service VAUXHALL ADAM 2018 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: ADAM, Model: VAUXHALL ADAM 2018Pages: 241, PDF Size: 7.34 MB

Page 109 of 241

Instruments and controls107The advisor can look up any address

or point of interest and directly send

the destination to the built-in

navigation system.

OnStar settings

OnStar PIN

To have full access to all OnStar

services, a four-digit PIN is required. The PIN has to be personalised when first talking to an advisor.

To change the PIN, press Z to call an

advisor.

Account data

An OnStar subscriber has an account

where all the data is stored. To

request a change of the account

information, press Z and talk to an

advisor or log in to your account.

If the OnStar service is used on

another vehicle, press Z and request

that the account be transferred to the

new vehicle.Notice

In any case, if the vehicle is disposed of, sold or otherwise transferred,

immediately inform OnStar about

the changes and terminate the

OnStar service on this vehicle.

Vehicle location

The vehicle location is transmitted to OnStar when service is requested ortriggered. A message on the Info-

Display informs about this

transmission.

To activate or deactivate the

transmission of the vehicle location,

press and hold j until an audio

message is heard.

The deactivation is indicated by the

status light flashing red and green for

a short period of time and each time

the vehicle is started.

Notice

If the transmission of the vehicle

location is deactivated, some

services are no longer available.

Notice

The vehicle location always remains accessible to OnStar in the case of

an emergency.Find the privacy policy in your

account.

Software updates

OnStar may remotely carry out

software updates without further

notice or consent. These updates are

to enhance or maintain safety and

security or the operation of the

vehicle.

These updates may concern privacy

issues. Find the privacy policy in your account.

Page 118 of 241

116Climate controlClimate controlClimate control systems.............116

Heating and ventilation system 116

Air conditioning system ...........117

Electronic climate control system .................................... 119

Air vents ..................................... 124

Adjustable air vents .................124

Fixed air vents ......................... 124

Maintenance .............................. 124

Air intake ................................. 124

Pollen filter ............................... 124

Air conditioning regular operation ................................ 125

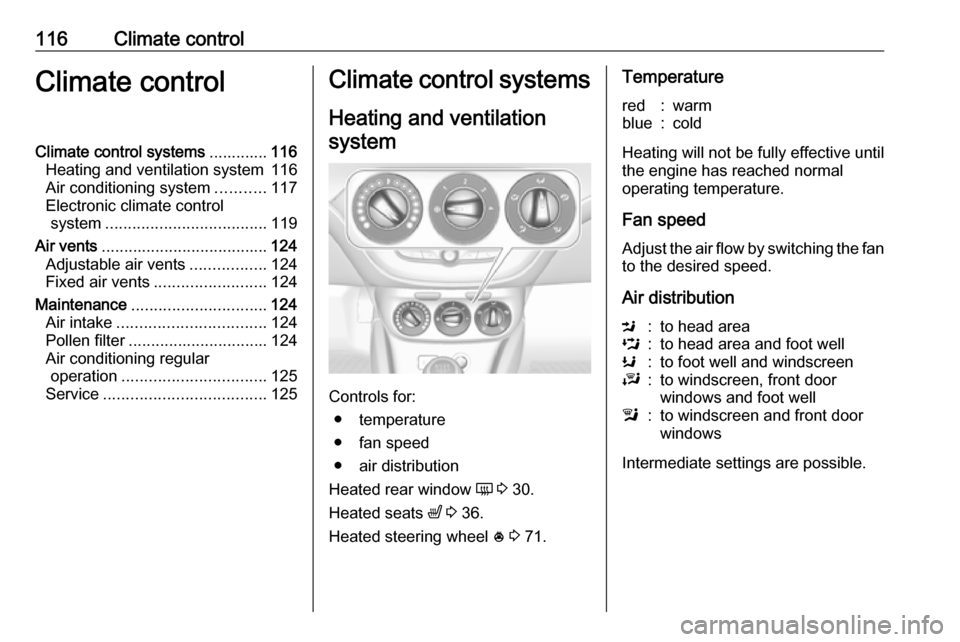

Service .................................... 125Climate control systems

Heating and ventilation system

Controls for: ● temperature

● fan speed

● air distribution

Heated rear window Ü 3 30.

Heated seats ß 3 36.

Heated steering wheel * 3 71.

Temperaturered:warmblue:cold

Heating will not be fully effective until

the engine has reached normal

operating temperature.

Fan speed

Adjust the air flow by switching the fan

to the desired speed.

Air distribution

M:to head areaL:to head area and foot wellK:to foot well and windscreenJ:to windscreen, front door

windows and foot welll:to windscreen and front door

windows

Intermediate settings are possible.

