battery VAUXHALL ASTRA J 2016.75 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.75, Model line: ASTRA J, Model: VAUXHALL ASTRA J 2016.75Pages: 291, PDF Size: 8.73 MB

Page 164 of 291

162Driving and operating● The charging level of the vehiclebattery is below a defined level.

● The brake vacuum is not sufficient.

● The vehicle is driven at least at walking speed.

● The climate control system requests an engine start.

● The air conditioning is manually switched on.

If the bonnet is not fully closed, a

warning message is displayed in the

Driver Information Centre.

If an electrical accessory, e.g. a

portable CD player, is connected to

the power outlet, a brief power drop during the restart might be noticeable.

Parking9 Warning

● Do not park the vehicle on an

easily ignitable surface. The

high temperature of the

exhaust system could ignite the

surface.

● Always apply the parking brake. Activate the manual

parking brake without pressing the release button. Apply as

firmly as possible on a downhill slope or uphill slope. Depress

brake pedal at the same time to

reduce operating force.

For vehicles with electric

parking brake, pull switch m for

a minimum of one second until

control indicator m illuminates

constantly and electric parking

brake is applied 3 109.

● Switch off the engine. ● If the vehicle is on a level surface or uphill slope, engage

first gear or set the selector

lever to position P before

removing the ignition key or

switching off ignition on

vehicles with power button. On

an uphill slope, turn the front

wheels away from the kerb.

If the vehicle is on a downhill

slope, engage reverse gear or

set the selector lever to positionP before removing the ignition

key or switching off ignition on

vehicles with power button.

Turn the front wheels towards

the kerb.

● Close the windows and the sunroof.

● Remove the ignition key from the ignition switch or switch off

ignition on vehicles with power

button. Turn the steering wheel until the steering wheel lock is

felt to engage.

For vehicles with automatic

transmission, the key can only

be removed when the selector

lever is in position P.

For vehicles with manual

transmission automated, the key can only be removed from

the ignition switch when the

parking brake is applied.

Page 170 of 291

168Driving and operatingFault

In the event of a fault a message is

displayed in the Driver Information Centre. Vehicle messages 3 120.

Electronic transmission control

enables only fourth gear. The

transmission no longer shifts

automatically.

Have the cause of the fault remedied

by a workshop.

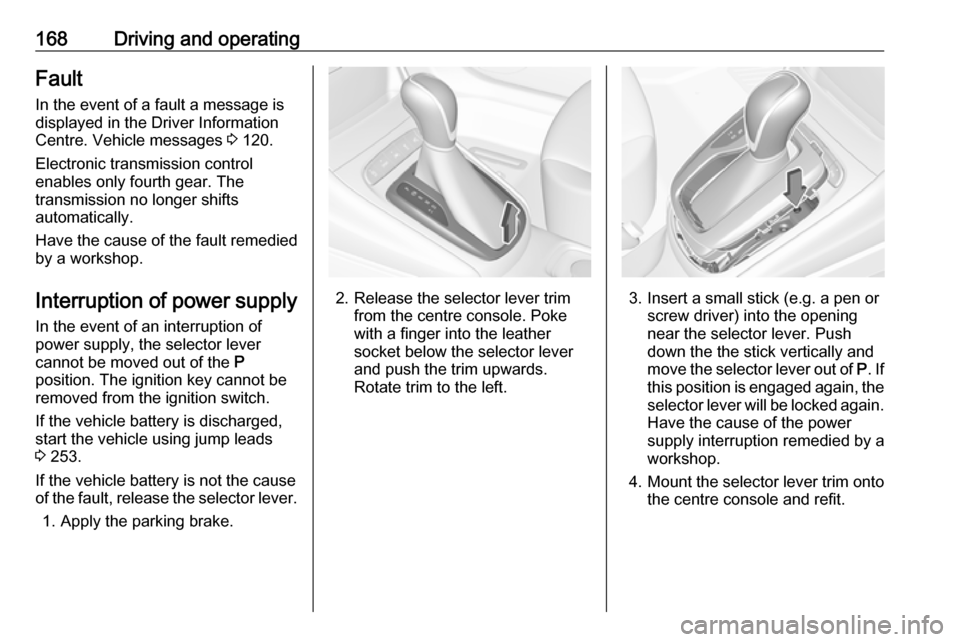

Interruption of power supply In the event of an interruption of

power supply, the selector lever

cannot be moved out of the P

position. The ignition key cannot be

removed from the ignition switch.

