tow VAUXHALL ASTRA J 2018 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: ASTRA J, Model: VAUXHALL ASTRA J 2018Pages: 311, PDF Size: 9.37 MB

Page 226 of 311

224Driving and operating

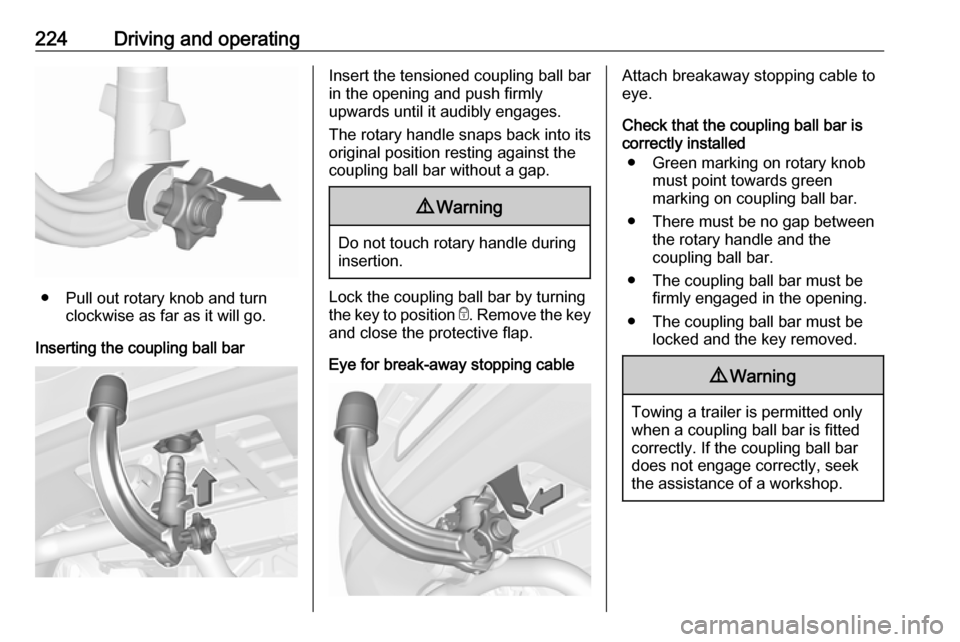

● Pull out rotary knob and turnclockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Page 227 of 311

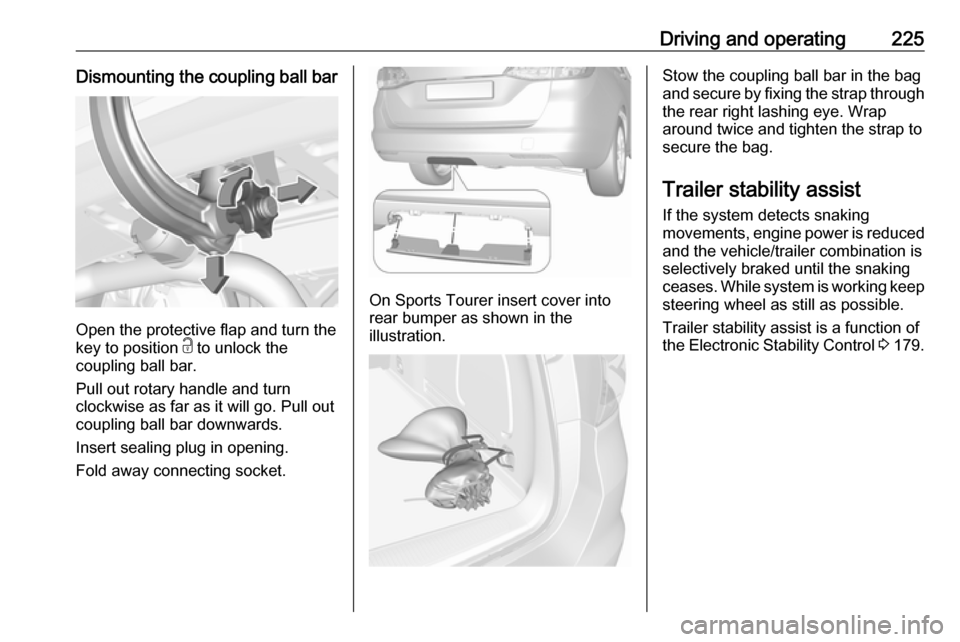

Driving and operating225Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening.

Fold away connecting socket.

On Sports Tourer insert cover into

rear bumper as shown in the

illustration.

