ECU VAUXHALL CORSA F 2017.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2017.5, Model line: CORSA F, Model: VAUXHALL CORSA F 2017.5Pages: 267, PDF Size: 7.81 MB

Page 183 of 267

Driving and operating181The fuel filler cap can be retained in

the bracket on the fuel filler flap.

To refuel, fully insert the pump nozzle

and switch it on.

After the automatic cut-off, the tank

can be topped up by operating the

pump nozzle a maximum of two more

times.Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and allow it to engage.

Liquid gas refuellingFollow the operating and safety

instructions of the filling station when

refuelling.

The filling valve for the liquid gas is

behind the fuel filler cap.

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH filler neck: Place the filler nozzle

into the adapter. Press locking lever

on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn clockwise or

anticlockwise through one quarter

turn. Pull locking lever of filler nozzle

fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button at the liquid gas

supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow securely in vehicle.

Page 187 of 267

Driving and operating185The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 240.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.Petrol and diesel engines

The maximum permissible vertical

coupling load (55 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Engine B14XEL LPG

The maximum permissible vertical

coupling load (45 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Rear axle loadPetrol and diesel engines

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 60 kg for the 3-door

vehicle, the gross vehicle weight

rating by 55 kg.Engine B14XEL LPG

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 70 kg for the 3-door

vehicle and the gross vehicle weight

rating by 45 kg.Delivery van

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 60 kg and the

gross vehicle weight rating by 55 kg.General

If the permitted rear axle load is

exceeded a maximum speed of

60 mph applies. If lower national

maximum speeds are specified for

trailer operation, they must be

complied with.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of coupling ball bar

The coupling ball bar is stowed in a

bag in the spare wheel well and

secured to the lashing eyes in the

load compartment.

Page 194 of 267

192Vehicle care

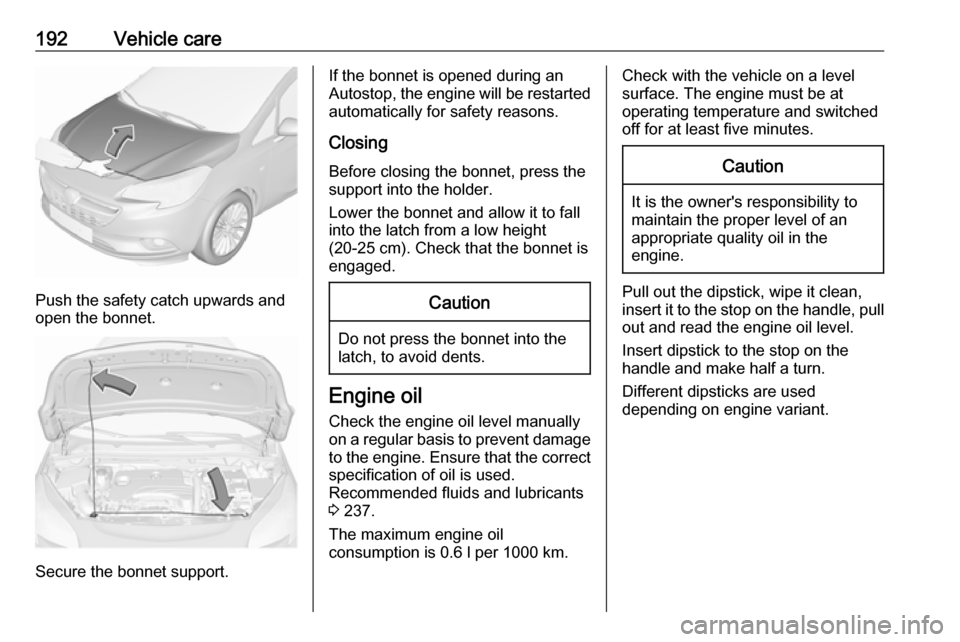

Push the safety catch upwards and

open the bonnet.

Secure the bonnet support.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing

Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is engaged.Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 237.

The maximum engine oil

consumption is 0.6 l per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Insert dipstick to the stop on the

handle and make half a turn.

Different dipsticks are used

depending on engine variant.

Page 203 of 267

Vehicle care201Sidelight/daytime running light

with LEDs

Sidelights and daytime running lightsare designed as LEDs and cannot be

changed. Consult a workshop in case of a defective LED.

Xenon headlights9 Danger

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Sidelight/daytime running lights are

designed as LEDs and cannot be

changed.

Bulbs for corner lighting can be

changed.

Front turn signal lights 3 202.

Corner lighting

1. Rotate the cap (3) anticlockwise

and remove it.

