ESP VAUXHALL ANTARA 2015 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: ANTARA, Model: VAUXHALL ANTARA 2015Pages: 223, PDF Size: 6.07 MB

Page 127 of 223

Driving and operating125

Before restarting or to switch off the

engine, turn key back to LOCK.

Start attempts should not last longer than 15 seconds. If engine does not

start, wait 10 seconds before

repeating starting procedure.

The increased engine speed

automatically returns to normal idling

speed as the engine temperature

rises. Drive at a moderate speed,

especially in cold weather, until

normal engine operating

temperatures have been reached.

During an Autostop, the engine can

be started by depressing the clutch

pedal.

Stop-start system 3 125.

Starting the vehicle at low

temperatures In extremely cold temperatures, i.e.

below -20 °С, it may be necessary to

crank the engine for up to

30 seconds for it to start.

Turn key to position START and hold

until engine starts. Start attempts

should not last longer than30 seconds. If engine does not start,

wait 10 seconds before repeating starting procedure.

Ensure the engine oil is of the correct

viscosity, the correct fuel is used,

vehicle services are performed

regularly and the battery is sufficiently charged.

Turbo engine warm-up

Upon start-up, engine available

torque may be limited for a short time, especially when the engine

temperature is cold. The limitation is

to allow the lubrication system to fully

protect the engine.

Overrun cut-off

The fuel supply is automatically cut-

off during overrun, i.e. when the

vehicle is driven with a gear engaged but accelerator is released.Stop-start system

The stop-start system helps to save

fuel and to reduce the exhaust

emissions. When conditions allow, it

switches off the engine as soon as the

vehicle is at a low speed or at a

standstill, e.g. at a traffic light or in a

traffic jam. It starts the engine

automatically as soon as the clutch is

depressed. A vehicle battery sensor

ensures that an Autostop is only

performed if the vehicle battery is

sufficiently charged for a restart.

Activation

The stop-start system is available as

soon as the engine is started, the

vehicle starts-off and the conditions

as stated below in this section are

fulfilled.

Page 137 of 223

Driving and operating135

Ensure tyres (including the spare) areinflated to the correct pressure

3 210 and are suitable for the

prevailing road conditions. For

optimum system performance, the

vehicle's tyres should not have

varying degrees of wear.

If control indicator B flashes in the

instrument cluster during driving, All-

wheel drive is temporarily disabled. If

B flashes continuously, there is a fault

in the system; seek the assistance of

a workshop.

All-wheel drive control indicator B

3 86.

On-road driving

The increased traction of All-wheel

drive vehicles offers greater driving

control in adverse road conditions,

particularly heavy snow and ice.

However, All-wheel drive vehicles are not "skid-proof" and do not decrease

stopping distances.

All-wheel drive vehicles have a higher

centre of gravity than conventional vehicles. Always approach curves at

an appropriate driving speed. Do notattempt to go as fast through turns as

you might in a conventional vehicle.

Strong crosswinds can affect the normal steering of the vehicle. Drive

slower under strong crosswind

conditions.

Off-road driving ■ Avoid protruding objects (such as rocks or tree stumps) that may

damage the underbody and tyres of your vehicle.

■ Test the brakes after operating in mud, to clear excess mud from the

braking surfaces.

■ Grip the steering wheel when travelling over rough terrain.

Terrain conditions can cause rapid

and unexpected movement in the

steering.

The ground clearance, ramp angle,

angle of approach and departure and

wading depth need to be considered, especially in hilly conditions and

when wading, to prevent the vehicle

becoming stuck and possibly

damaged.

Vehicle dimensions 3 207.Towing the vehicle 3 192.

Driving through water

Do not exceed the maximum wading

depth 3 207.

Check the depth of water: choose the

lowest entry and departure angles

before entering. Maintain a steady

engine speed, to help prevent water

from entering the exhaust system, but

do not exceed 3 mph, to avoid

splashing the water.

Drive with the flow wherever possible,

not against it. If you have to drive

against the flow, try to drive at an

angle to it, so that the leading corner

of the vehicle will help deflect water

from the engine compartment. Avoid

splashing the water - if the ignition

system becomes wet, the engine may

stall.

Avoid water entering the air intake

system. If water enters the air intake

system, engine seizure with severe

costly damage may result.

Test the brakes after leaving the

water - wet brakes are less effective

than dry ones. Perform the service

Page 138 of 223

136Driving and operating

operations for wading , involving

checks for water contamination, at

the earliest opportunity.

Service checks after wading

Check for the ingress of water into the following:

■ Brake fluid reservoir

■ Air cleaner element

■ Engine

■ Transmission

■ Axles

■ Interior of vehicle

Renew any lubricating oil or hydraulic

fluid that has a milky appearance,

indicating contamination with water.

Cleaning

Clean the vehicle thoroughly and as

soon as possible after driving off-

road.

