tow VAUXHALL ADAM 2014 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014, Model line: ADAM, Model: VAUXHALL ADAM 2014Pages: 217, PDF Size: 6.68 MB

Page 112 of 217

110Climate control

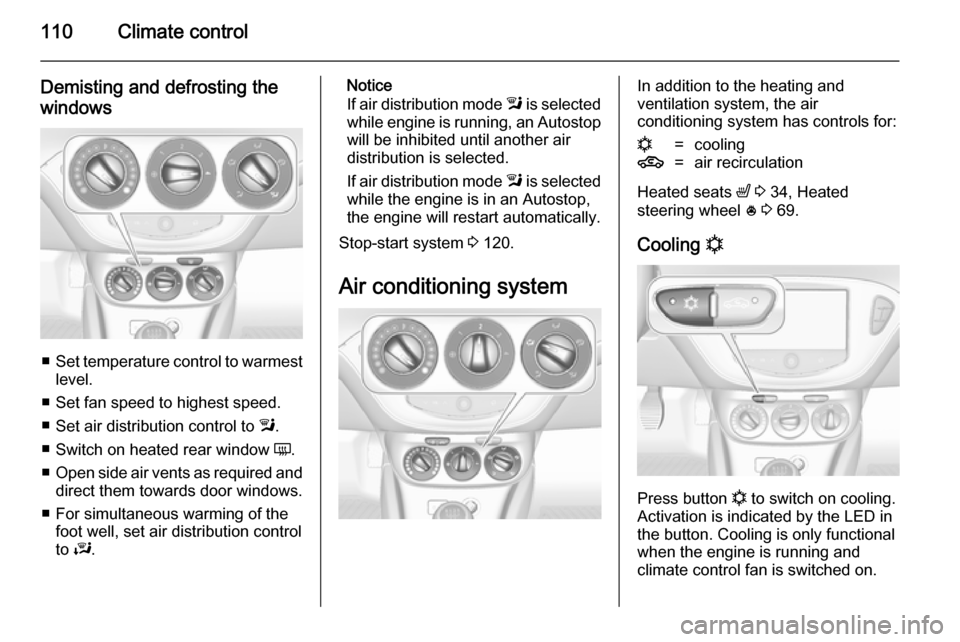

Demisting and defrosting the

windows

■ Set temperature control to warmest

level.

■ Set fan speed to highest speed.

■ Set air distribution control to l.

■ Switch on heated rear window Ü.

■ Open side air vents as required and

direct them towards door windows.

■ For simultaneous warming of the foot well, set air distribution control

to J.

Notice

If air distribution mode l is selected

while engine is running, an Autostop

will be inhibited until another air

distribution is selected.

If air distribution mode l is selected

while the engine is in an Autostop,

the engine will restart automatically.

Stop-start system 3 120.

Air conditioning systemIn addition to the heating and

ventilation system, the air

conditioning system has controls for:n=cooling4=air recirculation

Heated seats ß 3 34, Heated

steering wheel * 3 69.

Cooling n

Press button n

to switch on cooling.

Activation is indicated by the LED in

the button. Cooling is only functional

when the engine is running and

climate control fan is switched on.

