ECU VAUXHALL CORSA 2015 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: CORSA, Model: VAUXHALL CORSA 2015Pages: 249, PDF Size: 7.32 MB

Page 190 of 249

188Vehicle care

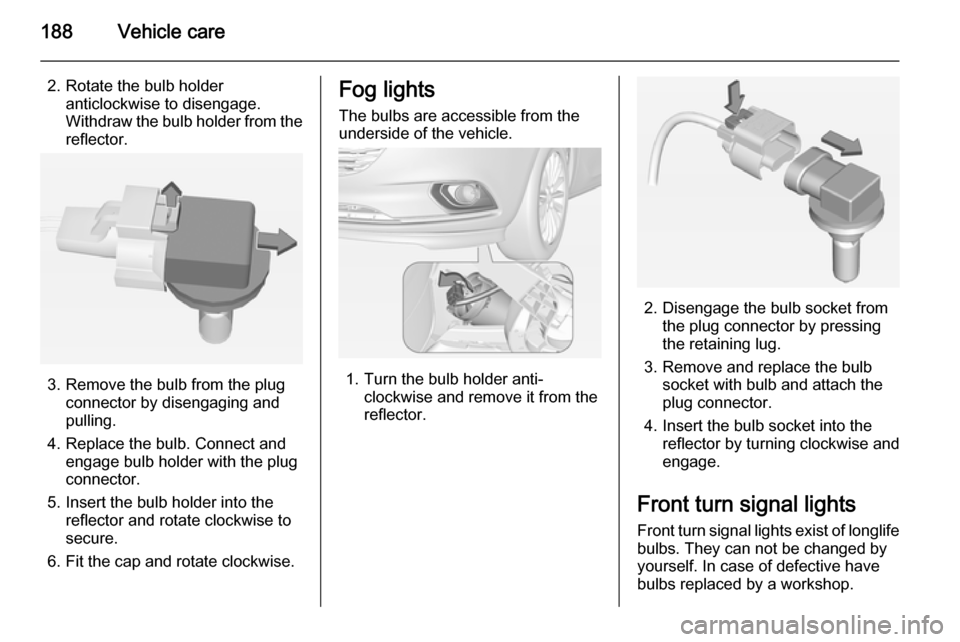

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Remove the bulb from the plug connector by disengaging and

pulling.

4. Replace the bulb. Connect and engage bulb holder with the plug

connector.

5. Insert the bulb holder into the reflector and rotate clockwise to

secure.

6. Fit the cap and rotate clockwise.

Fog lights

The bulbs are accessible from the

underside of the vehicle.

1. Turn the bulb holder anti- clockwise and remove it from the

reflector.

2. Disengage the bulb socket from the plug connector by pressing

the retaining lug.

3. Remove and replace the bulb socket with bulb and attach the

plug connector.

4. Insert the bulb socket into the reflector by turning clockwise and

engage.

Front turn signal lights

Front turn signal lights exist of longlife bulbs. They can not be changed by

yourself. In case of defective have

bulbs replaced by a workshop.

Page 191 of 249

Vehicle care189Tail lights

1. Release the cover in the loadcompartment on the respective

side and remove.

2. Unscrew both plastic securing nuts from the inside by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Press the retaining lugs and remove the bulb carrier from the

light assembly.

