brake VAUXHALL CORSA 2015.75 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.75, Model line: CORSA, Model: VAUXHALL CORSA 2015.75Pages: 261, PDF Size: 7.61 MB

Page 191 of 261

Vehicle care189

The brake fluid level must be betweenthe MIN and MAX marks.

If fluid level is below the MIN mark,

seek the assistance of a workshop.

Brake and clutch fluid 3 232.

Vehicle battery The vehicle is equipped with a lead

acid battery.

Vehicles with stop-start system will be

equipped with an AGM battery which

is not a lead acid battery.

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the vehicle battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Laying up the vehicle for more than

four weeks can lead to vehicle battery discharge. Disconnect the clamp from

the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

The anti-theft alarm siren must be

deactivated as follows: Switch the

ignition on then off, disconnect the

vehicle's battery within 15 seconds.

Battery discharge protection 3 119.

Replacing the vehicle battery

Notice

Any deviation from the instructions

given in this section may lead to

temporary deactivation of the stop-

start system.

When the vehicle battery is being

replaced, please ensure that there

are no open ventilation holes in the

vicinity of the positive terminal. If a

ventilation hole is open in this area, it

must be closed off with a dummy cap, and the ventilation in the vicinity of the

negative terminal must be opened.

Only use batteries that allow the fuse

box to be mounted above the vehicle

battery.

Vehicles with stop-start system

Be sure to have the AGM (Absorptive

Glass Mat) battery replaced with another AGM battery.

Page 199 of 261

Vehicle care197

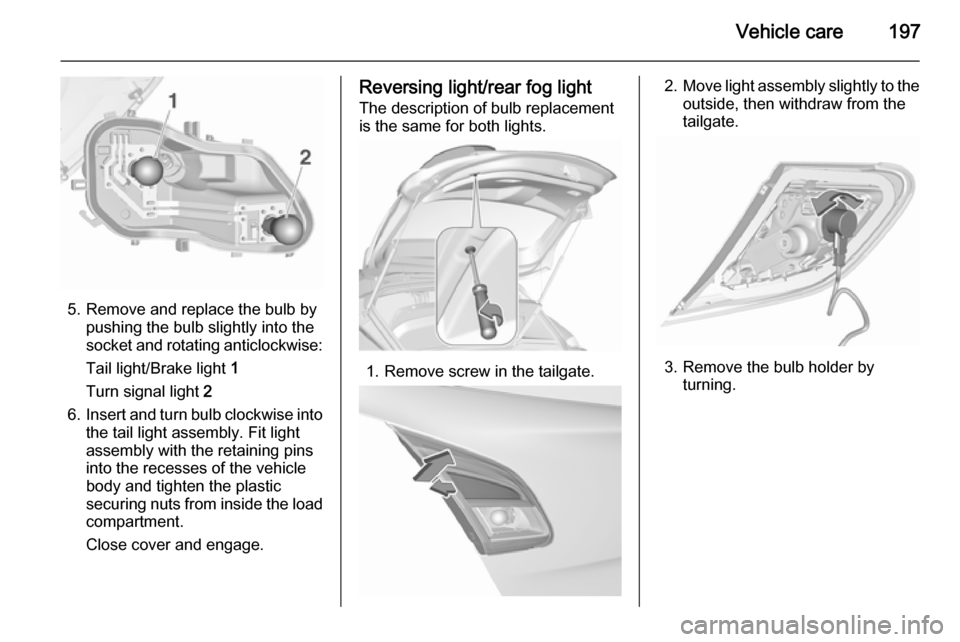

5. Remove and replace the bulb bypushing the bulb slightly into thesocket and rotating anticlockwise:

Tail light/Brake light 1

Turn signal light 2

6. Insert and turn bulb clockwise into

the tail light assembly. Fit light

assembly with the retaining pins

into the recesses of the vehicle

body and tighten the plastic

securing nuts from inside the load

compartment.

Close cover and engage.

Reversing light/rear fog light The description of bulb replacement

is the same for both lights.

1. Remove screw in the tailgate.

2. Move light assembly slightly to the

outside, then withdraw from the

tailgate.

3. Remove the bulb holder by turning.

Page 201 of 261

Vehicle care199

4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Centre high-mounted

brake light

Have LEDs replaced by a workshop.

