ECU VAUXHALL ADAM 2016.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.5, Model line: ADAM, Model: VAUXHALL ADAM 2016.5Pages: 239, PDF Size: 7.2 MB

Page 100 of 239

98Instruments and controlsWhen the vehicle battery voltage is

running low, a warning code 174 will

appear in the Driver Information

Centre.

Uplevel-Display

When the vehicle battery voltage is running low, a warning message will

appear in the Driver Information

Centre.

1. Switch off immediately any electrical consumers which are

not required for a safe drive, e.g.

seat heating, heated rear window

or other main consumers.

2. Charge the vehicle battery by driving continuously for a while or

by using a charging device.

The warning message or warning

code will disappear after the engine

has been started twice consecutively

without a voltage drop.

If the vehicle battery cannot be

recharged, have the cause of the fault

remedied by a workshop.Vehicle personalisation

The vehicle's behaviour can be

personalised via changing the

settings in the Info-Display.

Some of the personal settings for

different drivers can be memorised

individually for each vehicle key.

Memorised settings 3 21.

Depending on vehicle equipment and country-specific regulations some ofthe functions described below might

not be available.

Some functions are only displayed or

active when the engine is running.

Personal settings

Graphic-Info-Display

Press CONFIG for the Settings menu.

Turn the MENU-TUNE knob to move

to the desired setup menu, then press

MENU-TUNE .

Select Settings and then Vehicle

settings .

Vehicle settings

● Climate and air quality

Auto fan speed : Modifies the

level of the cabin airflow of the

climate control in automatic

mode.

Page 106 of 239

104Instruments and controlsmaintenance items and tyre pressure(only with tyre pressure monitoring

system).

To look at the information in greater

detail, select the link within the email and log in to your account.

Destination download

A desired destination can be directly

downloaded to the navigation system.

Press Z to call an advisor and

describe the destination or point of

interest.

The advisor can look up any address

or point of interest and directly send

the destination to the built-in

navigation system.

OnStar settings

OnStar PIN

To have full access to all OnStar

services, a four-digit PIN is required. The PIN has to be personalised when first talking to an advisor.

To change the PIN, press Z to call an

advisor.Account data

An OnStar subscriber has an account

where all the data is stored. To

request a change of the account

information, press Z and talk to an

advisor or log in to your account.

If the OnStar service is used on

another vehicle, press Z and request

that the account be transferred to the

new vehicle.

Notice

In any case, if the vehicle is disposed of, sold or otherwise transferred,

immediately inform OnStar about

the changes and terminate the

OnStar service on this vehicle.

Vehicle location

The vehicle location is transmitted to OnStar when service is requested ortriggered. A message on the Info-

Display informs about this

transmission.

To activate or deactivate the

transmission of the vehicle location,

press and hold j until an audio

message is heard.The deactivation is indicated by the

status light flashing red and green for a short period of time and each time

the vehicle is started.

Notice

If the transmission of the vehicle

location is deactivated, some

services are no longer available.

Notice

The vehicle location always remains

accessible to OnStar in the case of

an emergency.

Find the privacy policy in your

account.

Software updates

OnStar may remotely carry out

software updates without further

notice or consent. These updates are

to enhance or maintain safety and

security or the operation of the

vehicle.

These updates may concern privacy

issues. Find the privacy policy in your account.

Page 135 of 239

Driving and operating133Tyre pressure monitoring systemTo start the sensor matching process

of the tyre pressure monitoring

system, the selector lever must be

moved and held in position N for

five seconds. P illuminates in the

transmission display to indicate that

the sensor matching process can be

started.

Tyre pressure monitoring system

3 185.

Manual mode

If a higher gear is selected when the

engine speed is too low, or a lower

gear when the speed is too high, the

shift is not executed. This prevents

the engine from running at too low or

too high an engine speed. A warning

message is displayed in the Driver

Information Centre. Vehicle

messages 3 95.

If engine speed is too low, the

transmission automatically shifts to a

lower gear.

If engine speed is too high, the

transmission only switches to a higher gear via kickdown.When + or - is selected in automatic

mode, the transmission switches to

manual mode and shifts accordingly.