Page 127 of 241

Climate control125Air conditioning regular

operation

In order to ensure continuously

efficient performance, cooling must

be operated for a few minutes once a month, irrespective of the weather

and time of year. Operation with

cooling is not possible when the

outside temperature is too low.

Service For optimal cooling performance, it is

recommended to annually check the

climate control system, starting

three years after initial vehicle

registration, including:

● functionality and pressure test

● heating functionality

● leakage check

● check of drive belts

● cleaning of condenser and evaporator drainage

● performance check

Notice

Refrigerant R-134a contains

fluorinated greenhouse gases.

Page 130 of 241

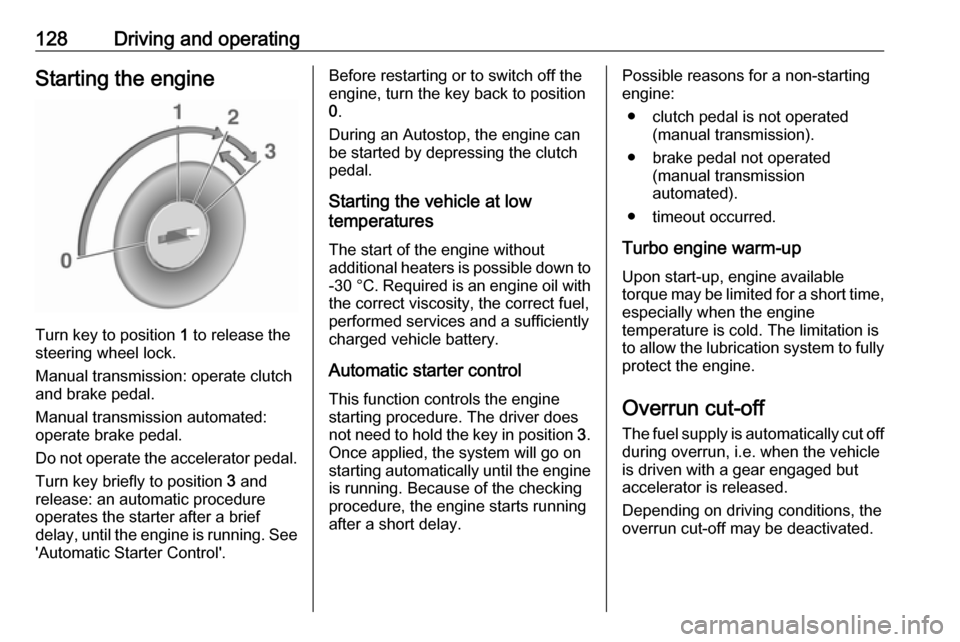

128Driving and operatingStarting the engine

Turn key to position 1 to release the

steering wheel lock.

Manual transmission: operate clutch

and brake pedal.

Manual transmission automated:

operate brake pedal.

Do not operate the accelerator pedal. Turn key briefly to position 3 and

release: an automatic procedure

operates the starter after a brief

delay, until the engine is running. See

'Automatic Starter Control'.

Before restarting or to switch off the

engine, turn the key back to position

0 .

During an Autostop, the engine can

be started by depressing the clutch

pedal.

Starting the vehicle at low

temperatures

The start of the engine without

additional heaters is possible down to -30 °C . Required is an engine oil with

the correct viscosity, the correct fuel,

performed services and a sufficiently

charged vehicle battery.

Automatic starter controlThis function controls the engine

starting procedure. The driver does

not need to hold the key in position 3.

Once applied, the system will go on

starting automatically until the engine

is running. Because of the checking

procedure, the engine starts running after a short delay.Possible reasons for a non-starting

engine:

● clutch pedal is not operated (manual transmission).

● brake pedal not operated (manual transmission

automated).

● timeout occurred.

Turbo engine warm-up

Upon start-up, engine available

torque may be limited for a short time,

especially when the engine

temperature is cold. The limitation is

to allow the lubrication system to fully

protect the engine.

Overrun cut-off

The fuel supply is automatically cut off

during overrun, i.e. when the vehicle

is driven with a gear engaged but accelerator is released.

Depending on driving conditions, the

overrun cut-off may be deactivated.

Page 165 of 241

Vehicle care163Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear. Prevent the vehicle from rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are not functional, e.g. anti-theft

alarm system.

Putting back into operation When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our

website. Only entrust this work to an

authorised recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.

