tow VAUXHALL ASTRA J 2016.25 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.25, Model line: ASTRA J, Model: VAUXHALL ASTRA J 2016.25Pages: 267, PDF Size: 7.72 MB

Page 189 of 267

Driving and operating1879Warning

Always keep your attention on the

road and maintain proper vehicle

position within the lane, otherwise

vehicle damage, injury or death

could occur.

Lane keep assist does not

continuously steer the vehicle.

The system may not keep the

vehicle in the lane or give an alert,

even if a lane marking is detected.

Lane keep assist may not provide

enough steering to avoid a lane

departure.

The system may not detect hands-

off driving due to external

influences (road condition and

surface, weather etc). The driver

has full responsibility to control the vehicle and is always required to

keep the hands on the steering

wheel while driving.

Using the system while towing a

trailer or on slippery roads could

cause loss of control of the vehicle

and a crash. Switch the system off.

Fuel

Fuel for petrol engines Only use unleaded fuel that complies

with European standard EN 228 or

E DIN 51626-1 or equivalent.

The engine is capable of running with fuel that contains up to 10% ethanol(e.g. named E10).

Use fuel with the recommended

octane rating 3 247.Caution

Do not use fuel or fuel additives

that contain metallic compounds

such as manganese-based

additives. This may cause engine

damage.

Caution

Use of fuel that does not comply to EN 228 or E DIN 51626-1 or

equivalent can lead to deposits or

engine damage.

Caution

Use of fuel with too low an octane

rating could lead to uncontrolled combustion and engine damage.

Fuel for diesel engines

Only use diesel fuel that complies

with EN 590.

In countries outside the European

Union use Euro-Diesel fuel with a

sulphur concentration below 50 ppm.

Caution

Use of fuel that does not comply to EN 590 or similar can lead to

engine powerloss, increased wear

or engine damage.

Do not use marine diesel oils, heating

oils, Aquazole and similar diesel-

water emulsions. Diesel fuels must

not be diluted with fuels for petrol

engines.

Page 192 of 267

190Driving and operatingTrailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for trailer brake light cannot detect a

partial bulb outage, e.g. in case of four

times five watt bulbs, the function only detects lamp outage when only a

single five Watt lamp remains or none

remain.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case use the coupling ball bar for towing. Always keep the

coupling ball bar in the vehicle when

not in use.Driving characteristics and

towing tips

Before attaching a trailer, lubricatethe coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1300 kg the use of a stabiliser is

strongly recommended when driving

above 50 mph.

If the trailer starts snaking, drive more

slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 253.Trailer towing

Trailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%.

The permitted trailer load applies up to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the air becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than 8%, e.g. motorways).

Page 193 of 267

Driving and operating191The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 242.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (75 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Rear axle load

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by

40 kg. If the permissible rear axle load is exceeded, a maximum speed of

60 mph applies.Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

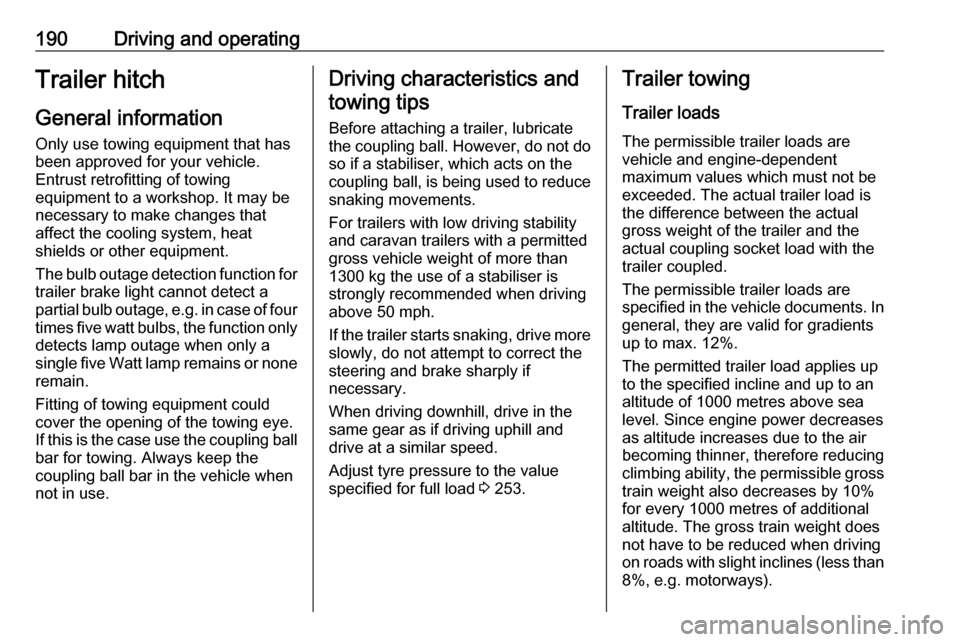

Stowage of coupling ball bar

The bag with the coupling ball bar is

stowed in the rear stowage

compartment on the floor.