Page 114 of 217

112Climate control

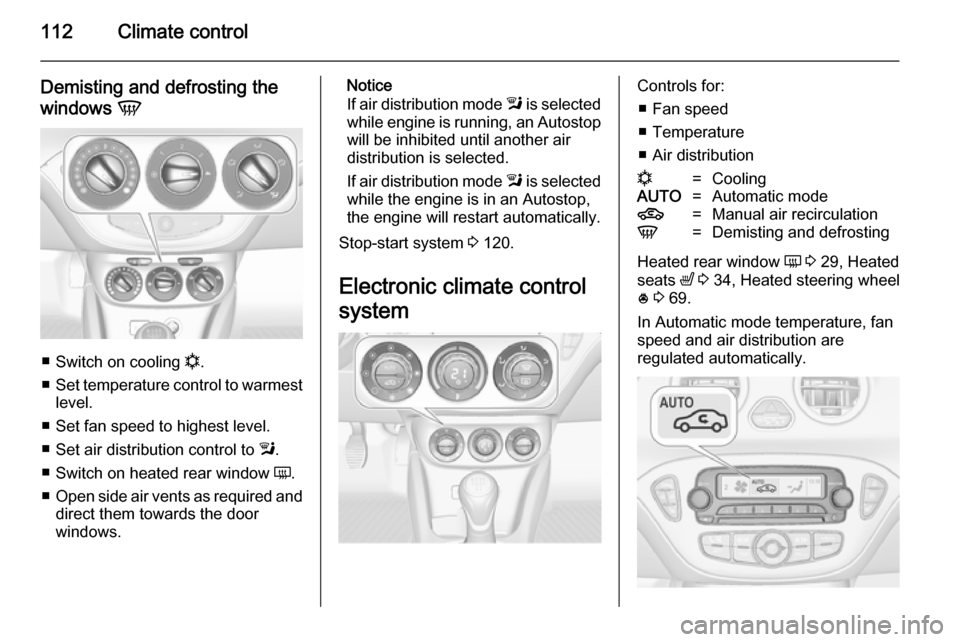

Demisting and defrosting the

windows V

■

Switch on cooling n.

■ Set temperature control to warmest

level.

■ Set fan speed to highest level.

■ Set air distribution control to l.

■ Switch on heated rear window Ü.

■ Open side air vents as required and

direct them towards the door

windows.

Notice

If air distribution mode l is selected

while engine is running, an Autostop

will be inhibited until another air

distribution is selected.

If air distribution mode l is selected

while the engine is in an Autostop,

the engine will restart automatically.

Stop-start system 3 120.

Electronic climate control

systemControls for: ■ Fan speed

■ Temperature

■ Air distributionn=CoolingAUTO=Automatic mode4=Manual air recirculationV=Demisting and defrosting

Heated rear window Ü 3 29, Heated

seats ß 3 34, Heated steering wheel

* 3 69.

In Automatic mode temperature, fan

speed and air distribution are

regulated automatically.

Page 124 of 217

122Driving and operating

Restart of the engine by the

stop-start system The selector lever must be in neutral

to enable an automatic restart.

If one of the following conditions

occurs during an Autostop, the

engine will be restarted automatically

by the stop-start system:

■ The stop-start system is manually deactivated:

■ the bonnet is opened

■ the driver's seat belt is unfastened and the driver's door is opened

■ the engine temperature is too low

■ the charging level of the vehicle battery is below a defined level

■ the brake vacuum is not sufficient

■ the vehicle is driven at least at walking speed

■ the climate control system requests

an engine start

■ the air conditioning is manually switched on

If the bonnet is not fully closed, a warning message is displayed in the

Driver Information Centre.If an electrical accessory, e.g. a

portable CD player, is connected to

the power outlet, a brief power drop

during restart might be noticeable.

Parking ■ Do not park the vehicle on an easily

ignitable surface. The high

temperature of the exhaust system

could ignite the surface.

■ Always apply parking brake. Apply manual parking brake without

pressing release button. Apply as

firmly as possible on downhill or

uphill slopes. Depress the foot

brake at the same time to reduce

operating force.

■ Switch off the engine and ignition. Turn the steering wheel until the

steering wheel lock engages.

■ If the vehicle is on a level surface or

uphill slope, engage first gear

before switching off the ignition. On

an uphill slope, turn the front

wheels away from the kerb.

If the vehicle is on a downhill slope, engage reverse gear beforeswitching off the ignition. Turn the

front wheels towards the kerb.

■ Lock the vehicle and activate the anti-theft alarm system.

Notice

In the event of an accident with airbag deployment, the engine is

turned off automatically if the vehicle comes to a standstill within a certain

time.

Page 125 of 217

Driving and operating123Engine exhaust9Danger

Engine exhaust gases contain

poisonous carbon monoxide,

which is colourless and odourless and could be fatal if inhaled.

If exhaust gases enter the interior

of the vehicle, open the windows.

Have the cause of the fault

rectified by a workshop.

Avoid driving with an open load

compartment, otherwise exhaust

gases could enter the vehicle.

Catalytic converter

The catalytic converter reduces the

amount of harmful substances in the

exhaust gases.

Caution

Fuel grades other than those listed on pages 3 143, 3 201 could

damage the catalytic converter or

electronic components.

Unburnt petrol will overheat and

damage the catalytic converter.

Therefore avoid excessive use of the starter, running the fuel tank

dry and starting the engine by

pushing or towing.

In the event of misfiring, uneven

engine running, a reduction in engine performance or other unusual

problems, have the cause of the fault

rectified by a workshop as soon as

possible. In an emergency, driving

can be continued for a short period,

keeping vehicle speed and engine

speed low.

