wheel bolts VAUXHALL ADAM 2019 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2019, Model line: ADAM, Model: VAUXHALL ADAM 2019Pages: 223, PDF Size: 6.54 MB

Page 21 of 223

Keys, doors and windows19Keys, doors and

windowsKeys, locks ................................... 19

Keys .......................................... 19

Radio remote control .................20

Memorised settings ...................21

Central locking system ..............21

Automatic locking ......................23

Doors ........................................... 24

Load compartment ....................24

Vehicle security ............................ 25

Anti-theft locking system ...........25

Immobiliser ................................ 25

Exterior mirrors ............................ 26

Convex shape ........................... 26

Electric adjustment ....................26

Folding mirrors .......................... 26

Heated mirrors ........................... 26

Interior mirrors ............................. 27

Manual anti-dazzle ....................27

Automatic anti-dazzle ................27

Windows ...................................... 27

Windscreen ............................... 27

Power windows ......................... 27Heated rear window ..................29

Sun visors .................................. 29

Roof ............................................. 29

Sunroof ...................................... 29

Glass panel ............................... 30Keys, locks

KeysCaution

Do not attach heavy or bulky items to the ignition key.

Replacement keys

The key number is specified on a

detachable tag.

The key number must be quoted

when ordering replacement keys as it

is a component of the immobiliser

system.

Locks 3 191.

The code number of the adapter for

the locking wheel bolts is specified on a card. It must be quoted when

ordering a replacement adapter.

Wheel changing 3 181.

Page 53 of 223

Storage51StorageStorage compartments................51

Glovebox ................................... 51

Cupholders ................................ 51

Front storage ............................. 52

Load compartment .......................53

Rear storage .............................. 54

Load compartment cover ...........54

Rear floor storage cover ............55

Lashing eyes ............................. 56

Warning triangle ........................57

First aid kit ................................. 57

Roof rack system .........................58

Roof rack ................................... 58

Loading information .....................58Storage compartments9Warning

Do not store heavy or sharp

objects in the storage

compartments. Otherwise, the

storage compartment lid could

open and vehicle occupants could be injured by objects being thrown

around in the event of hard

braking, a sudden change in

direction or an accident.

Glovebox

Pull lever to open the glovebox cover.

The glovebox features a coin holder

and an adapter for the locking wheel

bolts.

The glovebox should be closed whilst

driving.

Cupholders

Cupholders are located in the console between the front seats. They are

designed for cups of different sizes.

Page 178 of 223

176Vehicle careindicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

nominal tyre pressure and to make

other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.

Tyre pressure monitoring system

3 172.Caution

When converting to wheels with

14'', the ground clearance will be

reduced. This must be considered when passing over obstacles.

9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel bolts, do not attach wheel

covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Page 183 of 223

Vehicle care181The adapters possibly supplied can

be used to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They can be located on the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

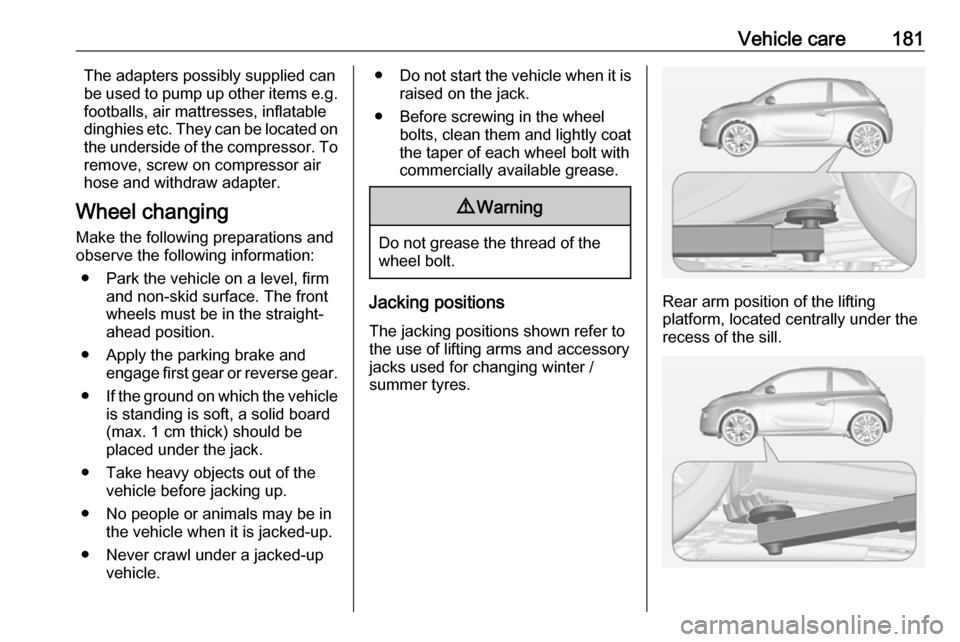

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● Apply the parking brake and engage first gear or reverse gear.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.●Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them and lightly coat

the taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

Jacking positions

The jacking positions shown refer to the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.Rear arm position of the lifting

platform, located centrally under the

recess of the sill.

Page 185 of 223

Vehicle care1836.Lift the spare wheel holder slightly

by hand and detach the safety

cable.

7. Lower holder all the way and remove spare wheel.

8. Change the wheel 3 181.

The damaged wheel must be

secured in the load compartment,

see below.

9. Lift the empty spare wheel holder and insert the safety cable.

10. Lift the spare wheel holder farther

and engage in catch. The open

side of the catch must point in the direction of travel.

11. Close the empty spare wheel holder by turning the hexagon boltclockwise successively using the

wheel wrench.

12. Close the load compartment floor.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear or reverse gear.

● Remove the spare wheel.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Before screwing in the wheel bolts, clean them and lightly coat

the taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

1. Steel wheels

Pull off the wheel cover.

Alloy wheels with bolt caps Disengage wheel bolt caps with a

screwdriver and remove. To

protect the wheel, place a soft

cloth between the screwdriver

and the alloy wheel.

Alloy wheels with centre cap

Page 186 of 223

184Vehicle care

Insert extractor in the hole of the

centre cap and withdraw the cap

from the wheel.

Vehicle tools 3 169.

2. Install the wheel wrench ensuring

that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

Some versions have sill panels

with covered vehicle jacking points: first pull out the cover at

the respective jacking point

before positioning the jack.

Page 187 of 223

Vehicle care1854. Set the jack to the necessaryheight. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it is securely located and

tighten each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Install wheel bolt caps or centre

cap on alloy wheel.

11. Stow and secure the replaced wheel, the vehicle tools 3 169 and

the adapter for the locking wheel

bolts 3 51.

12. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.

Stowing a damaged wheel in the

load compartment

The spare wheel holder is not

designed for other tyre sizes than the

spare wheel.

A damaged wheel wider than the

spare wheel must be stowed in the

load compartment and secured with a strap.

Vehicle tools 3 169.Wheels with tyre size up to

195/55 R 16 1. Remove load compartment cover and lift up load compartment floor.

Stow both behind the raised up

backrests of the rear seats.

2. Untwist wing nut and remove tool box.

3. Position the damaged wheel to stand upright into the tool box

spare, facing to the front.