wheel VAUXHALL CORSA 2015 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: CORSA, Model: VAUXHALL CORSA 2015Pages: 249, PDF Size: 7.32 MB

Page 178 of 249

176Vehicle careVehicle careGeneral Information...................176

Vehicle checks ........................... 177

Bulb replacement .......................184

Electrical system ........................193

Vehicle tools .............................. 198

Wheels and tyres .......................199

Jump starting ............................. 215

Towing ....................................... 217

Appearance care .......................219General Information

Accessories and vehicle

modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps may be damaged.

Vehicle storage

Storage for a long period of time If the vehicle is to be stored for severalmonths:

■ Wash and wax the vehicle.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve the rubber seals.

■ Fill up fuel tank completely.

■ Change the engine oil.

■ Drain the washer fluid reservoir. ■ Check the coolant antifreeze and corrosion protection.

■ Adjust tyre pressure to the value specified for full load.

■ Park the vehicle in a dry, well ventilated place. Engage first orreverse gear or set selector lever to P . Prevent the vehicle from rolling.

■ Do not apply the parking brake.

Page 199 of 249

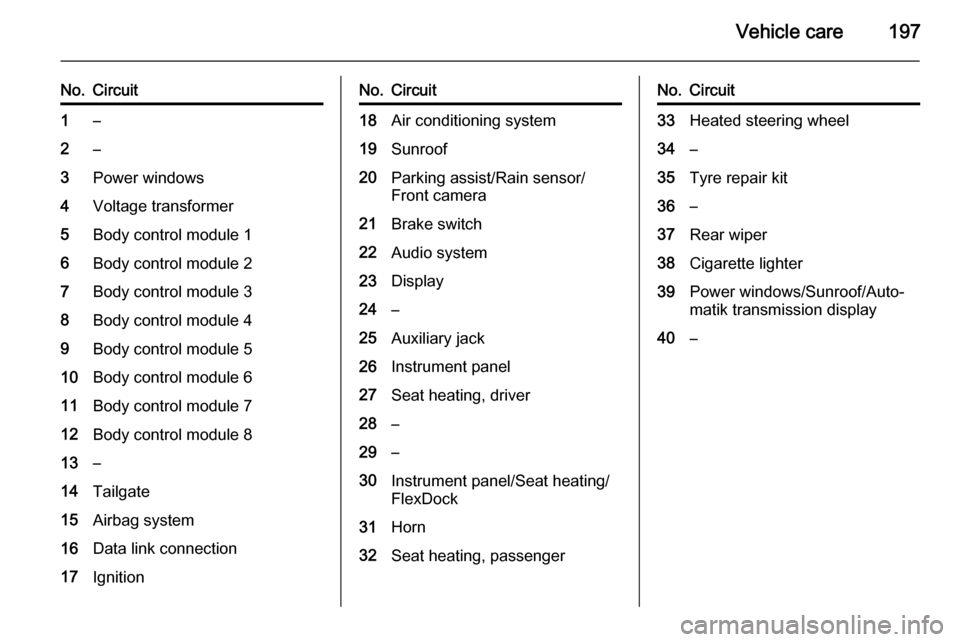

Vehicle care197

No.Circuit1–2–3Power windows4Voltage transformer5Body control module 16Body control module 27Body control module 38Body control module 49Body control module 510Body control module 611Body control module 712Body control module 813–14Tailgate15Airbag system16Data link connection17IgnitionNo.Circuit18Air conditioning system19Sunroof20Parking assist/Rain sensor/

Front camera21Brake switch22Audio system23Display24–25Auxiliary jack26Instrument panel27Seat heating, driver28–29–30Instrument panel/Seat heating/

FlexDock31Horn32Seat heating, passengerNo.Circuit33Heated steering wheel34–35Tyre repair kit36–37Rear wiper38Cigarette lighter39Power windows/Sunroof/Auto‐

matik transmission display40–

Page 200 of 249

198Vehicle careVehicle toolsTools

Vehicles with tyre repair kit

On versions with rear carrier system

or double load-bay floor, the tools are

located together with the towing eye

and tyre repair kit on the right side in

the load compartment behind a cover.

Some tools, the towing eye and the

tyre repair kit are located in the load

compartment below the floor cover.

Vehicles with spare wheel

The jack, the wheel bolt wrench and

some tools are located on the right

side in the load compartment behind

a cover 3 69.

