ECU VAUXHALL CASCADA 2018 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: CASCADA, Model: VAUXHALL CASCADA 2018Pages: 265, PDF Size: 7.81 MB

Page 187 of 265

Driving and operating185Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is

correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

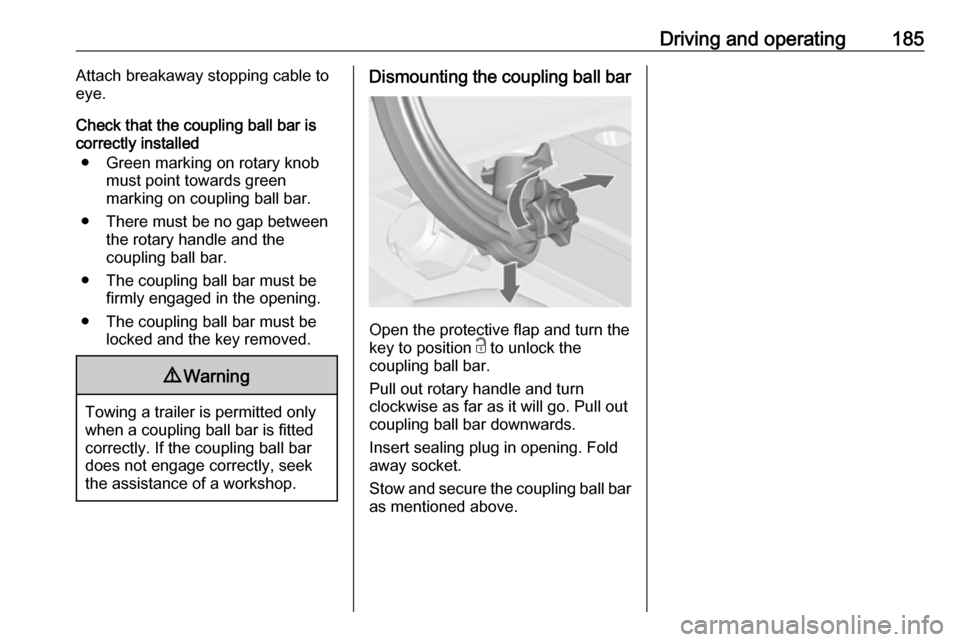

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Stow and secure the coupling ball bar

as mentioned above.

Page 191 of 265

Vehicle care189

Move the safety catch sideways to theleft vehicle side and open the bonnet.

Secure the bonnet support.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing

Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 232.

The maximum engine oil

consumption is 0.6 litres per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Pull out the dipstick, wipe it clean,

reinsert it fully, pull out and read the

engine oil level.

Different dipsticks are used

depending on engine variant.

