ignition VAUXHALL ADAM 2015.5 Workshop Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: ADAM, Model: VAUXHALL ADAM 2015.5Pages: 233, PDF Size: 6.98 MB

Page 162 of 233

160Vehicle care9Danger

The ignition system uses

extremely high voltage. Do not

touch.

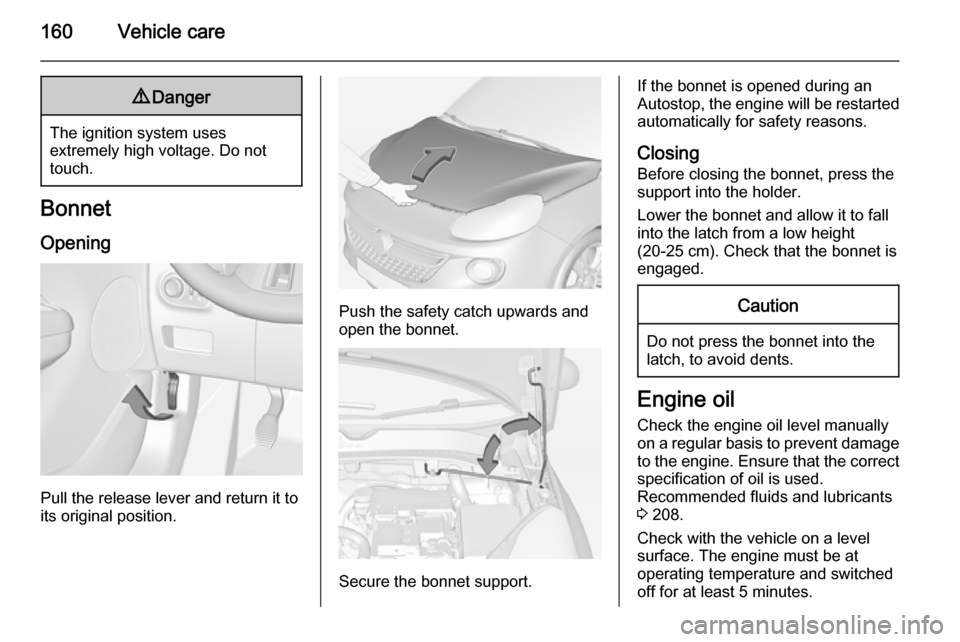

Bonnet

Opening

Pull the release lever and return it to

its original position.

Push the safety catch upwards and open the bonnet.

Secure the bonnet support.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manuallyon a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 208.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 5 minutes.

Page 165 of 233

Vehicle care163

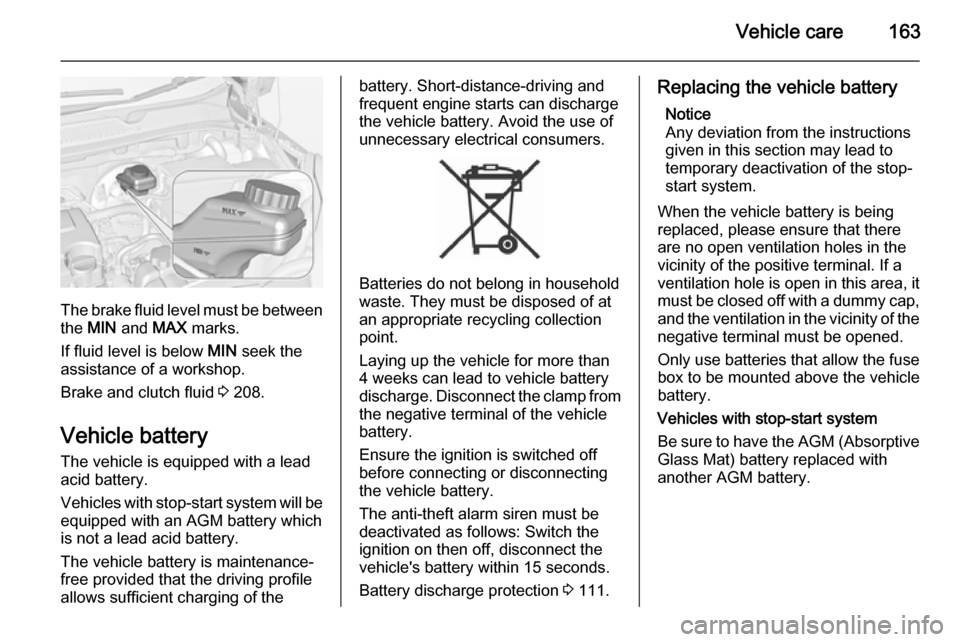

The brake fluid level must be betweenthe MIN and MAX marks.

