tow VAUXHALL CORSA F 2018.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018.5, Model line: CORSA F, Model: VAUXHALL CORSA F 2018.5Pages: 271, PDF Size: 7.85 MB

Page 183 of 271

Driving and operating181

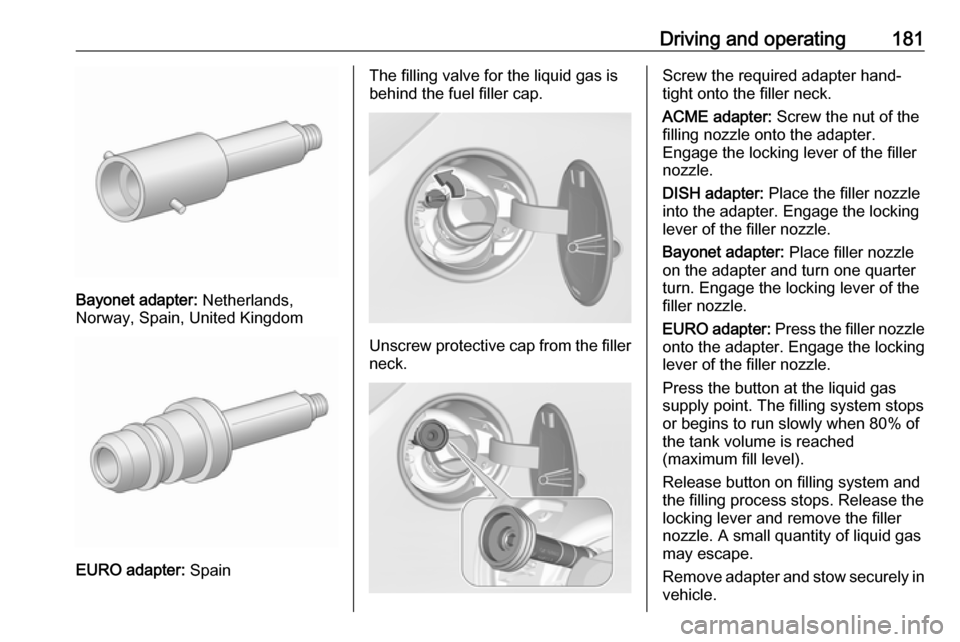

Bayonet adapter: Netherlands,

Norway, Spain, United Kingdom

EURO adapter: Spain

The filling valve for the liquid gas is

behind the fuel filler cap.

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

ACME adapter: Screw the nut of the

filling nozzle onto the adapter.

Engage the locking lever of the filler

nozzle.

DISH adapter: Place the filler nozzle

into the adapter. Engage the locking

lever of the filler nozzle.

Bayonet adapter: Place filler nozzle

on the adapter and turn one quarter

turn. Engage the locking lever of the

filler nozzle.

EURO adapter: Press the filler nozzle

onto the adapter. Engage the locking

lever of the filler nozzle.

Press the button at the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

may escape.

Remove adapter and stow securely in

vehicle.

Page 184 of 271

182Driving and operatingFit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank should only be

filled to 80% capacity, for safety

reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Fuel filler cap

Only use genuine fuel filler caps. Diesel-engined vehicles have special fuel filler caps.

Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

The bulb outage detection function for

trailer brake light cannot detect a

partial bulb outage. E.g. in case of

four bulbs with a power of 5 W each,

the function only detects lamp outage when only a single 5 W lamp remains

or none remain.

Fitting of towing equipment could

cover the opening of the towing eye. If this is the case use the coupling ball bar for towing. Always keep the

coupling ball bar in the vehicle when

not in use.Driving characteristics and

towing tips

Before attaching a trailer, lubricatethe coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce

snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

1000 kg a speed of 50 mph must not

be exceeded; the use of a stabiliser is

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 252.

Page 185 of 271

Driving and operating183Trailer towingTrailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12%

The permitted trailer loads apply up to the specified incline and up to an

altitude of 1000 m above sea level.