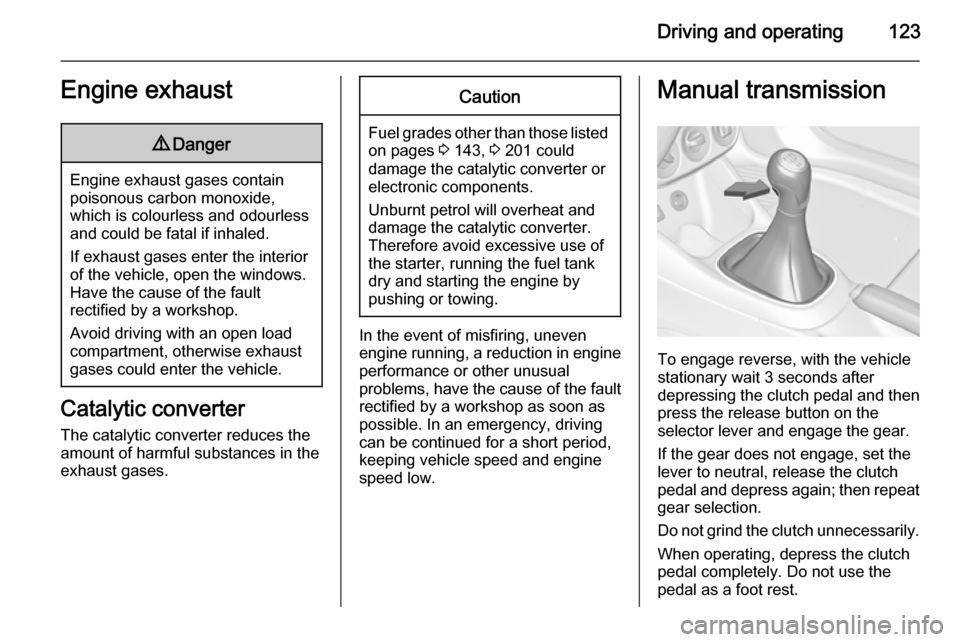

Manual transmission

To engage reverse, with the vehicle

stationary wait 3 seconds after

depressing the clutch pedal and then

press the release button on the

selector lever and engage the gear.

If the gear does not engage, set the

lever to neutral, release the clutch

pedal and depress again; then repeat

gear selection.

Do not grind the clutch unnecessarily. When operating, depress the clutchpedal completely. Do not use the

pedal as a foot rest.

Page 126 of 217

124Driving and operatingCaution

It is not advisable to drive with thehand resting on the selector lever.

Brakes

The brake system comprises two independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear

this in mind when being towed.

Control indicator R 3 83.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off the system performs a self-test which may be audible.

Control indicator u 3 83.

Adaptive brake light

During full braking, all three brake

lights flash for the duration of ABS

control.

Page 148 of 217

146Driving and operating

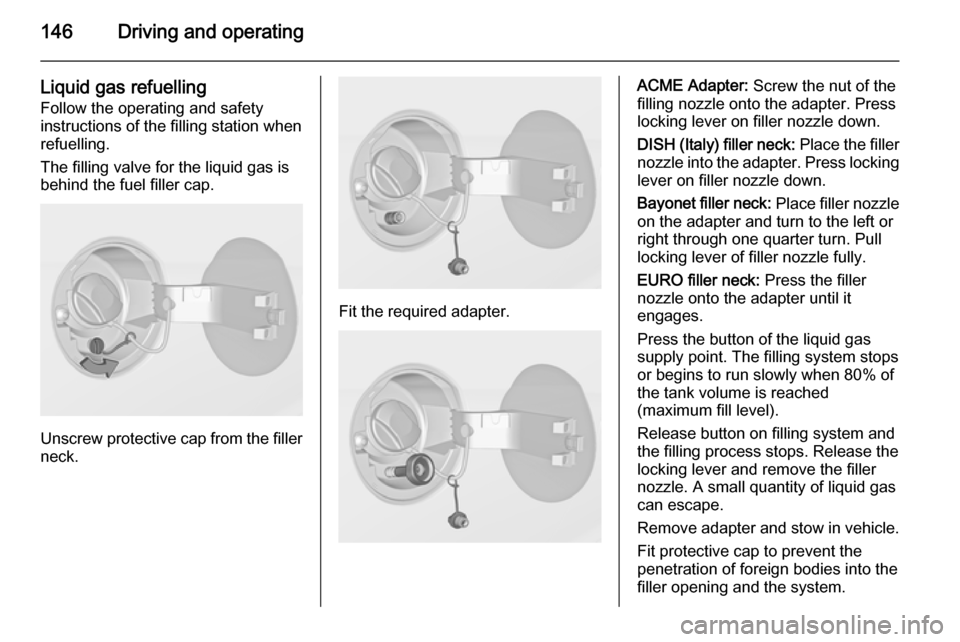

Liquid gas refuellingFollow the operating and safety

instructions of the filling station when

refuelling.