If fluid level is below MIN seek the

assistance of a workshop.

Brake and clutch fluid 3 208.

Vehicle battery The vehicle is equipped with a lead

acid battery.

Vehicles with stop-start system will be

equipped with an AGM battery which

is not a lead acid battery.

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the vehicle battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

4 weeks can lead to vehicle battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

The anti-theft alarm siren must be

deactivated as follows: Switch the

ignition on then off, disconnect the

vehicle's battery within 15 seconds.

Battery discharge protection 3 111.

Replacing the vehicle battery

Notice

Any deviation from the instructions

given in this section may lead to

temporary deactivation of the stop-

start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap,

and the ventilation in the vicinity of the negative terminal must be opened.

Only use batteries that allow the fuse

box to be mounted above the vehicle

battery.

Vehicles with stop-start system

Be sure to have the AGM (Absorptive

Glass Mat) battery replaced with

another AGM battery.

Page 167 of 233

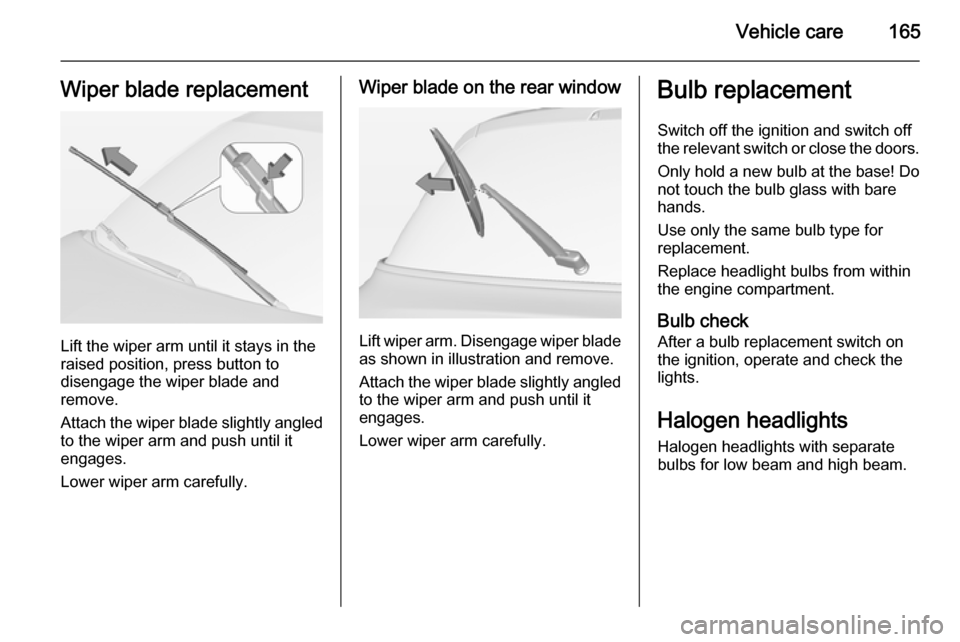

Vehicle care165Wiper blade replacement

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base! Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.

Halogen headlights

Halogen headlights with separate

bulbs for low beam and high beam.

Page 176 of 233

174Vehicle care

4. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and allow

it to engage.

Interior lights Courtesy light, reading lights

Have bulbs replaced by a workshop.

Load compartment light

Have bulbs replaced by a workshop.

Dome light

Have bulbs replaced by a workshop.

Ambient light

Have bulbs replaced by a workshop.

Starlight panelHave bulbs replaced by a workshop.

