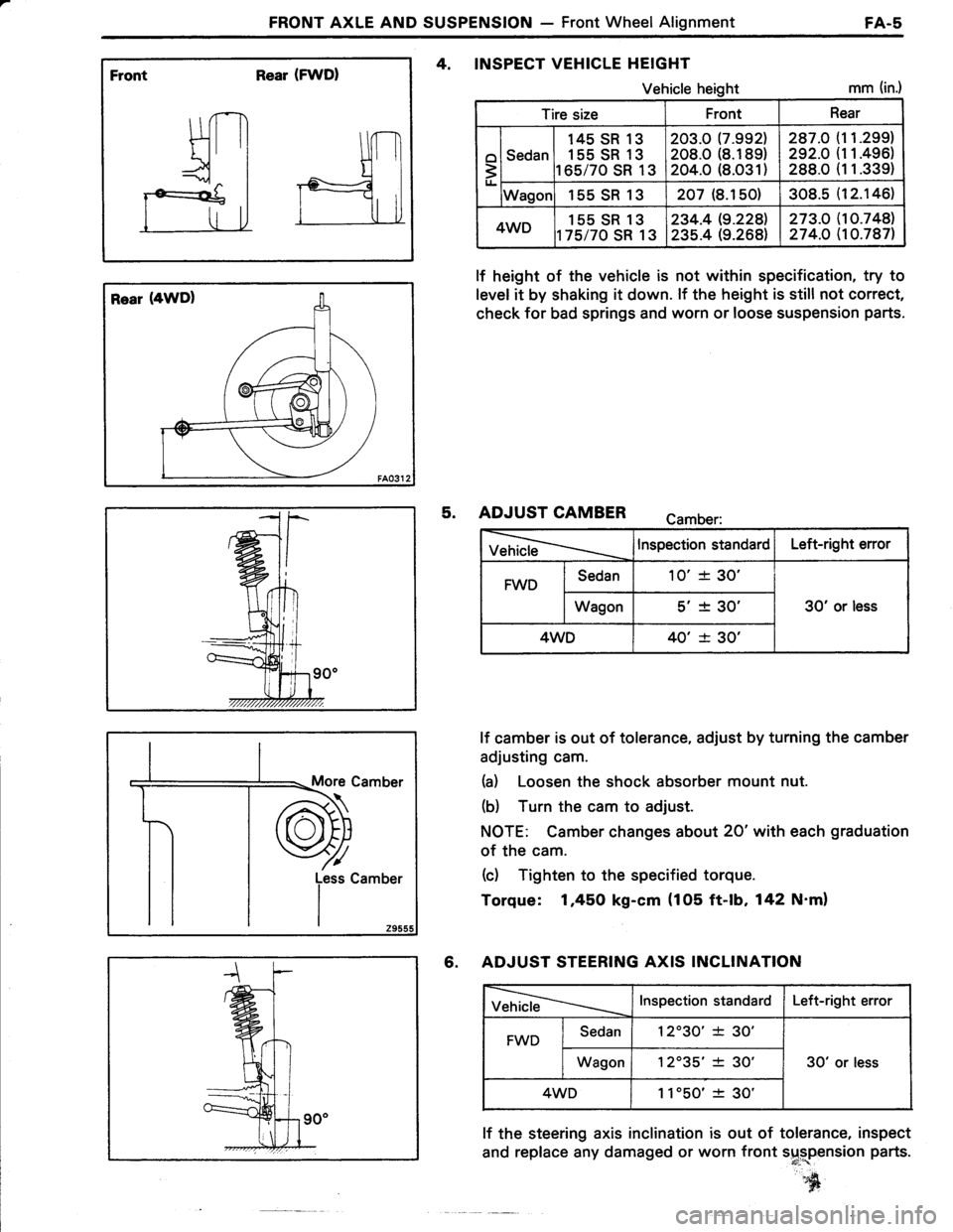

Front Rear (FWDI

Rear (4WD)

More Camber

4, INSPECT VEHICLE HEIGHT

Vehicle heightmm (in.)

lf height of the vehicle is not within specification, try to

level it by shaking it down. lf the height is still not correct,

check for bad springs and worn or loose suspension parts.

