check engine VAUXHALL ASTRA J 2016.25 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.25, Model line: ASTRA J, Model: VAUXHALL ASTRA J 2016.25Pages: 267, PDF Size: 7.72 MB

Page 161 of 267

Driving and operating159Functionality check

When the vehicle is not moving, the

electric parking brake might be

applied automatically. This is done to

check the system.

Fault

Failure mode of electric parking brake

is indicated by a control indicator j

and by a vehicle message which is

displayed in the Driver Information Centre. Vehicle messages 3 104.

Apply electric parking brake: pull and hold the switch m for more than

five seconds. If control indicator m

illuminates, electric parking brake is

applied.

Release electric parking brake: push and hold the switch m for more than

two seconds. If control indicator m

extinguishes, electric parking brake is

released.

Control indicator m flashes: electric

parking brake is not fully applied or

released. When continuously

flashing, release electric parking

brake and retry applying.Brake assist

If brake pedal is depressed quickly

and forcefully, maximum brake force

is automatically applied.

Operation of brake assist might

become apparent by a pulse in the

brake pedal and a greater resistance when depressing the brake pedal.

Maintain steady pressure on the

brake pedal as long as full braking is

required. Maximum brake force is

automatically reduced when brake

pedal is released.

Hill start assist The system helps prevent unintendedmovement when driving away on

inclines.

When releasing the brake pedal after

stopping on an incline, brakes remain

on for further two seconds. The

brakes release automatically as soon

as the vehicle begins to accelerate.Ride control systems

Traction Control systemThe Traction Control system (TC) is a

component of the Electronic Stability

Control (ESC).

TC improves driving stability when

necessary, regardless of the type of

road surface or tyre grip, by

preventing the drive wheels from

spinning.

As soon as the drive wheels starts to spin, engine output is reduced and

the wheel spinning the most is braked

individually. This considerably

improves the driving stability of the

vehicle on slippery road surfaces.

TC is operational after each engine

start as soon as the control indicator

b extinguishes.

When TC operates b flashes.

Page 195 of 267

Driving and operating193Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is

correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

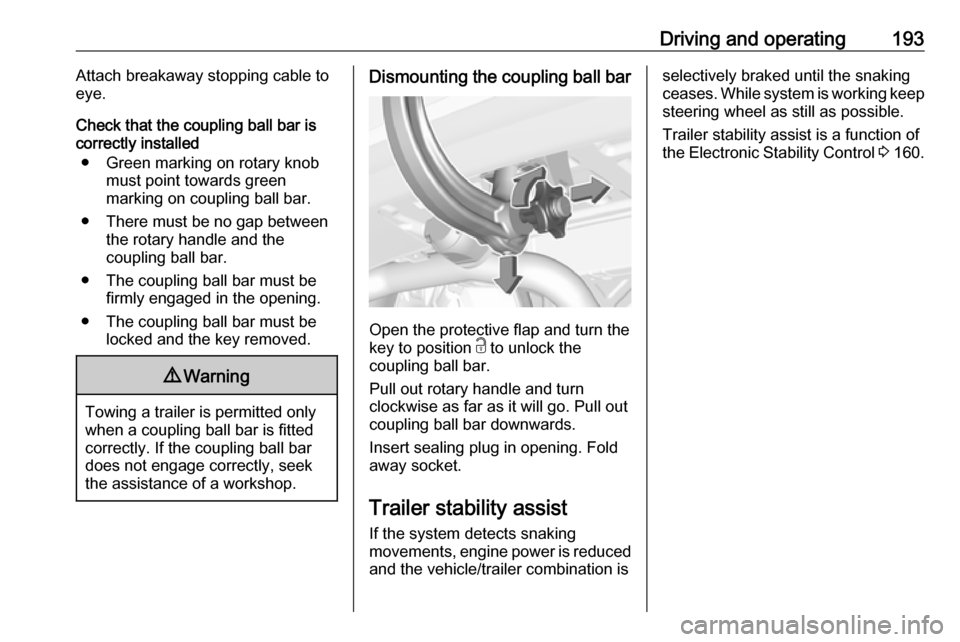

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep steering wheel as still as possible.

Trailer stability assist is a function of

the Electronic Stability Control 3 160.