Instrument panel

illumination

Have bulbs replaced by a workshop.Electrical system

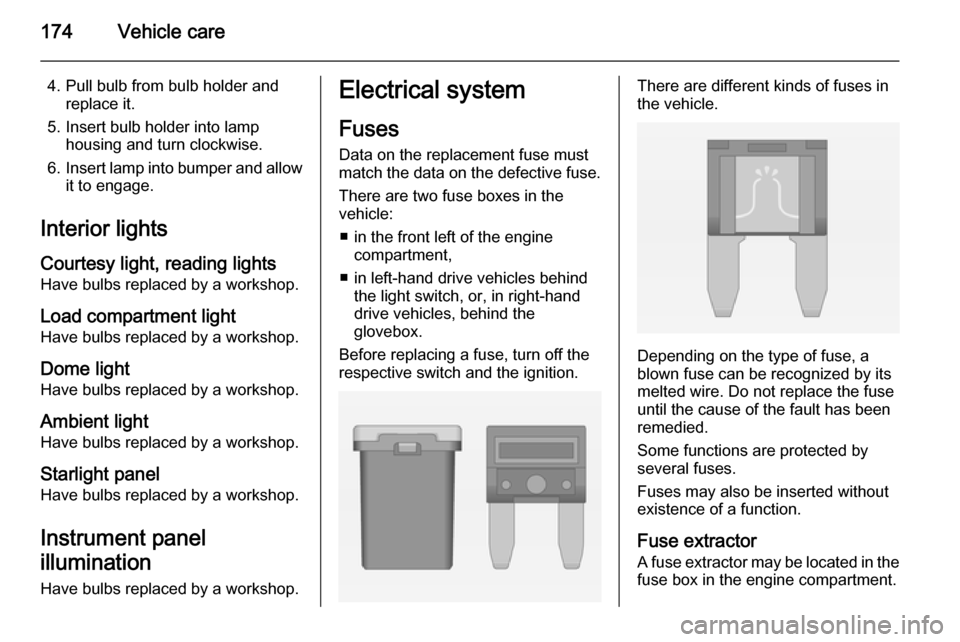

Fuses

Data on the replacement fuse must match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

■ in the front left of the engine compartment,

■ in left-hand drive vehicles behind the light switch, or, in right-hand

drive vehicles, behind the

glovebox.

Before replacing a fuse, turn off the

respective switch and the ignition.There are different kinds of fuses in

the vehicle.

Depending on the type of fuse, a

blown fuse can be recognized by its

melted wire. Do not replace the fuse until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

Fuse extractor A fuse extractor may be located in the fuse box in the engine compartment.

Page 180 of 233

178Vehicle care

No.Circuit1–2–3Power windows4Voltage transformer5Body control module 16Body control module 27Body control module 38Body control module 49Body control module 510Body control module 611Body control module 712Body control module 813–14Tailgate15Diagnostic connector16Data link connection17IgnitionNo.Circuit18Air conditioning system19Audio amplifier20Parking assist21Brake switch22Audio system23Display24–25Onstar26Instrument panel27Seat heating, driver28–29–30Instrument panel31Horn32Seat heating, passenger33Heated steering wheel34–

Page 184 of 233

182Vehicle care

Tyre pressure 3 221.

The tyre pressure information label on the right door frame indicates theoriginal equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

The tyre pressure tables show all

possible tyre combinations 3 221.

Identify the respective tyre.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased, switch off ignition. After

adjusting tyre pressure switch on

ignition and select the relevant setting

on the page Tyre load in the Driver

Information Centre 3 90.

Tyre pressure monitoring

system The tyre pressure monitoring system

(TPMS) checks the pressure of all

four tyres once a minute when vehicle speed exceeds a certain limit.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