Place the strap through the rear

lashing eye, wrap around twice and

tighten the strap to secure the bag.

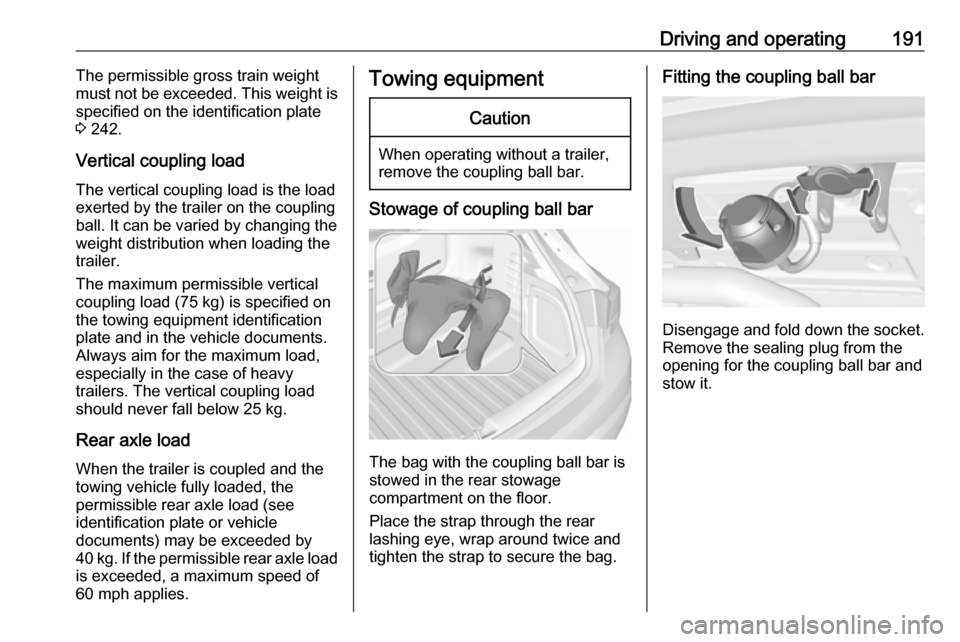

Fitting the coupling ball bar

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Page 194 of 267

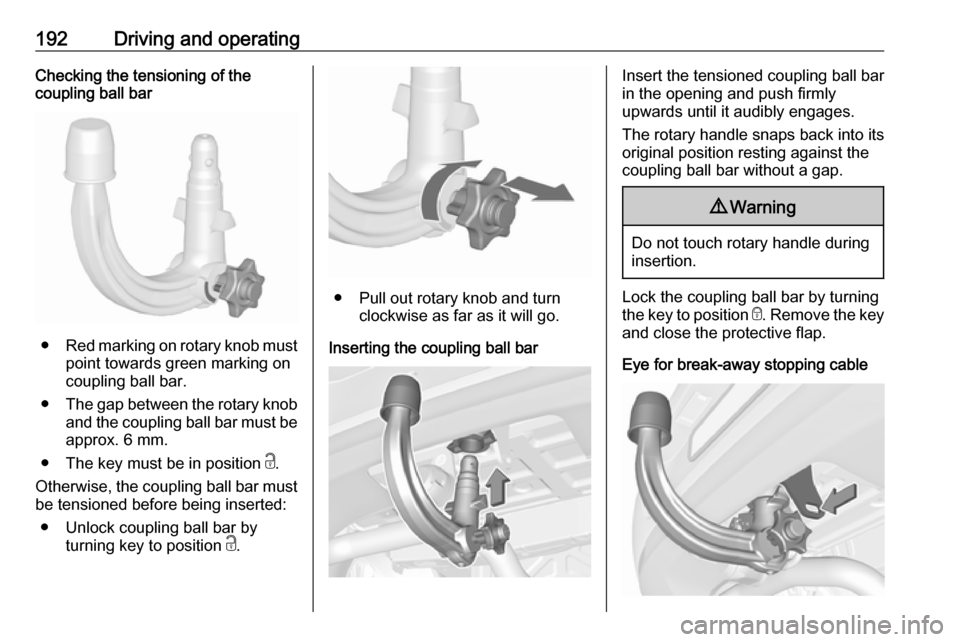

192Driving and operatingChecking the tensioning of the

coupling ball bar

● Red marking on rotary knob must

point towards green marking on

coupling ball bar.