Do not let mud remain dry on any part

of the vehicle as it becomes abrasive and can damage paint, glass, seals,

bearings and brake components. If

left to build up, mud can seriously

affect the airflow through and overmechanical components and cause

localised overheating and failure of

parts, especially in the engine

compartment.

Ensure the radiator core and the area

between the radiator and intercooler/

oil cooler (where installed) is cleaned, to maintain proper cooling air flow.

Check the radiator and cooler cores

for blockage (sand, silt etc.).

Check the tyre treads.

Clean and check the mechanical

parts of the vehicle, particularly the

following areas:

■ Driveshafts, including sealing bellows

■ Front brake calipers, pads and discs

■ Front suspension

■ Clutch fork sealing bellows

■ Rear brake calipers, pads and discs

■ Rear suspension

■ Fuel tank and underguard

■ Breathers, axles and fuel tank

■ Load sensing valve■ Transfer box and underguard

■ Engine oil pan and underguard

Observe the following: ■ Do not spray high-pressure water directly at the vehicle seals

■ The wheels must be removed to clean all mud and stones from the

brake calipers and to check brake

pad wear

■ The areas on the upper side of the underguards must be cleared of

stones, to prevent damage to the

engine oil pan and the fuel tank

Page 139 of 223

Driving and operating137Brakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 85.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off, the system performs a self-test which may be audible.

Control indicator u 3 86.

Fault9 Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS are no longer available. During

hard braking, the vehicle can nolonger be steered and may

swerve.

You can continue driving, provided

you drive with care and anticipation.

Have the cause of the fault remedied

by a workshop.

Parking brake Electrical parking brake

Page 143 of 223

Driving and operating141

FaultThe yellow control indicator u flashes

to indicate that the system is not ready for conditions to operate, due to the high temperature (approx.

350 - 400 °C) of friction material,

through severe or repeated braking. It

will extinguish when the temperature

drops below 350 °C.

The yellow control indicator u

illuminates when there is a

malfunction in the system, due to the

extremely high temperature

(over 400 °C) of friction material,

through severe or repeated braking. It will extinguish when the temperaturedrops below 350 °C. These

temperatures may differ according to

vehicle conditions or outside

conditions.

Flashing or illumination of the yellow

control indicator u reminds the driver

that the friction material needs to cool

down: drive the vehicle without

braking as much as possible. If the

control indicator does not extinguish,

have the cause of the fault remedied

by a workshop.DSC control indicators u 3 87.

Automatic level control The rear level of the vehicle is

automatically adjusted to the load

conditions while driving. Suspension

and ground clearance are increased,

which improves driving conditions.

The automatic level control is

activated after the vehicle has been

driven for some distance, depending

on the vehicle load and the road

conditions.

Do not use full payload in the event of

a fault. Have the cause of the fault

remedied by a workshop.

Headlight range adjustment 3 107.Driver assistance

systems9 Warning

Driver assistance systems are

developed to support the driver

and not to replace the driver's

attention.

The driver accepts full

responsibility when driving the

vehicle.

When using driver assistance

systems, always take care

regarding the current traffic

situation.

Cruise control

The cruise control can store and

maintain speeds above 25 mph.

Deviations from the stored speeds

may occur when driving uphill or

downhill.

For safety reasons the cruise control

cannot be activated until the foot

brake has been operated once.

Page 145 of 223

Driving and operating143Parking assist

The parking assist system makes

parking easier by measuring the

distance between the vehicle and obstacles to the front and rear, and

giving acoustic signals. It is the driver,

however, who bears full responsibility for the parking manoeuvre.

The system consists of four ultrasonic

parking sensors in both the front and

rear bumpers.

Control indicator r 3 87.

Activation

With the ignition on, the system must

be activated manually.

Press button r on the instrument

panel. The LED in the button will

illuminate and will activate when a

forward gear or reverse gear is

engaged and the electrical parking

brake is released.

An obstacle is indicated by an

acoustic signal. The interval between

the sounds becomes shorter as the

vehicle gets closer to the obstacle.

When the distance is less than

30 cm, the signal is continuous. The

acoustic signal may differ depending

on the type of object detected.

Deactivation

To deactivate, press the button again

and the LED in the button will

extinguish. The control indicator r

in the instrument cluster will illuminate

until the vehicle speed exceeds

18 mph.

The system is deactivated

automatically when the vehicle speed is above 5 mph or when selector leveris in neutral (automatic transmission

in N or P).

If the b button is pressed again, the

LED in the button will extinguish and the system will be reactivated as soon

as a forward gear or reverse gear is

engaged and the electrical parking

brake is released.

Fault

In the event of a fault in the system,

control indicator r illuminates in the

instrument cluster.