5. ADJUST CAMBER camber:

VehicleInspection standardLeft-right error

FWDSedan10'+ 30'

30' or lessWagons'� + 30'�

4WD40' -t- 30'

lf camber is out of tolerance, adjust by turning the camber

adjusting cam.

(a) Loosen the shock absorber mount nut.

(b) Turn the cam to adjust.

NOTE: Camber changes about 20'with each graduation

of the cam.

(c) Tighten to the specified torque.

Torque: 1,45O kg-cm {105 ft-lb, 142 N'm)

6. ADJUST STEERING AXIS INCLINATION

VehicleInspection standardLeft-right error

FWDSedan12'30'�* 30'

30' or lessWagon12035'�+ 30'�

4WD1 1'50'� -t- 30'

lf the steering axis inclination is out of tolerance, inspect

and replace any damaged or worn front s$rplnsion parts.

s[

Tire sizeFrontRear

o

3

Sedan

145 SR 13

155 SR 13

165/70 SR 13

203.0 17.9921208.0 (8.189)

204.0 (8.O31)

287.O

292.O

288.0

1 1.299)

11.496)

1 1.339)

Wagor155SR13207 (8.150)308.512.146l.

4WD155 SR 13

t75/70 SR 13

234.419.2281

235.4 (9.268)273.O274.O

10.748)10.787)

