wheel VAUXHALL COMBO 2016 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016, Model line: COMBO, Model: VAUXHALL COMBO 2016Pages: 189, PDF Size: 4.47 MB

Page 114 of 189

112Driving and operatingRestarting the engine

Manual transmission

The selector lever must be in neutral

to enable an automatic restart.

Depress the clutch pedal to restart the

engine.

Manual transmission automated

If the lever is in position N, select

another gear, otherwise release the

brake pedal or move the lever to +, –

or R to enable an automatic restart.

If an electrical accessory, e.g. a

portable CD player, is connected to

the power outlet, a brief power drop

during the restart may be noticeable.

Restarting the engine with the key When one of the following conditions

occurs during an Autostop, the

engine will need to be restarted

manually using the key.

● the driver's seat belt is unfastened and the driver's door

is opened

● three minutes have elapsed since the engine was switched offIn this event, control indicator ^

flashes in the DIC in conjunction with

a warning chime. Depending on

version, a corresponding message

may also appear in the DIC 3 85.

Fault

If control indicator Æ illuminates in the

instrument cluster, there is a fault in

the stop-start system 3 84.

Depending on version, 9 will

illuminate as an alternative if control

indicator Æ is not present. A warning

message may also be displayed in

the DIC 3 85.

Generic warning 9 3 76.

Seek the assistance of a workshop.

Parking9 Warning

● Do not park the vehicle on an

easily ignitable surface. The

high temperature of the

exhaust system could ignite the

surface.

● Always apply parking brake without pressing release

button. Apply as firmly as

possible on a downhill slope or

uphill slope. Depress brake

pedal at the same time to

reduce operating force.

● Switch off the engine. Turn the ignition key to position 0 and

remove it. Turn the steering

wheel until the steering wheel

lock is felt to engage.

● If the vehicle is on a level surface or uphill slope, engage

first gear before switching off

the ignition. On an uphill slope,

turn the front wheels away from

the kerb.

If the vehicle is on a downhill

slope, engage reverse gear

before switching off the ignition. Turn the front wheels towardsthe kerb.

Lock the vehicle 3 21 and activate the

anti-theft locking system 3 26 .

Page 121 of 189

Driving and operating119Brakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has

been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 79.

Antilock brake system

Antilock brake system (ABS)

prevents the wheels from locking.ABS starts to regulate brake pressure as soon as a wheel shows a tendency to lock. The vehicle remains

steerable, even during hard braking.

ABS control is made apparent

through a pulse in the brake pedal

and the noise of the regulation

process.

For optimum braking, keep the brake

pedal fully depressed throughout the

braking process, despite the fact that

the pedal is pulsating. Do not reduce

the pressure on the pedal.

After starting off the system performs

a self-test which may be audible.

Control indicator u 3 79.

Fault9 Warning

If there is a fault in the ABS, the

wheels may be liable to lock due

to braking that is heavier than

normal. The advantages of ABS

are no longer available. During

hard braking, the vehicle can nolonger be steered and may

swerve.

Have the cause of the fault remedied

by a workshop.

Parking brake

Manual parking brake

Page 123 of 189

Driving and operating121Ride control systems

Traction Control system The Anti-Slip Regulator (ASR) is a

component of the Electronic Stability

Control (ESC).

ASR improves driving stability when

necessary, regardless of the type of

road surface or tyre grip, by

preventing the drive wheels from

spinning.

As soon as the drive wheels starts to spin, engine output is reduced and

the wheel spinning the most is braked

individually. This considerably

improves the driving stability of the

vehicle on slippery road surfaces.

ASR is operational as soon as the

control indicator R extinguishes.

When ASR is active, control indicator

R flashes.9 Warning

Do not let this special safety

feature tempt you into taking risks

when driving.

Adapt speed to the road

conditions.

Deactivation

ASR can be switched off when

spinning of drive wheels is required:

press ASR OFF briefly.

LED in button illuminates and,

depending on version, a message may also appear in the Driver

Information Centre (DIC) 3 85.

ASR is reactivated by pressing

ASR OFF again.

ASR is also reactivated the next time

the ignition is switched on.

