SIDE VAUXHALL COMBO E 2020 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2020, Model line: COMBO E, Model: VAUXHALL COMBO E 2020Pages: 279, PDF Size: 28.6 MB

Page 224 of 279

222Vehicle careSidelight / daytime running light

with bulbs

1. Rotate the bulb socket anticlockwise to disengage and

withdraw from the reflector.

2. Remove the bulb from the bulb socket by pulling.

3. Replace and insert the new bulb into the bulb socket.

4. Insert the bulb socket into the light

assembly and turn clockwise.

Sidelight / daytime running light

with LEDs

In case of defective LEDs, have them replaced by a workshop.

LED headlights Daytime running lights are designed

as LEDs and can not be changed.

Have lights repaired by a workshop in case of failure.

Front fog lights

1. Wrap a cloth around the tip of a flat

screwdriver to prevent paint

damage. Insert the screwdriver in

the recess at the edge of the

cover. Release the cover by

levering it out carefully.

Page 228 of 279

226Vehicle careTail light / brake light (1)

Turn light / hazard warning flasher ( 2 ) outer bulb

Reversing light ( 3) inner bulb

Rear fog light ( 4)

6. Attach the bulb carrier to the light assembly.

7. Attach the cable to the retainer. 8. Attach the light assembly to the vehicle body and tighten both

screws.

3rd-brake light The 3rd-brake light is designed as

LED and can not be changed.

Have lights repaired by a workshop in case of failure.

Bulb check

Switch on the ignition, operate and

check all lights.Side turn lights

To replace the bulb, remove the lamp

housing:

1. Slide the lamp housing forward and remove it at the back.

2. Press the retaining lug upwardsand remove the bulb socket from

the plug connector.

3. Replace the complete unit.

4. Insert left end of the lamp, slide to

the left and insert right end.

Page 230 of 279

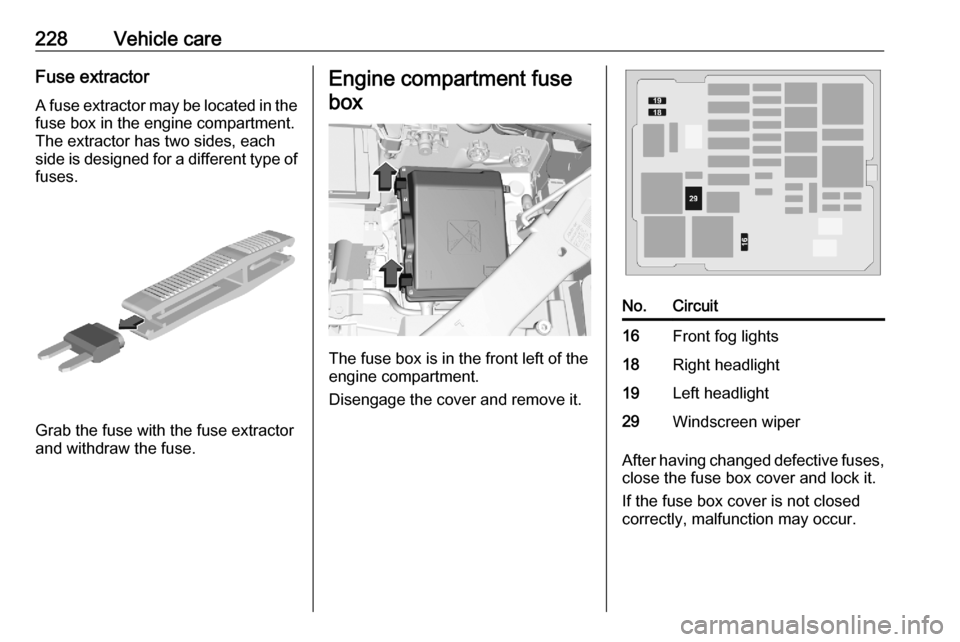

228Vehicle careFuse extractorA fuse extractor may be located in the

fuse box in the engine compartment.

The extractor has two sides, each

side is designed for a different type of fuses.

Grab the fuse with the fuse extractor

and withdraw the fuse.

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover and remove it.

No.Circuit16Front fog lights18Right headlight19Left headlight29Windscreen wiper

After having changed defective fuses,

close the fuse box cover and lock it.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 231 of 279

Vehicle care229Instrument panel fuse boxThe fuse box is located behind a

cover in the instrument panel at the

left side.

