tyre pressure VAUXHALL COMBO E 2019.75 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2019.75, Model line: COMBO E, Model: VAUXHALL COMBO E 2019.75Pages: 281, PDF Size: 10.44 MB

Page 238 of 281

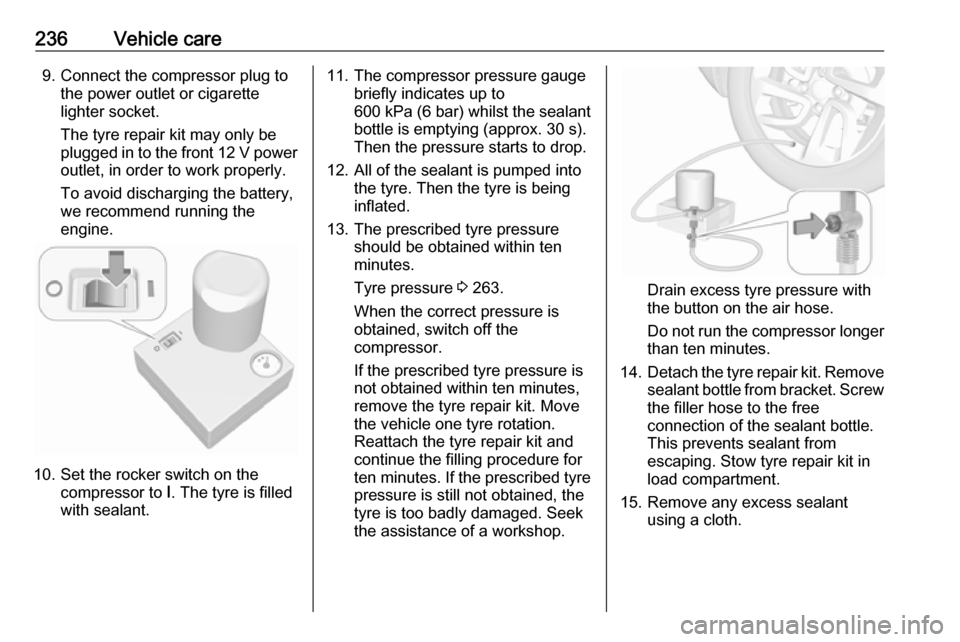

236Vehicle care9. Connect the compressor plug tothe power outlet or cigarette

lighter socket.

The tyre repair kit may only be

plugged in to the front 12 V power

outlet, in order to work properly.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to

600 kPa (6 bar) whilst the sealant

bottle is emptying (approx. 30 s).

Then the pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is being

inflated.

13. The prescribed tyre pressure should be obtained within ten

minutes.

Tyre pressure 3 263.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button on the air hose.

Do not run the compressor longer than ten minutes.

14. Detach the tyre repair kit. Remove

sealant bottle from bracket. Screw the filler hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

Page 239 of 281

Vehicle care237

16. Continue driving immediately sothat sealant is evenly distributed

in the tyre. After driving approx.

three miles but no more than ten

minutes, stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve when

doing this. Fill tyre as described

before. Drain excess tyre

pressure with the button on the air

hose.

If tyre pressure hasn't decreased

under 150 kPa (1.5 bar), set it to

the correct value. Otherwise the

vehicle must not be used. Seek

assistance of a workshop. 3 263

Repeat the checking procedure

once more after driving further

three miles but no more than ten

minutes to check that there is no

more loss of pressure.

If the tyre pressure has fallen

below 150 kPa (1.5 bar), the

vehicle must not be used. Seek

the assistance of a workshop.

17. Stow away tyre repair kit in load compartment.

Notice

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of seven bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear orP .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

Page 244 of 281

242Vehicle careEnsure that the edge of the body

fits into the notch of the jack.

Attach wheel wrench and with the

jack correctly aligned rotate wheel wrench until wheel is clear of the

ground.

5. Unscrew the wheel nuts. 6. Change the wheel. Spare wheel 3 239.

7. Screw on the wheel nuts.

8. Lower the vehicle and remove jack.

9. Install the wheel wrench ensuring that it is located securely and

tighten each bolt in a crosswise

sequence. Tightening torque is

115 Nm.

If the vehicle is equipped with

alloy wheels, note that the wheel

bolts can also be used for the steel spare wheel. In this case, the

spare wheel is secured by the

conical contact of each bolt.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow the replaced wheel 3 239,

the vehicle tools 3 229 and the

adapter for the locking wheel nuts.

12. Check the tyre pressure of the installed tyre and the wheel nut

torque as soon as possible.Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

Page 249 of 281

Vehicle care247Do not clean the engine compartment

with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the

vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Have the door hinges of all doors

greased by a workshop.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them dry.