Fault

ASR will switch off automatically in

the event of a fault. Control indicator R will illuminate in the instrument

cluster. Depending on version, a

message may also appear in the DIC 3 85.

Have the cause of the fault remedied

by a workshop.

Control indicator R 3 80.

Electronic Stability Control Electronic Stability Control (ESC)

improves driving stability when

necessary, regardless of the type of

road surface or tyre grip. It also

prevents the drive wheels from

spinning.

As soon as the vehicle starts to

swerve (understeer/oversteer),

engine output is reduced and the wheels are braked individually. This

Page 134 of 189

132Vehicle careVehicle careGeneral Information...................132

Accessories and vehicle modifications .......................... 132

Vehicle storage ........................133

End-of-life vehicle recovery .....133

Vehicle checks ........................... 134

Performing work ......................134

Bonnet ..................................... 134

Engine oil ................................. 135

Engine coolant ......................... 136

Power steering fluid .................136

Washer fluid ............................ 137

Brakes ..................................... 137

Brake fluid ............................... 137

Vehicle battery ......................... 137

Wiper blade replacement ........139

Bulb replacement .......................140

Halogen headlights ..................140

Fog lights ................................. 142

Tail lights ................................. 142

Side turn signal lights ..............143

Centre high-mounted brake light ......................................... 143

Number plate light ...................143Interior lights ............................ 144

Instrument panel illumination ...145

Electrical system ........................146

Fuses ....................................... 146

Engine compartment fuse box . 147

Instrument panel fuse box .......148

Vehicle tools .............................. 149

Tools ........................................ 149

Wheels and tyres .......................150

Winter tyres ............................. 150

Tyre designations ....................150

Tyre pressure .......................... 151

Tyre pressure monitoring

system .................................... 151

Tread depth ............................. 153

Changing tyre and wheel size . 153 Wheel covers ........................... 154

Tyre chains .............................. 154

Tyre repair kit .......................... 154

Wheel changing .......................157

Spare wheel ............................ 158

Jump starting ............................. 161

Towing ....................................... 162

Towing the vehicle ...................162

Towing another vehicle ...........163

Appearance care .......................164

Exterior care ............................ 164

Interior care ............................. 166General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the

electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Page 152 of 189

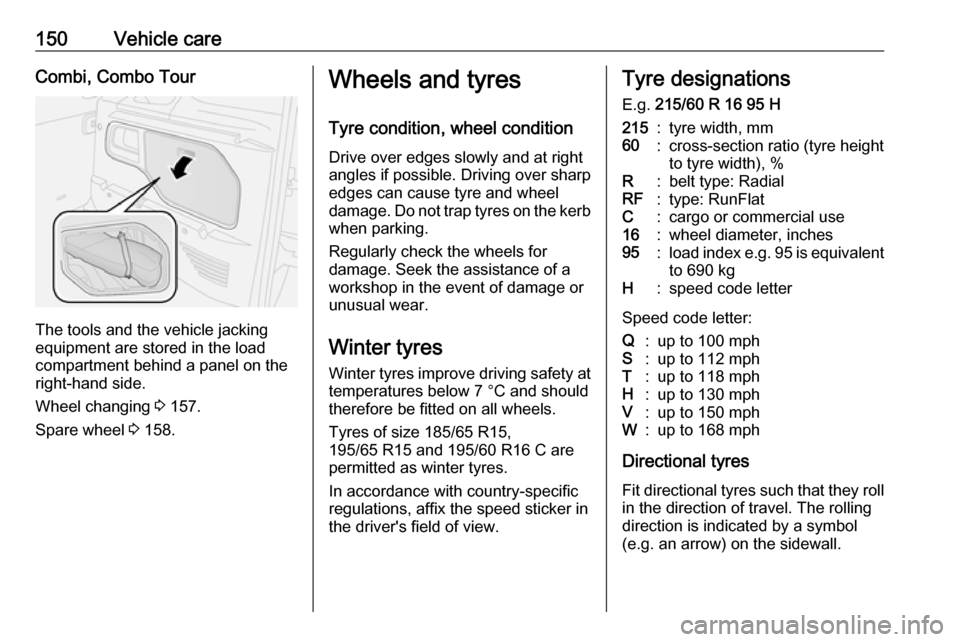

150Vehicle careCombi, Combo Tour

The tools and the vehicle jacking

equipment are stored in the load

compartment behind a panel on the

right-hand side.

