jacking VAUXHALL ADAM 2015 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: ADAM, Model: VAUXHALL ADAM 2015Pages: 225, PDF Size: 6.81 MB

Page 187 of 225

Vehicle care185

Notice

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 102 psi.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.Wheel changing

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-skid surface. The front wheels

must be in the straight-ahead

position.

■ Apply the parking brake and engage first gear or reverse gear.

■ Never change more than one wheel

at once.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ The jack is maintenance-free.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ Take heavy objects out of the vehicle before jacking up.

■ No people or animals may be in the

vehicle when it is jacked-up.

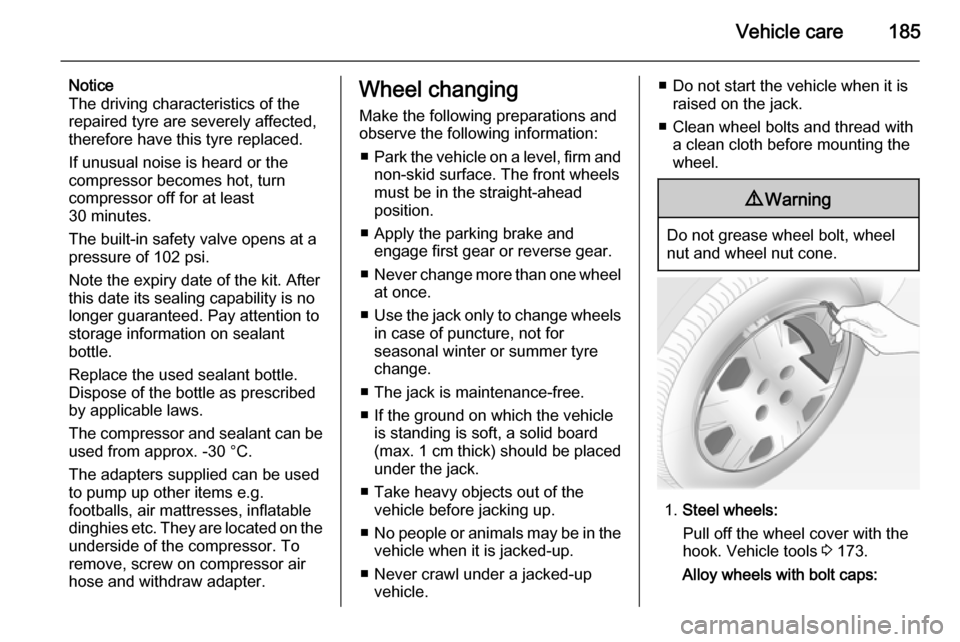

■ Never crawl under a jacked-up vehicle.■ Do not start the vehicle when it israised on the jack.

■ Clean wheel bolts and thread with a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Steel wheels:

Pull off the wheel cover with the

hook. Vehicle tools 3 173.

Alloy wheels with bolt caps:

Page 188 of 225

186Vehicle care

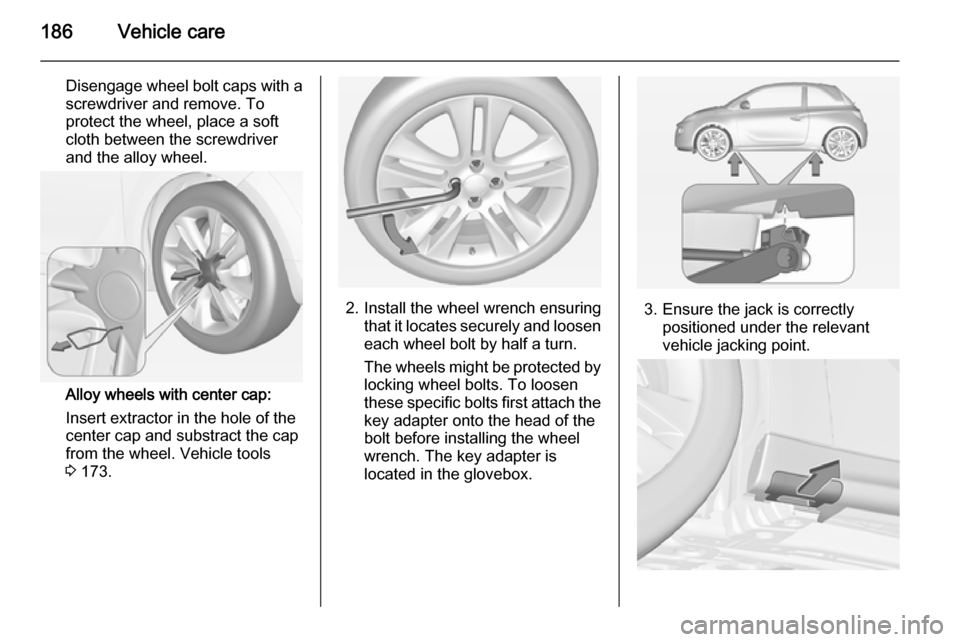

Disengage wheel bolt caps with a

screwdriver and remove. To

protect the wheel, place a soft

cloth between the screwdriver

and the alloy wheel.

Alloy wheels with center cap:

Insert extractor in the hole of the

center cap and substract the cap

from the wheel. Vehicle tools

3 173.

