lock VAUXHALL ASTRA K 2019.5 Manual PDF

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2019.5, Model line: ASTRA K, Model: VAUXHALL ASTRA K 2019.5Pages: 311, PDF Size: 9.6 MB

Page 220 of 311

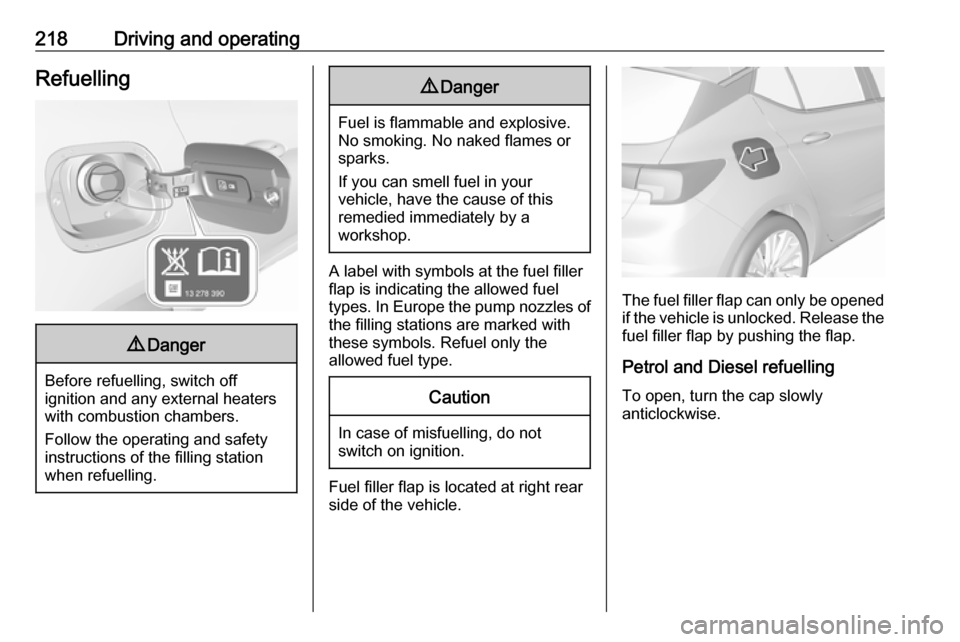

218Driving and operatingRefuelling9Danger

Before refuelling, switch off

ignition and any external heaters

with combustion chambers.

Follow the operating and safety

instructions of the filling station

when refuelling.

9 Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

A label with symbols at the fuel filler

flap is indicating the allowed fuel

types. In Europe the pump nozzles of the filling stations are marked with

these symbols. Refuel only the

allowed fuel type.

Caution

In case of misfuelling, do not

switch on ignition.

Fuel filler flap is located at right rear

side of the vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.

Petrol and Diesel refuelling To open, turn the cap slowly

anticlockwise.

Page 221 of 311

Driving and operating219

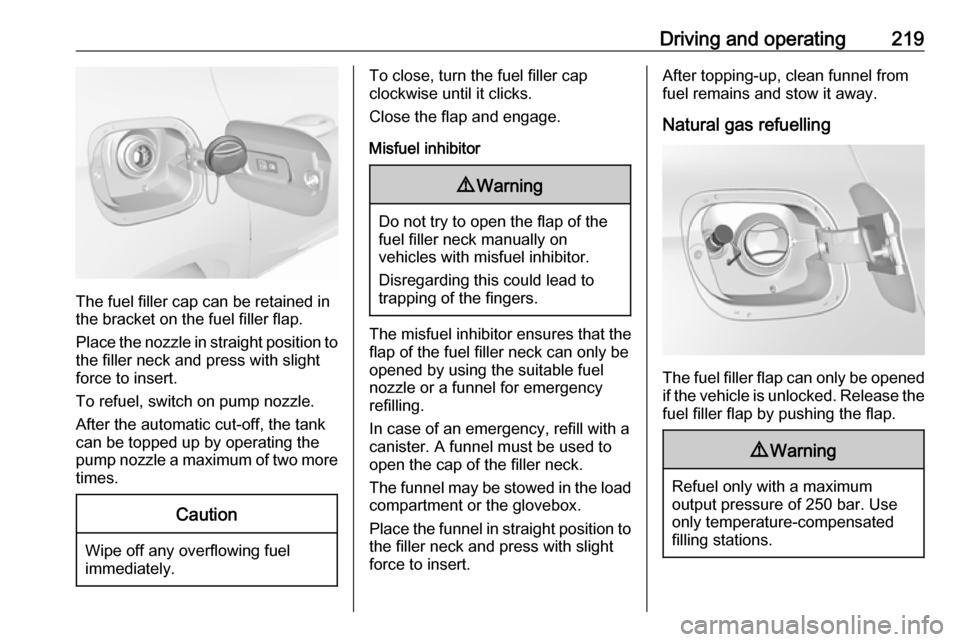

The fuel filler cap can be retained in

the bracket on the fuel filler flap.