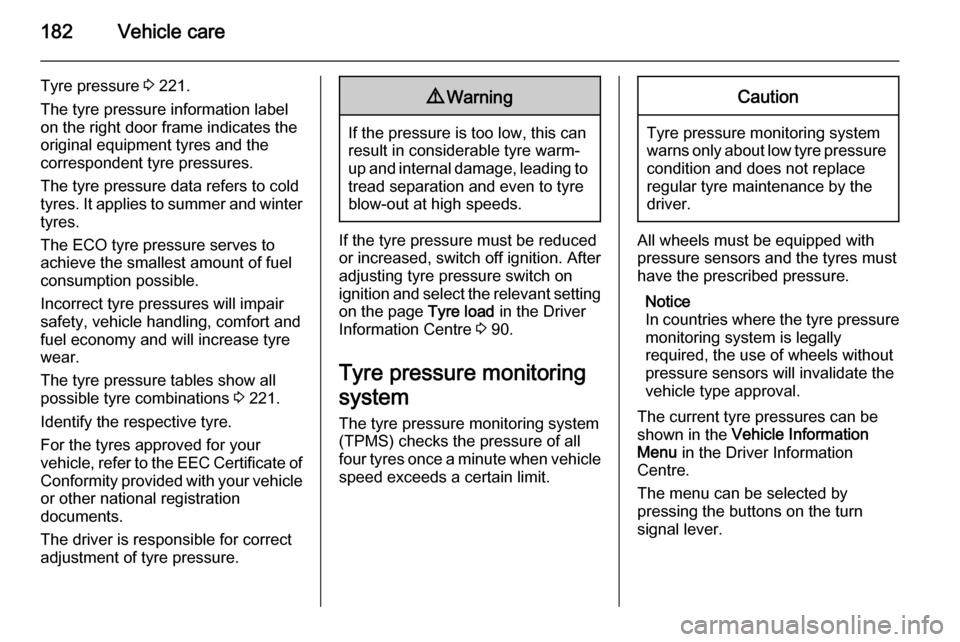

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information

Centre.

The menu can be selected by

pressing the buttons on the turn

signal lever.

Page 185 of 233

Vehicle care183

Press the MENU button to select the

Vehicle Information Menu X.

Turn the adjuster wheel to select the

tyre pressure monitoring system.

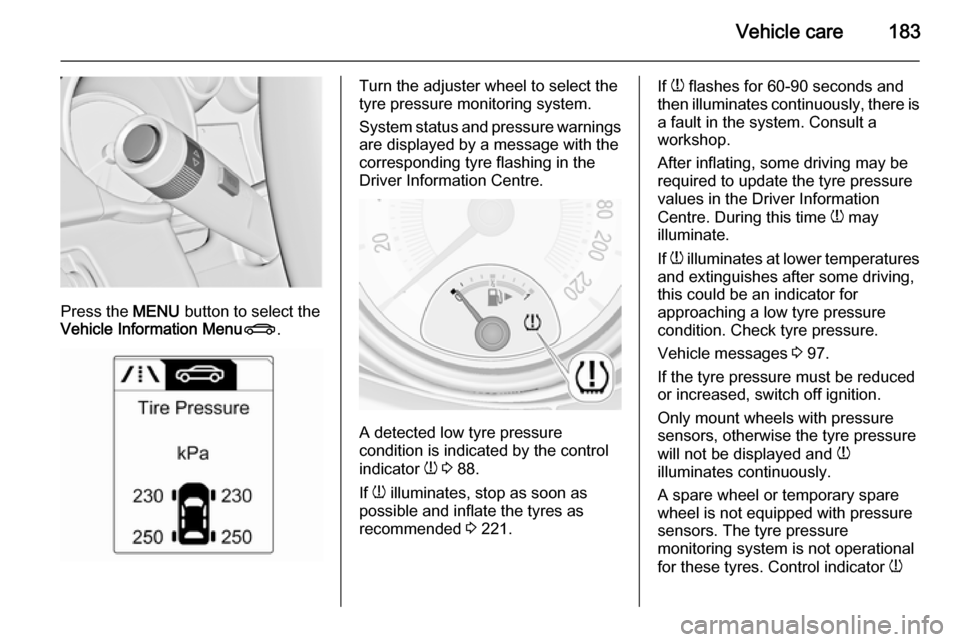

System status and pressure warnings

are displayed by a message with the

corresponding tyre flashing in the

Driver Information Centre.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 88.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 221.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure.

Vehicle messages 3 97.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

Page 186 of 233

184Vehicle care

illuminates. For the further three

tyres, the system remains

operational.