If the vehicle battery is discharged,

start the vehicle using jump leads

3 253.

If the vehicle battery is not the cause

of the fault, release the selector lever.

1. Apply the parking brake.

2. Release the selector lever trim from the centre console. Poke

with a finger into the leather

socket below the selector lever

and push the trim upwards.

Rotate trim to the left.3. Insert a small stick (e.g. a pen or screw driver) into the opening

near the selector lever. Push

down the the stick vertically and

move the selector lever out of P. If

this position is engaged again, the selector lever will be locked again.

Have the cause of the power

supply interruption remedied by a

workshop.

4. Mount the selector lever trim onto

the centre console and refit.

Page 176 of 291

174Driving and operating3 109. The electric parking brake

operates automatically with

adequate force.

Before leaving the vehicle, check

the electric parking brake status.

Control indicator m 3 109.

The electric parking brake can always

be activated, even if the ignition is off.

Do not operate electric parking brake

system too often without engine

running as this will discharge the

vehicle battery.

Releasing

Switch on ignition. Keep foot brake

pedal depressed and then push

switch m.

Drive away function

Vehicles with manual transmission:

Depressing the clutch pedal and then

slightly releasing the clutch pedal and slightly depressing the accelerator

pedal releases the electric parking

brake automatically. This is not

possible when switch m is pulled at

the same time.

Vehicles with automatic transmission

or manual transmission automated:

Engaging D and then depressing the

accelerator pedal releases the

electric parking brake automatically.

This is not possible when switch m is

pulled at the same time.

Dynamic braking when vehicle is

moving

When the vehicle is moving and the

switch m is kept pulled, the electric

parking brake system will decelerate

the vehicle, but will not apply

statically.

As soon as the switch m is released,

dynamic braking will be stopped.

Automatic applying

If the vehicle is equipped with

automatic transmission and adaptive

cruise control is active, electric

parking brake is applied automatically when vehicle is stopped by the

system for more than two minutes.

Parking brake releases automatically

after moving off.Functionality check

When the vehicle is not moving, the

electric parking brake might be

applied automatically. This is done to

check the system.

Fault

Failure mode of electric parking brake

is indicated by a control indicator j

and by a vehicle message which is

displayed in the Driver Information

Centre. Vehicle messages 3 120.

Apply electric parking brake: pull and

hold the switch m for more than

five seconds. If control indicator m

illuminates, electric parking brake is

applied.

Release electric parking brake: push and hold the switch m for more than

two seconds. If control indicator m

extinguishes, electric parking brake is

released.

Control indicator m flashes: electric

parking brake is not fully applied or

released. When continuously

flashing, release electric parking

brake and retry applying.

Page 213 of 291

Vehicle care211Vehicle careGeneral Information...................211

Accessories and vehicle modifications .......................... 211

Vehicle storage ........................212

End-of-life vehicle recovery .....212

Vehicle checks ........................... 213

Performing work ......................213

Bonnet ..................................... 213

Engine oil ................................. 214

Engine coolant ......................... 215

Washer fluid ............................ 216

Brakes ..................................... 216

Brake fluid ............................... 216

Vehicle battery ......................... 217

Diesel fuel system bleeding .....218

Wiper blade replacement ........219

Bulb replacement .......................219

Halogen headlights ..................219

Fog lights ................................. 221

Tail lights ................................. 222

Side turn signal lights ..............228

Number plate light ...................229

Interior lights ............................ 229

Instrument panel illumination ...229Electrical system ........................230

Fuses ....................................... 230

Engine compartment fuse box . 231

Instrument panel fuse box .......233

Load compartment fuse box ....235

Vehicle tools .............................. 236

Tools ........................................ 236

Wheels and tyres .......................238

Winter tyres ............................. 238

Tyre designations ....................238

Tyre pressure .......................... 238

Tyre pressure monitoring system .................................... 239

Tread depth ............................. 243

Changing tyre and wheel size . 244 Wheel covers ........................... 244

Tyre chains .............................. 244

Tyre repair kit .......................... 245

Wheel changing .......................248

Spare wheel ............................ 250

Jump starting ............................. 253

Towing ....................................... 255

Towing the vehicle ...................255

Towing another vehicle ...........256

Appearance care .......................257

Exterior care ............................ 257

Interior care ............................. 258General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the

electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Page 214 of 291

212Vehicle careVehicle storageStorage for a long period of timeIf the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir. ● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 219 of 291

