engine VAUXHALL CASCADA 2016.5 Manual PDF

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.5, Model line: CASCADA, Model: VAUXHALL CASCADA 2016.5Pages: 263, PDF Size: 7.72 MB

Page 216 of 263

214Vehicle care8.Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate the sensor

identification code has been

matched to the left side rear tyre,

and the tyre pressure sensor

matching process is no longer

active.

13. Turn off the ignition.14. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

information label.

15. Ensure the tyre loading status is set according to the selected

pressure 3 95.

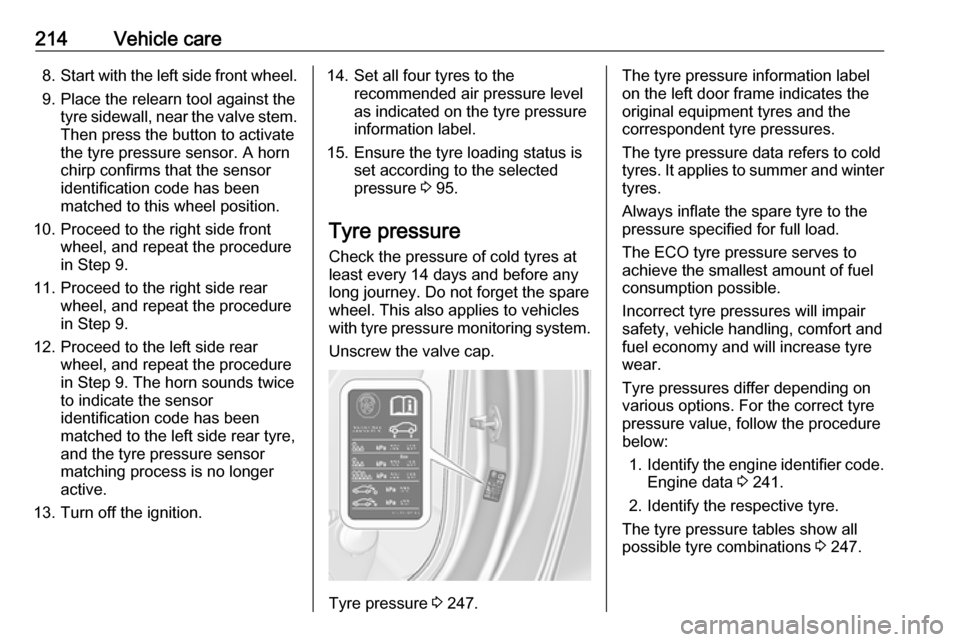

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 247.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 241.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 247.

Page 220 of 263

218Vehicle care

4.Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the vehicle

battery, we recommend running

the engine.10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 247 . When the correct pressure

is obtained, switch off the

compressor.

Page 228 of 263

226Vehicle careJump startingDo not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

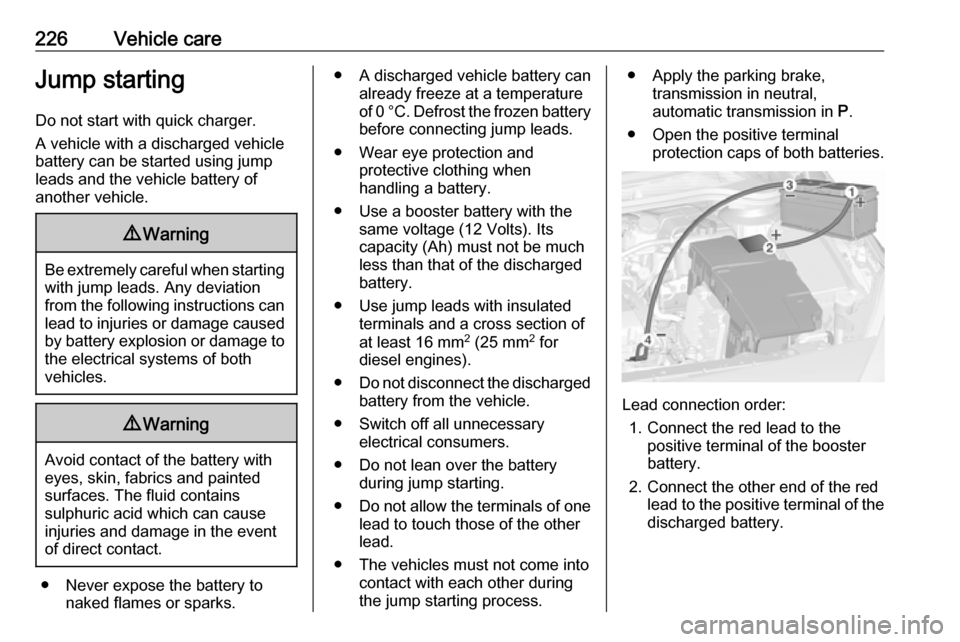

the jump starting process.● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

Page 229 of 263

Vehicle care2273. Connect the black lead to thenegative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Insert a screwdriver in the slot at the

lower part of the cap. Release the cap

by carefully moving the screwdriver

downwards.

The towing eye is stowed with the

vehicle tools 3 209.