Page 151 of 223

Driving and operating149

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

When measuring the vertical coupling

load, ensure the drawbar of the

loaded trailer is at the same height as it will be when the trailer is coupled

with the towing vehicle loaded. This is

particularly important for trailers with

tandem axle.

Rear axle load

When the trailer is coupled and the

towing vehicle is fully loaded

(including all occupants), the

permissible rear axle load (see

identification plate or vehicle

documents) must not be exceeded.

National regulations regarding

maximum speeds for vehicles towing

a trailer must be observed.Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

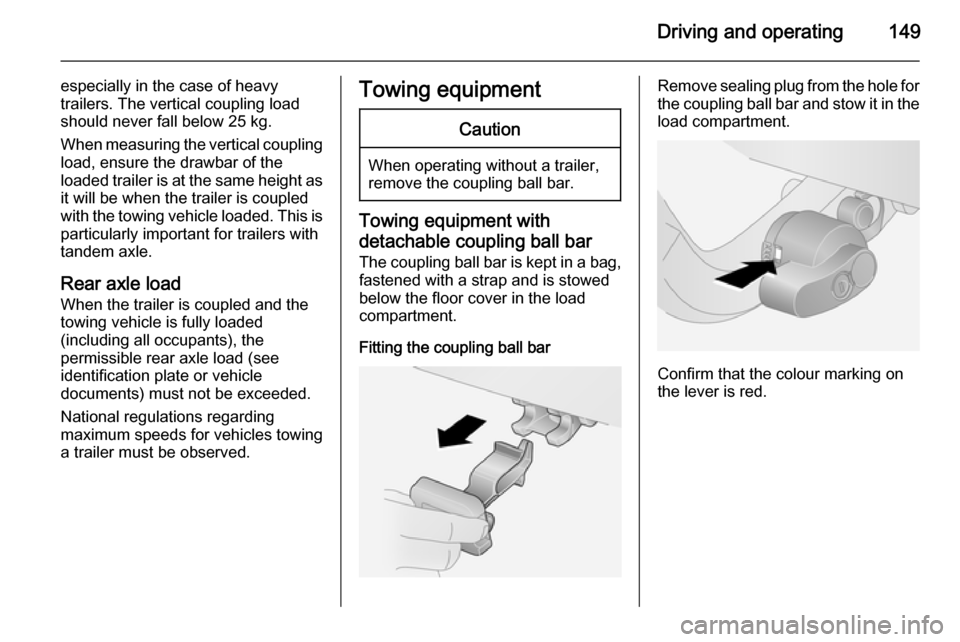

Towing equipment with

detachable coupling ball bar The coupling ball bar is kept in a bag,

fastened with a strap and is stowed

below the floor cover in the load

compartment.

Fitting the coupling ball bar

Remove sealing plug from the hole for

the coupling ball bar and stow it in the load compartment.

Confirm that the colour marking on

the lever is red.

Page 156 of 223

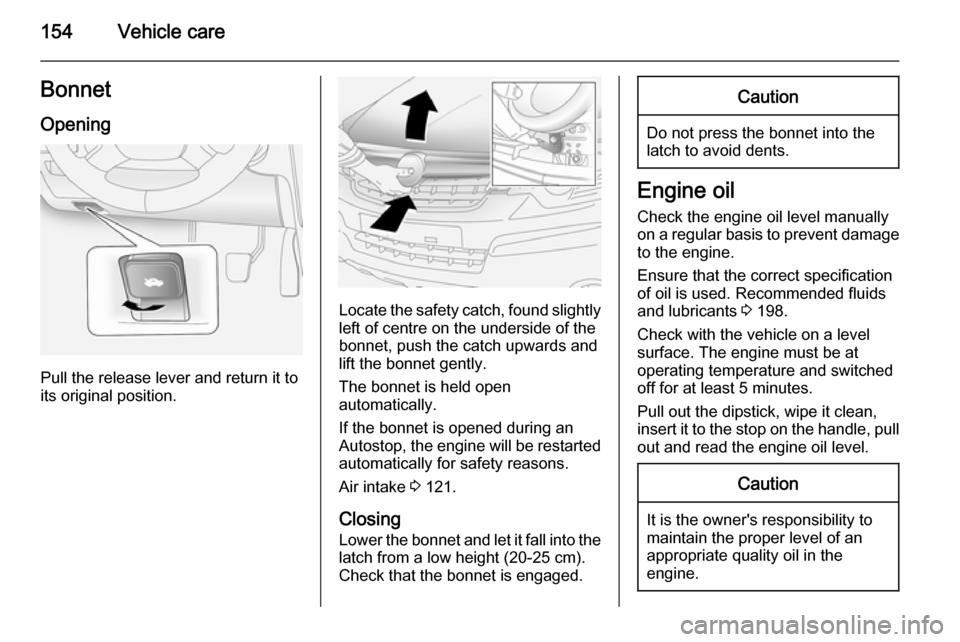

154Vehicle careBonnetOpening

Pull the release lever and return it to

its original position.