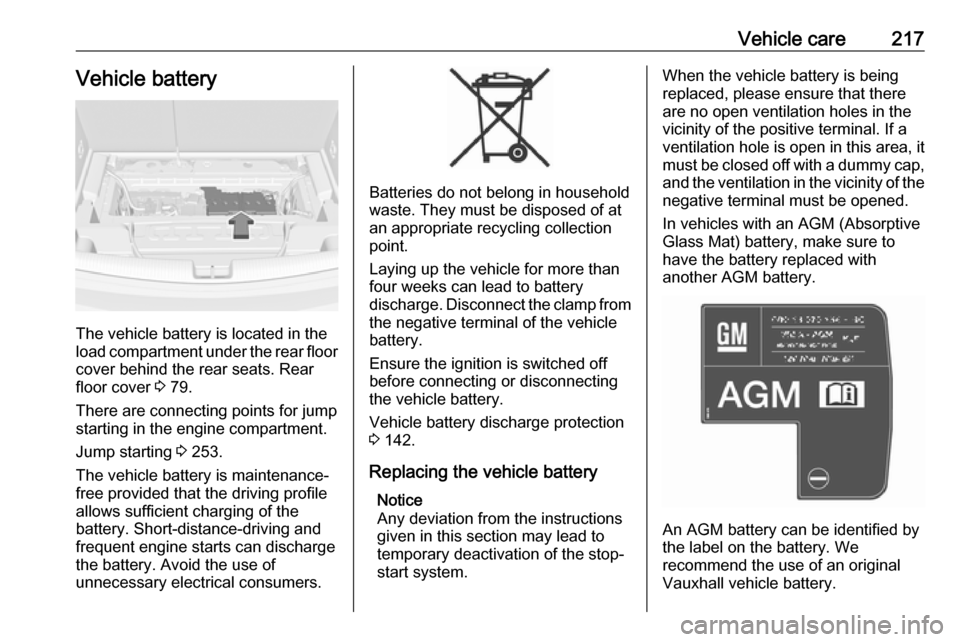

Vehicle care217Vehicle battery

The vehicle battery is located in the

load compartment under the rear floor cover behind the rear seats. Rear

floor cover 3 79.

There are connecting points for jump starting in the engine compartment.

Jump starting 3 253.

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to battery

discharge. Disconnect the clamp from

the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Vehicle battery discharge protection

3 142.

Replacing the vehicle battery Notice

Any deviation from the instructions

given in this section may lead to

temporary deactivation of the stop-

start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap, and the ventilation in the vicinity of the

negative terminal must be opened.

In vehicles with an AGM (Absorptive

Glass Mat) battery, make sure to

have the battery replaced with

another AGM battery.

An AGM battery can be identified by

the label on the battery. We

recommend the use of an original

Vauxhall vehicle battery.

Page 220 of 291

218Vehicle careNotice

Using an AGM vehicle battery

different from the original Vauxhall vehicle battery may result in a lower performance.

We recommend that you have the vehicle battery replaced by a

workshop.

Stop-start system 3 159.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 253.