2. Rotate the bulb holderanticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Remove the bulb from the plug connector by disengaging and

pulling.

4. Replace the bulb. Connect and engage bulb holder with the plug

connector.

5. Insert the bulb holder into the reflector and rotate clockwise to

secure.

6. Fit the cap and rotate clockwise.

Page 205 of 267

Vehicle care203

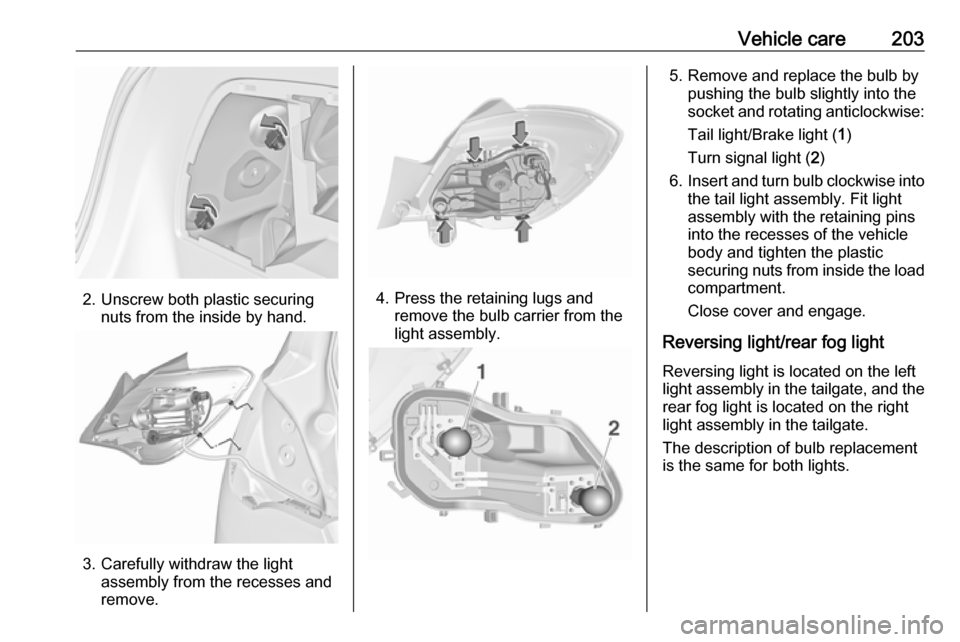

2. Unscrew both plastic securingnuts from the inside by hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Press the retaining lugs and remove the bulb carrier from the

light assembly.

5. Remove and replace the bulb by pushing the bulb slightly into thesocket and rotating anticlockwise:

Tail light/Brake light ( 1)

Turn signal light ( 2)

6. Insert and turn bulb clockwise into

the tail light assembly. Fit light

assembly with the retaining pins

into the recesses of the vehicle

body and tighten the plastic

securing nuts from inside the load

compartment.

Close cover and engage.

Reversing light/rear fog light Reversing light is located on the left

light assembly in the tailgate, and the rear fog light is located on the right

light assembly in the tailgate.

The description of bulb replacement

is the same for both lights.

Page 206 of 267

204Vehicle care

1. Remove screw from the tailgate.

2.Move light assembly slightly to the

outside, then withdraw from the

tailgate.

3. Remove the bulb holder by turning.

4. Remove the bulb by pushingslightly into the socket and

rotating anticlockwise. Replace

the bulb.

5. Insert the bulb socket into the assembly and turn to secure.

6. Attach light assembly into the tailgate and secure with the

screw.

Side turn signal lights

To replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

Page 228 of 267

226Vehicle care2. Install the wheel wrench ensuringthat it locates securely and loosen

each wheel bolt by half a turn.

The wheels might be protected by locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox.

3. Ensure the jack is correctly positioned under the relevant

vehicle jacking point.

On versions with sill panelling or

retrofitted sill panelling, no jack

may be used. The vehicle may be

damaged.

4. Set the jack to the necessary height. Position it directly below

the jacking point in a manner that

prevents it from slipping.

Attach jack handle and with the

jack correctly aligned rotate handle until wheel is clear of theground.

5. Unscrew the wheel bolts.

6. Change the wheel.

7. Screw on the wheel bolts.

8. Lower vehicle.

9. Install the wheel wrench ensuring that it locates securely and tighten

each bolt in a crosswise

sequence. Tightening torque is

110 Nm.

10. Align the valve hole in the wheel cover of the steel wheel with the

tyre valve before installing.

