transmission VAUXHALL CASCADA 2017.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2017.5, Model line: CASCADA, Model: VAUXHALL CASCADA 2017.5Pages: 263, PDF Size: 7.71 MB

Page 207 of 263

Vehicle care205No.Circuit35Power windows, rain sensor,

exterior mirror36Climate control37–38Vacuum pump39Fuel system control module40Windscreen washer system41Right high beam (Halogen)42Radiator fan43Windscreen wiper44–45Radiator fan46–47Horn48Radiator fan49Fuel pump50Headlamp levelling, adaptive

forward lightingNo.Circuit51–52Auxiliary heater, diesel engine53Transmission control module,

Engine control module54Vacuum pump, instrument

panel cluster, heating ventila‐

tion, air conditioning system

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

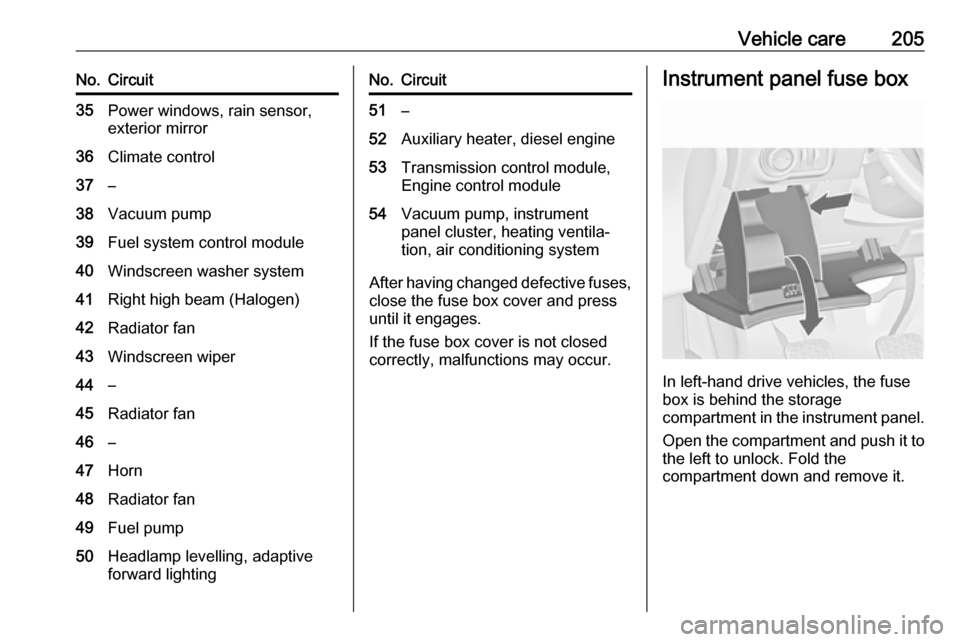

Instrument panel fuse box

In left-hand drive vehicles, the fuse

box is behind the storage

compartment in the instrument panel.

Open the compartment and push it to the left to unlock. Fold the

compartment down and remove it.

Page 213 of 263

Vehicle care211

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 91.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 246.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

After inflating, driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 99.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

wheels the system remains

operational.

The use of commercially-available liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.Each time the tyres are replaced, tyre pressure sensors must be

dismounted and serviced. For the

screwed sensor: replace valve core

and sealing ring. For clipped sensor:

replace complete valve stem.

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 246, and

select the appropriate setting in the

Tyre load menu in the Driver

Information Centre 3 93. This setting

is the reference for the tyre pressure

warnings.

The menu Tyre Load only appears if

the vehicle is at a standstill and the parking brake is applied. On vehicles

with automatic transmission, the

selector lever must be in P.

Page 214 of 263

212Vehicle care

Select:● Light for comfort pressure up to

3 people

● Eco for Eco pressure up to

3 people

● Max for full loading

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating the wheels or exchanging the

complete wheel set and if one or more tyre pressure sensors were replaced.

The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure

sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until the sensor is matched.

Consult your workshop for service.