Page 197 of 265

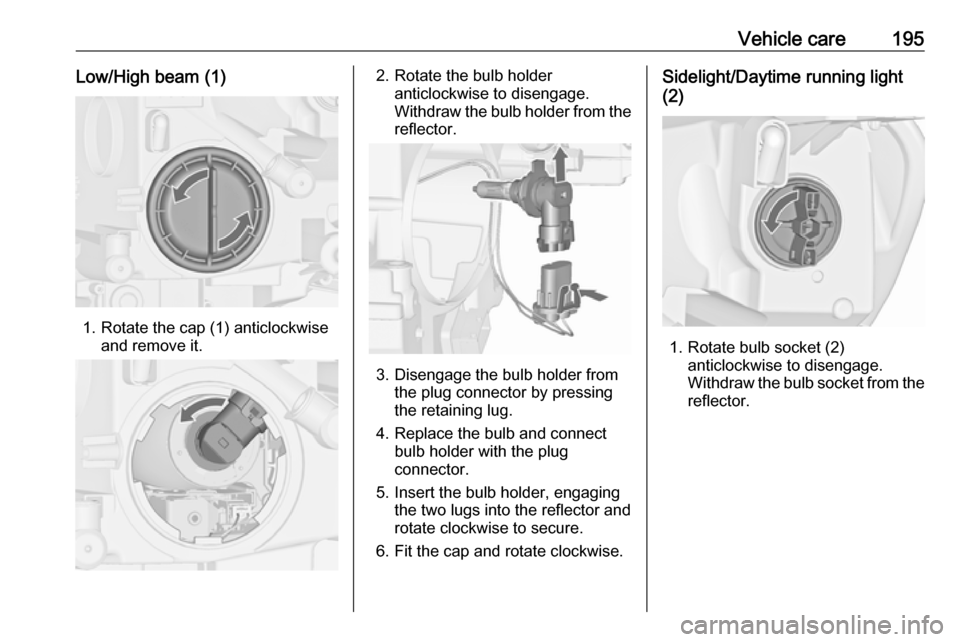

Vehicle care195Low/High beam (1)

1. Rotate the cap (1) anticlockwiseand remove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb holder from the plug connector by pressing

the retaining lug.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

Sidelight/Daytime running light

(2)

1. Rotate bulb socket (2) anticlockwise to disengage.

Withdraw the bulb socket from the

reflector.

Page 199 of 265

Vehicle care1972. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the reflector.

3. Disengage the bulb from the plug connector by pulling.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

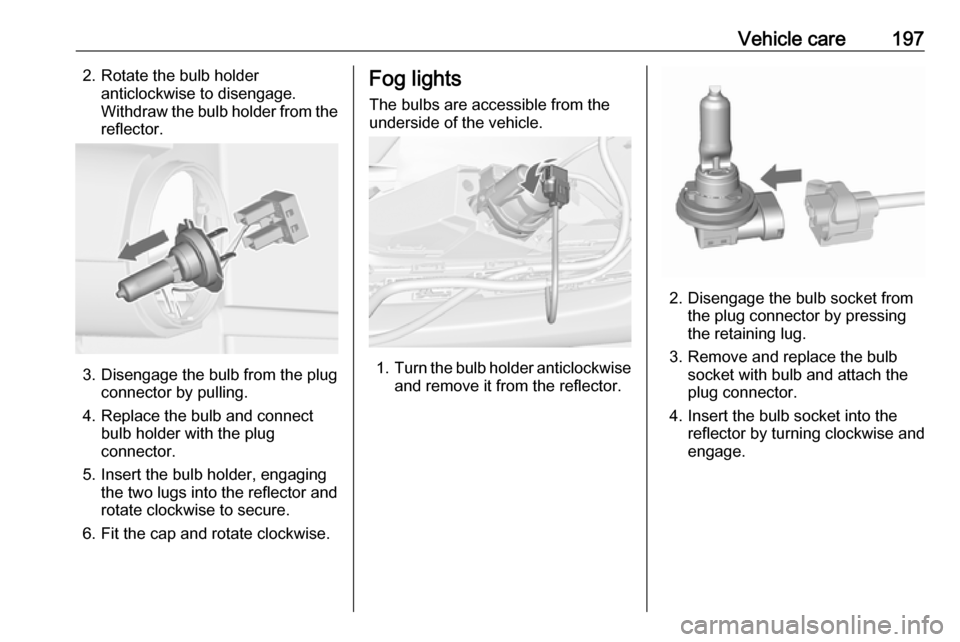

Fog lights

The bulbs are accessible from the

underside of the vehicle.

1. Turn the bulb holder anticlockwise

and remove it from the reflector.

2. Disengage the bulb socket from the plug connector by pressing

the retaining lug.

3. Remove and replace the bulb socket with bulb and attach the

plug connector.

4. Insert the bulb socket into the reflector by turning clockwise and

engage.