The filling valve for the liquid gas is

behind the fuel filler cap.

Unscrew protective cap from the filler

neck.

Fit the required adapter.

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.

Page 151 of 217

Vehicle care149Vehicle careGeneral Information...................149

Vehicle checks ........................... 150

Bulb replacement .......................156

Electrical system ........................164

Vehicle tools .............................. 169

Wheels and tyres .......................170

Jump starting ............................. 186

Towing ....................................... 188

Appearance care .......................190General Information

Accessories and vehicle

modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

■ Wash and wax the vehicle.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve the rubber seals.

■ Fill up fuel tank completely.

■ Change the engine oil.

■ Drain the washer fluid reservoir.

■ Check the coolant antifreeze and corrosion protection.

■ Adjust tyre pressure to the value specified for full load.

■ Park the vehicle in a dry, well ventilated place. Engage first orreverse gear. Prevent the vehiclefrom rolling.

■ Do not apply the parking brake.

Page 171 of 217

Vehicle care169Vehicle tools

Tools Vehicles with tyre repair kit

Some tools and the towing eye are

located together with the tyre repair

kit in a tool box in the load

compartment below the floor cover.

On version with storage box, remove

box first 3 61.

On versions with rear carrier system

or liquid gas engine, the tools are

located together with the towing eye

and tyre repair kit in a suitcase, fixed

with a strap at the left sidewall in the

load compartment.On version with storage box, the

suitcase with the tools, the towing eye

and the tyre repair kit is located in a

chamber of the box in the load

compartment 3 61.

Page 172 of 217

170Vehicle care

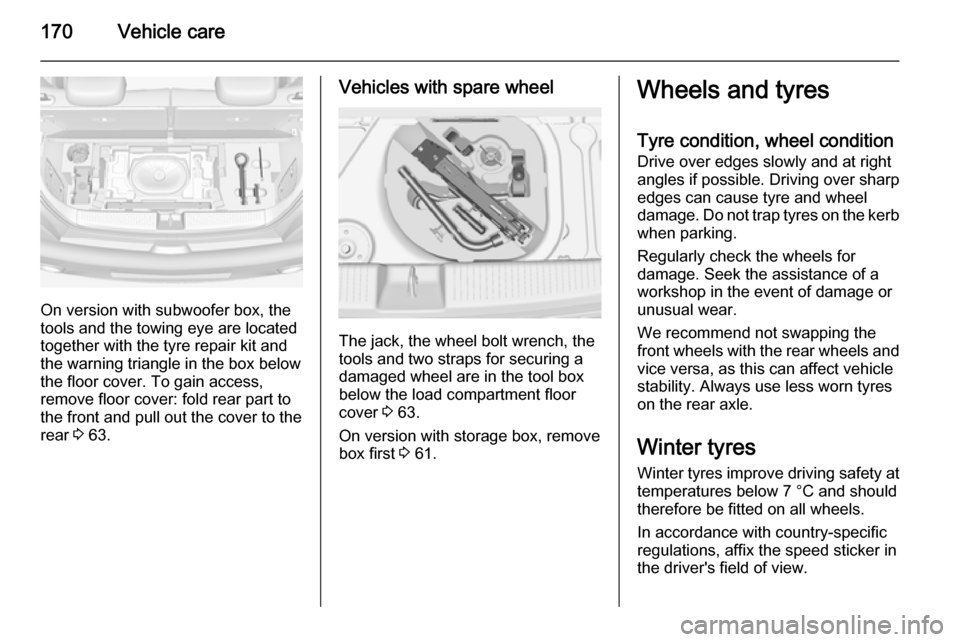

On version with subwoofer box, the

tools and the towing eye are located

together with the tyre repair kit and

the warning triangle in the box below

the floor cover. To gain access,

remove floor cover: fold rear part to

the front and pull out the cover to the

rear 3 63.

Vehicles with spare wheel

The jack, the wheel bolt wrench, the

tools and two straps for securing a

damaged wheel are in the tool box below the load compartment floor

cover 3 63.

On version with storage box, remove

box first 3 61.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres Winter tyres improve driving safety attemperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Page 179 of 217

Vehicle care177

On versions with subwoofer box the

tyre repair kit is located in the box

under the floor cover in the load

compartment. To use tyre repair kit,

firstly remove floor cover: fold rear

part to the front and pull out the cover to the rear 3 63.

1. Take the tyre repair kit from the

compartment.

2. Remove the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.