There are two minutes to match the

first wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching process is as follows:

1. Apply the parking brake.

2. Turn the ignition on.3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this wheel position.

Page 227 of 263

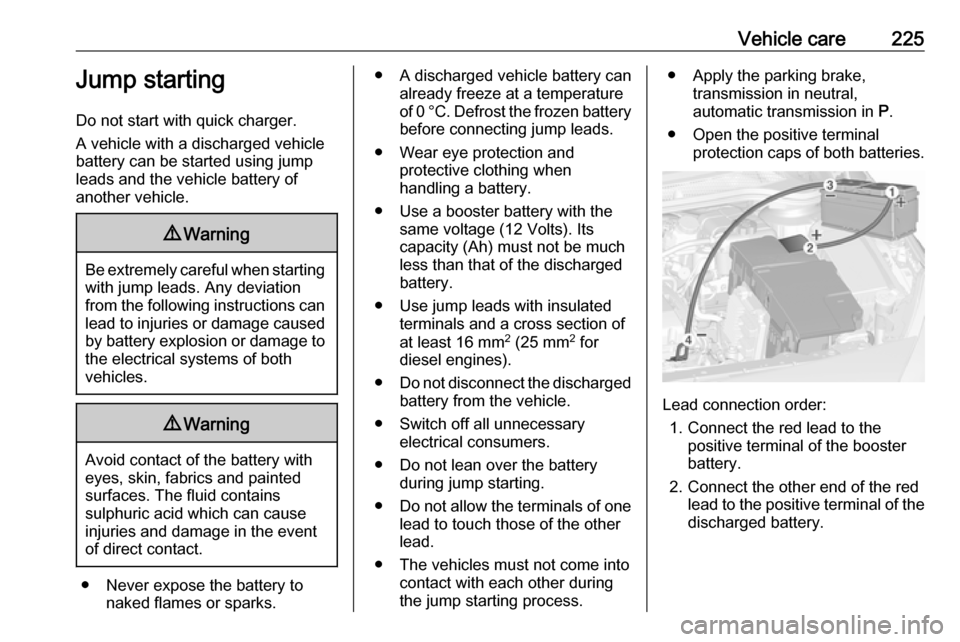

Vehicle care225Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

Page 229 of 263

Vehicle care227

Screw in the towing eye anticlockwise

as far as it will go until it stops in a

horizontal position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows, when soft top is closed.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye

clockwise.

Insert cap at the top and engage

downwards.

Towing another vehicle

Insert a screwdriver in the slot at the

lower bend of the cap. Release the

cap by carefully moving the

screwdriver downwards.

The towing eye is stowed with the

vehicle tools 3 208.

Page 243 of 263

![VAUXHALL CASCADA 2017.5 Owners Guide Technical data241Sales designation2.0 CDTI2.0 CDTIEngine identifier codeA20DTHB20DTHEngineering codeA20DTHB20DTHPiston displacement [cm3

]19561956Engine power [kW]121125at rpm40003750Torque [Nm]350400 VAUXHALL CASCADA 2017.5 Owners Guide Technical data241Sales designation2.0 CDTI2.0 CDTIEngine identifier codeA20DTHB20DTHEngineering codeA20DTHB20DTHPiston displacement [cm3

]19561956Engine power [kW]121125at rpm40003750Torque [Nm]350400](/img/38/19385/w960_19385-242.png)

Technical data241Sales designation2.0 CDTI2.0 CDTIEngine identifier codeA20DTHB20DTHEngineering codeA20DTHB20DTHPiston displacement [cm3

]19561956Engine power [kW]121125at rpm40003750Torque [Nm]350400at rpm1750-25001750-2500Fuel typeDieselDieselPerformanceEngineB14NELB14NETA16XHTB16SHTB16SHLMaximum speed [mph]Manual transmission121129138146–Automatic transmission––––136

Page 244 of 263

![VAUXHALL CASCADA 2017.5 Owners Guide 242Technical dataEngineA20DTHB20DTHMaximum speed [mph]Manual transmission135135Automatic transmission132– VAUXHALL CASCADA 2017.5 Owners Guide 242Technical dataEngineA20DTHB20DTHMaximum speed [mph]Manual transmission135135Automatic transmission132–](/img/38/19385/w960_19385-243.png)