Page 210 of 265

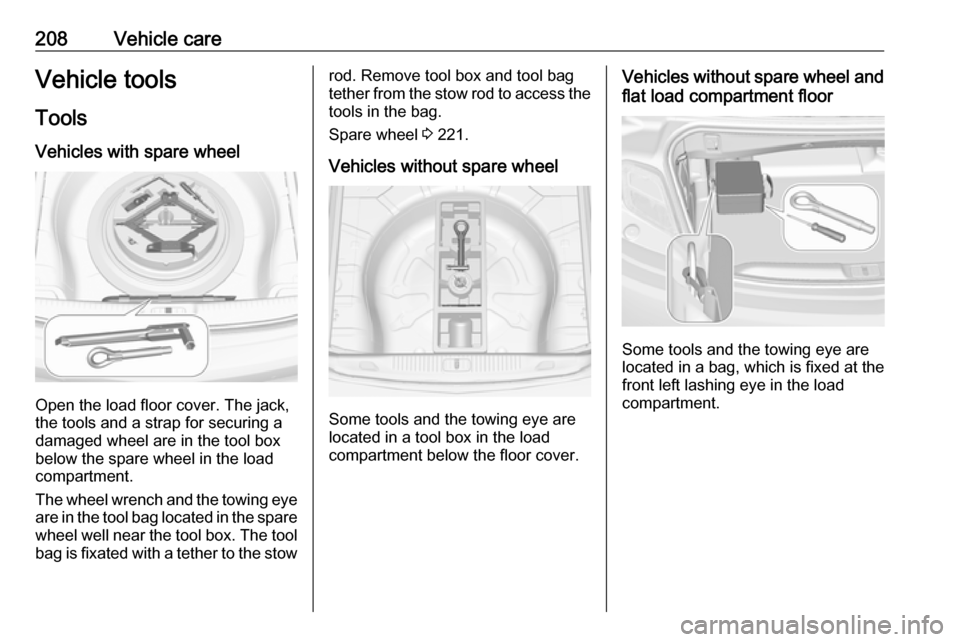

208Vehicle careVehicle tools

Tools

Vehicles with spare wheel

Open the load floor cover. The jack,

the tools and a strap for securing a

damaged wheel are in the tool box

below the spare wheel in the load

compartment.

The wheel wrench and the towing eye

are in the tool bag located in the spare wheel well near the tool box. The toolbag is fixated with a tether to the stow

rod. Remove tool box and tool bag

tether from the stow rod to access the

tools in the bag.

Spare wheel 3 221.

Vehicles without spare wheel

Some tools and the towing eye are

located in a tool box in the load

compartment below the floor cover.

Vehicles without spare wheel and

flat load compartment floor

Some tools and the towing eye are

located in a bag, which is fixed at the

front left lashing eye in the load

compartment.