Gear shift indication

The symbol R, with a number

alongside it, is indicated when

gearshifting is recommended for fuel

saving reasons.

Shift indication appears only in

manual mode.

Electronic driving programmes

● Following a cold start, the operating temperature

programme increases engine

speed to quickly bring the

catalytic converter to the required

temperature.

● The adaptive programme tailors gearshifting to the driving

conditions, e.g. greater load or

gradients.Kickdown

If the accelerator pedal is pressed down completely in automatic mode, the transmission shifts to a lower gear

depending on engine speed.

Fault

To prevent damage to the manual

transmission automated, the clutch is engaged automatically at high clutch

temperatures.

In the event of a fault, control indicator

g illuminates. Additionally, a

warning message is displayed in the

Driver Information Centre. Vehicle

messages 3 95.

Continued driving is restricted or not

possible, depending on the fault.

Have the cause of the fault remedied

by a workshop.

Page 159 of 239

Driving and operating157ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH filler neck: Place the filler nozzle

into the adapter. Press locking lever

on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn clockwise or

anticlockwise through one quarter

turn. Pull locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button at the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow securely in

vehicle.Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank should only be

filled to 80% capacity, for safety

reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

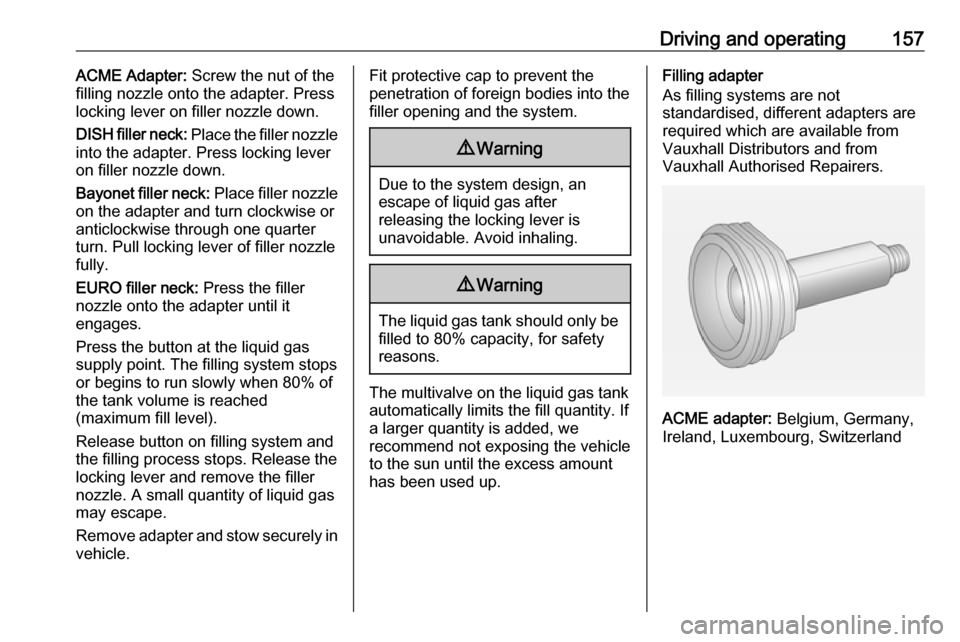

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Page 164 of 239

162Vehicle careVehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system uses

extremely high voltage. Do not

touch.