242Technical dataEngineA20DTHB20DTHMaximum speed [mph]Manual transmission135135Automatic transmission132–

Page 245 of 263

![VAUXHALL CASCADA 2017.5 Owners Guide Technical data243Vehicle weightKerb weight, basic model without any optional equipmentEngineManual transmissionAutomatic transmissionwithout/with air conditioning

[kg]B14NEL1701/1714–B14NET1701/1714 VAUXHALL CASCADA 2017.5 Owners Guide Technical data243Vehicle weightKerb weight, basic model without any optional equipmentEngineManual transmissionAutomatic transmissionwithout/with air conditioning

[kg]B14NEL1701/1714–B14NET1701/1714](/img/38/19385/w960_19385-244.png)

Technical data243Vehicle weightKerb weight, basic model without any optional equipmentEngineManual transmissionAutomatic transmissionwithout/with air conditioning

[kg]B14NEL1701/1714–B14NET1701/1714–A16XHT–/1733–B16SHT–/1733–B16SHL––/1733A20DTH–/1816–/1816B20DTH–/1843–

Optional equipment and accessories increase the kerb weight.

Loading information 3 75.

Vehicle dimensionsLength [mm]4696Length max. when operating soft top [mm]4760Width without exterior mirrors [mm]1839Width with two exterior mirrors [mm]2020Height (without antenna) [mm]1443

Page 250 of 263

248Customer informationCustomer

informationCustomer information ................248

Declaration of conformity .........248

Collision damage repair ...........251

Software acknowledgement ....251

Registered trademarks ............253

Vehicle data recording and pri‐

vacy ........................................... 253

Event data recorders ...............253

Radio Frequency Identification (RFID) ..................................... 254Customer information

Declaration of conformity

Transmission systems

This vehicle has systems that

transmit and/or receive radio waves

subject to Directive 1999/5/EC or 2014/53/EU. These systems are incompliance with the essential

requirements and other relevant

provisions of Directive 1999/5/EC or 2014/53/EU. Copies of the original

Declarations of Conformity can be

obtained on our website.

Radar systems

Country-specific Declarations of

Conformity for radar systems are

shown on the following page:

Page 258 of 263

256IndexAAccessories and vehicle modifications .......................... 187

Active head restraints ...................46

Adaptive forward lighting ....92,

114, 196

AdBlue .................................. 91, 141

Adjustable air vents ...................131

Airbag, belt tensioners and roll bars ........................................... 87

Airbag deactivation ................61, 88

Airbag label................................... 57 Airbag system .............................. 57

Air conditioning regular operation ................................ 132

Air conditioning system .............. 124

Air intake .................................... 131

Air vents...................................... 131

Antilock brake system ................ 148

Antilock brake system (ABS) .......89

Anti-theft alarm system ................26

Anti-theft locking system .............. 26

Appearance care ........................228

Armrest ......................................... 53

Armrest storage ........................... 70

Ashtrays ....................................... 82

Automatic anti-dazzle ..................30

Automatic light control ...............111

Automatic locking ........................23

Automatic transmission .............144Autostop..................................... 136

Auxiliary heater ........................... 130

B Battery discharge protection ......122

Battery voltage ........................... 100 BlueInjection ............................... 141

Bonnet ....................................... 188

Brake and clutch fluid .................233

Brake and clutch system .............88

Brake assist ............................... 151

Brake fluid .................................. 192

Brakes ............................... 148, 192

Breakdown.................................. 226

Bulb replacement ....................... 194

C Capacities .................................. 245

Car Pass ...................................... 20

Catalytic converter .....................141

Central locking system ................22

Centre console storage ...............70

Changing tyre and wheel size ...215

Charging system .......................... 88

Child restraint installation locations ................................... 64

Child restraints.............................. 62

Child restraint systems ................62

Cigarette lighter ........................... 82

Climate control ............................. 14

Climate control systems .............123