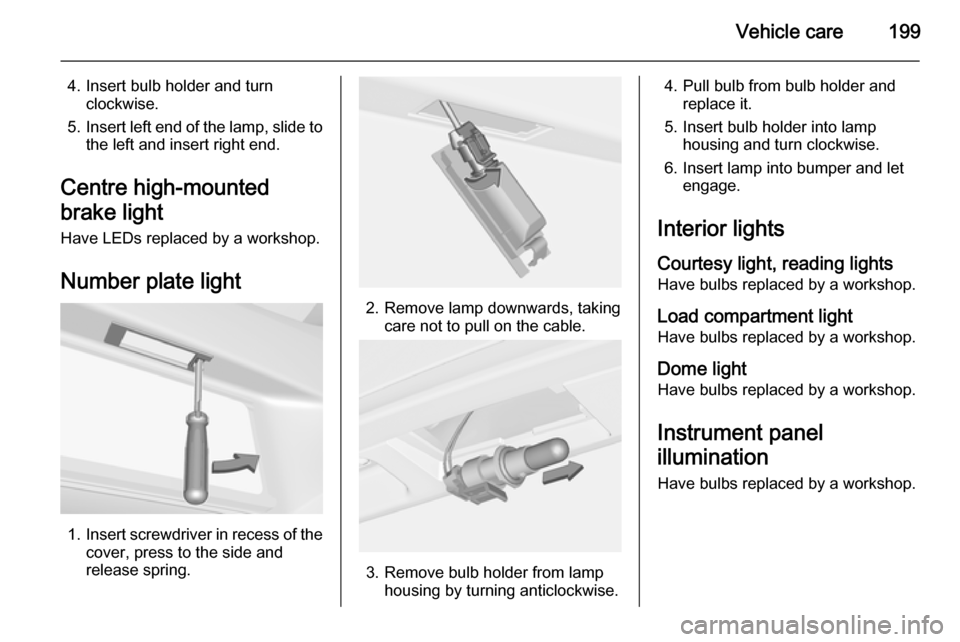

Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring.

2. Remove lamp downwards, taking care not to pull on the cable.

3. Remove bulb holder from lamp housing by turning anticlockwise.

4. Pull bulb from bulb holder andreplace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Interior lights Courtesy light, reading lights

Have bulbs replaced by a workshop.

Load compartment light Have bulbs replaced by a workshop.

Dome light

Have bulbs replaced by a workshop.

Instrument panel

illumination

Have bulbs replaced by a workshop.

Page 204 of 261

202Vehicle care

No.Circuit13Low beam and Daytime runninglight right14Mirror defog15–16Brake booster kit17Ignition, crank power supply18Engine control module19Fuel pump20–21Engine Solenoids, engine

sensors22–23Injection system24Washer system25–26Engine sensors27Heater shut off valveNo.Circuit28Engine control module29Engine control module30Engine control module31High beam left, Xenon low

beam left32High beam right, Xenon low

beam right33Engine control module34Horn35Air condition compressor clutch36Front fog lights

Page 206 of 261

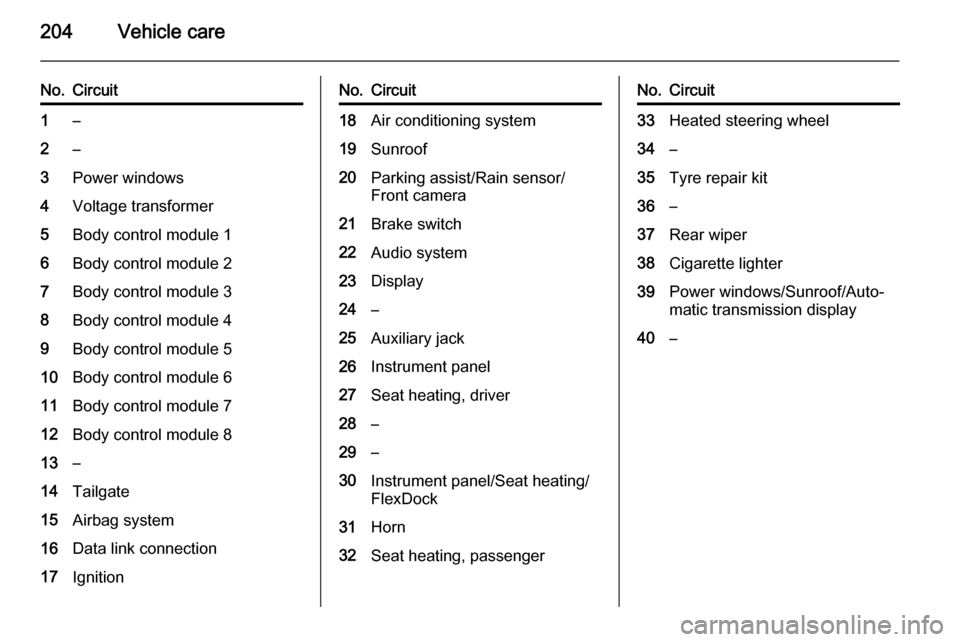

204Vehicle care

No.Circuit1–2–3Power windows4Voltage transformer5Body control module 16Body control module 27Body control module 38Body control module 49Body control module 510Body control module 611Body control module 712Body control module 813–14Tailgate15Airbag system16Data link connection17IgnitionNo.Circuit18Air conditioning system19Sunroof20Parking assist/Rain sensor/