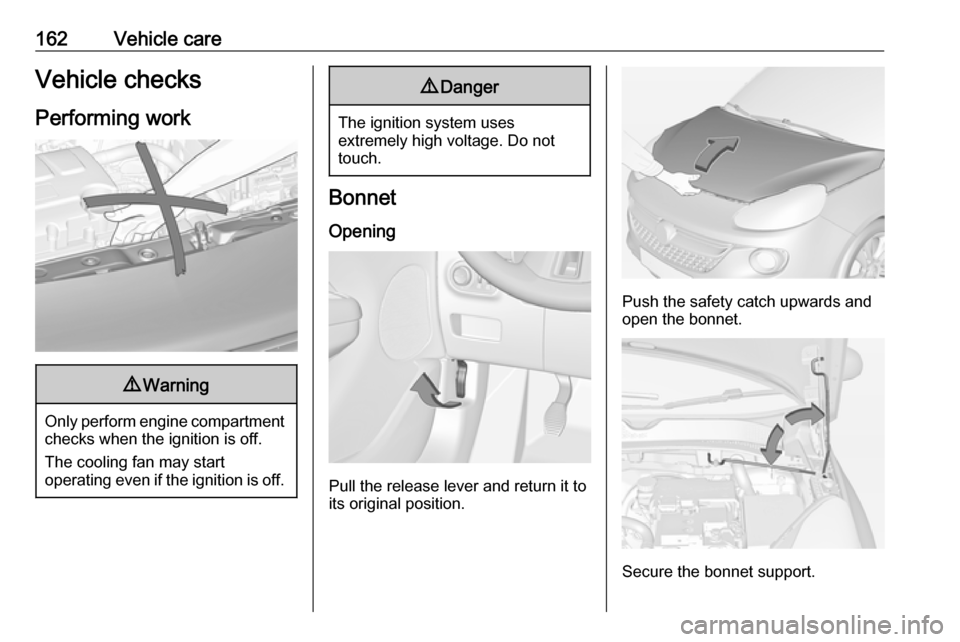

Bonnet

Opening

Pull the release lever and return it to

its original position.

Push the safety catch upwards and open the bonnet.

Secure the bonnet support.

Page 174 of 239

172Vehicle care6. Insert the bulb socket into theassembly and turn clockwise.

7. Attach light assembly into the bumper and fix with both screws.

8. Insert and engage cover into the bumper. Insert small cap.

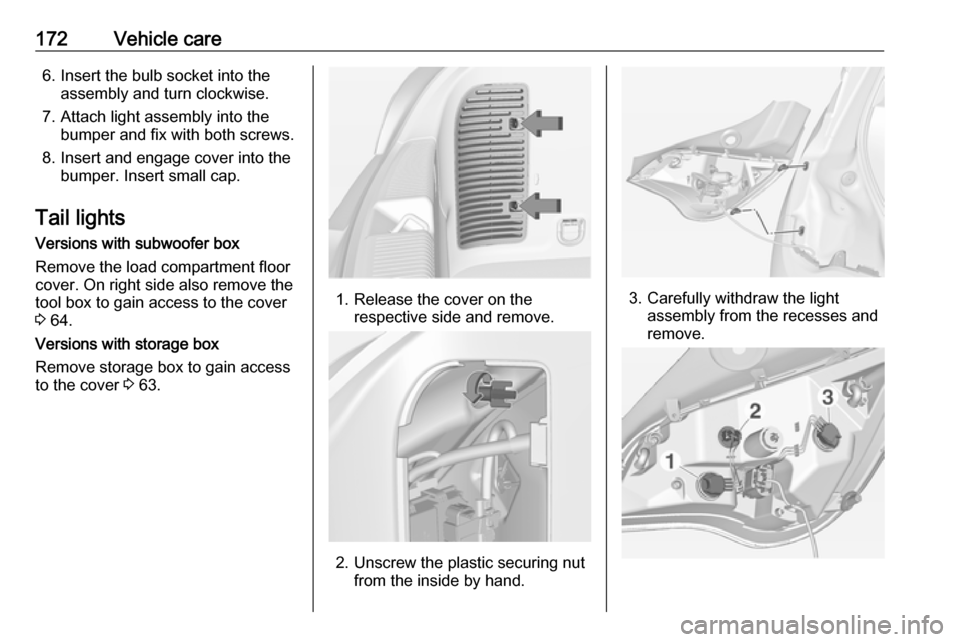

Tail lights Versions with subwoofer box

Remove the load compartment floor

cover. On right side also remove the

tool box to gain access to the cover

3 64.

Versions with storage box

Remove storage box to gain access

to the cover 3 63.

1. Release the cover on the

respective side and remove.

2. Unscrew the plastic securing nutfrom the inside by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

Page 175 of 239

Vehicle care1734. Turn bulb holder anticlockwiseand remove. Replace bulb by

withdrawing:

turn signal light 1

tail light 2

tail light / brake light 3

If tail light 2 and tail light/brake

light 3 are LEDs, seek the

assistance of a workshop for

replacement.