Stow the coupling ball bar in the bag

and secure by fixing the strap through the rear right lashing eye. Wrap

around twice and tighten the strap to

secure the bag.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is selectively braked until the snaking

ceases. While system is working keep

steering wheel as still as possible.

Trailer stability assist is a function of

the Electronic Stability Control 3 179.

Page 228 of 311

226Vehicle careVehicle careGeneral Information...................226

Accessories and vehicle modifications .......................... 226

Vehicle storage ........................227

End-of-life vehicle recovery .....227

Vehicle checks ........................... 228

Performing work ......................228

Bonnet ..................................... 228

Engine oil ................................. 229

Engine coolant ......................... 230

Washer fluid ............................ 231

Brakes ..................................... 231

Brake fluid ............................... 231

Vehicle battery ......................... 232

Diesel fuel system bleeding .....233

Wiper blade replacement ........233

Bulb replacement .......................234

Halogen headlights ..................234

Fog lights ................................. 236

Tail lights ................................. 237

Side turn signal lights ..............243

Number plate light ...................243

Interior lights ............................ 244

Instrument panel illumination ...244Electrical system ........................244

Fuses ....................................... 244

Engine compartment fuse box . 245

Instrument panel fuse box .......247

Load compartment fuse box ....249

Vehicle tools .............................. 251

Tools ........................................ 251

Wheels and tyres .......................253

Winter tyres ............................. 253

Tyre designations ....................253

Tyre pressure .......................... 253

Tyre pressure monitoring system .................................... 254

Tread depth ............................. 258

Changing tyre and wheel size . 259 Wheel covers ........................... 259

Tyre chains .............................. 259

Tyre repair kit .......................... 260

Wheel changing .......................263

Spare wheel ............................ 265

Jump starting ............................. 268

Towing ....................................... 270

Towing the vehicle ...................270

Towing another vehicle ...........271

Appearance care .......................272

Exterior care ............................ 272

Interior care ............................. 273General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Vauxhall. Furthermore,

such changes may affect driver

assistance systems, may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the operating permit,

impacting the validity of your vehicle

registration.

Page 249 of 311

Vehicle care247No.Circuit33Anti theft warning34Horn35Power outlet load compartment36Right high beam (Halogen)/

Right low beam (LED)37Left high beam (Halogen)38LED headlight/Automatic head‐

light range adjustment39Front fog light40OnStar41Water in fuel sensor/Water

pump42Manual headlight range adjust‐

ment43Fuel pump44Rear view camera/Inside rear

view mirror/Trailer module45LED headlight left/Automatic

headlight range adjustment leftNo.Circuit46Instrument cluster47Steering column lock48Rear wiper49–50LED headlight right/Automatic

headlight range adjustment

right51Left low beam (LED)52Engine control module/Trans‐

mission control module53–54Windscreen wiper55Diesel exhaust system56–57–

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Instrument panel fuse box

The fuse box is located behind a

cover.

Pull the cover and remove.

Vehicles with power connector:

If the fuse cover has a power

connector, it must be removed by

using an adapter and a screwdriver.

The adapter is stowed in the glovebox 3 70 . The screwdriver is stowed in the

load compartment 3 251.

Page 253 of 311

Vehicle care251No.Circuit16Trailer outlet17Trailer outlet18–19–20–21Electrical rear seat folding22Power tailgate

After having changed defective fuses,

close the fuse box cover and press

until it engages.

Additional fuses are located near the

vehicle battery.