Front camera21Brake switch22Audio system23Display24–25Auxiliary jack26Instrument panel27Seat heating, driver28–29–30Instrument panel/Seat heating/

FlexDock31Horn32Seat heating, passengerNo.Circuit33Heated steering wheel34–35Tyre repair kit36–37Rear wiper38Cigarette lighter39Power windows/Sunroof/Auto‐

matic transmission display40–

Page 211 of 261

Vehicle care209

After inflating, some driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 103.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.The use of commercially-available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 249, and

select the appropriate setting in the

menu Tyre Load in the Driver

Information Centre (DIC), Vehicle

Information Menu ? 3 95. This

setting is the reference for the tyre

pressure warnings.The menu Tyre Load only appears if

the vehicle is in a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Baselevel display and Midlevel

display:

Select

■ LO for comfort pressure up to

three people.

■ ECO for Eco pressure up to

three people.

■ Hi for full loading.

Uplevel display:

Page 212 of 261

210Vehicle care

Select■ Light for comfort pressure up to

three people.

■ Eco for Eco pressure up to

three people.

■ Max for full loading.

TPMS sensor matching process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new

wheel position after rotating the

wheels or exchanging the complete

wheel set and if one or more TPMS

sensors were replaced. The TPMS sensor matching process should also

be performed after replacing a spare

wheel with a road wheel containing

the TPMS sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a TPMS relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

2 minutes to match the first wheel

position, and 5 minutes overall to

match all four wheel positions. If it

takes longer, the matching process

stops and must be restarted.

The TPMS sensor matching process

is:

1. Apply the parking brake.

2. Turn the ignition on.3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission automated: Press

and hold brake pedal. Move and

hold the selector lever for

5 seconds in position N until P is

displayed in the DIC. P indicates

that the sensor matching process

of the TPMS can be started.

On vehicles with manual

transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu ? in the DIC.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Baselevel display and Midlevel

display:

Page 215 of 261

Vehicle care213Wheel coversWheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel nuts don't attach wheel covers.

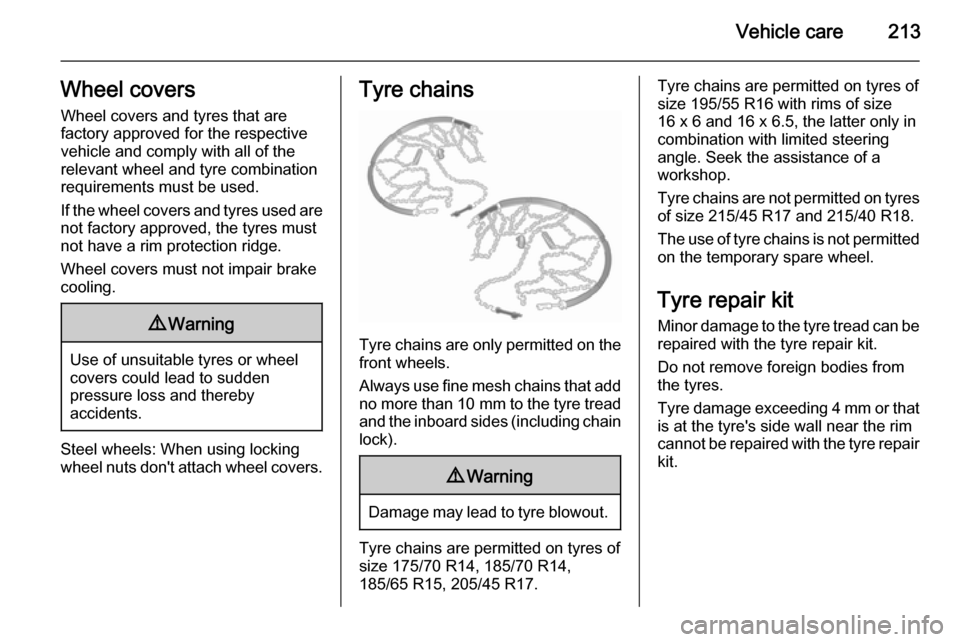

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 175/70 R14, 185/70 R14,

185/65 R15, 205/45 R17.

Tyre chains are permitted on tyres of

size 195/55 R16 with rims of size

16 x 6 and 16 x 6.5, the latter only in combination with limited steering

angle. Seek the assistance of a

workshop.

Tyre chains are not permitted on tyres of size 215/45 R17 and 215/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at the tyre's side wall near the rim

cannot be repaired with the tyre repair kit.

Page 216 of 261

214Vehicle care9Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is stowed in the load

compartment.

Depending on the equipment, the tyre repair kit is in a compartment in the

right sidewall or in a compartment

under the floor cover.