5. Insert and turn bulb holder clockwise into the tail light

assembly. Ensure the wires

remain in the cable ducts.

Fit light assembly with the

retaining pins into the recesses of

the vehicle body and tighten the

plastic securing nut from inside

the load compartment. Pull the

circular gasket over the recess in

the lamp housing.

Close cover and engage.

Reversing light/rear fog light

Reversing light is located on the left

side of the bumper, and the rear fog

light is located on the right side of the bumper.

The description of bulb replacement

is the same for both lights.

1. Undo screw and remove cover.

2. Undo screw and remove light assembly from the bumper.

3. Disengage and remove the bulbsocket by turning anticlockwise.

Page 185 of 239

Vehicle care183On version with subwoofer box, the

tools and the towing eye are located

together with the tyre repair kit and

the warning triangle in the box below

the floor cover. To gain access,

remove floor cover: fold rear part to

the front and pull out the cover to the

rear 3 64.

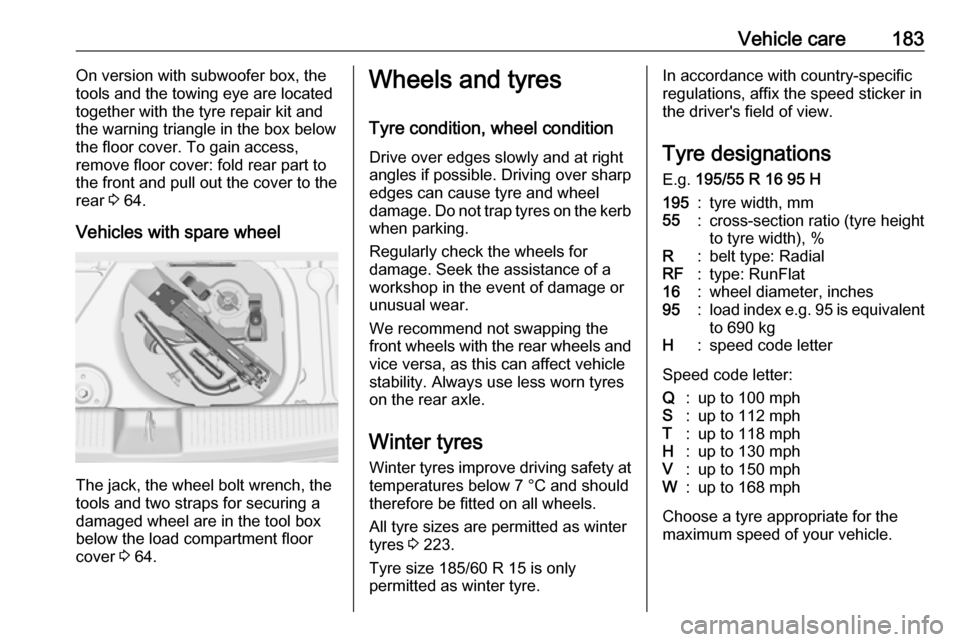

Vehicles with spare wheel

The jack, the wheel bolt wrench, the

tools and two straps for securing a

damaged wheel are in the tool box

below the load compartment floor

cover 3 64.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 223.

Tyre size 185/60 R 15 is only

permitted as winter tyre.In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Tyre designations

E.g. 195/55 R 16 95 H195:tyre width, mm55:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent

to 690 kgH:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropriate for the

maximum speed of your vehicle.

Page 197 of 239

Vehicle care195cap from the wheel. Vehicle tools

3 182.

