engine VAUXHALL CASCADA 2015 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: CASCADA, Model: VAUXHALL CASCADA 2015Pages: 251, PDF Size: 7.47 MB

Page 190 of 251

188Vehicle care

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled to the wiper arm and push until it

engages.

Lower wiper arm carefully.Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.Halogen headlights

Bi-Halogen Headlight (1) with one

bulb for low and high beam.

Sidelight/Daytime running light (2) .

Page 198 of 251

196Vehicle care

5. Insert bulb holder into lamphousing and turn clockwise.

6. Insert lamp into bumper and let engage.

Interior lights Courtesy light, reading lights

Have bulbs replaced by a workshop.

Load compartment light

Have bulbs replaced by a workshop.

Instrument panel

illumination

Have bulbs replaced by a workshop.Electrical system

Fuses

Data on the replacement fuse must match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

■ in the front left of the engine compartment,

■ in left-hand drive vehicles, in the interior behind the storage

compartment, or, in right-hand

drive vehicles, behind the

glovebox,

■ behind a cover on the left side of the

load compartment.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognized by its melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

Page 199 of 251

Vehicle care197

Place the fuse extractor on the

various types of fuse from the top or

side, and withdraw fuse.

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover and fold it

upwards until it stops. Remove the

cover vertically upwards.

Page 200 of 251

198Vehicle care

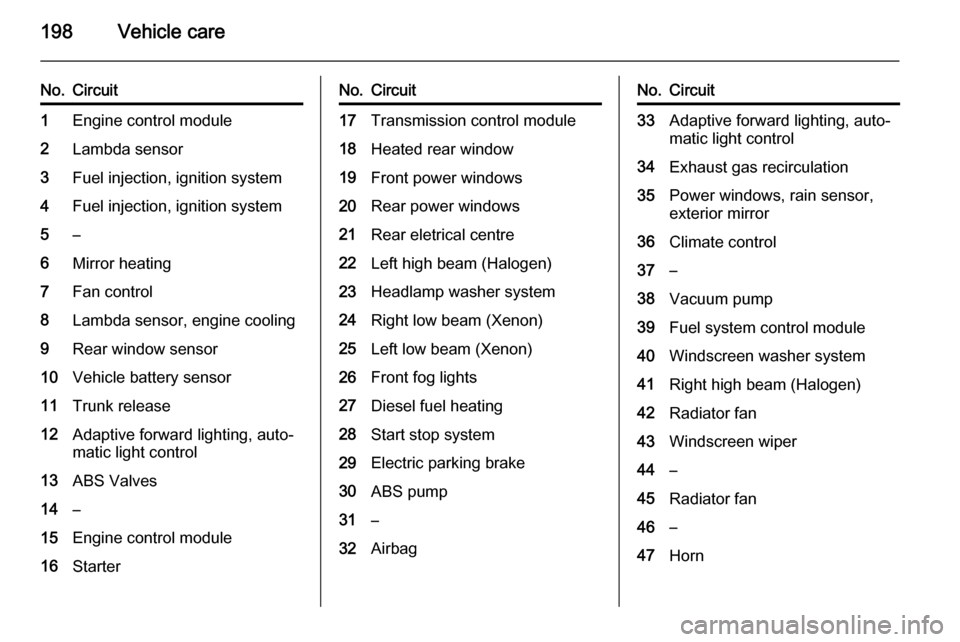

No.Circuit1Engine control module2Lambda sensor3Fuel injection, ignition system4Fuel injection, ignition system5–6Mirror heating7Fan control8Lambda sensor, engine cooling9Rear window sensor10Vehicle battery sensor11Trunk release12Adaptive forward lighting, auto‐

matic light control13ABS Valves14–15Engine control module16StarterNo.Circuit17Transmission control module18Heated rear window19Front power windows20Rear power windows21Rear eletrical centre22Left high beam (Halogen)23Headlamp washer system24Right low beam (Xenon)25Left low beam (Xenon)26Front fog lights27Diesel fuel heating28Start stop system29Electric parking brake30ABS pump31–32AirbagNo.Circuit33Adaptive forward lighting, auto‐

matic light control34Exhaust gas recirculation35Power windows, rain sensor,

exterior mirror36Climate control37–38Vacuum pump39Fuel system control module40Windscreen washer system41Right high beam (Halogen)42Radiator fan43Windscreen wiper44–45Radiator fan46–47Horn