Page 196 of 267

194Vehicle careVehicle careGeneral Information...................194

Accessories and vehicle modifications .......................... 194

Vehicle storage ........................195

End-of-life vehicle recovery .....195

Vehicle checks ........................... 196

Performing work ......................196

Bonnet ..................................... 196

Engine oil ................................. 197

Engine coolant ......................... 198

Washer fluid ............................ 199

Brakes ..................................... 199

Brake fluid ............................... 199

Vehicle battery ......................... 200

Diesel fuel system bleeding .....201

Wiper blade replacement ........202

Bulb replacement .......................202

Halogen headlights ..................202

Fog lights ................................. 204

Tail lights ................................. 205

Side turn signal lights ..............208

Number plate light ...................209

Interior lights ............................ 210

Instrument panel illumination ...210Electrical system ........................210

Fuses ....................................... 210

Engine compartment fuse box . 211

Instrument panel fuse box .......213

Load compartment fuse box ....215

Vehicle tools .............................. 217

Tools ........................................ 217

Wheels and tyres .......................217

Winter tyres ............................. 217

Tyre designations ....................218

Tyre pressure .......................... 218

Tyre pressure monitoring system .................................... 219

Tread depth ............................. 223

Changing tyre and wheel size . 224 Wheel covers ........................... 224

Tyre chains .............................. 224

Tyre repair kit .......................... 224

Wheel changing .......................227

Spare wheel ............................ 230

Jump starting ............................. 232

Towing ....................................... 234

Towing the vehicle ...................234

Towing another vehicle ...........235

Appearance care .......................236

Exterior care ............................ 236

Interior care ............................. 237General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the

electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Page 197 of 267

Vehicle care195Vehicle storageStorage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 198 of 267

196Vehicle careVehicle checks

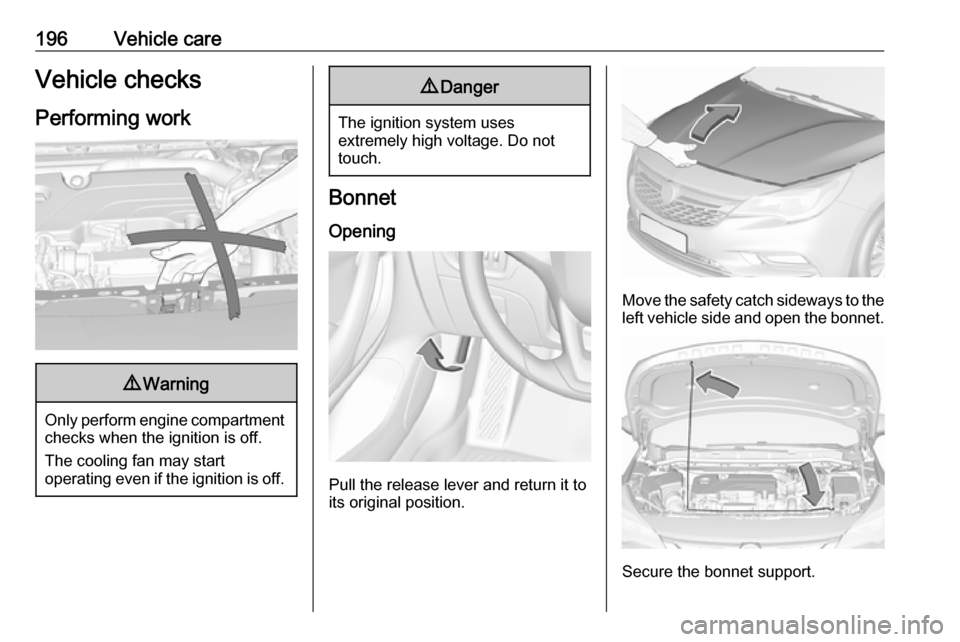

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system uses

extremely high voltage. Do not

touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch sideways to the left vehicle side and open the bonnet.

Secure the bonnet support.

Page 199 of 267

Vehicle care197If the bonnet is opened during an

Autostop, the engine will be restarted

automatically for safety reasons.

Closing Before closing the bonnet, press the

support into the holder.

Lower the bonnet and let it fall into the

latch from a low height (20-25 cm).

Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct

specification of oil is used.

Recommended fluids and lubricants

3 240.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.

Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle and make half a turn.

Different dipsticks are used

depending on engine variant.

When the engine oil level has

dropped to the MIN mark, top up

engine oil.

We recommend the use of the same

grade of engine oil that was used at

last change.

Page 200 of 267

198Vehicle care

The engine oil level must not exceed

the MAX mark on the dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

Capacities 3 252.

Fit the cap on straight and tighten it.

Engine coolant The coolant provides freeze

protection down to approx. -28 °C. In

cold regions with very low

temperatures, the factory filled

coolant provides frost protection

down to approx. -37 °C.Caution

Only use approved antifreeze.

Coolant level

Caution

Too low a coolant level can cause engine damage.

If the cooling system is cold, the

coolant level should be above the

filling line mark. Top up if the level is

low.9 Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top up, use a 1:1 mixture of

released coolant concentrate mixed

with clean tap water. If no coolant

concentrate is available, use clean

tap water. Install the cap tightly. Have the coolant concentration checked

and have the cause of the coolant

loss remedied by a workshop.

