tow VAUXHALL CORSA 2016 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016, Model line: CORSA, Model: VAUXHALL CORSA 2016Pages: 267, PDF Size: 7.79 MB

Page 187 of 267

Driving and operating185Trailer towingTrailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%

The permitted trailer loads apply up to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the air becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8%, e.g. motorways).The permissible gross train weight

must not be exceeded. This weight is specified on the identification plate

3 240.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.Petrol and diesel engines

The maximum permissible vertical

coupling load (55 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Engine B14XEL LPG

The maximum permissible vertical

coupling load (45 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Rear axle loadPetrol and diesel engines

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 60 kg for the 3-door

vehicle, the gross vehicle weight

rating by 55 kg.Engine B14XEL LPG

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 70 kg for the 3-door

vehicle and the gross vehicle weight

rating by 45 kg.Delivery van

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 60 kg and the

gross vehicle weight rating by 55 kg.

Page 188 of 267

186Driving and operatingGeneral

If the permitted rear axle load is

exceeded a maximum speed of

60 mph applies. If lower national

maximum speeds are specified for

trailer operation, they must be

complied with.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of coupling ball bar

The coupling ball bar is stowed in a

bag in the spare wheel well and

secured to the lashing eyes in the

load compartment.

When inserting, fit protective cap over rotary knob with key.

Fitting the coupling ball bar

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

● The rotary knob rests on the

coupling ball bar.

● Green marking on the rotary knob is not visible.

● Locking pin at the top of the coupling ball bar is set inwards.

● The key is in the lock.

Page 190 of 267

188Driving and operatingEye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob is visible.

● There must be no gap between the rotary knob and the coupling

ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.

9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball bar

Insert the key in the lock and unlock

the coupling ball bar.

Push the rotary knob onto the

coupling ball bar and rotate right while pressed down until it engages. Pull

out the ball bar downwards.

Insert sealing plug in opening for

coupling ball bar. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep

steering wheel as still as possible.

Trailer stability assist is a function of

the Electronic Stability Control 3 154.

Page 191 of 267

Vehicle care189Vehicle careGeneral Information...................190

Accessories and vehicle modifications .......................... 190

Vehicle storage ........................190

End-of-life vehicle recovery .....190

Vehicle checks ........................... 191

Performing work ......................191

Bonnet ..................................... 191

Engine oil ................................. 192

Engine coolant ......................... 193

Washer fluid ............................ 195

Brakes ..................................... 195

Brake fluid ............................... 195

Vehicle battery ......................... 195

Diesel fuel system bleeding .....197

Wiper blade replacement ........197

Bulb replacement .......................198

Halogen headlights ..................198

Xenon headlights .....................201

Fog lights ................................. 202

Front turn signal lights .............202

Tail lights ................................. 202

Side turn signal lights ..............204

Centre high-mounted brake light ......................................... 205Number plate light...................205

Interior lights ............................ 205

Instrument panel illumination ...205

Electrical system ........................206

Fuses ....................................... 206

Engine compartment fuse box . 207

Instrument panel fuse box .......209

Vehicle tools .............................. 211

Tools ........................................ 211

Wheels and tyres .......................212

Winter tyres ............................. 212

Tyre designations ....................212

Tyre pressure .......................... 212

Tyre pressure monitoring system .................................... 213

Tread depth ............................. 217

Changing tyre and wheel size . 218

Wheel covers ........................... 218

Tyre chains .............................. 218

Tyre repair kit .......................... 219

Wheel changing .......................224

Spare wheel ............................ 226

Jump starting ............................. 228

Towing ....................................... 230

Towing the vehicle ...................230

Towing another vehicle ...........231Appearance care .......................232

Exterior care ............................ 232

Interior care ............................. 234

Page 213 of 267

Vehicle care211Vehicle tools

Tools

Vehicles with tyre repair kit

The tools are located together with

the towing eye and tyre repair kit in the load compartment below the floor cover.

On VXR or LPG version or versions

with rear carrier system or double

load-bay floor, the tools are located

together with the towing eye and tyre

repair kit on the right side of the load

compartment, behind a cover.

Vehicles with spare wheel

The jack, wheel bolt wrench and

some tools are located on the right

side of the load compartment, behind a cover 3 70.

Page 221 of 267

Vehicle care219Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add

no more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 175/70 R14, 185/70 R14,

185/65 R15, 205/45 R17.