● The gap between the rotary knob

and the coupling ball bar must be approx. 6 mm.

● The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

● Unlock coupling ball bar by turning key to position c.

● Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Page 195 of 267

Driving and operating193Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is

correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

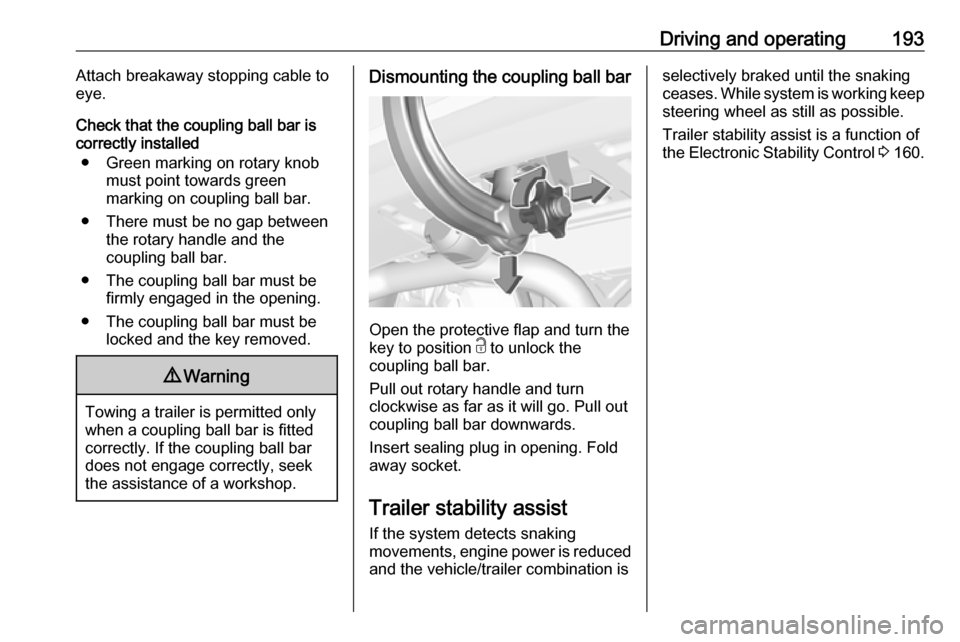

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep steering wheel as still as possible.

Trailer stability assist is a function of

the Electronic Stability Control 3 160.

Page 196 of 267

194Vehicle careVehicle careGeneral Information...................194

Accessories and vehicle modifications .......................... 194

Vehicle storage ........................195

End-of-life vehicle recovery .....195

Vehicle checks ........................... 196

Performing work ......................196

Bonnet ..................................... 196

Engine oil ................................. 197

Engine coolant ......................... 198

Washer fluid ............................ 199

Brakes ..................................... 199

Brake fluid ............................... 199

Vehicle battery ......................... 200

Diesel fuel system bleeding .....201

Wiper blade replacement ........202

Bulb replacement .......................202

Halogen headlights ..................202

Fog lights ................................. 204

Tail lights ................................. 205

Side turn signal lights ..............208

Number plate light ...................209

Interior lights ............................ 210

Instrument panel illumination ...210Electrical system ........................210

Fuses ....................................... 210

Engine compartment fuse box . 211

Instrument panel fuse box .......213

Load compartment fuse box ....215

Vehicle tools .............................. 217

Tools ........................................ 217

Wheels and tyres .......................217

Winter tyres ............................. 217

Tyre designations ....................218

Tyre pressure .......................... 218

Tyre pressure monitoring system .................................... 219

Tread depth ............................. 223

Changing tyre and wheel size . 224 Wheel covers ........................... 224

Tyre chains .............................. 224

Tyre repair kit .......................... 224

Wheel changing .......................227

Spare wheel ............................ 230

Jump starting ............................. 232

Towing ....................................... 234

Towing the vehicle ...................234

Towing another vehicle ...........235

Appearance care .......................236

Exterior care ............................ 236

Interior care ............................. 237General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the

electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Page 215 of 267

Vehicle care213No.Circuit46Instrument cluster47Steering column lock48Rear wiper49Heated mirror50LED headlight right/Automatic