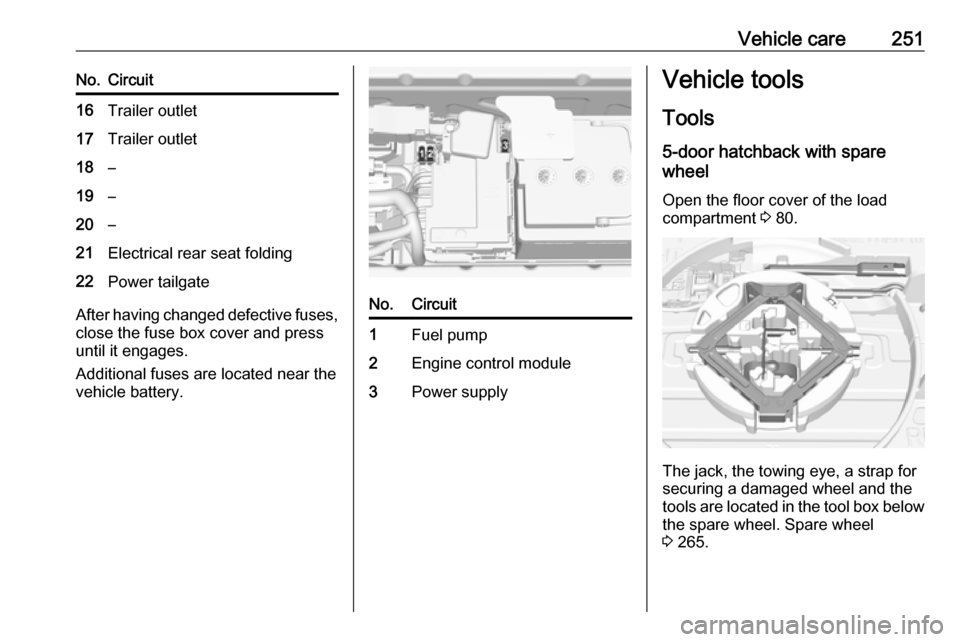

No.Circuit1Fuel pump2Engine control module3Power supplyVehicle tools

Tools

5-door hatchback with spare

wheel

Open the floor cover of the load

compartment 3 80.

The jack, the towing eye, a strap for

securing a damaged wheel and the

tools are located in the tool box below the spare wheel. Spare wheel

3 265.

Page 254 of 311

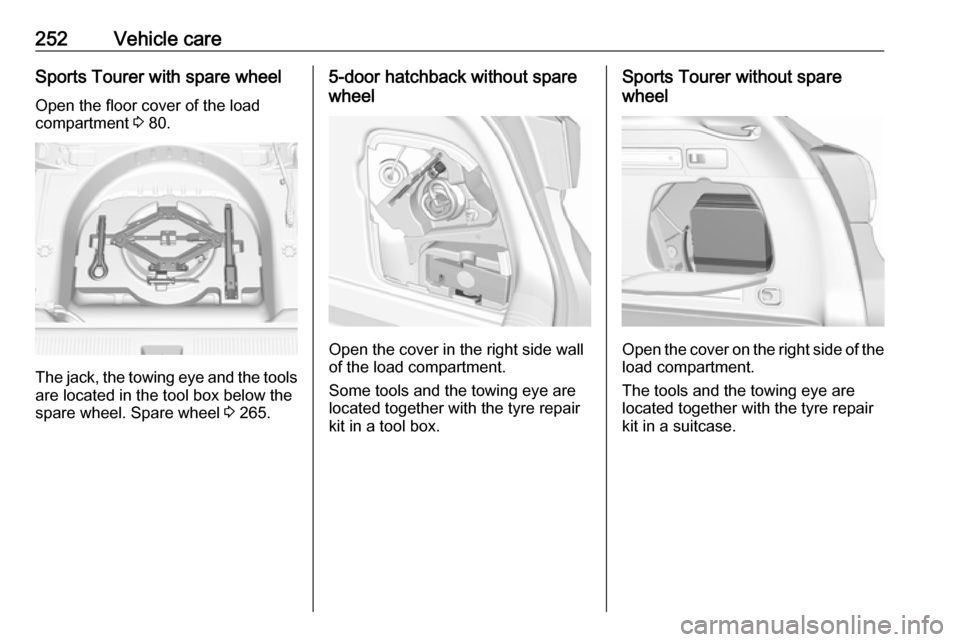

252Vehicle careSports Tourer with spare wheel

Open the floor cover of the load

compartment 3 80.

The jack, the towing eye and the tools

are located in the tool box below the

spare wheel. Spare wheel 3 265.

5-door hatchback without spare

wheel

Open the cover in the right side wall

of the load compartment.

Some tools and the towing eye are

located together with the tyre repair

kit in a tool box.

Sports Tourer without spare

wheel

Open the cover on the right side of the load compartment.

The tools and the towing eye are

located together with the tyre repair

kit in a suitcase.