Polishing and waxing

Wax the vehicle regularly at the latest

when water no longer beads.

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.Plastic body parts must not be treated with wax or polishing agents.

Windows and wiper blades Switch off wipers before handling in

their areas.

Use a soft lint-free cloth or chamois leather together with window cleanerand insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Remove dirt residues from smearing

wiper blades by using a soft cloth and window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Ice residues, pollution and continuous

wiping on dry windows will damage or

even destroy the wiper blades.Glass panel

Never clean with solvents or abrasive

agents, fuels, aggressive media e.g.

paint cleaner, acetone-containing solutions, acidic or highly alkaline

media or abrasive pads.

Wheels and tyres Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damage Rectify minor paintwork damage witha touch-up pen before rust forms.

Have more extensive damage or rust areas repaired by a workshop.

Underbody

Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

Page 258 of 281

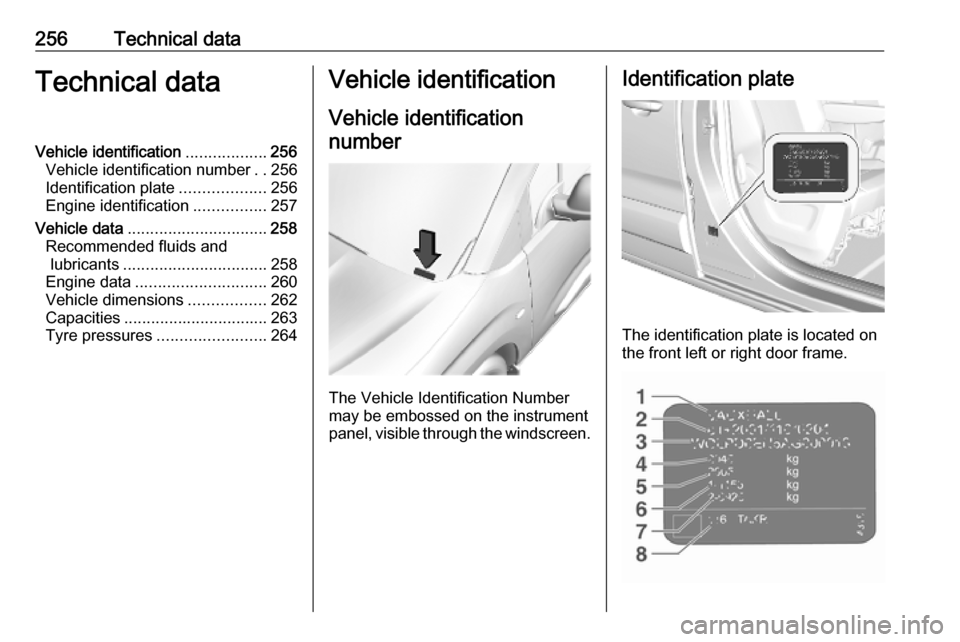

256Technical dataTechnical dataVehicle identification..................256

Vehicle identification number ..256

Identification plate ...................256

Engine identification ................257

Vehicle data ............................... 258

Recommended fluids and lubricants ................................ 258

Engine data ............................. 260

Vehicle dimensions .................262

Capacities ................................ 263

Tyre pressures ........................ 264Vehicle identification

Vehicle identificationnumber

The Vehicle Identification Number

may be embossed on the instrument

panel, visible through the windscreen.

Identification plate

The identification plate is located on

the front left or right door frame.

Page 266 of 281

![VAUXHALL COMBO E 2019.75 User Guide 264Technical dataTyre pressures

ComboPayload 650 kgVehicle with up to 3 peopleWith full loadTyresfrontrearfrontrear[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])195/65 R16260/2,6 VAUXHALL COMBO E 2019.75 User Guide 264Technical dataTyre pressures

ComboPayload 650 kgVehicle with up to 3 peopleWith full loadTyresfrontrearfrontrear[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])195/65 R16260/2,6](/img/38/19409/w960_19409-265.png)

264Technical dataTyre pressures

ComboPayload 650 kgVehicle with up to 3 peopleWith full loadTyresfrontrearfrontrear[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])[kPa/bar] ([psi])195/65 R16260/2,6 (38)290/2,9 (42)260/2,6 (38)320/3,2 (46)205/60 R16250/2,5 (36)250/2,5 (36)250/2,5 (36)320/3,2 (46)215/65 R16260/2,6 (38)280/2,8 (41)260/2,6 (38)300/3,0 (44)

Page 273 of 281

Customer information271Depending on technical equipment

level, the data stored is as follows:

● system component operating states (e.g. fill level, tyre

pressure, battery status)

● faults and defects in important system components (e.g. lights,

brakes)

● system reactions in special driving situations (e.g. triggeringof an airbag, actuation of the

stability control systems)

● information on events damaging the vehicle

● for electric vehicles the amount of

charge in the high-voltage

battery, estimated range

In special cases (e.g. if the vehicle

has detected a malfunction), it may be

necessary to save data that would

otherwise just be volatile.