Tyre chains are permitted on tyres of

size 195/55 R16 with rims of size

16 x 6 and 16 x 6.5, the latter only in combination with limited steering

angle. Seek the assistance of a

workshop.

Tyre chains are not permitted on tyres of size 215/45 R17 and 215/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's side wall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is stowed in the load

compartment.

Depending on the equipment, the tyre repair kit is in a compartment in the

right sidewall or in a compartment

under the floor cover.

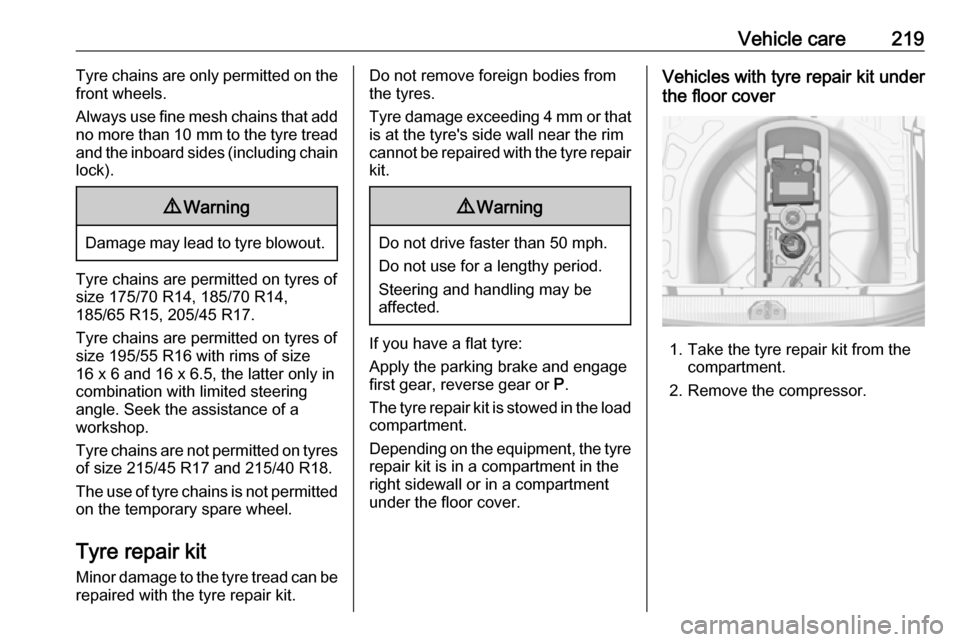

Vehicles with tyre repair kit under

the floor cover

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

Page 222 of 267

220Vehicle care

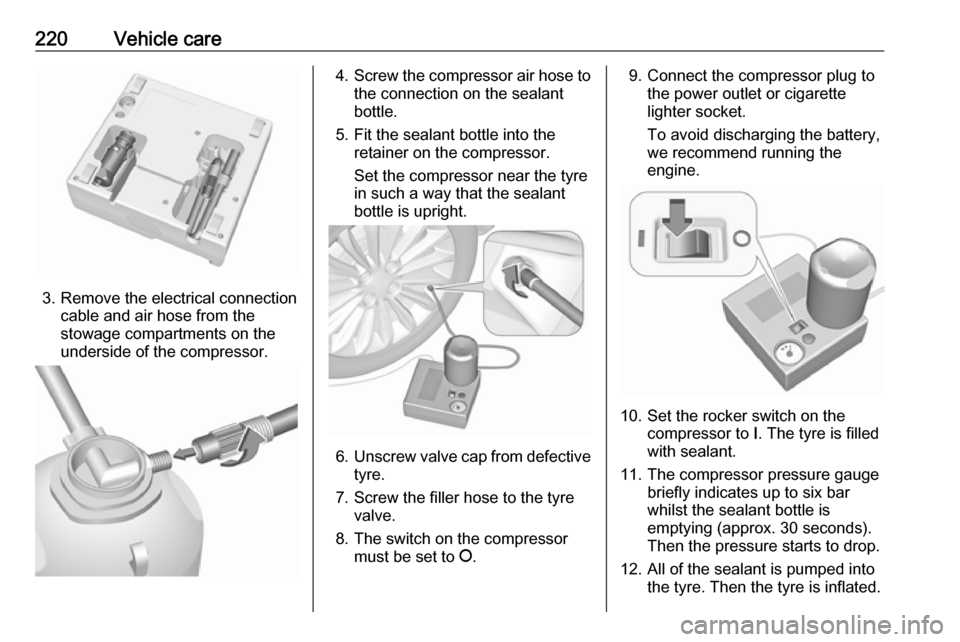

3. Remove the electrical connectioncable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to six bar

whilst the sealant bottle is

emptying (approx. 30 seconds).