Page 190 of 241

188Vehicle care

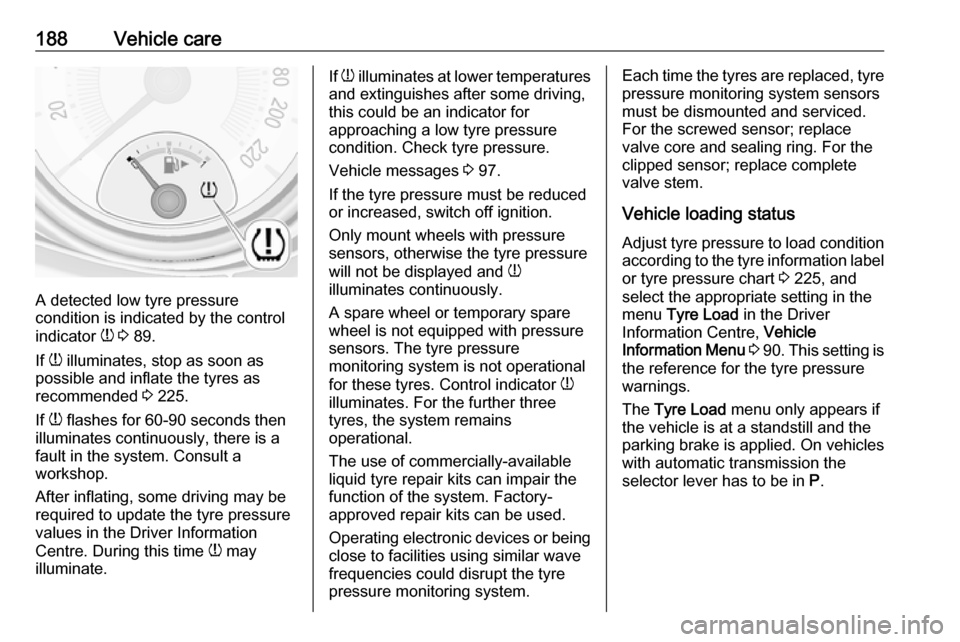

A detected low tyre pressure

condition is indicated by the control

indicator w 3 89.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 225.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure.

Vehicle messages 3 97.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.

The use of commercially-available liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.Each time the tyres are replaced, tyre

pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 225, and

select the appropriate setting in the menu Tyre Load in the Driver

Information Centre, Vehicle

Information Menu 3 90 . This setting is

the reference for the tyre pressure

warnings.

The Tyre Load menu only appears if

the vehicle is at a standstill and the parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Page 191 of 241

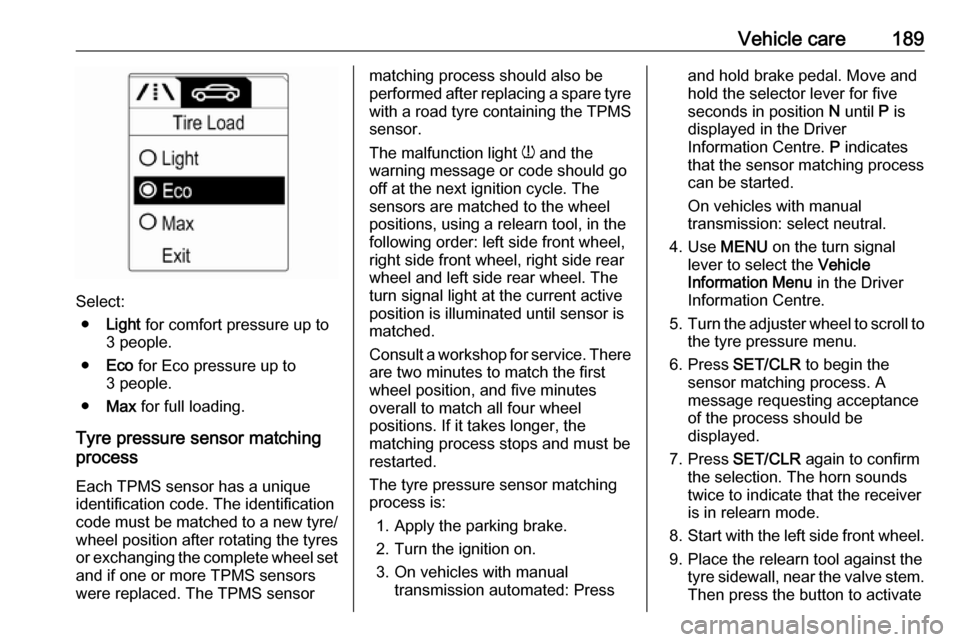

Vehicle care189

Select:● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full loading.

Tyre pressure sensor matching

process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/ wheel position after rotating the tyres

or exchanging the complete wheel set

and if one or more TPMS sensors

were replaced. The TPMS sensor

matching process should also be

performed after replacing a spare tyre

with a road tyre containing the TPMS

sensor.

The malfunction light w and the

warning message or code should go off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a relearn tool, in the

following order: left side front wheel,

right side front wheel, right side rear

wheel and left side rear wheel. The

turn signal light at the current active

position is illuminated until sensor is

matched.