Page 503 of 885

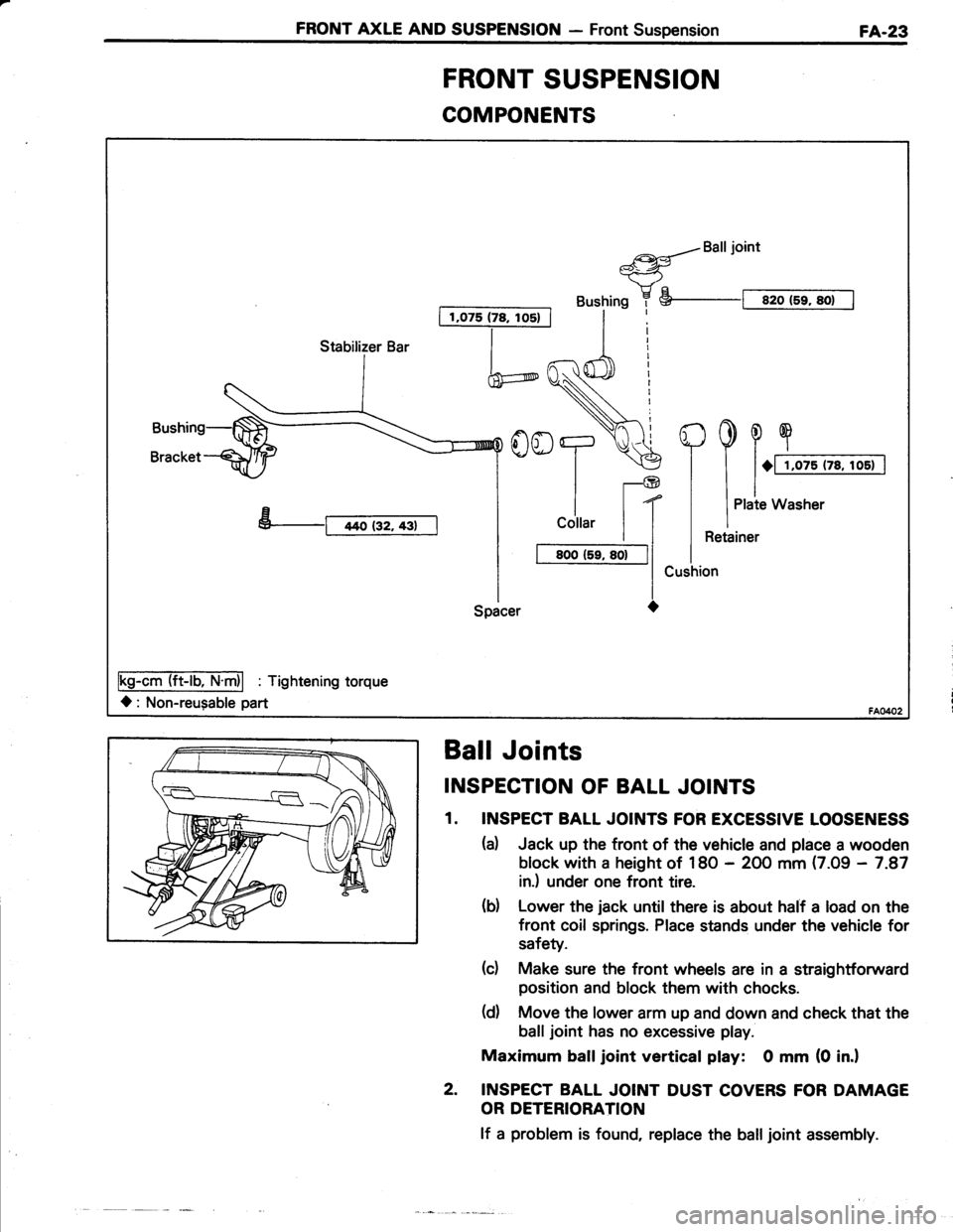

FRONT AXLE AND SUSPENSION - Front SuspensionFA-23

COMPONENTS

I 1,075 (78, los) |

a{Balljoint*-<-ry"

Bushing 7 S--t sro (5r, sot I

h

YooT.\€

ll-@

| | t(

I

cottar | |

I t BooCr, so-|l

l-lSpacer O

Fs-AmTliET'fri| : Tishtenins torque

l: Non-reugable part

Stabilizer Bar

FRONT SUSPENSION

Ball Joints

INSPECTION OF BALL JOINTS

1. INSPECT BALL JOINTS FOR EXCESSIVE LOOSENESS

(d Jack up the tront of the vehicle and place a wooden

block with a height of 18O - 2OO mm (7.09 - 7.87

in.) under one front tire.

(d Lower the jack until there is about half a load on the

front coil springs. Place stands under the vehicle for

safety.

(c) Make sure the front wheels are in a straightforward

position and block them with chocks.

(d) Move the lower arm up and down and check that the

balljoint has no excessive play.

Maximum balljoint vertical play: 0 mm (0 in.l

2. INSPECT BALL JOINT DUST COVERS FOR DAMAGE

OR DETERIORATION

lf a problem is found, replace the balljoint assembly.