Page 204 of 267

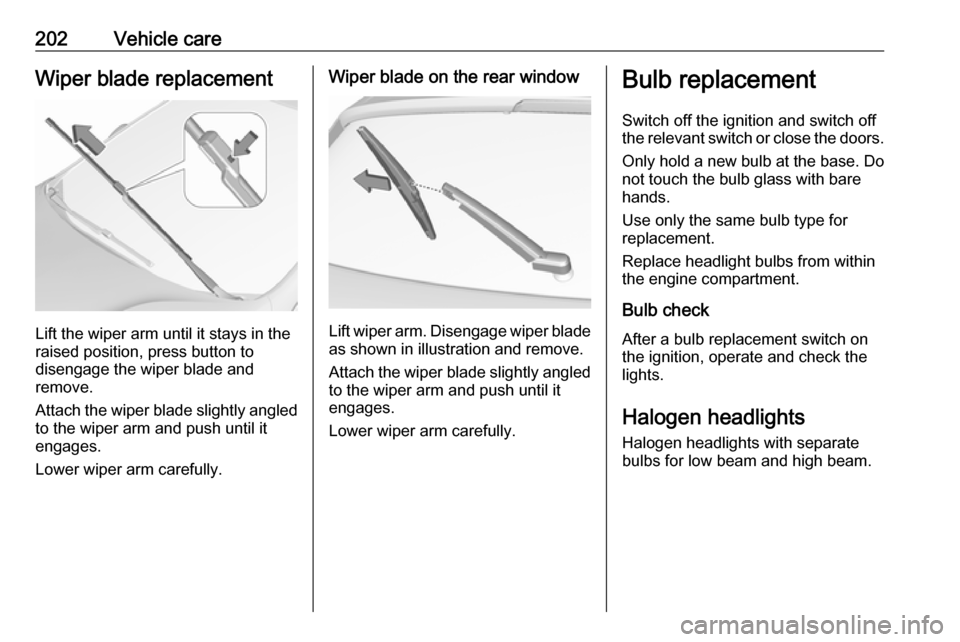

202Vehicle careWiper blade replacement

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check

After a bulb replacement switch on

the ignition, operate and check the

lights.

Halogen headlights Halogen headlights with separate

bulbs for low beam and high beam.

Page 220 of 267

218Vehicle careTyre designationsE.g. 215/60 R 16 95 H215:Tyre width, mm60:Cross-section ratio (tyre height

to tyre width), %R:Belt type: RadialRF:Type: RunFlat16:Wheel diameter, inches95:Load index e.g. 95 is

equivalent to 690 kgH:Speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropiate for the

maximum speed of your verhicle.

The maximum speed is achievable at

kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 249.

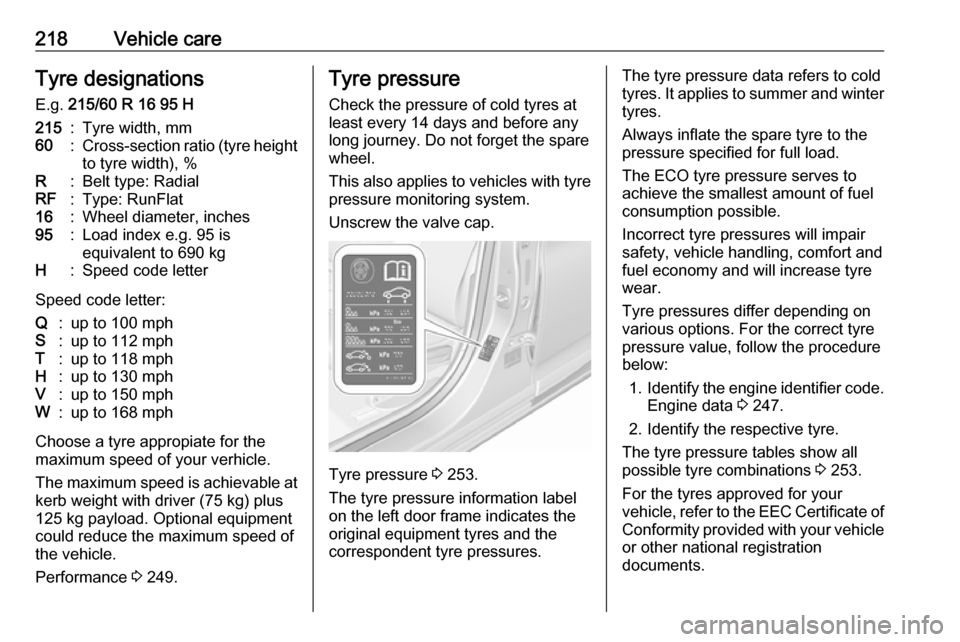

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 253.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 247.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 253.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.