Consult a workshop for service. There are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with manual transmission automated: Pressand hold brake pedal. Move and

hold the selector lever for five

seconds in position N until P is

displayed in the Driver Information Centre. P indicates

that the sensor matching process

can be started.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

Page 212 of 241

210Service and maintenanceService and

maintenanceGeneral information ...................210

Service information ..................210

Recommended fluids, lubricants

and parts .................................... 211

Recommended fluids and lubricants ................................ 211General information

Service information In order to ensure economical and

safe vehicle operation and to

maintain the value of your vehicle, it

is of vital importance that all

maintenance work is carried out at the proper intervals as specified.

The detailed, up-to-date service

schedule for your vehicle is available

at the workshop.

Service display 3 82.

European service intervals

Maintenance of your vehicle is

required every 20,000 miles or after

1 year , whichever occurs first, unless

otherwise indicated in the service

display.

A shorter service interval can be valid

for severe driving behaviour, e.g. for

taxis and police vehicles.

The European service intervals are

valid for the following countries:Andorra, Austria, Belgium, Bosnia-

Herzegovina, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany,

Greece, Greenland, Hungary,

Iceland, Ireland, Italy, Latvia,

Liechtenstein, Lithuania,

Luxembourg, Macedonia, Malta,

Monaco, Montenegro, Netherlands,

Norway, Poland, Portugal, Romania, San Marino, Serbia, Slovakia,

Slovenia, Spain, Sweden,

Switzerland, United Kingdom.

Service display 3 82.

International service intervals Maintenance of your vehicle is

required every 10,000 miles or after

1 year , whichever occurs first, unless

otherwise indicated in the service

display.

Severe operating conditions exist if

one or more of the following

circumstances occur frequently: Cold starting, stop and go operation, trailer

operation, mountain driving, driving

on poor and sandy road surfaces,

increased air pollution, presence of

airborne sand and high dust content,

Page 213 of 241

Service and maintenance211driving at high altitude and large

variations of temperature. Under

these severe operating conditions, certain service work may be required

more frequently than the regular service interval.

The international service intervals are

valid for the countries which are not

listed in the European service

intervals.

Service display 3 82.

Confirmations

Confirmation of service is recorded in the Service and Warranty Booklet.

The date and mileage is completed

with the stamp and signature of the

servicing workshop.

Make sure that the Service and

Warranty Booklet is completed

correctly as continuous proof of

service is essential if any warranty or

goodwill claims are to be met, and is

also a benefit when selling the

vehicle.Service interval with remaining

engine oil life duration

The service interval is based on

several parameters depending on

usage.

The service display lets you know when to change the engine oil.

Service display 3 82.Recommended fluids,

lubricants and parts

Recommended fluids andlubricants

Only use products that meet the

recommended specifications.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Page 214 of 241

212Service and maintenanceDexos is the newest engine oil quality

that provides optimum protection for

petrol and diesel engines. If it is

unavailable, engine oils of other listed qualities have to be used.

Recommendations for petrol engines

are also valid for Compressed Natural

Gas (CNG), Liquified Petroleum Gas

(LPG) and Ethanol (E85) fuelled

engines.

Select the appropriate engine oil based on its quality and on the

minimum ambient temperature

3 216.

Topping up engine oilCaution

In case of any spilled oil, wipe it up and dispose it properly.

Engine oils of different manufacturersand brands can be mixed as long as

they comply with the required engine

oil quality and viscosity.

Use of engine oils for all petrol

engines with only ACEA quality is

prohibited, since it can cause engine

damage under certain operating

conditions.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 216.

Additional engine oil additives

The use of additional engine oil

additives could cause damage and

invalidate the warranty.

Engine oil viscosity grades

The SAE viscosity grade gives

information of the thickness of the oil.

Multigrade oil is indicated by two

figures, e.g. SAE 5W-30. The first

figure, followed by a W, indicates the

low temperature viscosity and the

second figure the high temperature viscosity.

Select the appropriate viscosity grade depending on the minimum ambient

temperature 3 216.All of the recommended viscosity

grades are suitable for high ambient

temperatures.

Coolant and antifreeze

Use only silicate-free long life coolant

(LLC) antifreeze. Consult a

workshop.

The system is factory filled with

coolant designed for excellent

corrosion protection and frost

protection down to approx. -28 °C. In

northern countries with very low

temperatures the factory filled coolant

provides frost protection down to

approx. -37 °C. This concentration

should be maintained all year round.

The use of additional coolant

additives that intend to give additional corrosion protection or seal against

minor leaks can cause function

problems. Liability for consequences

resulting from the use of additional

coolant additives will be rejected.