Remove the cover by pulling at the

top left, then at the right side.

No.Circuit1Inductive charging, clutch

switch, selective ride control,

power steering, diesel exhaust

system, interior mirror4Horn6Windscreen washer7Power outlet rear10Door lock12Diagnostic connector, power

supply transformerNo.Circuit13Head-up display, climate

control, Infotainment system14Anti-theft alarm system, tele‐

matic unit15Automatic transmission, instru‐

ment cluster, climate control16Starter, power supply trans‐

former17Instrument cluster19Trailer socket, steering wheel

controls21Anti-theft system, power button22Rear view camera, rain and light sensor23Seat belt reminder, special

vehicle control module, start-

stop, trailer socket24Parking assist, Infotainment

system, rear view camera, side

blind spot camera25Airbag

Page 234 of 279

232Vehicle careDirectional tyres

Directional tyres should be mounted so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

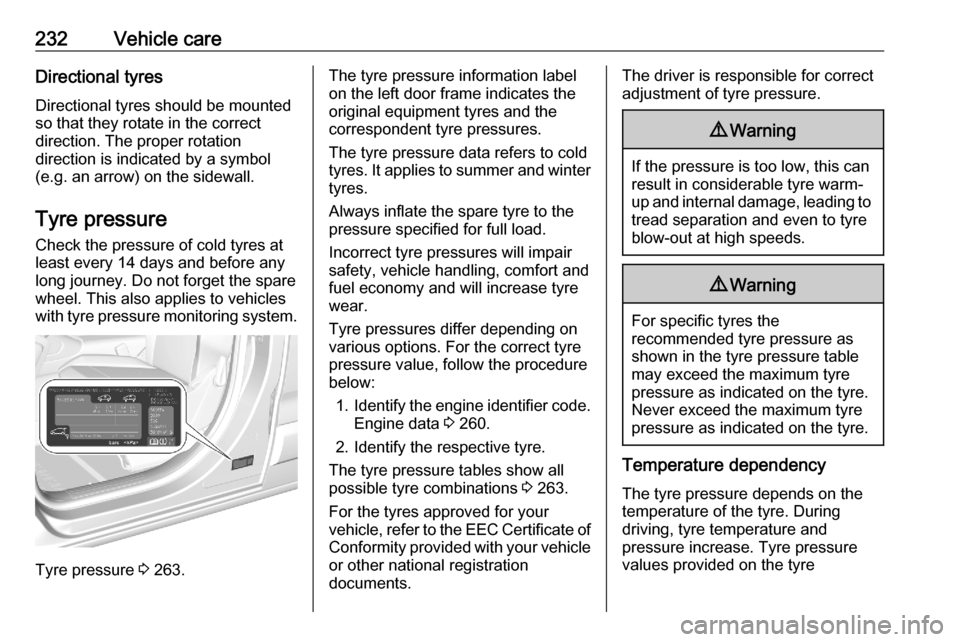

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Tyre pressure 3 263.

The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 260.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 263.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

Page 235 of 279

Vehicle care233information label and tyre pressure

chart are valid for cold tyres, which

means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

Tyre deflation detectionsystem

The tyre deflation detection system

continually checks the rotation speed

of all four wheels and warns on low

tyre pressure condition once vehicle

is driving. This is achieved by

comparing tyre rolling circumference

with reference values and further

signals.

If a tyre loses pressure the control

indicator w illuminates, a warning

chime is given and a warning

message is displayed in the Driver

Information Centre.

In this case reduce speed, avoid

sharp cornering and strong braking.

Stop at next safe opportunity and

check tyre pressure.

Control indicator w 3 105.After adjusting tyre pressure initialise

system to extinguish the control

indicator and restart system.Caution

Deflation detection system warns

just about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

In case of a system malfunction a

message is displayed in the Driver

Information Centre. Set correct tyre

pressure and reinitialise system. If the

failure continues to be displayed,

contact a workshop. The system is

inoperable when ABS or ESC has a

malfunction or a temporary spare

wheel is used. Once the road tyre has

been refitted, check the tyre pressure with cold tyres and initialise the

system.