Then the pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

Page 223 of 267

Vehicle care22113. The prescribed tyre pressureshould be obtained within ten

minutes. Tyre pressure 3 252.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor for

longer than ten minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the freeconnection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

six miles (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

18. Stow away tyre repair kit in load compartment.

Page 225 of 267

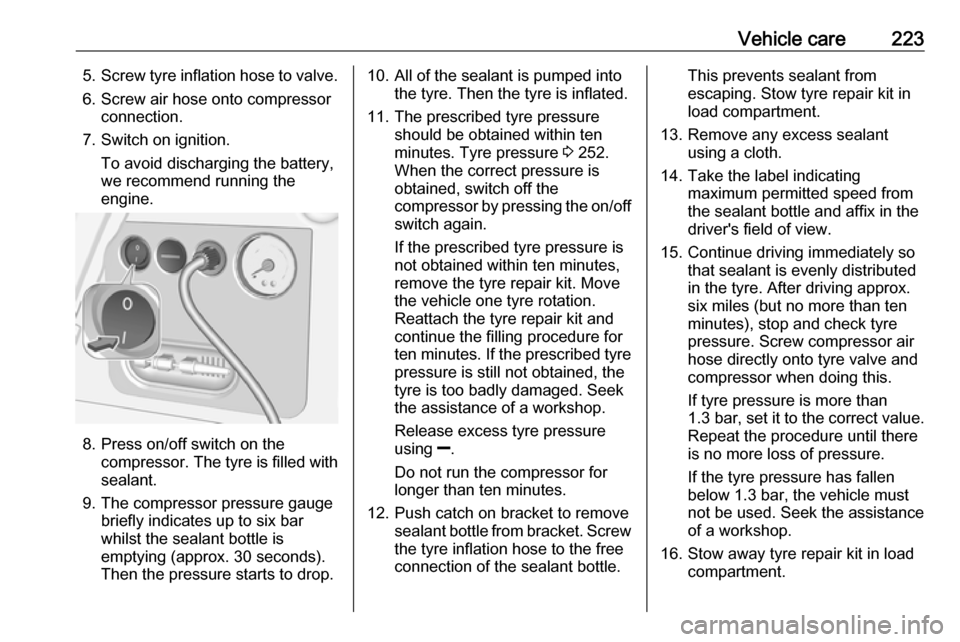

Vehicle care2235.Screw tyre inflation hose to valve.

6. Screw air hose onto compressor connection.

7. Switch on ignition. To avoid discharging the battery,we recommend running the

engine.

8. Press on/off switch on the compressor. The tyre is filled withsealant.

9. The compressor pressure gauge briefly indicates up to six bar

whilst the sealant bottle is

emptying (approx. 30 seconds).

Then the pressure starts to drop.

10. All of the sealant is pumped into the tyre. Then the tyre is inflated.

11. The prescribed tyre pressure should be obtained within ten

minutes. Tyre pressure 3 252.

When the correct pressure is

obtained, switch off the

compressor by pressing the on/off

switch again.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Release excess tyre pressure

using ].

Do not run the compressor for

longer than ten minutes.

12. Push catch on bracket to remove sealant bottle from bracket. Screw

the tyre inflation hose to the free

connection of the sealant bottle.This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

13. Remove any excess sealant using a cloth.

14. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

15. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

six miles (but no more than ten

minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

16. Stow away tyre repair kit in load compartment.

Page 228 of 267

226Vehicle care

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Install wheel bolt caps or centre

cap on alloy wheel.

11. Install vehicle jacking point cover.

12. Stow and secure the replaced wheel, the vehicle tools 3 211 and

the adapter for the locking wheel

bolts 3 57.

13. Check the tyre pressure of the installed tyre and the wheel bolt

torque as soon as possible.

Have the defective tyre renewed or repaired as soon as possible.

Jacking position for lifting platformRear arm position of the lifting

platform located centrally under the

recess of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.