Page 263 of 311

Vehicle care261

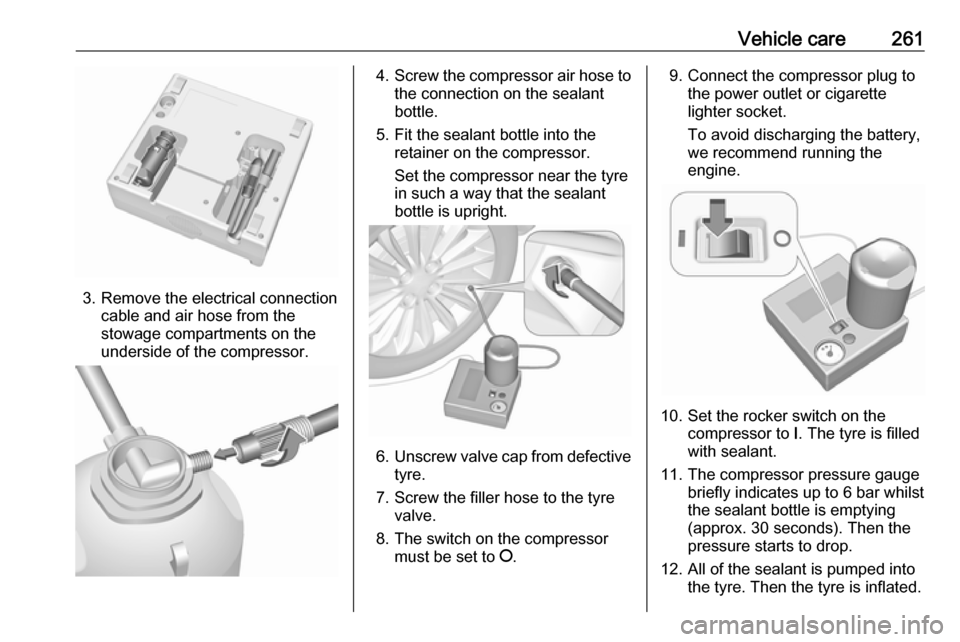

3. Remove the electrical connectioncable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

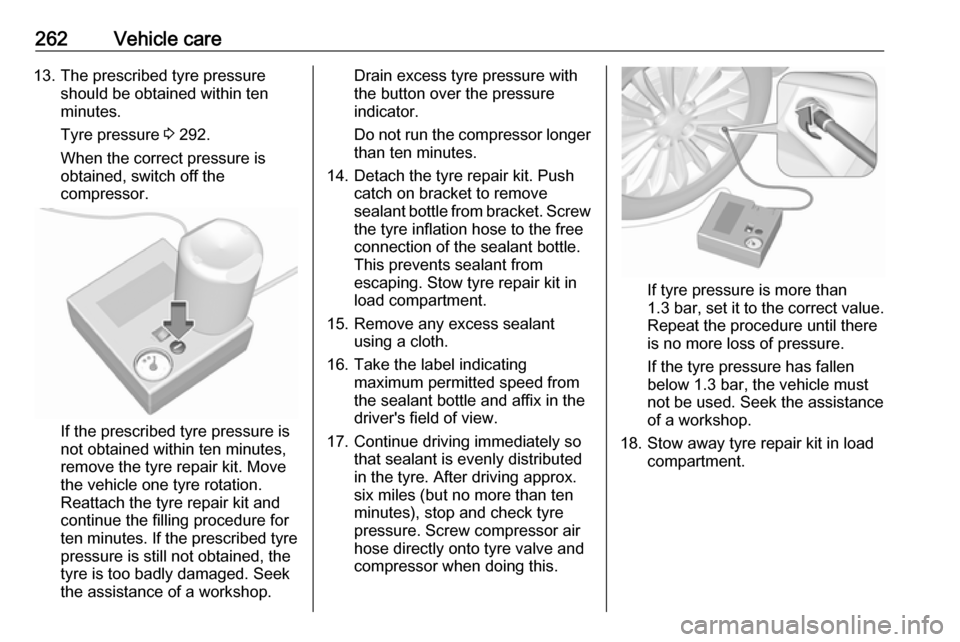

Page 264 of 311

262Vehicle care13. The prescribed tyre pressureshould be obtained within ten

minutes.

Tyre pressure 3 292.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor longer

than ten minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

six miles (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Page 267 of 311

Vehicle care265ground. Do not raise the jack any

further.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 265.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 265

and the vehicle tools 3 251.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

