lock VAUXHALL ANTARA 2015 Workshop Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: ANTARA, Model: VAUXHALL ANTARA 2015Pages: 223, PDF Size: 6.07 MB

Page 176 of 223

174Vehicle care

FuseCircuitAMPAmplifierAPO JACK

(CONSOLE)Power outlet

(centre console)APO JACK

(REAR CARGO)Power outlet

(load compart‐

ment)AWD/VENTAll-wheel drive,

ventilationBCM (CTSY)Courtesy lightsBCM (DIMMER)Instrument illu‐

minationBCM (INT LIGHT

TRLR FOG)Interior lights,

trailer fog lightBCM (PRK/TRN)Parking lights,

turn signalsBCM (STOP)Brake lightsBCM (TRN SIG)Turn signalsBCM (VBATT)Battery voltageFuseCircuitCIMCommunica‐

tions Integration

ModuleCLSTRInstrument

clusterDRLDaytime running

lightsDR/LCKDriver door lockDRVR PWR

SEATDriver power

seatDRV/PWR

WNDWDriver power

windowF/DOOR LOCKFuel filler flapFRT WSRFront washerFSCMFuel systemFSCM/VENT SOLFuel system,

vent solenoidHEATING MAT

SWHeating mat

switchHTD SEAT PWRSeat heatingFuseCircuitHVAC BLWRClimate control,

air conditioning

fanIPCInstrument panel clusterISRVM/RCMInterior mirror,

remote compass moduleKEY CAPTUREKey captureL/GATETailgateLOGISTIC MODELogistic modeOSRVMExterior mirrorsPASS PWR

WNDWPassenger

power windowPWR DIODEPower diodePWR MODINGPower modingRADIORadioRR FOGHeated rear

window

Page 178 of 223

176Vehicle care

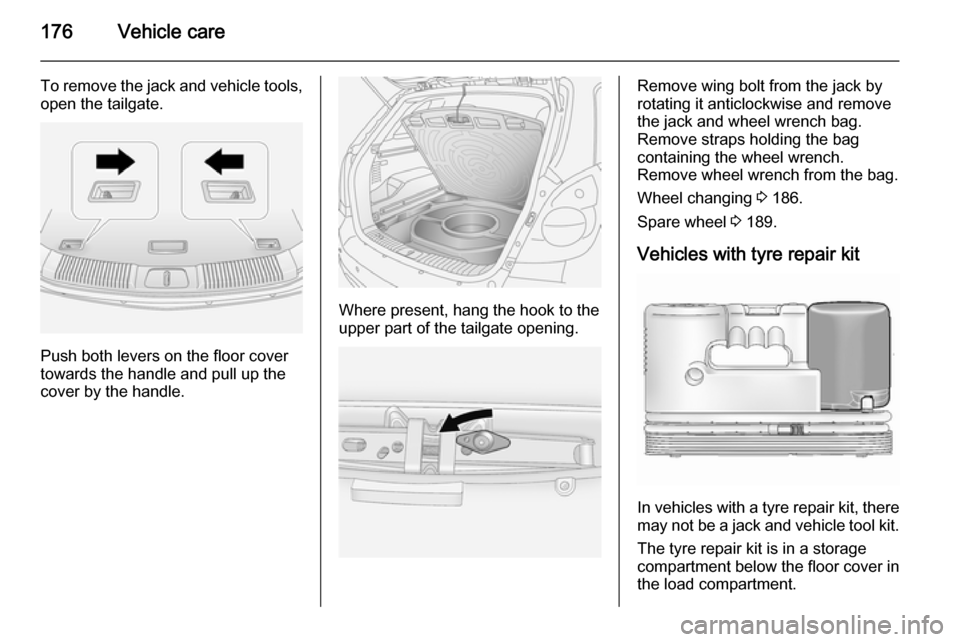

To remove the jack and vehicle tools,open the tailgate.

Push both levers on the floor cover

towards the handle and pull up the

cover by the handle.

Where present, hang the hook to the

upper part of the tailgate opening.

Remove wing bolt from the jack by

rotating it anticlockwise and remove

the jack and wheel wrench bag.

Remove straps holding the bag

containing the wheel wrench.

Remove wheel wrench from the bag.

Wheel changing 3 186.

Spare wheel 3 189.

Vehicles with tyre repair kit

In vehicles with a tyre repair kit, there may not be a jack and vehicle tool kit.

The tyre repair kit is in a storage

compartment below the floor cover in the load compartment.