Wheel changing 3 157.

Spare wheel 3 158.

Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres Winter tyres improve driving safety at

temperatures below 7 °C and should

therefore be fitted on all wheels.

Tyres of size 185/65 R15,

195/65 R15 and 195/60 R16 C are

permitted as winter tyres.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.Tyre designations

E.g. 215/60 R 16 95 H215:tyre width, mm60:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlatC:cargo or commercial use16:wheel diameter, inches95:load index e.g. 95 is equivalent to 690 kgH:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Directional tyres

Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Page 153 of 189

Vehicle care151Tyre pressure

Check the pressure of cold tyres at least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 179.

The tyre pressure information label

on the door frame (if fitted) indicates the original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 173.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 179.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressures.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Tyre pressure monitoring

system

The Tyre Pressure Monitoring

System (TPMS) uses radio and

sensor technology to check tyre

pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

The TPMS sensors monitor the air pressure in the tyres and transmit tyre

pressure readings to a receiver

located in the vehicle.

All wheels must be equipped with

pressure sensors and the tyres must

have the prescribed pressure.

Tyre pressure chart 3 179.

Page 154 of 189

152Vehicle careNotice

In countries where the tyre pressure monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

Low tyre pressure condition

A detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 82 together

with a warning chime. In vehicles with Multifunction version of the Driver

Information Centre (DIC), a

corresponding message is also

displayed.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 179.

After inflating, driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure of all

four tyres.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

value cannot be recognised by the

system and w flashes for several

seconds then illuminates

continuously. In vehicles with

Multifunction version of the DIC, a

corresponding message is also

displayed.A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. TPMS is not operational for

these wheels. For the further three

wheels, TPMS remains operational.

Spare wheel 3 158, Wheel changing

3 157.

Control indicator w and (depending

on version) a corresponding message appears at each ignition cycle until

the tyres are inflated to the correct

tyre pressure.

Driver Information Centre (DIC) 3 85.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

Tyre pressure values provided on the tyre information label and tyre

pressure chart are valid for cold tyres,

which means at 20 °C. The pressure

increases by nearly 1.5 psi for a 10 °C temperature increase. This

must be considered when warm tyres are checked.

Page 155 of 189

Vehicle care153Relearn function

After changing wheels, TPMS needs

to recalculate. The relearn process

takes up to 20 minutes of driving with

a minimum speed of 15 mph.

If problems occur during the relearn

process, control indicator w flashes

for several seconds then illuminates

continuously and (depending on

version) a warning message is

displayed in the DIC.

Driver Information Centre (DIC) 3 85.

General information The use of tyre chains or

commercially available liquid tyre

repair kits can impair the function of

the system. Factory-approved tyre

repair kits can be used.

Tyre repair kit 3 154, Tyre chains

3 154.

External high-power radio equipment

could disrupt the TPMS.

Each time the tyres are replaced,

TPMS sensors must be dismounted

and serviced by a workshop.Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of the tyres on one axle should not vary

by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

is the same as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.

Page 156 of 189

154Vehicle care9Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

Do not exceed 30 mph when tyre

chains are fitted.

9 Warning

Damage may lead to tyre blowout.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at tyre's sidewall cannot be repairedwith the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first or reverse gear.

The tyre repair kit may be located

under the front seat, in the glovebox,

or on the right side of the load

compartment behind a cover.

Page 159 of 189

Vehicle care1572. Turn the canister anticlockwise tolift it out.

3. Insert the new canister and turn it clockwise.

4. Connect the compressor air hose to the canister and fit the flexible

filler tube into its allocated space.

Wheel changing Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 154.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first or reverse gear.

● Remove the spare wheel 3 158.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.

● Clean wheel nuts and thread with

a clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover using a suitable

tool.

2. Attach wheel wrench securely and loosen each wheel nut by halfa turn.