Page 229 of 267

Vehicle care227Install wheel bolt caps or centre

cap on alloy wheel.

11. Install vehicle jacking point cover.

12. Stow and secure the replaced wheel, the vehicle tools 3 211 and

the adapter for the locking wheel

bolts 3 56.

13. Check the tyre pressure of the installed tyre and the wheel bolttorque as soon as possible.

Have the defective tyre renewed or

repaired as soon as possible.

Jacking position for lifting platformRear arm position of the lifting

platform located centrally under the

recess of the sill.

Front arm position of the lifting

platform at the underbody.

Spare wheel If mounting a spare wheel, which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

The spare wheel has a steel rim.

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

3-door/5-door hatchback

The spare wheel is located in the load

compartment beneath the floor

covering. It is secured with a wing nut.

Fitting a double load-bay floor in this

case in the upper position 3 69.

Page 230 of 267

228Vehicle careTo remove, unscrew wing nut, liftspare wheel, move to a vertical

position and remove from above.

When stowing the replaced wheel or

the temporary spare wheel back in

the spare wheel well, always secure

with the wing nut.Delivery van

Remove load floor.

The spare wheel is screwed down

together with the floor cover.

Unscrew wing nut and lift load cover.

Remove spacer above the spare

wheel, lift the wheel, move to a

vertical position and remove from

above.

When stowing the replaced wheel or

the temporary spare wheel back in

the spare wheel well, always insert

the adapter and secure the load cover with the wing nut.

Depending on the defective replaced

wheel, the spacer can be omitted if

necessary, or the wheel can be bolted down without the floor cover.

Temporary spare wheelCaution

The use of the temporary spare

wheel could affect driveability.

Have the defective tyre renewed

or repaired as soon as possible.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full size tyre in the

rear.

Tyre chains 3 219.

Spare wheel with directional tyre If possible, fit directional tyres such

that they roll in the direction of travel.

The rolling direction is indicated by a

symbol (e.g. an arrow) on the

sidewall.

Page 259 of 267

Customer information257copyright holders be liable for any

claim, damages or other liability,

whether in an action of contract, tort

or otherwise, arising from, out of or in

connection with the software or the

use or other dealings in the software.

Except as contained in this notice, the

name of a copyright holder shall not

be used in advertising or otherwise to

promote the sale, use or other

dealings in this Software without prior

written authorization of the copyright

holder.

unzip

This is version 2005-Feb-10 of the Info-ZIP copyright and license. The

definitive version of this document

should be available at ftp://ftp.info-

zip.org/pub/infozip/license.html

indefinitely.

Copyright (c) 1990-2005 Info-ZIP. All

rights reserved.

For the purposes of this copyright and license, “Info-ZIP” is defined as thefollowing set of individuals:

Mark Adler, John Bush, Karl Davis,

Harald Denker, Jean-Michel Dubois,

Jean-loup Gailly, Hunter Goatley, EdGordon, Ian Gorman, Chris Herborth,

Dirk Haase, Greg Hartwig, Robert

Heath, Jonathan Hudson, Paul

Kienitz, David Kirschbaum, Johnny

Lee, Onno van der Linden, Igor

Mandrichenko, Steve P. Miller, Sergio Monesi, Keith Owens, George

Petrov, Greg Roelofs, Kai Uwe

Rommel, Steve Salisbury, Dave

Smith, Steven M. Schweda, Christian Spieler, Cosmin Truta, Antoine

Verheijen, Paul von Behren, Rich

Wales, Mike White.

This software is provided “as is,”

without warranty of any kind, express

or implied. In no event shall Info-ZIP

or its contributors be held liable for

any direct, indirect, incidental, special

or consequential damages arising out of the use of or inability to use this

software.

Permission is granted to anyone to

use this software for any purpose,

including commercial applications,

and to alter it and redistribute it freely,

subject to the following restrictions:1. Redistributions of source code must retain the above copyright

notice, definition, disclaimer, and

this list of conditions.

2. Redistributions in binary form (compiled executables) must

reproduce the above copyright

notice, definition, disclaimer, and

this list of conditions in

documentation and/or other

materials provided with the distribution. The sole exception to

this condition is redistribution of a

standard UnZipSFX binary

(including SFXWiz) as part of a

self-extracting archive; that is

permitted without inclusion of this

license, as long as the normal

SFX banner has not been

removed from the binary or

disabled.

3. Altered versions--including, but not limited to, ports to new

operating systems, existing ports

with new graphical interfaces, and dynamic, shared, or static library

versions--must be plainly marked

as such and must not be

misrepresented as being the