Page 185 of 223

Vehicle care1839Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Tyre chains are only permitted on the

front wheels.

They must be fitted to the tyres

symmetrically in order to achieve a

concentric fit.

Always use fine mesh chains that add no more than 15 mm to the tyre tread

and the inboard sides (including chain lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted only on

16 inch wheels. We recommend you consult a workshop.

If the use of tyre chains is required

after suffering a flat front tyre, fit the

temporary spare wheel on the rear

axle and transfer one of the rear

wheels to the front axle.

General

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread or

sidewall can be repaired with the tyre

repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at the tyre's sidewall near the rim

cannot be repaired with the tyre repair kit.

In vehicles with a tyre repair kit, there may not be a jack and vehicle tool kit.

Vehicle tools 3 175.

Temporary spare wheel 3 189.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the electrical parking brake

3 137 and engage first gear, reverse

gear or P.

The tyre repair kit is in a storage

compartment below the floor cover in the load compartment.

To remove the tyre repair kit, open the

tailgate.

Page 186 of 223

184Vehicle care

Pull the floor cover handle upwards

3 69.

Vehicle tools 3 175.Caution

Do not allow objects to protrude

above the top of the rear floor

storage compartment, to avoid

damage to the storage area and

the load compartment floor.

1. Release the sealant filler hose 1

and the power plug 2.

2. Unscrew valve cap from defective

tyre.

Screw the sealant filler hose onto

the tyre valve.

3. Connect the power plug to the power outlet. Unplug all items

from other power outlets.

4. Switch on ignition. To avoid discharging the battery, werecommend running the engine.

5. Turn the selector switch anticlockwise to the sealant +

air position.

6. Press the on/off button to turn the

tyre repair kit on. The tyre is filled

with sealant.

The pressure gauge briefly shows a high pressure while the sealant

canister is emptying. Then the

pressure starts to drop.

All of the sealant is pumped into

the tyre. Then the tyre is inflated.

7. Inflate the tyre to the recommended inflation pressure

using the pressure gauge. The

prescribed tyre pressure should

be obtained within 10 minutes

3 210 . When the correct pressure

Page 188 of 223

186Vehicle care

13.Turn the selector switch clockwise

to the air only position. Switch on

the compressor to inflate the tyre

with air only.

Notice

The driving characteristic of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

canister.

Replace the used sealant canister.

To remove sealant canister, release sealant filler hose and air hose, slide

canister out of housing and unscrew hose from canister. Dispose of thecanister as prescribed by applicable

laws.

The accessory adapter supplied can

be used to pump up other items

e.g. footballs, air mattresses,

inflatable dinghies etc. The adapter

is located on the underside of the

tyre repair kit.

Wheel changing Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 183.Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-slippery surface. The frontwheels must be in the straight-

ahead position.

■ Apply the electrical parking brake 3 137 and engage first gear,

reverse gear or P.

■ Remove the spare wheel 3 189.

■ Never change more than one wheel

at a time.

■ Block wheel diagonally opposite the wheel to be changed, by placing

wedge blocks or equivalent in front

and behind the wheel.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

changes.

■ Never exceed jack maximum working load (900 kg).