Page 201 of 251

Vehicle care199

No.Circuit48Radiator fan49Fuel pump50Headlamp levelling, adaptive

forward lighting51–52Auxiliary heater, diesel engine53Transmission control module,

Engine control module54Vacuum pump, instrument

panel cluster, heating ventila‐

tion, air conditioning system

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

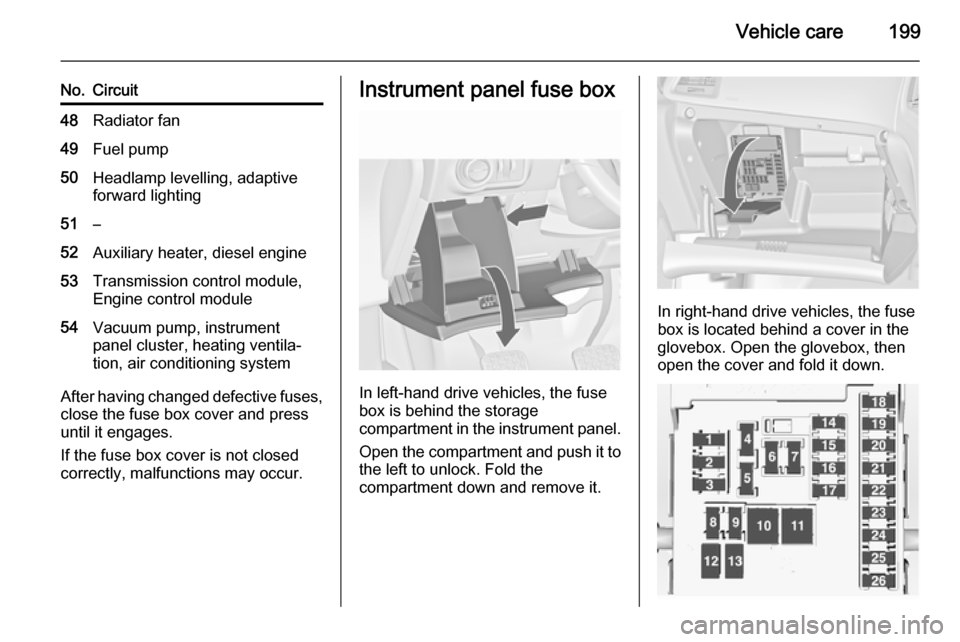

Instrument panel fuse box

In left-hand drive vehicles, the fuse

box is behind the storage

compartment in the instrument panel.

Open the compartment and push it to the left to unlock. Fold the

compartment down and remove it.

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox, then

open the cover and fold it down.

Page 205 of 251

Vehicle care203Wheels and tyresWheels

On vehicles with Diesel engines no steel rims and only special, for this

vehicle approved alloy wheels are

permitted.

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres Winter tyres improve driving safety at

temperatures below 7 °C and should

therefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 238.Use tyre size 225/55 R17 only as

winter tyres.

On vehicles with Diesel engines, no

steel rims and only special, vehicle-

approved alloy wheels are permitted.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Tyre designations E.g. 235/55 R 17 99 V235=Tyre width, mm55=Cross-section ratio (tyre height

to tyre width), %R=Belt type: RadialRF=Type: RunFlat17=Wheel diameter, inches99=Load index e.g. 99 is

equivalent to 775 kgV=Speed code letter

Speed code letter:

Q=up to 100 mphS=up to 112 mphT=up to 118 mphH=up to 130 mphV=up to 150 mphW=up to 168 mphDirectional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure Check the pressure of cold tyres atleast every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 238.