Page 222 of 265

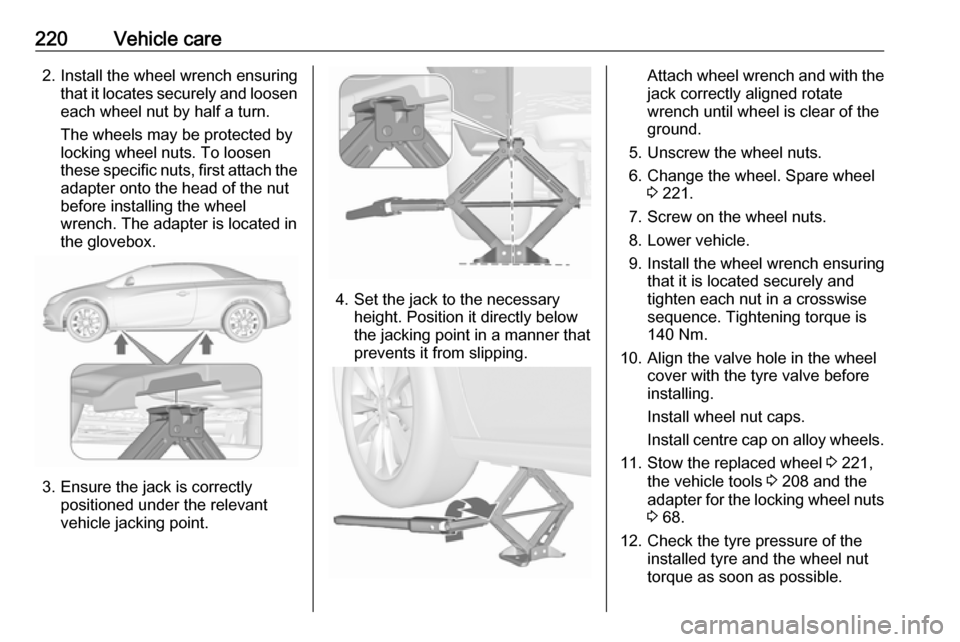

220Vehicle care2. Install the wheel wrench ensuringthat it locates securely and loosen

each wheel nut by half a turn.

The wheels may be protected by

locking wheel nuts. To loosen

these specific nuts, first attach the adapter onto the head of the nut

before installing the wheel

wrench. The adapter is located in

the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach wheel wrench and with the

jack correctly aligned rotate

wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 221.

7. Screw on the wheel nuts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it is located securely and

tighten each nut in a crosswise

sequence. Tightening torque is

140 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

Install centre cap on alloy wheels.

11. Stow the replaced wheel 3 221,

the vehicle tools 3 208 and the

adapter for the locking wheel nuts

3 68.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.

Page 224 of 265

222Vehicle care

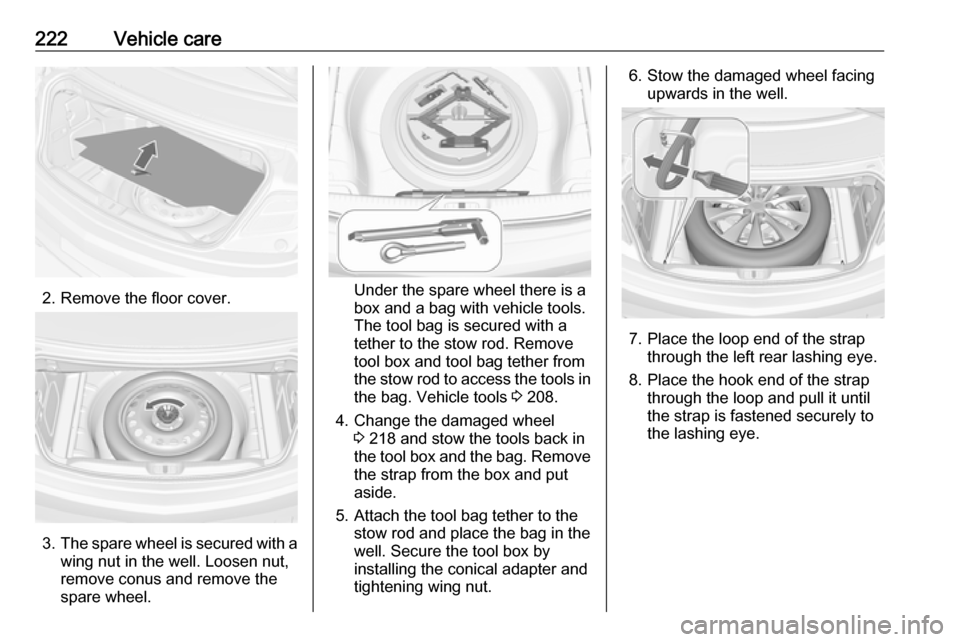

2. Remove the floor cover.

3.The spare wheel is secured with a

wing nut in the well. Loosen nut, remove conus and remove the

spare wheel.

Under the spare wheel there is a box and a bag with vehicle tools.

The tool bag is secured with a

tether to the stow rod. Remove

tool box and tool bag tether from

the stow rod to access the tools in the bag. Vehicle tools 3 208.

4. Change the damaged wheel 3 218 and stow the tools back in

the tool box and the bag. Remove

the strap from the box and put

aside.

5. Attach the tool bag tether to the stow rod and place the bag in the

well. Secure the tool box by

installing the conical adapter and

tightening wing nut.