The use of commercially-available liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

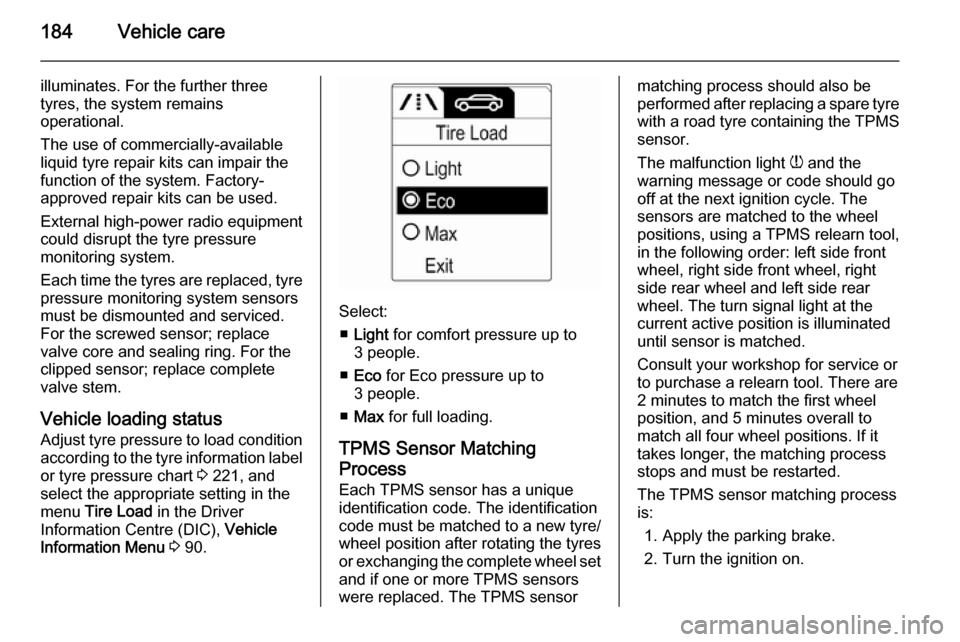

Vehicle loading status Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 221, and

select the appropriate setting in the

menu Tire Load in the Driver

Information Centre (DIC), Vehicle

Information Menu 3 90.

Select:

■ Light for comfort pressure up to

3 people.

■ Eco for Eco pressure up to

3 people.

■ Max for full loading.

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/ wheel position after rotating the tyres

or exchanging the complete wheel set

and if one or more TPMS sensors

were replaced. The TPMS sensor

matching process should also be

performed after replacing a spare tyre with a road tyre containing the TPMS

sensor.

The malfunction light w and the

warning message or code should go off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a TPMS relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

2 minutes to match the first wheel

position, and 5 minutes overall to

match all four wheel positions. If it

takes longer, the matching process

stops and must be restarted.

The TPMS sensor matching process

is:

1. Apply the parking brake.

2. Turn the ignition on.

Page 187 of 233

Vehicle care185

3. On vehicles with manualtransmission automated: Press

and hold brake pedal. Move and

hold the selector lever for

5 seconds in position N until P is

displayed in the DIC. P indicates

that the sensor matching process of the TPMS can be started.

On vehicles with manual

transmission: select neutral.

4. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the DIC.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

6. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should

be displayed.

7. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to indicate that the

receiver is in relearn mode.

8. Start with the left side front wheel.9. Place the relearn tool against the

tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp

confirms that the sensor

identification code has been

matched to this wheel position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate that the sensor

identification code has been

matched to the left side rear

wheel, and the TPMS sensor

matching process is no longer

active.

13. Turn off the ignition.14. Set all four tyres to the recommended air pressure level

as indicated on the tyre

information label.

15. Ensure the tyre loading status is set according to the selected

pressure 3 90.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

Page 203 of 233

Vehicle care201

2. Screw in the towing eye as far asit will go until it stops in a

horizontal position.

3. Attach a tow rope – or better still a

tow rod – to the towing eye.

Adam Rocks

1. Disengage the small cap with a screwdriver at the marked

position.

2. Screw in the towing eye as far as it will go until it stops in a

horizontal position.

3. Attach a tow rope – or better still a

tow rod – to the towing eye.General

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.