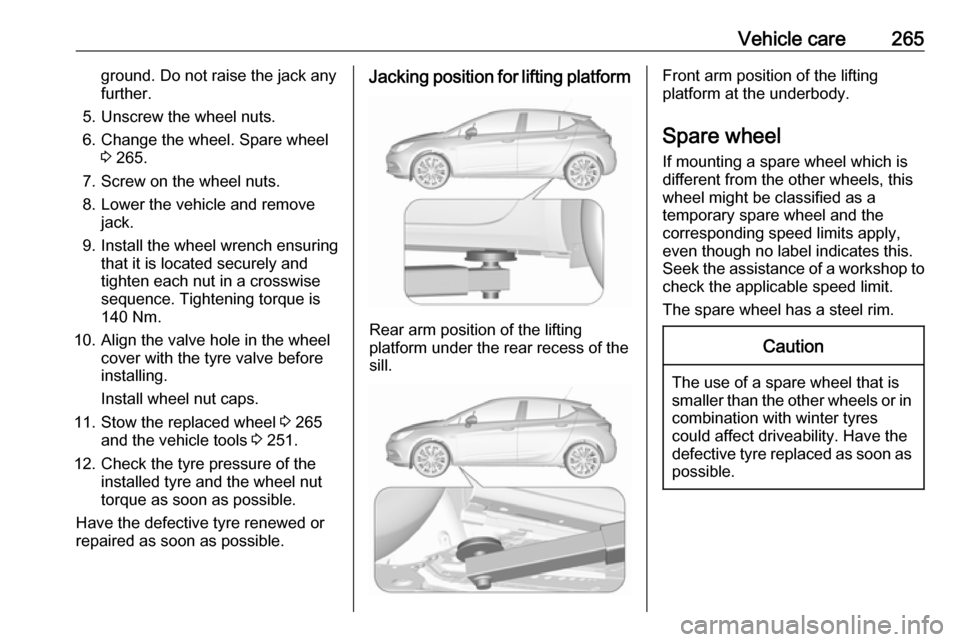

Have the defective tyre renewed or repaired as soon as possible.Jacking position for lifting platform

Rear arm position of the lifting

platform under the rear recess of the

sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Page 268 of 311

266Vehicle care

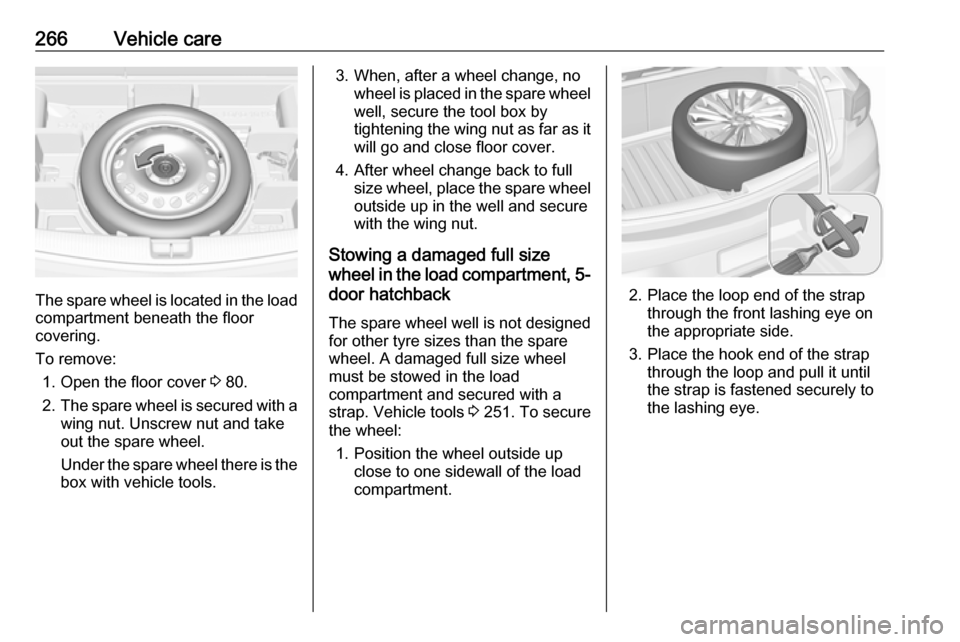

The spare wheel is located in the load

compartment beneath the floor

covering.

To remove: 1. Open the floor cover 3 80.

2. The spare wheel is secured with a

wing nut. Unscrew nut and take

out the spare wheel.

Under the spare wheel there is the

box with vehicle tools.

3. When, after a wheel change, no wheel is placed in the spare wheel

well, secure the tool box by

tightening the wing nut as far as it will go and close floor cover.

4. After wheel change back to full size wheel, place the spare wheel

outside up in the well and secure

with the wing nut.

Stowing a damaged full size

wheel in the load compartment, 5- door hatchback

The spare wheel well is not designed for other tyre sizes than the spare

wheel. A damaged full size wheel

must be stowed in the load

compartment and secured with a

strap. Vehicle tools 3 251. To secure

the wheel:

1. Position the wheel outside up close to one sidewall of the load

compartment.

2. Place the loop end of the strap through the front lashing eye on

the appropriate side.

3. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.