6. Stow the damaged wheel facing upwards in the well.

7. Place the loop end of the strap through the left rear lashing eye.

8. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.

Page 225 of 265

Vehicle care223

9. Insert the strap through thespokes of the wheel as shown in

the illustration.

10. Mount the hook to the right rear lashing eye.

11. Tighten the strap and secure it using the buckle.

12. Place the floor cover over the damaged wheel.

13. If equipped, secure coupling ball bar in the bag to a lashing eye in

the load compartment.

14. Fold out the load compartment partition before opening the soft

top.

Stowing the spare wheel back in

the well after replacing the

damaged wheel

1. Close the soft top and fold in the load compartment partition.

2. Remove floor cover, loosen and remove wing nut and conus.

3. Stow the tools in the tool box and the bag.

4. Place spare wheel facing upwards in the well.

5. Insert and turn the excentric conus in the recess of the spare

wheel so that the wheel is

positioned as far as possible

towards the front. Secure the

wheel by turning the wing nut

clockwise.

6. Insert and close floor cover.9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not secured properly.

During a sudden stop or a

collision, loose equipment could cause personal injury or damage

to the load or vehicle.

Always store jack and tools in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load compartment must always be

secured with the strap.

Page 255 of 265

Customer information253Permission to use, copy, modify, and

distribute this software for any

purpose with or without fee is hereby

granted, provided that the above

copyright notice and this permission

notice appear in all copies.

The software is provided "as is",

without warranty of any kind, express

or implied, including but not limited to

the warranties of merchantability,

fitness for a particular purpose and

noninfringement of third party rights.

In no event shall the authors or

copyright holders be liable for any

claim, damages or other liability,

whether in an action of contract, tort

or otherwise, arising from, out of or in connection with the software or the

use or other dealings in the software.

Except as contained in this notice, the name of a copyright holder shall not

be used in advertising or otherwise to

promote the sale, use or other

dealings in this Software without prior

written authorization of the copyright

holder.unzip

This is version 2005-Feb-10 of the

Info-ZIP copyright and license. The

definitive version of this document

should be available at ftp://ftp.info-

zip.org/pub/infozip/license.html

indefinitely.

Copyright (c) 1990-2005 Info-ZIP. All

rights reserved.

For the purposes of this copyright and

license, “Info-ZIP” is defined as the

following set of individuals:

Mark Adler, John Bush, Karl Davis,

Harald Denker, Jean-Michel Dubois,

Jean-loup Gailly, Hunter Goatley, Ed

Gordon, Ian Gorman, Chris Herborth, Dirk Haase, Greg Hartwig, Robert

Heath, Jonathan Hudson, Paul

Kienitz, David Kirschbaum, Johnny

Lee, Onno van der Linden, Igor

Mandrichenko, Steve P. Miller, Sergio Monesi, Keith Owens, George

Petrov, Greg Roelofs, Kai Uwe

Rommel, Steve Salisbury, Dave

Smith, Steven M. Schweda, Christian

Spieler, Cosmin Truta, Antoine

Verheijen, Paul von Behren, Rich

Wales, Mike White.This software is provided “as is,”

without warranty of any kind, express or implied. In no event shall Info-ZIP

or its contributors be held liable for

any direct, indirect, incidental, special

or consequential damages arising out

of the use of or inability to use this

software.

Permission is granted to anyone to

use this software for any purpose,

including commercial applications,

and to alter it and redistribute it freely,

subject to the following restrictions:

1. Redistributions of source code must retain the above copyright

notice, definition, disclaimer, and

this list of conditions.

2. Redistributions in binary form (compiled executables) must

reproduce the above copyright

notice, definition, disclaimer, and

this list of conditions in

documentation and/or other

materials provided with the

distribution. The sole exception to this condition is redistribution of a

standard UnZipSFX binary

(including SFXWiz) as part of a

self-extracting archive; that is

Page 258 of 265

256Customer informationRadio Frequency

Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in

Vauxhall vehicles does not use or

record personal information or link

with any other Vauxhall system

containing personal information.