Place the nozzle in straight position to the filler neck and press with slight

force to insert.

To refuel, switch on pump nozzle.

After the automatic cut-off, the tank can be topped up by operating the

pump nozzle a maximum of two more

times.

Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and engage.

Misfuel inhibitor9 Warning

Do not try to open the flap of the

fuel filler neck manually on

vehicles with misfuel inhibitor.

Disregarding this could lead to

trapping of the fingers.

The misfuel inhibitor ensures that the flap of the fuel filler neck can only be

opened by using the suitable fuel

nozzle or a funnel for emergency

refilling.

In case of an emergency, refill with a

canister. A funnel must be used to

open the cap of the filler neck.

The funnel may be stowed in the load

compartment or the glovebox.

Place the funnel in straight position to the filler neck and press with slight

force to insert.

After topping-up, clean funnel from

fuel remains and stow it away.

Natural gas refuelling

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.

9 Warning

Refuel only with a maximum

output pressure of 250 bar. Use

only temperature-compensated

filling stations.

Page 225 of 311

Driving and operating223Checking the tensioning of the

coupling ball bar

● Red marking on rotary knob must

point towards green marking on

coupling ball bar.

● The gap between the rotary knob

and the coupling ball bar must be approx. 6 mm.

● The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

● Unlock coupling ball bar by turning key to position c.

● Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Page 226 of 311

224Driving and operatingIllustration shows 5-door hatchback.

Illustration shows Sports Tourer.

Attach breakaway stopping cable to eye.

Check that the coupling ball bar is

correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening.

Fold away connecting socket.

On Sports Tourer insert cover into

rear bumper as shown in the

illustration.

Page 229 of 311

Vehicle care227Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Note that all systems are

not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Initialize the power

windows 3 40.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.

Page 237 of 311

Vehicle care2351. Rotate the cap anticlockwise andremove it.

2. Disengage spring clip from retainer by pulling. Withdraw the

bulb holder from the reflector

housing.

3. Detach the bulb from the bulb holder and replace the bulb.

4. Insert the bulb holder, engaging the two lugs into the reflector

housing and rotate clockwise to

secure.

5. Push spring clip back in place. 6. Fit the cap and rotate clockwise.

High beam (2)

1. Rotate the cap anticlockwise and remove it.

Page 238 of 311

236Vehicle care2. Disengage spring clip fromretainer by moving it forward and

to the side. Swivel spring clip

downwards.

3. Withdraw the bulb holder from the

reflector housing.

4. Detach the bulb from the bulb holder and replace the bulb.

5. Insert the bulb holder and install spring clip.

Fit the cap and rotate clockwise.

Front turn lights

In case of defective LEDs, have them replaced by a workshop.

Side light

In case of defective LEDs, have them replaced by a workshop.

Daytime running light

In case of defective LEDs, have them replaced by a workshop.

Front fog lights The bulbs are accessible from the

underside of the vehicle.

1. Turn the bulb holder anti- clockwise and remove it from the

reflector housing.

2. Disengage the bulb socket from the plug connector by pressing

the retaining lug.

3. Remove and replace the bulb socket with bulb and attach the

plug connector.

4. Insert the bulb socket into the reflector housing by turning

clockwise and engage.

Page 245 of 311

Vehicle care243Depending on the version, tail lights

are designed as LEDs. In case of failure, have LEDs replaced by aworkshop.

Side turn lights

To replace bulb, remove lamp

housing:

1. Slide the lamp housing forward and remove it at the back.

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder and replace it.

4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring.

Page 246 of 311

244Vehicle care

2. Remove lamp downwards, takingcare not to pull on the cable.

3. Remove bulb holder from lamp housing by turning anticlockwise.

4. Pull bulb from bulb holder and replace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Some versions have LED number

plate lights. In case of defective

LEDs, have them replaced by a

workshop.

Interior lights

Have the following bulbs replaced by

a workshop:

● courtesy light, reading lights

● load compartment light

● instrument panel illuminationElectrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

● engine compartment

● instrument panel

● load compartment

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognized by its melted wire.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Page 248 of 311

246Vehicle careNo.Circuit1Starter2Starter3Exhaust sensor4Engine control module5Engine functions / Aeroshutter6Transmission control module7Forward collision alert / Adap‐

tive Cruise Control8Engine control module9Climate control system10Diesel exhaust system11Tailgate locking system / Trans‐ mission12Seat lumbar massage13After boil pump14Diesel exhaust system15Exhaust sensor16Fuel injectionNo.Circuit17Fuel injection18Diesel exhaust system19Diesel exhaust system20–21–22ABS23Washer system for windscreen

and rear window24Washer Headlamp25Diesel fuel heating26Transmission control module27Power tailgate module28–29Heated rear window30Mirror defrost31Anti theft warning module