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

Page 189 of 223

Vehicle care187

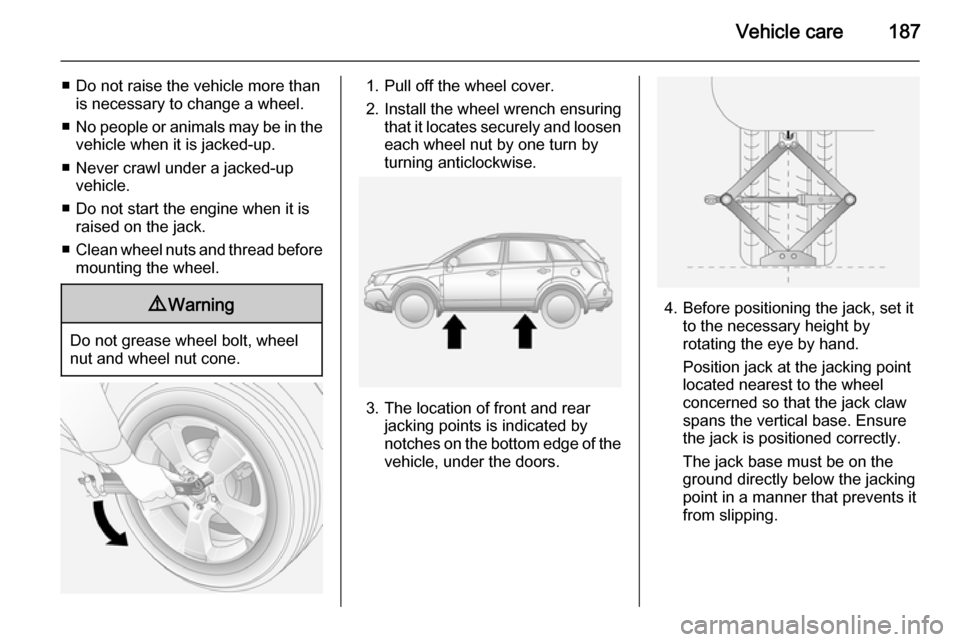

■ Do not raise the vehicle more thanis necessary to change a wheel.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the engine when it is raised on the jack.

■ Clean wheel nuts and thread before

mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Pull off the wheel cover.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel nut by one turn by

turning anticlockwise.

3. The location of front and rear jacking points is indicated by

notches on the bottom edge of the

vehicle, under the doors.

4. Before positioning the jack, set it to the necessary height by

rotating the eye by hand.

Position jack at the jacking point

located nearest to the wheel

concerned so that the jack claw

spans the vertical base. Ensure

the jack is positioned correctly.

The jack base must be on the

ground directly below the jacking

point in a manner that prevents it

from slipping.

Page 190 of 223

188Vehicle care

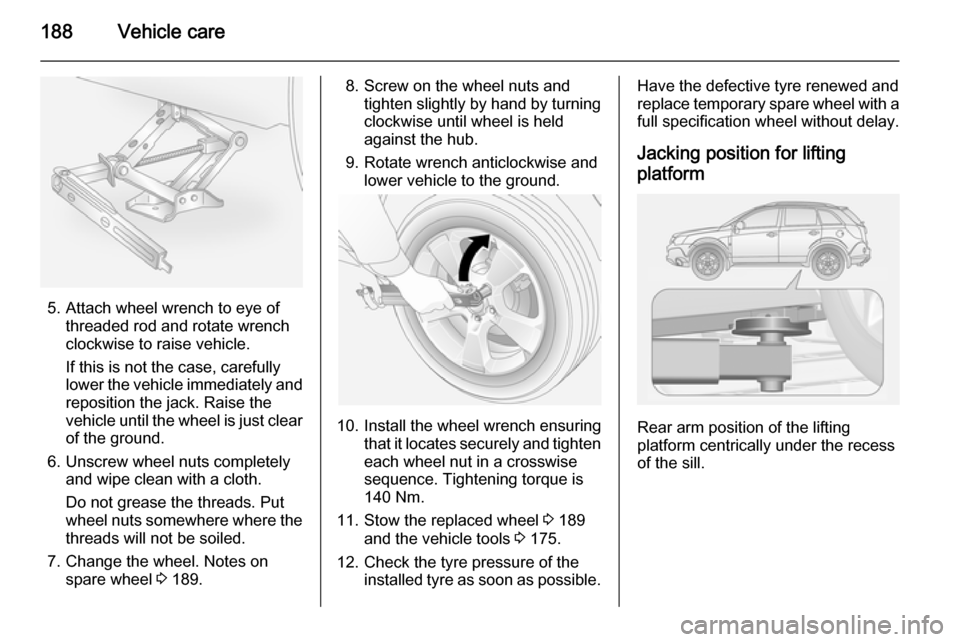

5. Attach wheel wrench to eye ofthreaded rod and rotate wrench

clockwise to raise vehicle.

If this is not the case, carefully

lower the vehicle immediately and

reposition the jack. Raise the

vehicle until the wheel is just clear of the ground.

6. Unscrew wheel nuts completely and wipe clean with a cloth.

Do not grease the threads. Put

wheel nuts somewhere where the threads will not be soiled.

7. Change the wheel. Notes on spare wheel 3 189.

8. Screw on the wheel nuts and

tighten slightly by hand by turning

clockwise until wheel is held

against the hub.

9. Rotate wrench anticlockwise and lower vehicle to the ground.

10. Install the wheel wrench ensuring that it locates securely and tighten

each wheel nut in a crosswise

sequence. Tightening torque is

140 Nm.

11. Stow the replaced wheel 3 189

and the vehicle tools 3 175.

12. Check the tyre pressure of the installed tyre as soon as possible.

Have the defective tyre renewed and

replace temporary spare wheel with a

full specification wheel without delay.