2. Install the wheel wrench ensuring

that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts first attach the key adapter onto the head of the

bolt before installing the wheel

wrench. The key adapter is

located in the glovebox.3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Page 189 of 225

Vehicle care187

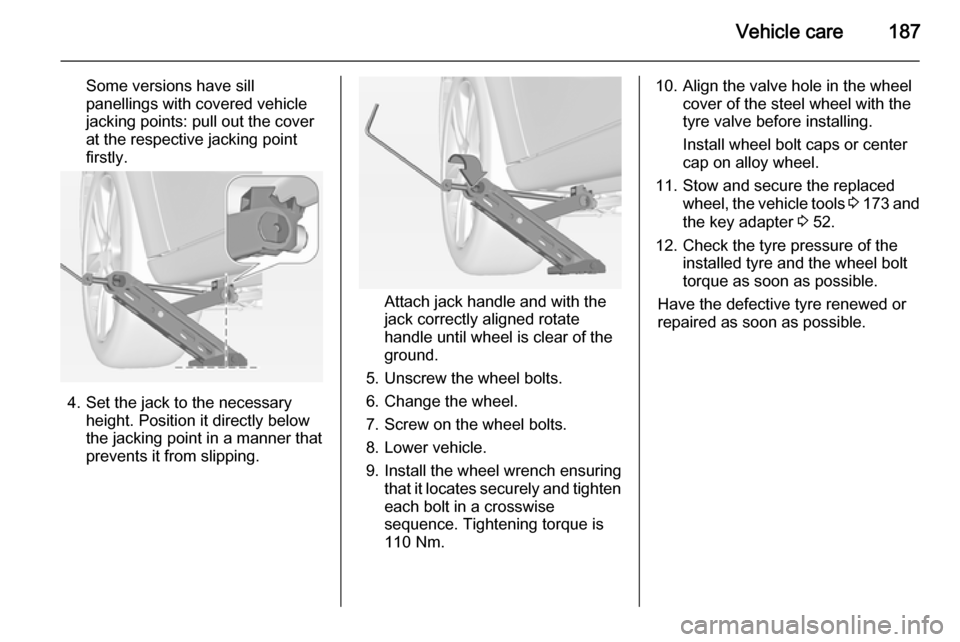

Some versions have sill

panellings with covered vehicle

jacking points: pull out the cover

at the respective jacking point

firstly.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Install wheel bolt caps or center

cap on alloy wheel.

11. Stow and secure the replaced wheel, the vehicle tools 3 173 and

the key adapter 3 52.

12. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Page 190 of 225

188Vehicle care

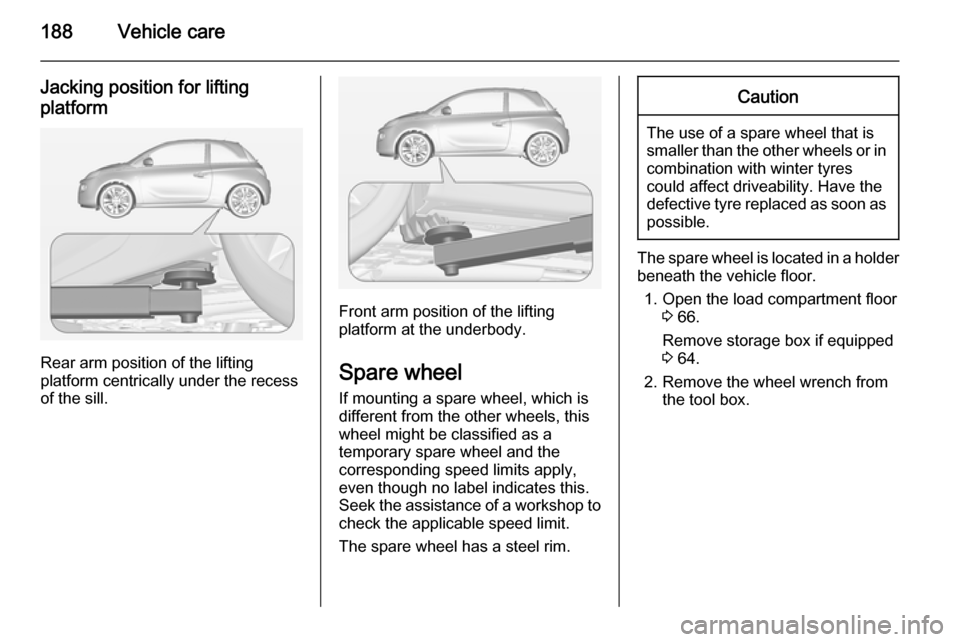

Jacking position for liftingplatform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in a holder

beneath the vehicle floor.

1. Open the load compartment floor 3 66.

Remove storage box if equipped

3 64.

2. Remove the wheel wrench from the tool box.

Page 217 of 225

Customer information215Customer informationCustomer information................215

Vehicle data recording and pri‐

vacy ........................................... 216Customer information

Declaration of conformity Transmission systems

This vehicle has systems that

transmit and/or receive radio waves

subject to Directive 1999/5/EC.

These systems are in compliance with the essential requirements and

other relevant provisions of Directive

1999/5/EC. Copies of the original

Declarations of Conformity can be

obtained on our website.

Jack

Translation of the original declaration

of conformity

Declaration of conformity according

to EC Directive 2006/42/EC

We declare that the product:

Product designation: Jack

Type/GM part number: 13331922 is in compliance with the provisions of

Directive 2006/42/EC.Applied technical standards:GMN9737=JackingGM 14337=Standard

Equipment Jack –

Hardware TestsGMN5127=Vehicle Integrity –

Hoisting and

Service Station

JackingGMW15005=Standard

Equipment Jack

and Spare Tyre,

Vehicle TestISO TS 16949=Quality

management

systems

The signatory is authorised to

compile the technical documentation.

Rüsselsheim, 31st January 2014

signed by

Hans-Peter Metzger

Engineering Group Manager Chassis

& Structure

Adam Opel AG

D-65423 Rüsselsheim