Page 201 of 249

Vehicle care199Wheels and tyresTyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb

when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres Winter tyres improve driving safety attemperatures below 7 °C and shouldtherefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 237.

Tyre size 185/60 R 15 is only

permitted as winter tyre.In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Tyre designations E.g. 195/55 R 16 95 H195=tyre width, mm55=cross-section ratio (tyre height

to tyre width), %R=belt type: RadialRF=type: RunFlat16=wheel diameter, inches95=load index e.g. 95 is equivalent

to 690 kgH=speed code letter

Speed code letter:

Q=up to 100 mphS=up to 112 mphT=up to 118 mphH=up to 130 mphV=up to 150 mphW=up to 168 mphDirectional tyres

Directional tyres must be mounted so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Unscrew the valve cap.

Page 202 of 249

200Vehicle care

Tyre pressure 3 237.

The tyre pressure information label on the right door frame indicates theoriginal equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

■ Identify the engine identifier code. Engine data 3 230.

■ Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 237.For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased, switch off ignition. After

adjusting tyre pressure switch on

ignition and select the relevant setting on the page Tyre load in the Driver

Information Centre 3 93.

Tyre pressure monitoring

system The tyre pressure monitoring system

(TPMS) checks the pressure of all

four tyres once a minute when vehicle speed exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Menu in the

Driver Information Centre (DIC).

Page 203 of 249

Vehicle care201

The menu can be selected by the

buttons on the turn signal lever.

Press the MENU button to select the

Vehicle Menu .

Turn the adjuster wheel to select the

tyre pressure monitoring system.

Baselevel display and Midlevel

display:

The tyre pressure for each tyre is

displayed on its own page.

Uplevel display:

The tyre pressures for all tyres are

displayed on one page.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in the DIC.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 91.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 237.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

Page 204 of 249

202Vehicle care

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for getting low

pressure. Check tyre pressure.

Vehicle messages 3 100.

If the tyre pressure must be reduced or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three tyres

the system remains operational.

The use of commercially-available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

Vehicle loading status

Adjust tyre pressure to load condition according tyre information label or

tyre pressure chart 3 237, and select

the according setting in the menu Tire

Load in the DIC, Vehicle Menu 3 93.

Baselevel display and Midlevel

display:Select

■ LO for comfort pressure up to

three people

■ ECO for Eco pressure up to

three people

■ Hi for full loading

Uplevel display:

Select ■ Light for comfort pressure up to

three people

■ Eco for Eco pressure up to

three people

■ Max for full loading

Page 205 of 249

Vehicle care203

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new

wheel position after rotating the

wheels or exchanging the complete

wheel set and if one or more TPMS sensors were replaced. The TPMS

sensor matching process should also be performed after replacing a spare

wheel with a road wheel containing

the TPMS sensor.

The malfunction light and the warning

message or code should go off at the

next ignition cycle. The sensors are

matched to the wheel positions, using a TPMS relearn tool, in the following

order: left side front wheel, right side

front wheel, right side rear wheel and

left side rear wheel. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

two minutes to match the first wheel position, and five minutes overall tomatch all four wheel positions. If it

takes longer, the matching process

stops and must be restarted.

The TPMS sensor matching process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission automated: move

and hold the selector lever for

five seconds in position N until P

is displayed in the DIC. P

indicates that the sensor

matching process of the TPMS

can be started.

4. Use the MENU button on the turn

signal lever to select the Vehicle

Menu in the DIC.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Baselevel display and Midlevel

display:

Uplevel display:

Page 206 of 249

204Vehicle care

6. Press the SET/CLR button to

begin the sensor matching process. A message requesting

acceptance of the process should

display.

7. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to signal the

receiver is in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp

confirms that the sensor

identification code has been

matched to this wheel position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate the sensoridentification code has been

matched to the left side rear

wheel, and the TPMS sensor

matching process is no longer

active.

13. Turn off the ignition.

14. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

label.

15. Ensure the tyre loading status is set according selected pressure

3 93.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving tyre temperature and pressure increase.

The tyre pressure value displayed in

the DIC shows the actual tyre

pressure. Therefore it is important to

check tyre pressure with cold tyres.

Tread depth Check tread depth at regular

intervals.Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Page 207 of 249

Vehicle care205

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and to make other

vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.Caution

When converting to wheels with 14'', the ground clearance will be

reduced. This must be considered when passing over obstacles.

9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.

9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel nuts don't attach wheel covers.

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.