Jacking position for lifting platform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Page 191 of 223

Vehicle care189

Front arm position of the lifting

platform centrically under the recess

of the sill.

Spare wheel

Temporary spare wheel

Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

The temporary spare wheel is

designed for use on your vehicle only.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

Use of the temporary spare wheel

could affect driveability, particularly if

using winter tyres. Have the defective

tyre renewed as soon as possible and

have the wheel balanced and fitted to the vehicle.Caution

The use of a spare wheel that issmaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.The temporary spare wheel is located in the load compartment below the

floor cover and is secured with a

screw-in retainer.

Push both levers on the floor cover

towards the handle and pull up the

cover by the handle. Hang the hook

to the upper part of the tailgate

opening.

Vehicle tools 3 175.

Remove the retainer by rotating it

anticlockwise and remove temporary

spare wheel from the spare wheel

well.

Page 193 of 223

Vehicle care191

■ A discharged battery can alreadyfreeze at a temperature of 0 °C.

Defrost the frozen battery before

connecting jump leads.

■ Wear eye protection and protective

clothing when handling a battery.

■ Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

■ Use jump leads with insulated terminals and a cross section of at

least 16 mm 2

(25 mm 2

for diesel

engines).

■ Do not disconnect the discharged battery from the vehicle.

■ Switch off all unnecessary electrical

consumers. The Infotainment

system may be damaged if

switched on while jump starting.

■ Do not lean over the battery during jump starting.

■ Do not allow the terminals of one lead to touch those of the other

lead.■ The vehicles must not come into contact with each other during the

jump starting process.

■ Apply the electrical parking brake 3 137, transmission in neutral,

automatic transmission in P.

■ Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal 1 of the booster

battery.

2. Connect the other end of the red lead to the positive terminal 2 of

the discharged battery.

3. Connect the black lead to the negative terminal 3 of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block 4 or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

Page 194 of 223

192Vehicle care

4. Switch on electrical consumers(e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Operate discharged vehicle for approx. 20 minutes to allow for

adequate battery recharging.

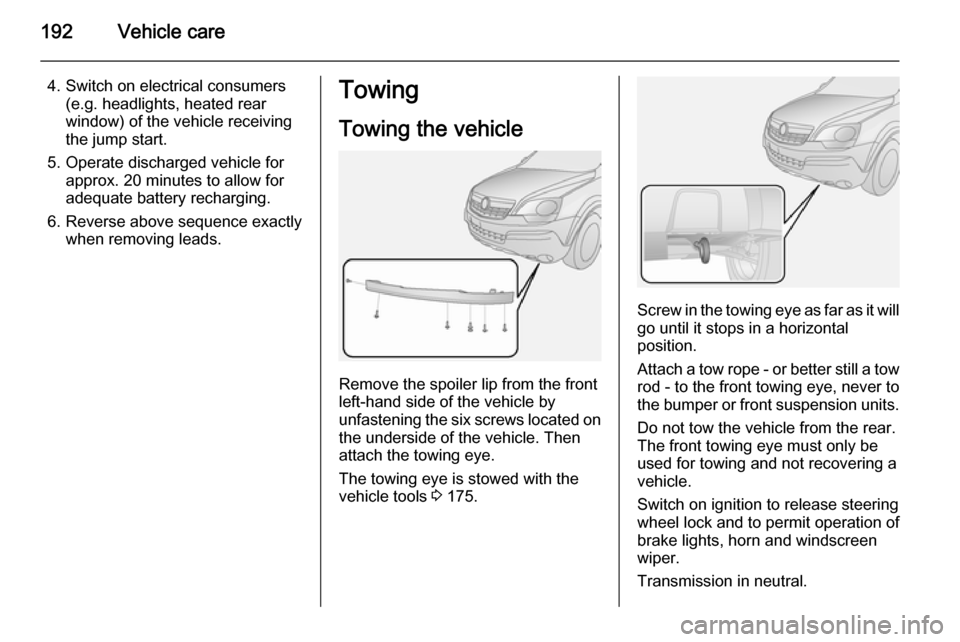

6. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Remove the spoiler lip from the front

left-hand side of the vehicle by

unfastening the six screws located on the underside of the vehicle. Then

attach the towing eye.

The towing eye is stowed with the

vehicle tools 3 175.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope - or better still a tow

rod - to the front towing eye, never to

the bumper or front suspension units.

Do not tow the vehicle from the rear.

The front towing eye must only be

used for towing and not recovering a

vehicle.

Switch on ignition to release steering wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.