change wheel VAUXHALL CORSA 2014.5 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014.5, Model line: CORSA, Model: VAUXHALL CORSA 2014.5Pages: 231, PDF Size: 6.8 MB

Page 13 of 231

In brief11

1Side air vents ...................... 112

2 Light switch .......................... 98

Instrument illumination .......103

Rear fog light ....................... 102

Front fog lights ...................102

Headlight range

adjustment ........................... 99

3 Turn and lane-change

signals, headlight flash,

low beam and high beam ...101

Exit lighting .......................... 105

Parking lights ...................... 102

Cruise control ....................... 85

4 Steering wheel controls ........70

5 Horn ...................................... 71

Driver airbag ......................... 44

6 Instruments .......................... 76

7 Windscreen wiper,

windscreen washer system ...72

Trip computer ........................ 91

8 Centre air vents ................... 1129Info-Display ........................... 86

Trip computer ........................ 91

Electronic climate control

system ................................. 109

10 Left heated seat ....................38

Heated steering wheel ..........71

Tyre deflation detection

system ................................. 175

Parking assist ...................... 132

Hazard warning flashers .....101

Central locking system ..........21

Electronic stability program . 130

Airbag deactivation ...............46

Right heated seat ..................38

Eco button ........................... 116

Fuel selector ........................ 77

11 Front passenger airbag .........44

12 Glovebox .............................. 53

13 Climate control system ........ 10614Cigarette lighter ..................... 75

Power outlet .......................... 75

15 Ashtray .................................. 75

16 Ignition switch with

steering wheel lock .............115

17 Accelerator pedal ................115

18 Brake pedal ......................... 128

19 Clutch pedal ........................ 114

20 Steering wheel adjustment ...70

21 Bonnet release lever ...........147

Page 55 of 231

Storage53StorageStorage compartments................53

Load compartment .......................63

Roof rack system .........................67

Loading information .....................68Storage compartments9Warning

Do not store heavy or sharp

objects in the storage

compartments. Otherwise, the

storage compartment lid could

open and vehicle occupants could be injured by objects being thrown

around in the event of hard

braking, a sudden change in

direction or an accident.

Glovebox

The glovebox features:

■ a card holder in cheque card format

■ a pen holder

■ pocket torch holder

■ a key adapter for the locking wheel

bolts

The glovebox should be closed whilst driving.

Cupholders

A cupholder is located in the front of

the centre console.

In the 3-door passenger vehicle: also

located on the side of the rear seat.

Page 98 of 231

96Instruments and controls

■Pull turn signal stalk and wiper stalk

simultaneously to the steering

wheel until you hear a confirmation

signal (approx. 3 seconds).

■ The miles display shows P1.■ Push the turn signal stalk (left) up

or down and select the desired

function P1 - P7 .

■ Push the wiper stalk (right) up or

down and select status On or OFF ,

or input a value for speed ( P6) or

value for volume ( P7).

■ Pull turn signal stalk (left) and wiper

stalk (right) simultaneously to the

steering wheel until you hear a

confirmation signal (approx.

3 seconds).

The selected settings are now stored

for the key in the ignition switch. To

activate and deactivate the functions

and set the functions selected, please see the relevant sections.

Repeat the procedure to programme

additional keys.

Programmable functions P1 : Switch on the external lighting

using the remote control (Entry

lighting). Entry lighting 3 105.

P2 : Automatic rear windscreen wiper

when reverse gear is selected. Rear

window wiperwasher 3 73.

P3 : Lane change indication: three

flashes when the lever is moved

slightly. Turn and lane-change

signals 3 101.

Page 103 of 231

Lighting101Hazard warning flashers

Operated with the ¨ button.

The hazard warning flashers activate

automatically if the airbags deploy.

Turn and lane-change

signalsLever up=right turn signalLever down=left turn signal

The lever always springs back to its

original position.

If the lever is moved past the

resistance point, the turn signal is

switched on constantly. When the

steering wheel moves back, the turn

signal is automatically deactivated.

For three flashes, e.g. when changing lanes, press the lever until resistance

is felt and then release. This function

can be activated or deactivated

depending on the key used 3 95.

Move the lever to the resistance point

and hold for longer indication.

Switch the turn signal off manually by moving the lever slightly.

Acoustic turn signal The volume of the acoustic turn signal

can be adjusted. This function can be programmed depending on the key

used 3 95.

Page 114 of 231

112Climate control9Warning

The exchange of fresh air is

reduced in air recirculation mode.

In operation without cooling the air humidity increases, so the

windows may mist up from inside.

The quality of the passenger

compartment air deteriorates,

which may cause the vehicle

occupants to feel drowsy.

In warm and very humid ambient air conditions, the windscreen might mist up from outside, when cold air is

directed to it. If windscreen mists up

from outside, activate windscreen

wiper and deactivate s.

Auxiliary heater Air heater

Quickheat is an electric auxiliary air

heater which automatically warms up

the passenger compartment more

quickly.

Coolant heater

Diesel-engined vehicles have a fuel-

powered auxiliary heater.Air vents

Adjustable air vents At least one air vent must be open

while cooling is on in order to prevent

the evaporator from icing up due to

lack of air movement.

Set the direction of the air flow by

turning the adjuster wheel from right to left and raise or lower the horizontal slats.