Locate the safety catch, found slightly left of centre on the underside of the

bonnet, push the catch upwards and

lift the bonnet gently.

The bonnet is held open

automatically.

If the bonnet is opened during an Autostop, the engine will be restarted automatically for safety reasons.

Air intake 3 121.

Closing

Lower the bonnet and let it fall into the latch from a low height (20-25 cm).

Check that the bonnet is engaged.

Caution

Do not press the bonnet into the

latch to avoid dents.

Engine oil

Check the engine oil level manually on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 198.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 5 minutes.

Pull out the dipstick, wipe it clean, insert it to the stop on the handle, pull

out and read the engine oil level.

Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Page 167 of 223

Vehicle care165

1. Remove 2 screws from panel onunderside of vehicle below front

fog lights and remove panel.

2. Disconnect harness connector from bulb holder and rotate bulb

holder anticlockwise.

3. Remove bulb holder from lamp assembly, rotate bulb

anticlockwise and remove from

bulb holder.

4. Insert new bulb into bulb holder and rotate it clockwise.

5. Reinstall bulb holder in lamp assembly and reconnect harnessconnector.

6. Reinstall panel to underside of vehicle using 2 screws removed

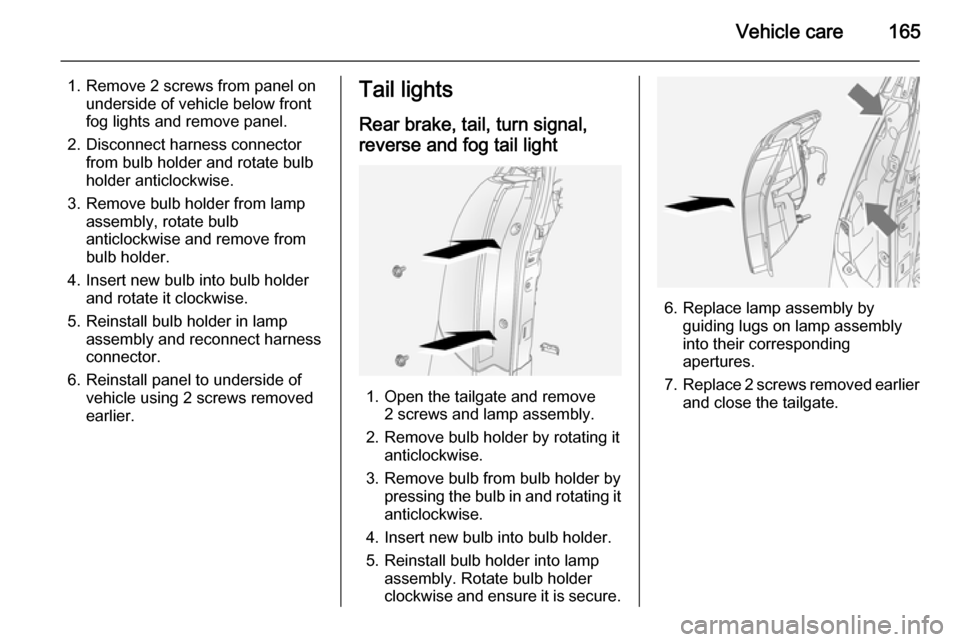

earlier.Tail lights

Rear brake, tail, turn signal,

reverse and fog tail light

1. Open the tailgate and remove 2 screws and lamp assembly.

2. Remove bulb holder by rotating it anticlockwise.

3. Remove bulb from bulb holder by pressing the bulb in and rotating it

anticlockwise.

4. Insert new bulb into bulb holder.

5. Reinstall bulb holder into lamp assembly. Rotate bulb holder

clockwise and ensure it is secure.

6. Replace lamp assembly by guiding lugs on lamp assembly

into their corresponding

apertures.

7. Replace 2 screws removed earlier

and close the tailgate.

Page 169 of 223

Vehicle care167

Rear reading lights

1. Using a suitable screwdriver, prylamp lens away from roof lining.

2. Remove bulb.

3. Insert new bulb.

4. Reinstall lamp lens in roof lining.

Load compartment light

1. Using a suitable screwdriver, remove lens from lamp assembly.

2. Remove bulb.

3. Insert new bulb.

4. Reinstall lens to lamp assembly.

Glovebox light

Have bulbs replaced by a workshop.

Instrument panel

illumination Have bulbs replaced by a workshop.

Electrical system

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

■ in the engine compartment next to the coolant reservoir,

■ in the instrument panel, on the left- hand side of the front passenger

seat foot well, or, in right-hand drive

vehicles, on the left-hand side of

the driver's seat foot well.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognized by its melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

Some functions are protected by

several fuses. Fuses may also be

inserted without existence of a

function.