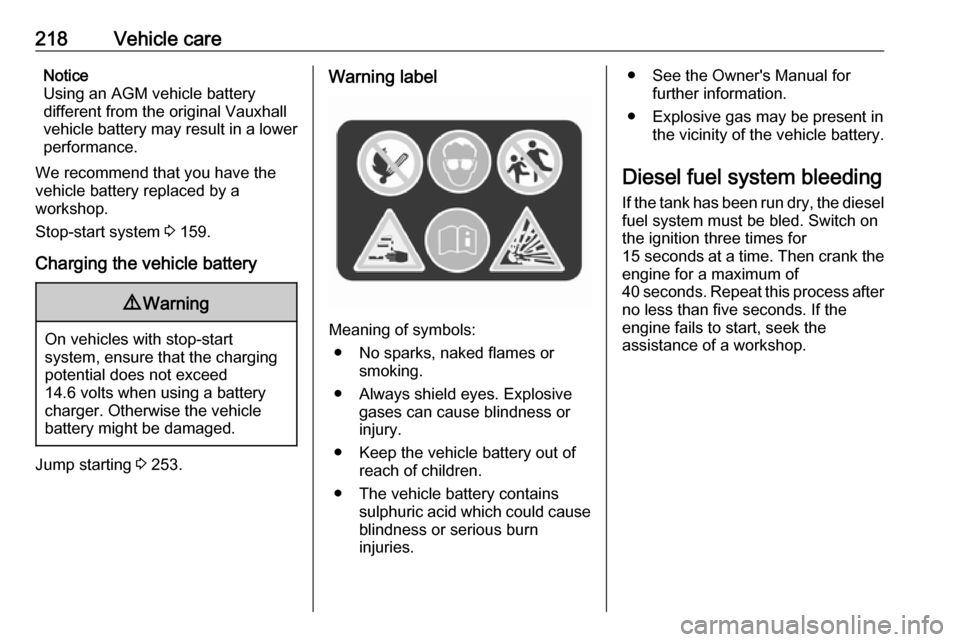

Warning label

Meaning of symbols:

● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

● The vehicle battery contains sulphuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding If the tank has been run dry, the diesel

fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of 40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

assistance of a workshop.

Page 248 of 291

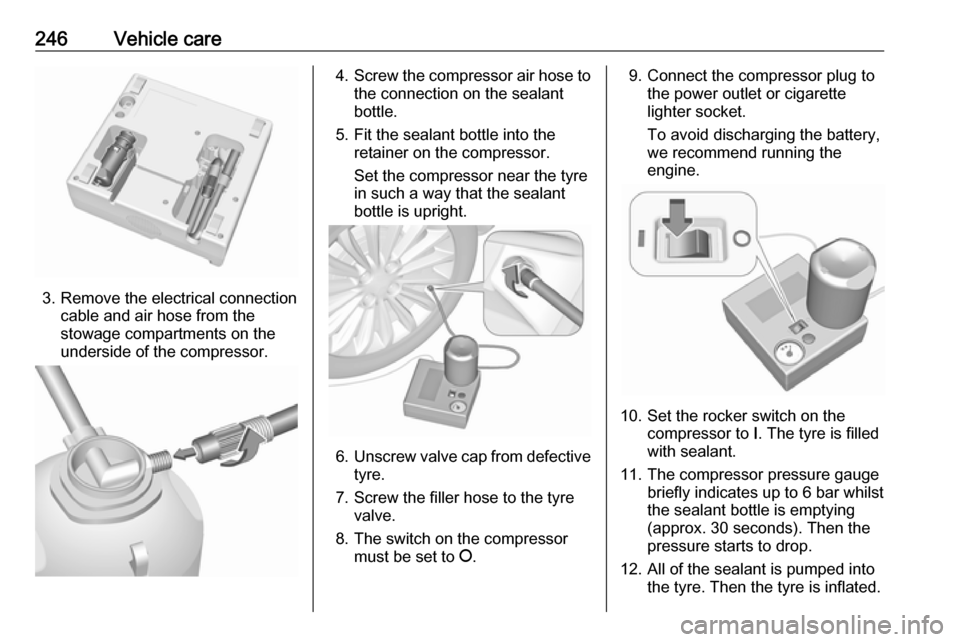

246Vehicle care

3. Remove the electrical connectioncable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

Page 255 of 291

Vehicle care253Spare wheel with directional tyreIf possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Drive particularly carefully on wet

and snow-covered road

surfaces.Jump starting

The vehicle battery is located in the

load compartment under a cover. There are connecting points for jump

starting in the engine compartment.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.

Do not start with quick charger.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

● A discharged vehicle battery can already freeze at a temperature

of 0 °C. Defrost the frozen vehicle

battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a vehicle battery.

● Use a booster vehicle battery with the same voltage (12 Volt).

Its capacity (Ah) must not be

much less than that of the

discharged vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

Page 256 of 291

254Vehicle care● Do not lean over the vehiclebattery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection cap of your vehicle in

the engine compartment and of

the booster vehicle battery.Lead connection order:

1. Connect the red lead to the positive terminal of the booster

vehicle battery.

2. Connect the other end of the red lead to the positive terminal of

your vehicle near the fuse box in

the engine compartment.

3. Connect the black lead to the negative terminal of the booster

vehicle battery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of one

minute.3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.