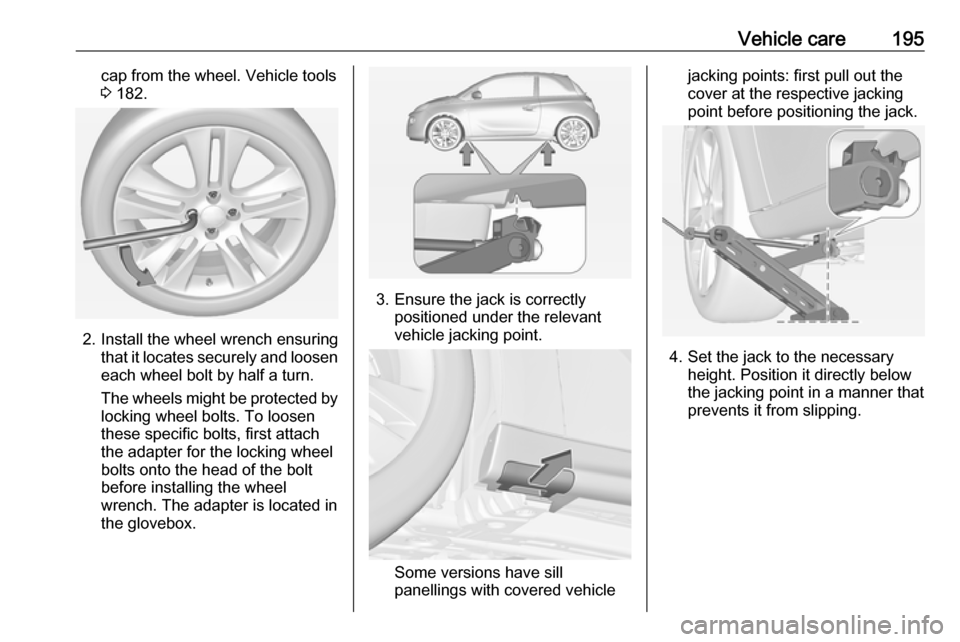

2. Install the wheel wrench ensuring

that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Some versions have sill

panellings with covered vehicle

jacking points: first pull out the

cover at the respective jacking

point before positioning the jack.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Page 198 of 239

196Vehicle care

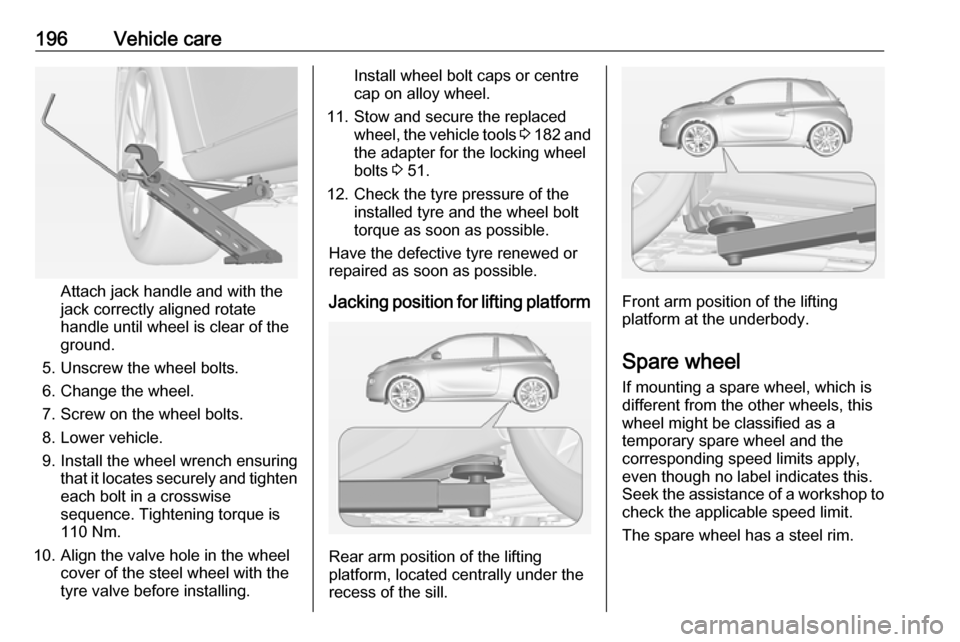

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Install wheel bolt caps or centre

cap on alloy wheel.

11. Stow and secure the replaced wheel, the vehicle tools 3 182 and

the adapter for the locking wheel

bolts 3 51.

12. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for lifting platform

Rear arm position of the lifting

platform, located centrally under the

recess of the sill.

Front arm position of the lifting platform at the underbody.

Spare wheel If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.