Page 192 of 249

190Vehicle care

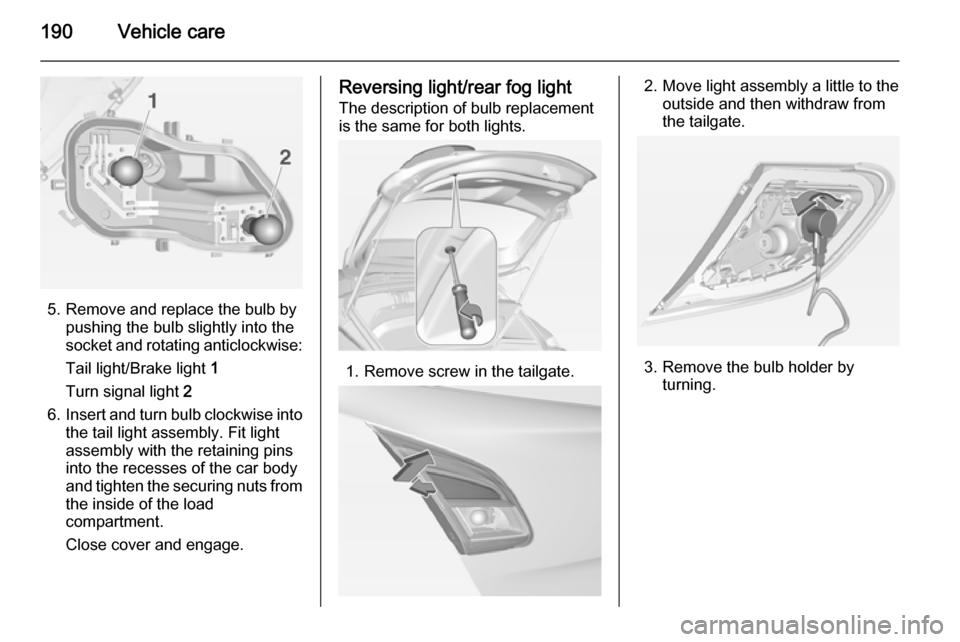

5. Remove and replace the bulb bypushing the bulb slightly into thesocket and rotating anticlockwise:

Tail light/Brake light 1

Turn signal light 2

6. Insert and turn bulb clockwise into

the tail light assembly. Fit light

assembly with the retaining pins

into the recesses of the car body

and tighten the securing nuts from

the inside of the load

compartment.

Close cover and engage.

Reversing light/rear fog light

The description of bulb replacement

is the same for both lights.

1. Remove screw in the tailgate.

2. Move light assembly a little to the outside and then withdraw from

the tailgate.

3. Remove the bulb holder by turning.

Page 214 of 249

212Vehicle care

■ Never crawl under a jacked-upvehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Before screwing in the wheel bolts,

clean them and lightly coat thetaper of each wheel bolt with

commercially available grease.9 Warning

Do not grease the thread of the

wheel bolt.

1. Steel wheels:

Pull off the wheel cover with the

hook. Vehicle tools 3 198.

Alloy wheels with bolt caps: Disengage wheel bolt caps with a

screwdriver and remove. To

protect the wheel, place a soft

cloth between the screwdriver

and the alloy wheel.

Alloy wheels with center cap:

Insert extractor in the open slot of

the center cap and substract the

cap from the wheel. Vehicle tools 3 198.

2. Install the wheel wrench ensuring

that it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by locking wheel bolts. To loosen

these specific bolts first attach the

key adapter onto the head of the

bolt before installing the wheel

wrench. The key adapter is

located in the glovebox.

Page 215 of 249

Vehicle care213

3. Ensure the jack is correctlypositioned under the relevant

vehicle jacking point.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel. Spare wheel 3 214.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Install wheel bolt caps or center

cap on alloy wheel.

11. Install vehicle jacking point cover.

12. Stow the replaced wheel 3 214,

the vehicle tools 3 198 and the

key adapter 3 56.

13. Check the tyre pressure of the installed tyre and the wheel bolttorque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Page 216 of 249

214Vehicle care

Jacking position for liftingplatform

Rear arm position of the lifting

platform centrically under the recess

of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare

wheel.

If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has always a steel

rim.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

Page 217 of 249

Vehicle care215

Fitting a double load-bay floor in this

case in the upper position 3 69.

To remove, unscrew wing nut, lift spare wheel, move to a vertical

position and remove from above.

When stowing the replaced wheel or

the temporary spare wheel back in

the spare wheel well, always secure

with the wing nut.

Temporary spare wheelCaution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full size tyre in the

rear.

Tyre chains 3 205.

Spare wheel with directional tyre If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Drive particularly carefully on wet and snow-covered road surfaces.Jump starting

Do not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

Page 243 of 249

Customer information241Radio Frequency

Identification (RFID)

RFID technology is used in some vehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in- vehicle transmitters for garage dooropeners. RFID technology in

Vauxhall vehicles does not use or

record personal information or link with any other Vauxhall system

containing personal information.

Page 248 of 249

246

VVehicle battery ........................... 182

Vehicle checks............................ 177

Vehicle data ................................ 227

Vehicle data recording and privacy ..................................... 240

Vehicle detected ahead ................92

Vehicle dimensions .................... 234

Vehicle Identification Number ....225

Vehicle jack ................................ 198

Vehicle messages .....................100

Vehicle personalisation .............103

Vehicle security ............................ 26

Vehicle specific data ......................3

Vehicle storage ........................... 176

Vehicle tools ............................... 198

Vehicle unlocking ........................... 6

Vehicle weight ........................... 233

Ventilation ................................... 118

W

Warning chimes .........................102

Warning lights ............................... 82

Warning triangle .......................... 70

Washer and wiper systems .........14

Washer fluid ............................... 181

Wheel changing .........................211

Wheel covers ............................. 205

Wheels and tyres .......................199Windows....................................... 29

Windscreen................................... 29 Windscreen wiper/washer ...........76

Winter tyres ............................... 199

Wiper blade replacement ..........184

X Xenon headlights .......................187

Xenon lighting system ................111