Page 147 of 231

Vehicle care145Vehicle careGeneral Information...................145

Vehicle checks ........................... 146

Bulb replacement .......................153

Electrical system ........................166

Vehicle tools .............................. 170

Wheels and tyres .......................172

Jump starting ............................. 187

Towing ....................................... 189

Appearance care .......................191General Information

Accessories and vehicle

modifications

We recommend using genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

The following must be carried out if

the vehicle is to be stored for several

months:

■ Wash and wax the vehicle.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve rubber seals.

■ Fill up fuel tank completely.

■ Change engine oil.

■ Drain washer fluid reservoir.

■ Check coolant antifreeze and corrosion protection.

■ Adjust tyre pressure to the value specified for full load.

■ Park vehicle in dry, well ventilated place. Engage first or reverse gear

or set selector lever to P. Prevent

the vehicle from rolling.

■ Do not apply parking brake.

Page 177 of 231

Vehicle care175

on your vehicle to ensure that the

replacement or alternate tyres and wheels allow the tyre pressure

monitoring system to continue to

function properly.

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory

approved repair kits can be used.

System initialisation After a wheel change or tyre pressure

adjustment the system must be

initialised: inflate the cold tyres to the

prescribed pressure according to the

tyre information label or this

document 3 217. Then switch on

ignition and press and hold the DDS

button for approx. 4 seconds. The

control indicator A flashes three

times.

If the tyre pressure difference

between the left and the right wheel

on one axle is more than 30 kPa, tyre

pressure monitoring system

malfunction will be indicated, as the

vehicle starts moving for the first time after initialisation. Adjust tyre

pressure and repeat initialisation.Notice

The system needs to be initialised

after tyre pressure change,

otherwise it will not be able to warn

properly.

Each time the tyres are replaced, the

tyre pressure monitoring system

sensors have to be dismounted and

serviced. For the screwed sensor

replace the valve core and sealing

ring, for the clipped sensor replace

complete rubber valve stem.

Auto learn function

After changing wheels the vehicle

must be stationary for approx.

20 minutes, before the system

recalculates. The following relearn

process takes up to 10 minutes of

driving with a minimum speed of

16 mph.

Tyre deflation detection

system The tyre deflation detection system

continually checks the rotation speed

of all four tyres.

If a tyre loses pressure the control

indicator w illuminates red. Stop

immediately and check tyre pressure.

Control indicator w 3 83.

Page 178 of 231

176Vehicle care

System initialisation

After tyre pressure correction or

wheel change, the system must be

initiated: Switch on the ignition, press and hold the DDS button for approx.

4 seconds, control indicator w flashes

three times.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the wheels on

one axle should not vary by more than 2 mm.

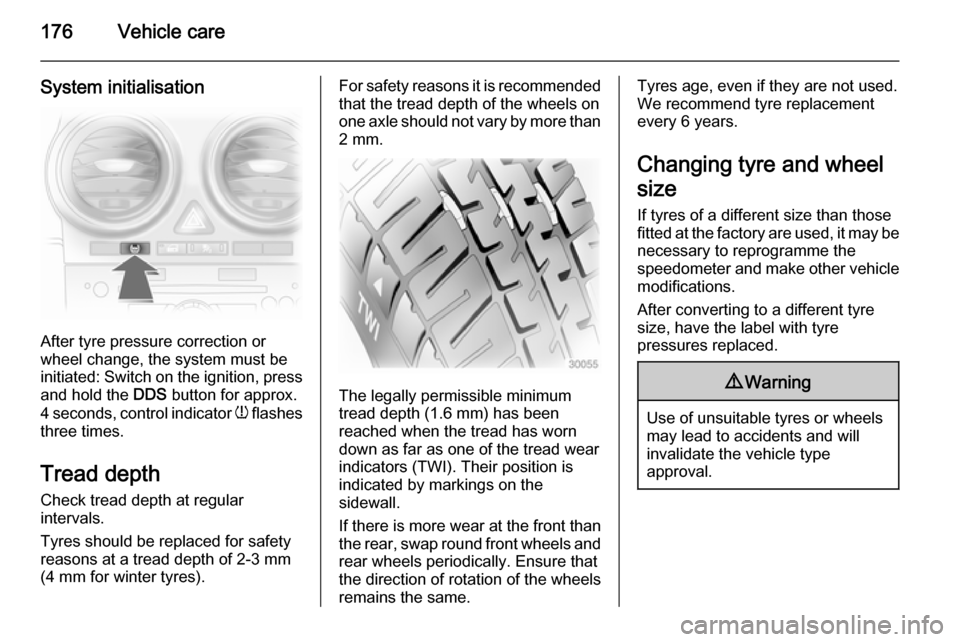

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and

rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer and make other vehicle

modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Page 185 of 231

Vehicle care183

General informationNotice

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on theunderside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 177.

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-skid surface. The front wheels

must be in the straight-ahead

position.

■ Apply the parking brake and engage first gear, reverse gear or

P .

■ Remove the spare wheel 3 185.

■ Never change more than one wheel

at a time.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ Take heavy objects out of the vehicle before jacking up.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Before screwing in the wheel bolts,

clean them and lightly coat the

taper of each wheel bolt with

commercially available grease.

Page 187 of 231

Vehicle care185

4. Set the jack to the necessaryheight. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Variant 1:Variant 2:

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw in the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel bolt caps.

11. Stow the replaced wheel 3 177,

the vehicle tools 3 170 and the

key adapter 3 53.

12. Check the tyre pressure of the installed tyre and also the wheelbolt torque as soon as possible.

Have the defective tyre renewed or

repaired.

Spare wheel

Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.