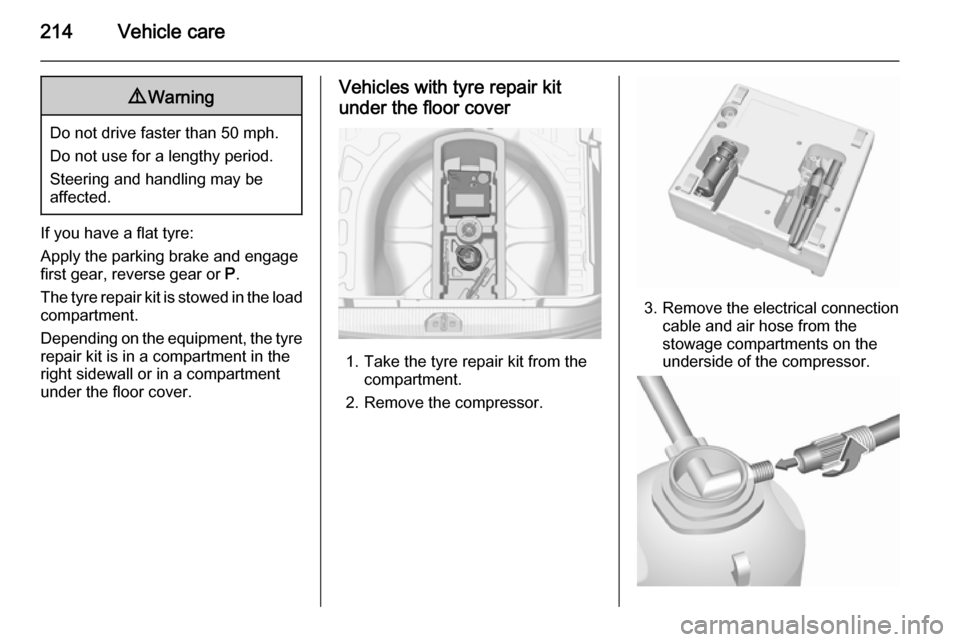

Vehicles with tyre repair kit

under the floor cover

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

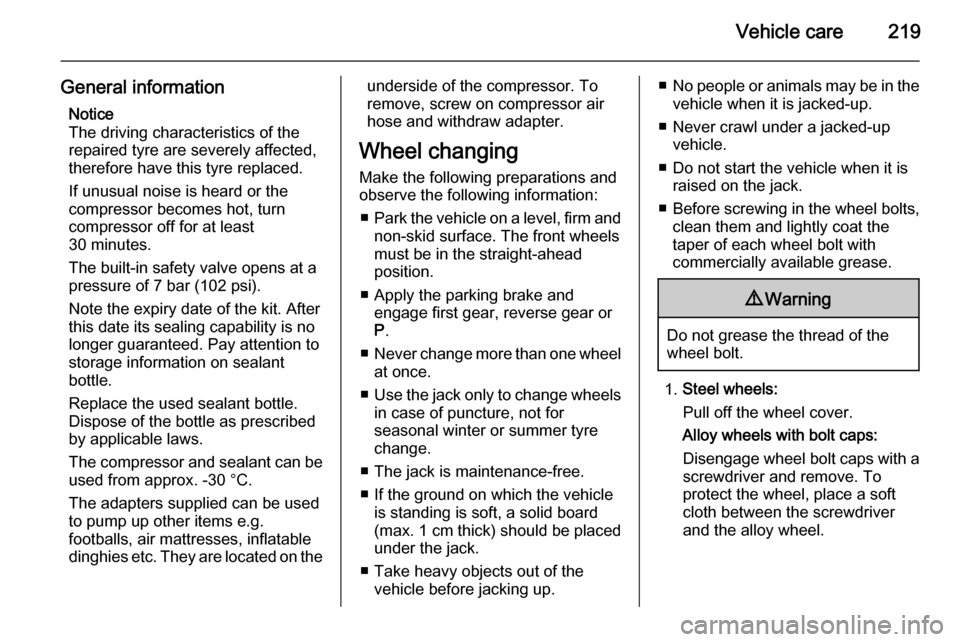

3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

Page 221 of 261

Vehicle care219

General informationNotice

The driving characteristics of the

repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on theunderside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

Wheel changing

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-skid surface. The front wheels

must be in the straight-ahead

position.

■ Apply the parking brake and engage first gear, reverse gear or

P .

■ Never change more than one wheel

at once.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ The jack is maintenance-free.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ Take heavy objects out of the vehicle before jacking up.■No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Before screwing in the wheel bolts,

clean them and lightly coat the

taper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

1. Steel wheels:

Pull off the wheel cover.

Alloy wheels with bolt caps: Disengage wheel bolt caps with a

screwdriver and remove. To

protect the wheel, place a soft

cloth between the screwdriver

and the alloy wheel.