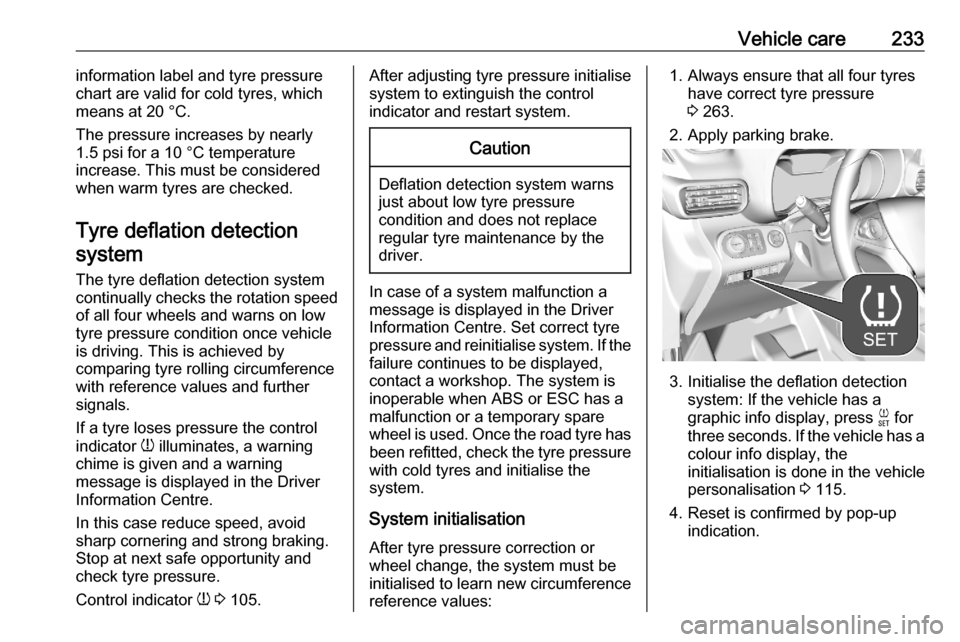

System initialisation

After tyre pressure correction or

wheel change, the system must be

initialised to learn new circumference reference values:

1. Always ensure that all four tyres have correct tyre pressure

3 263.

2. Apply parking brake.

3. Initialise the deflation detection system: If the vehicle has a

graphic info display, press F for

three seconds. If the vehicle has a

colour info display, the

initialisation is done in the vehicle

personalisation 3 115.

4. Reset is confirmed by pop-up indication.

Page 236 of 279

234Vehicle careAfter initialisation system

automatically calibrates to new tyre

pressures during driving. After longer

drive the system will adopt and

monitor new pressures.

Always check tyre pressure with cold

tyres.

System has to be reinitialised when: ● Tyre pressure has been changed

● Load condition has been changed

● Wheels have been swapped or exchanged

The system will not warn

instantaneously on a tyre blow out or a rapid deflation. This is due to

required calculation time.