Page 206 of 251

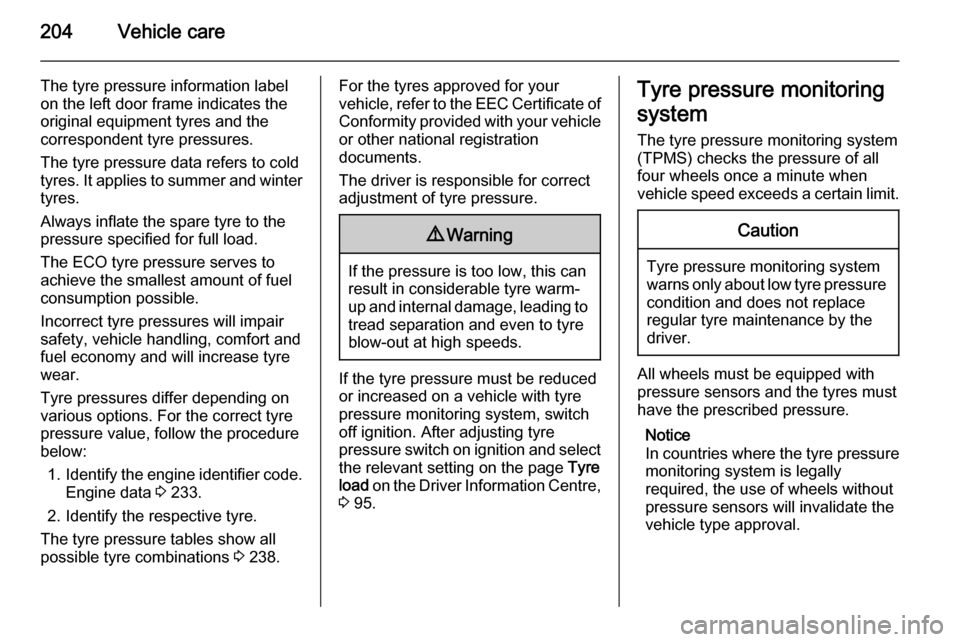

204Vehicle care

The tyre pressure information labelon the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 233.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 238.For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition. After adjusting tyre

pressure switch on ignition and select the relevant setting on the page Tyre

load on the Driver Information Centre,

3 95.

Tyre pressure monitoring

system The tyre pressure monitoring system

(TPMS) checks the pressure of all

four wheels once a minute when

vehicle speed exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

Page 212 of 251

210Vehicle care

On another version, a bag with thetyre repair kit is fixed at the left rear

lashing eye in the load compartment.

1. Take the tyre repair kit from the load compartment.

2. Remove the compressor.

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the vehicle

battery, we recommend running

the engine.

Page 220 of 251

218Vehicle careJump startingDo not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

■ Never expose the battery to naked flames or sparks.

■ A discharged vehicle battery can already freeze at a temperature of

0 °C. Defrost the frozen battery

before connecting jump leads.

■ Wear eye protection and protective

clothing when handling a battery.

■ Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

■ Use jump leads with insulated terminals and a cross section of at

least 16 mm 2

(25 mm 2

for diesel

engines).

■ Do not disconnect the discharged battery from the vehicle.

■ Switch off all unnecessary electrical

consumers.

■ Do not lean over the battery during jump starting.

■ Do not allow the terminals of one lead to touch those of the other

lead.■ The vehicles must not come into contact with each other during the

jump starting process.

■ Apply the parking brake, transmission in neutral, automatictransmission in P.

■ Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

Page 221 of 251

Vehicle care219

3. Connect the black lead to thenegative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Insert a screwdriver in the slot at the

lower part of the cap. Release the cap

by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 202.