When you use services (e.g. repairs,

maintenance), the operating data

saved can be read together with the

vehicle identification number and

used when necessary. Staff working

for the service network ( e.g. garages,

manufacturers) or third parties (e.g.breakdown services) can read the

data from the vehicle. The same

applies to warranty work and quality

assurance measures.

Data is generally read via the OBD

(On-Board Diagnostics) port

prescribed by law in the vehicle. The operating data which is read out,

documents the technical condition of

the vehicle or individual components

and assists with fault diagnosis,

compliance with warranty obligations

and quality improvement. This data,

in particular information on

component stress, technical events,

operator errors and other faults, is

transmitted to the manufacturer

where appropriate, together with the

vehicle identification number. The

manufacturer is also subject to

product liability. The manufacturer

potentially also uses operating data

from vehicles for product recalls. This

data can also be used to check

customer warranty and guarantee

claims.

Fault memories in the vehicle can be

reset by a service company when

carrying out servicing or repairs or at

your request.Comfort and infotainment

functions

Comfort settings and custom settings can be stored in the vehicle and

changed or reset at any time.

Depending on the equipment level in

question, these include

● seat and steering wheel position settings

● chassis and air conditioning settings

● custom settings such as interior lighting

You can input your own data in the

infotainment functions for your

vehicle as part of the selected

features.

Depending on the equipment level in

question, these include

● multimedia data such as music, videos or photos for playback in

an integrated multimedia system

● address book data for use with an

integrated hands-free system or an integrated navigation system

Page 275 of 281

Customer information273processing and use of personal data

for the purposes of preparation of services take place solely on the

basis of legal permission, e.g. in the

case of a legally prescribed

emergency communication system or

a contractual agreement, or by virtue

of consent.

You can activate or deactivate the services and functions (which are

subject to charges to some extent)

and, in some cases, the vehicle's

entire radio network connection. This

does not include statutory functions

and services such as an emergency

communication system.

Third party services

If you make use of online services

from other providers (third parties),

these services are subject to the

liability and data protection and usage conditions of the provider in question.

The manufacturer frequently has no

influence over the content exchanged

in this regard.Therefore, please note the nature,

scope and purpose of the collection

and use of personal data within the

scope of third party services provided by the service provider in question.

Radio Frequency

Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and immobiliser.

It is also used in connection with

conveniences such as radio remote

controls for door locking / unlocking

and starting. RFID technology in

Vauxhall vehicles does not use or

record personal information or link

with any other Vauxhall system

containing personal information.

Page 280 of 281

278Three-point seat belt .................... 55

Tools .......................................... 229

Tow bar....................................... 205

Towing ................................ 205, 244

Towing another vehicle .............245

Towing equipment .....................207

Towing the vehicle .....................244

Trailer coupling ........................... 205

Trailer stability assist .................209

Trailer towing ............................. 206

Transmission ............................... 17

Transmission display .................155

Tread depth ............................... 233

Trip odometer .............................. 97

Turn lights .......................... 100, 125

Tyre chains ................................ 234

Tyre deflation detection system . 232

Tyre designations ......................230

Tyre pressure ............................ 231

Tyre pressures ........................... 264

Tyre repair kit ............................. 234

U

Ultrasonic parking assist............. 183

Underseat storage .......................72

Upholstery .................................. 248

USB port ....................................... 93

Using this manual ..........................3V

Valet mode ................................. 110

Vauxhall Connect .......................119

Vehicle battery ........................... 216

Vehicle checks............................ 212

Vehicle data ................................ 258

Vehicle data recording and privacy ..................................... 270

Vehicle detected ahead ..............107

Vehicle dimensions .................... 262 Vehicle identification number ....256

Vehicle jack ................................ 229

Vehicle locator lighting ...............129

Vehicle messages .....................114

Vehicle personalisation .............115

Vehicle security ............................ 34

Vehicle specific data ......................3

Vehicle storage ........................... 211

Vehicle tools ............................... 229

Vehicle unlocking ........................... 6

Ventilation ................................... 138

W

Warning chimes .........................114

Warning lights ............................... 97

Warning triangle .......................... 84

Washer and wiper systems .........13

Washer fluid ............................... 215

Wheel changing .........................237

Wheel covers ............................. 234Wheels and tyres .......................230

Windows ....................................... 40

Windscreen................................... 40

Windscreen wiper and washer ....90

Winter tyres ............................... 230

Wiper blade replacement ..........218