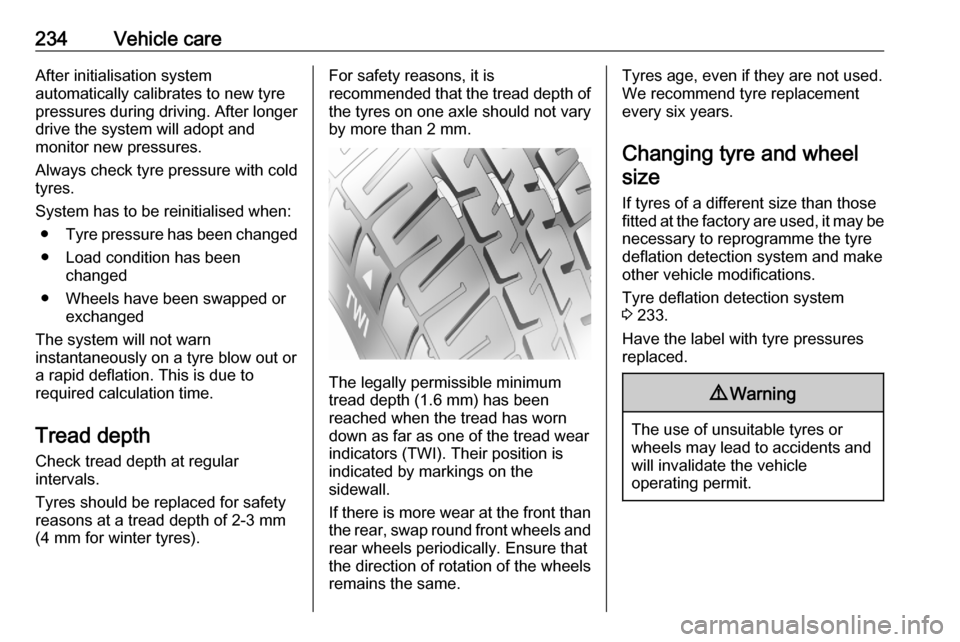

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the tyre

deflation detection system and make

other vehicle modifications.

Tyre deflation detection system

3 233.

Have the label with tyre pressures

replaced.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Page 237 of 279

Vehicle care235Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 9 mm to the tyre tread

and the inboard sides (including chain

lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on all tyres

sizes allowed for the vehicle.

Temporary spare wheel

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

In the case of a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

Open the cover of the footwell storage

3 73.

Page 238 of 279

236Vehicle care

The tyre repair kit is located in the

storage compartment underneath the passenger front seat.

1. Remove the sealant bottle and the

compressor.

2. Pull speed limit label from sealant

bottle and place it in driver's

visible area.3. Remove the electrical connection cable and air hose from the

storage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the bracket on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

Page 243 of 279

Vehicle care2415. Change the wheel.

6. Position the damaged wheel with the outside down in the spare

wheel holder.

7. Lift the spare wheel holder and engage in the catch. The open

side of the catch must point in the direction of travel.

8. Close the spare wheel holder by turning the hexagon bolt

clockwise using the wheel

wrench.

9. Stow wheel wrench in the storage.

10. Close the tailgate or the rear doors.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

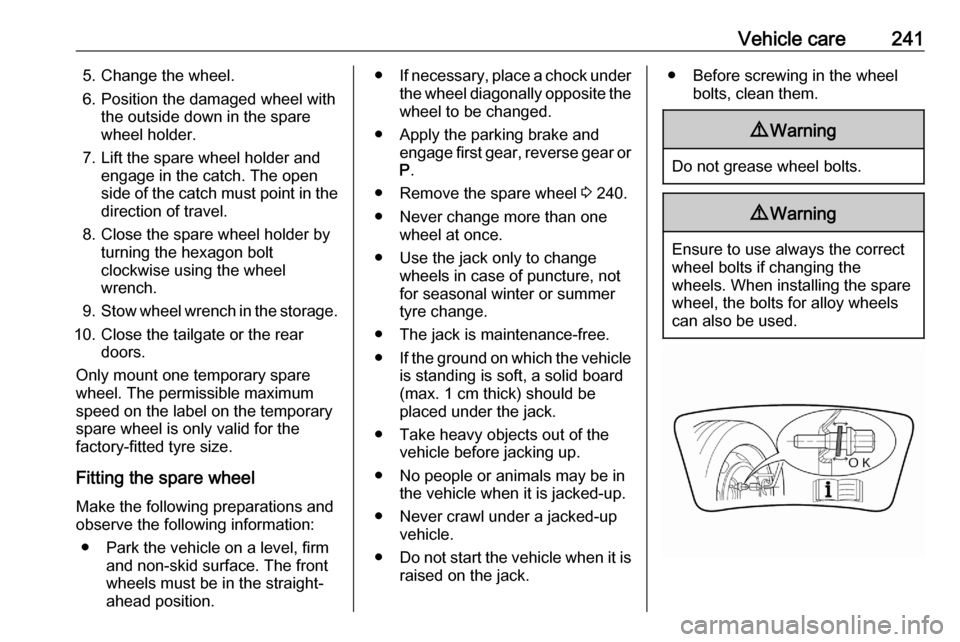

Fitting the spare wheel Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.● If necessary, place a chock under

the wheel diagonally opposite the wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 240.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the vehicle when it is

raised on the jack.● Before screwing in the wheel bolts, clean them.9Warning

Do not grease wheel bolts.

9Warning

Ensure to use always the correct

wheel bolts if changing the

wheels. When installing the spare

wheel, the bolts for alloy wheels can also be used.