headlight range adjustment

right51Left low beam (LED)52Engine control module/Trans‐

mission control module53–54Windscreen wiper55–56–57–

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

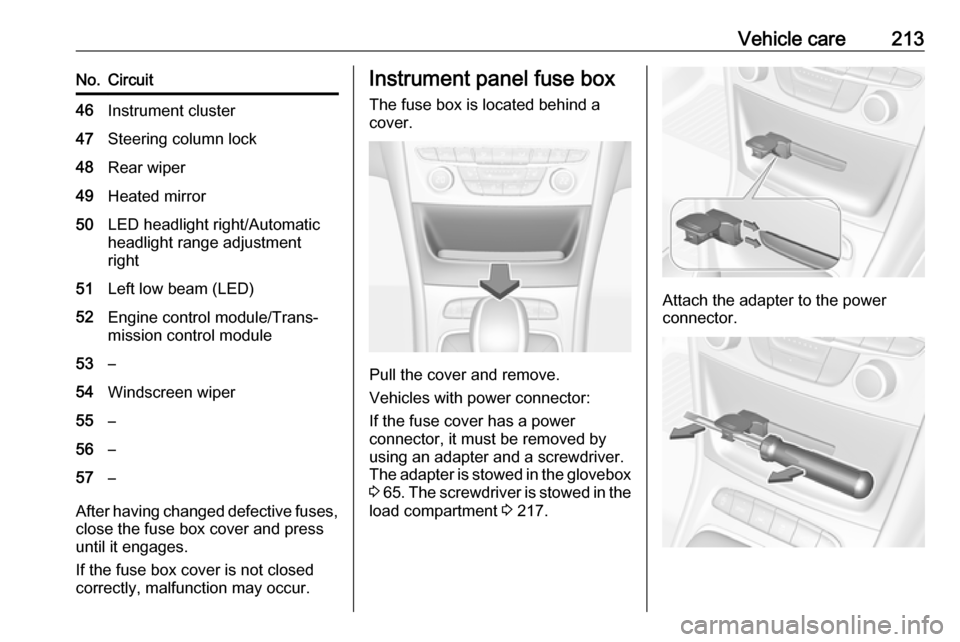

Instrument panel fuse box

The fuse box is located behind a

cover.

Pull the cover and remove.

Vehicles with power connector:

If the fuse cover has a power

connector, it must be removed by

using an adapter and a screwdriver.

The adapter is stowed in the glovebox 3 65 . The screwdriver is stowed in the

load compartment 3 217.

Attach the adapter to the power

connector.

Page 219 of 267

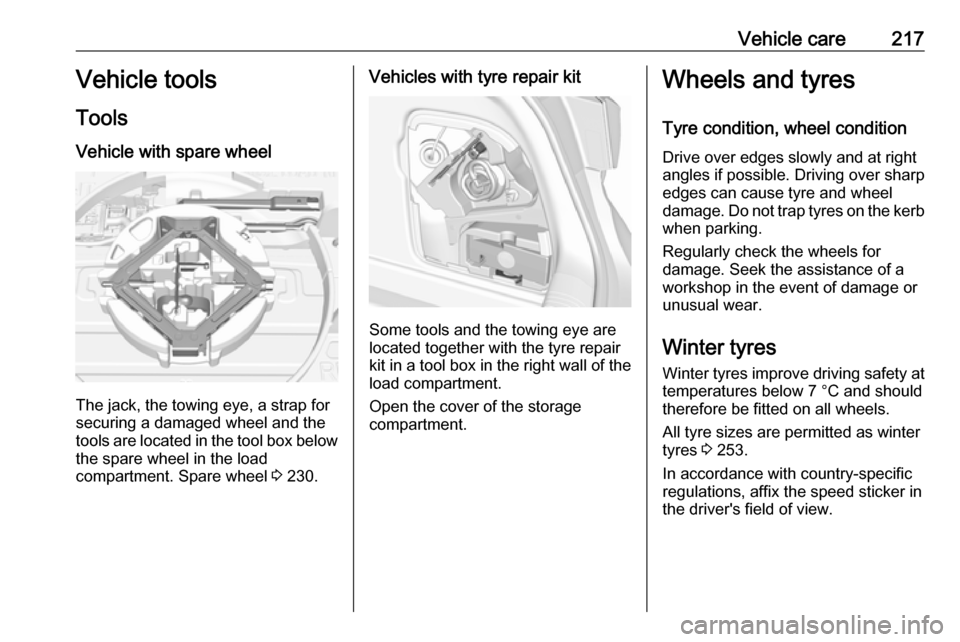

Vehicle care217Vehicle tools

Tools

Vehicle with spare wheel

The jack, the towing eye, a strap for

securing a damaged wheel and the tools are located in the tool box below the spare wheel in the load

compartment. Spare wheel 3 230.