Page 230 of 263

228Vehicle care

Screw in the towing eye anticlockwise

as far as it will go until it stops in a

horizontal position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows, when soft top is closed.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye

clockwise.

Insert cap at the top and engage

downwards.

Towing another vehicle

Insert a screwdriver in the slot at the

lower bend of the cap. Release the

cap by carefully moving the

screwdriver downwards.

The towing eye is stowed with the

vehicle tools 3 209.

Page 231 of 263

Vehicle care229

Screw in the towing eye anticlockwise

as far as it will go until it stops in a

horizontal position.

The lashing eye at the rear

underneath the vehicle must never be used as a towing eye.

Attach a tow rope – or even better a

tow bar – to the towing eye.

The towing eye must only be used for

towing and not for recovering a

vehicle.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

After towing, unscrew the towing eye clockwise.

Insert cap at the top and engage

downwards.

Appearance care

Exterior care Locks

The locks are lubricated at the factory using a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has a

degreasing effect and impairs lock

function. After using a de-icing agent,

have the locks regreased by a

workshop.

WashingThe paintwork of your vehicle is

exposed to environmental influences,

therefore wash your vehicle regularly.

When using automatic vehicle

washes, we recommend one with

textile brushes and a programme

without wax additives.

When doing a hand wash, use clear

water and a soft brush, cleaning in the

grain direction of the textile hood.

Never use a steam-jet or high-

pressure jet cleaner for the soft top or

the engine compartment.

Page 236 of 263

234Service and maintenanceConfirmations

Confirmation of service is recorded in the Service and Warranty Booklet.The date and mileage is completed

with the stamp and signature of the servicing workshop.

Make sure that the Service and

warranty booklet is completed

correctly as continuous proof of

service is essential if any warranty or goodwill claims are to be met, and is

also a benefit when selling the

vehicle.

Service interval with remaining

engine oil life duration

The service interval is based on

several parameters depending on

usage.

The service display lets you know

when to change the engine oil.

Service display 3 85.Recommended fluids,

lubricants and parts

Recommended fluids andlubricants

Only use products that meet the

recommended specifications.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Dexos is the newest engine oil quality

that provides optimum protection for

petrol and diesel engines. If it is

unavailable, engine oils of other listed qualities must be used.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 238.

Topping up engine oil

Engine oils of different manufacturers

and brands can be mixed as long as

they comply with the required engine

oil quality and viscosity.

Use of engine oil with only

ACEA A1/B1 or only A5/B5 quality is

prohibited, since it can cause long-

term engine damage under certain

operating conditions.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 238.

Additional engine oil additives

The use of additional engine oil

additives could cause damage and

invalidate the warranty.

Page 237 of 263

Service and maintenance235Engine oil viscosity grades

The SAE viscosity grade gives

information on the thickness of the oil.

Multigrade oil is indicated by two

figures, e.g. SAE 5W-30. The first

figure, followed by a W, indicates the

low temperature viscosity and the

second figure the high temperature

viscosity.

Select the appropriate viscosity grade depending on the minimum ambient

temperature 3 238.

All of the recommended viscosity

grades are suitable for high ambient

temperatures.

Coolant and antifreeze

Use only organic acid type-long life

coolant (LLC) antifreeze approved for

the vehicle. Consult a workshop.

The system is factory filled with

coolant designed for excellent

corrosion protection and frost

protection down to approx. -28 °C. In

northern countries with very low

temperatures the factory filled coolant

provides frost protection down to

approx. -37 °C. This concentrationshould be maintained all year round.

The use of additional coolant

additives that intend to give additional

corrosion protection or seal against

minor leaks can cause function

problems. Liability for consequences resulting from the use of additional

coolant additives will be rejected.

Brake and clutch fluidOver time, brake fluid absorbs

moisture which will reduce braking

effectiveness. The brake fluid should

therefore be replaced at the specified interval.

AdBlue

Only use AdBlue to reduce the

nitrogen oxides in the exhaust

emission 3 143.

Page 238 of 263

236Technical dataTechnical dataVehicle identification..................236

Vehicle Identification Number ..236

Identification plate ...................236

Engine identification ................237

Vehicle data ............................... 238

Recommended fluids and lubricants ................................ 238

Engine data ............................. 241

Performance ............................ 242

Vehicle weight ......................... 244

Vehicle dimensions .................244

Capacities ................................ 246

Tyre pressures ........................ 247Vehicle identification

Vehicle IdentificationNumber

The Vehicle Identification Number

may be stamped on the identification plate and on the floor pan, under thefloor covering, visible under a cover.

The Vehicle Identification Number

may be embossed on the instrument

panel, visible through the windscreen,

or in the engine compartment on the

right body panel.

Identification plate

The identification plate is located on

the front left or right door frame.

Page 239 of 263

Technical data237Information on identification label:1:Manufacturer2:Type approval number3:Vehicle Identification Number4:Permissible gross vehicle weight

rating in kg5:Permissible gross train weight

in kg6:Maximum permissible front axle

load in kg7:Maximum permissible rear axle

load in kg8:Vehicle-specific or country-

specific data

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The technical data tables show the

engine identifier code. Engine data

3 241.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.