Page 565 of 885

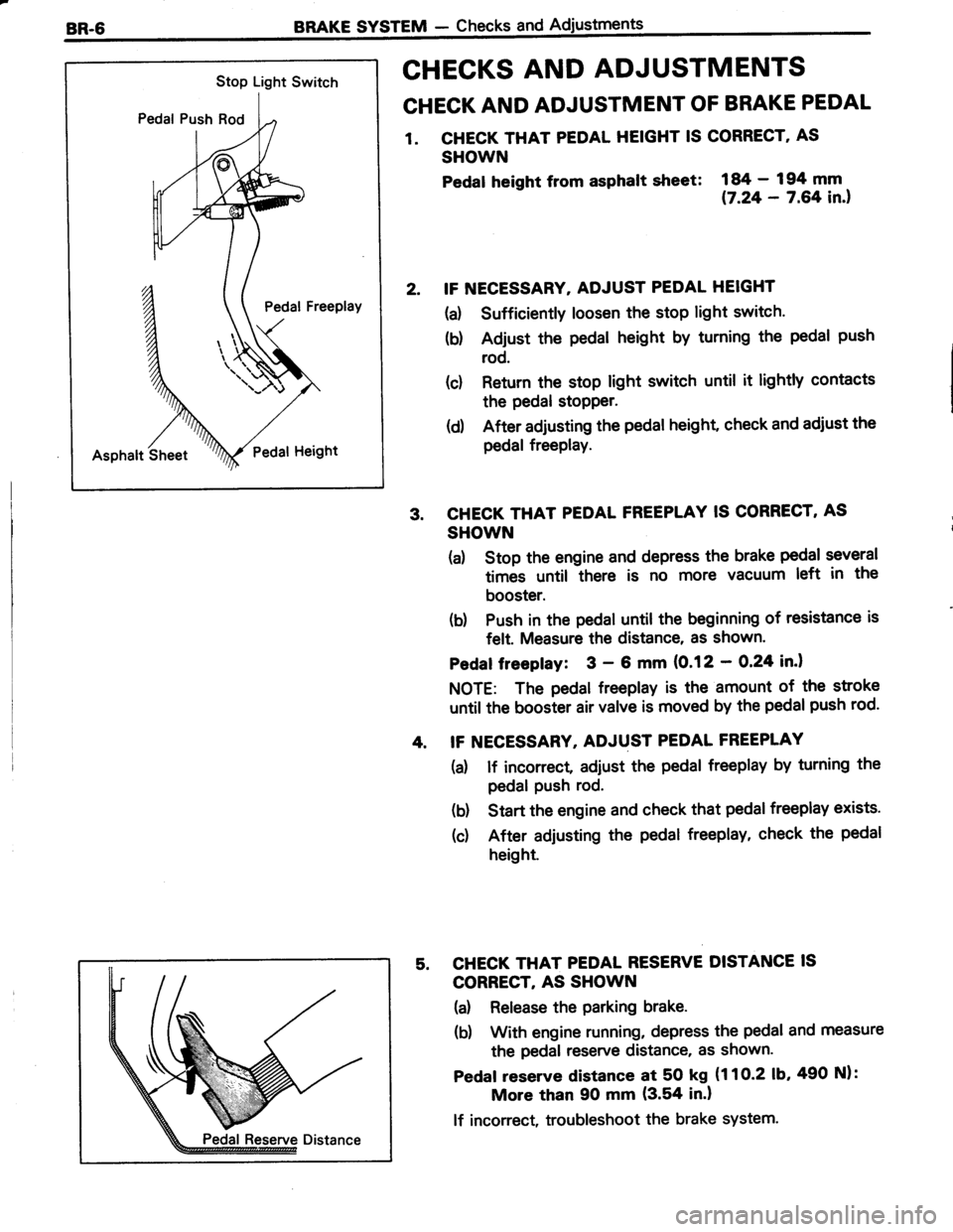

Stop Light Switch

Pedal Push Rod

Pedal Freeplay

Asphalt SheetPedat Height

BRAKE SYSTEM - Checks and

CHECKS AND ADJUSTMENTS

CHECK AND ADJUSTMENT OF BRAKE PEDAL

1. CHECK THAT PEDAL HEIGHT IS CORRECT' AS

SHOWN

Pedat heisht from asphalt slreet:

i#;:?ifil.,

IF NECESSARY. ADJUST PEDAL HEIGHT

(a) Sufficiently loosen the stop light switch.

(b) Adjust the pedal height by turning the pedal push

rod.

(c) Return the stop light switch until it lightly contacts

the pedal stopper.

(d) After adjusting the pedal height, check and adiust the

pedal freePlay.

CHECK THAT PEDAL FREEPLAY IS CORRECT, AS

SHOWN

(a) Stop the engine and depress the brake pedal several

times until there is no more vacuum left in the

booster.

(b) Push in the pedal until the beginning of resistance is

felt. Measure the distance, as shown'

Pedaf freepfay: 3 - 6 mm (0.12 - O,24 in.l

NOTE: The pedal freeplay is the amount of the stroke

until the booster air valve is moved by the pedal push rod.

IF NECESSARY, ADJUST PEDAL FREEPLAY

(a) lf incorrect adiust the pedal freeplay by turning the

pedal Push rod.

(b) Start the engine and check that pedal freeplay exists.

(c) After adjusting the pedal freeplay, check the pedal

height.

CHECK THAT PEDAL RESERVE DISTANCE IS

CORRECT, AS SHOWN

(a) Release the parking brake.

(b) With engine running, depress the pedal and measure

the pedal reserve distance, as shown.

Pedaf reserve distance at 50 kg (1 1 O-2 1b,490 Nl:

More than 90 mm (3.54 in.l

lf incorrect, troubleshoot the brake system.