Vehicles with tyre repair kit

Some tools and the towing eye are

located together with the tyre repair

kit in a tool box in the right wall of the

load compartment.

Open the cover of the storage

compartment.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 253.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Page 227 of 267

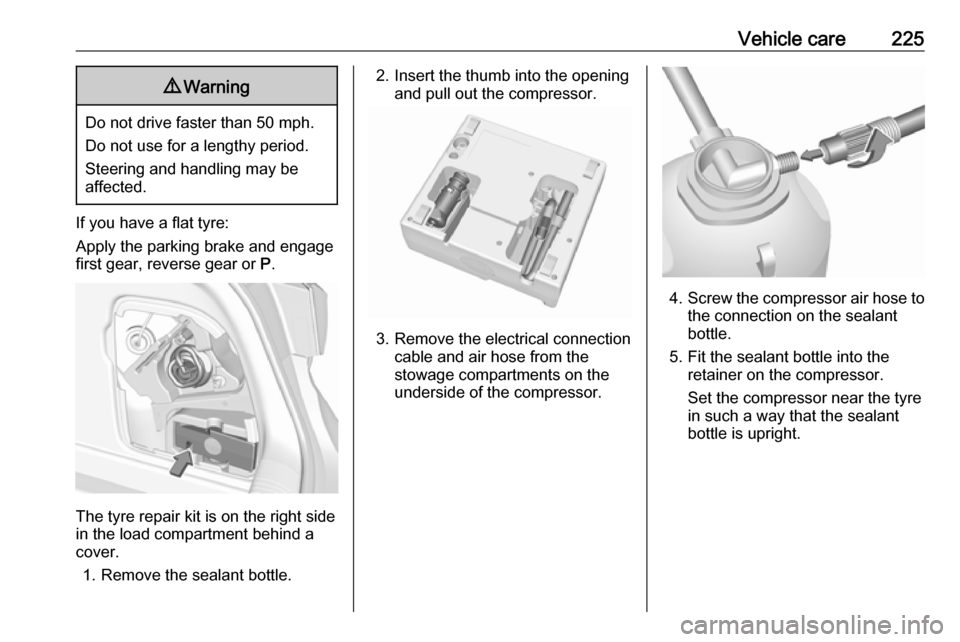

Vehicle care2259Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is on the right side

in the load compartment behind a

cover.

1. Remove the sealant bottle.

2. Insert the thumb into the opening and pull out the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

Page 229 of 267

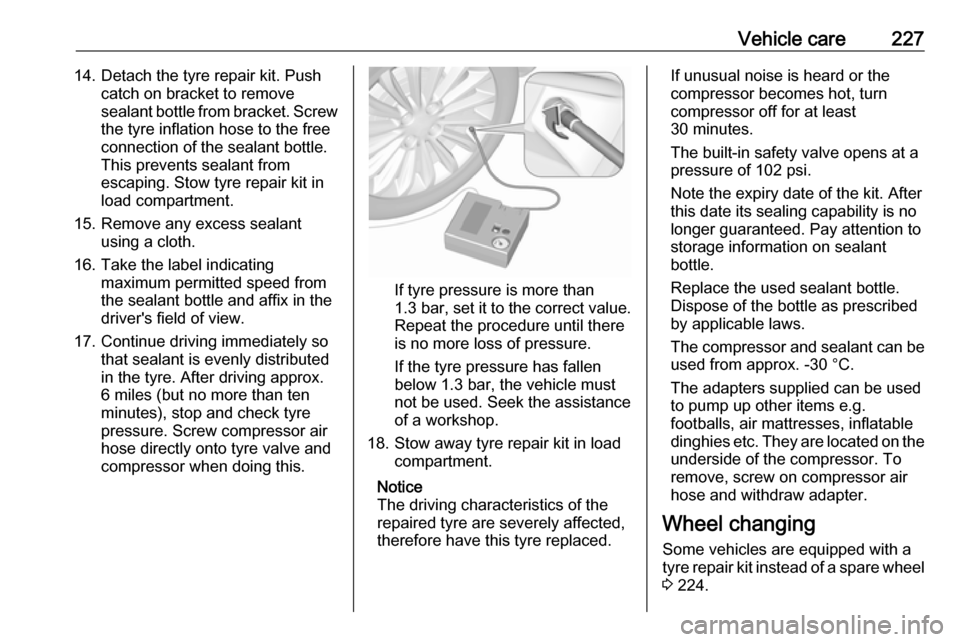

Vehicle care22714. Detach the tyre repair kit. Pushcatch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

6 miles (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Notice

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 102 psi.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 224.