Since engine power decreases as

altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10%

for every 1000 m of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8%, e.g. motorways).The permissible gross train weight

must not be exceeded. This weight is specified on the identification plate

3 238.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.Petrol and diesel engines

The maximum permissible vertical

coupling load (55 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Engine B14XEL LPG / D14XEL LPG

The maximum permissible vertical

coupling load (45 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Rear axle loadPetrol and diesel engines

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 60 kg for the 3-door

vehicle, the gross vehicle weight

rating by 55 kg.Engine B14XEL LPG / D14XEL LPG

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 70 kg for the 3-door

vehicle and the gross vehicle weight

rating by 45 kg.Delivery van

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 60 kg and the

gross vehicle weight rating by 55 kg.

Page 186 of 271

184Driving and operatingGeneral

If the permitted rear axle load is

exceeded a maximum speed of

60 mph applies. If lower national

maximum speeds are specified for

trailer operation, they must be

complied with.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of coupling ball bar

The coupling ball bar is stowed in a

bag in the spare wheel well and

secured to the lashing eyes in the

load compartment.

When inserting, fit protective cap over rotary knob with key.

Fitting the coupling ball bar

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

● The rotary knob rests on the

coupling ball bar.

● Green marking on the rotary knob is not visible.

● Locking pin at the top of the coupling ball bar is set inwards.

● The key is in the lock.

Page 188 of 271

186Driving and operatingEye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob is visible.

● There must be no gap between the rotary knob and the coupling

ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.

9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball bar

Insert the key in the lock and unlock

the coupling ball bar.

Push the rotary knob onto the

coupling ball bar and rotate right while pressed down until it engages. Pull

out the ball bar downwards.

Insert sealing plug in opening for

coupling ball bar. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep

steering wheel as still as possible.

Trailer stability assist is a function of

the Electronic Stability Control 3 151.

Page 189 of 271

Vehicle care187Vehicle careGeneral Information...................187

Accessories and vehicle modifications .......................... 187

Vehicle storage ........................188

End-of-life vehicle recovery .....188

Vehicle checks ........................... 189

Performing work ......................189

Bonnet ..................................... 189

Engine oil ................................. 190

Engine coolant ......................... 191

Washer fluid ............................ 192

Brakes ..................................... 193

Brake fluid ............................... 193

Vehicle battery ......................... 193

Diesel fuel system bleeding .....194

Wiper blade replacement ........195

Bulb replacement .......................195

Halogen headlights ..................195

Xenon headlights .....................198

Fog lights ................................. 199

Front turn lights .......................199

Tail lights ................................. 200

Side turn lights ......................... 202

Centre high-mounted brake light ......................................... 202Number plate light...................202

Interior lights ............................ 203

Electrical system ........................203

Fuses ....................................... 203

Engine compartment fuse box . 204

Instrument panel fuse box .......207

Vehicle tools .............................. 208

Tools ........................................ 208

Wheels and tyres .......................209

Winter tyres ............................. 209

Tyre designations ....................210

Tyre pressure .......................... 210

Tyre pressure monitoring

system .................................... 211

Tread depth ............................. 215

Changing tyre and wheel size . 216

Wheel covers ........................... 216

Tyre chains .............................. 217

Tyre repair kit .......................... 217

Wheel changing .......................222

Spare wheel ............................ 224

Jump starting ............................. 226

Towing ....................................... 228

Towing the vehicle ...................228

Towing another vehicle ...........229

Appearance care .......................230

Exterior care ............................ 230

Interior care ............................. 232General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Vauxhall. Furthermore,

such changes may affect driver

assistance systems, fuel

consumption, CO 2 emissions and

other emissions of the vehicle. They

may also invalidate the vehicle

operating permit.

Page 210 of 271

208Vehicle careNo.Circuit18Air conditioning system19Sunroof20Parking assist / Rain sensor /

Front camera21Brake switch22Audio system23Display24–25Auxiliary jack26Instrument panel27–28–29–30–31Horn32–33Heated steering wheelNo.Circuit34–35Tyre repair kit36–37Rear wiper38Cigarette lighter39Power windows / Sunroof /

Automatic transmission display40–Vehicle tools

Tools

Vehicles without spare wheel

The tools are located together with

the towing eye in the load

compartment below the floor cover.

Page 211 of 271

Vehicle care209

The tools and the towing eye are

located on the right side of the load compartment behind a cover.

On VXR or LPG version or versions

with rear carrier system, the tools are located together with the towing eye

on the right side of the load

compartment, behind a cover.

Vehicles with spare wheel

The jack, wheel bolt wrench and

some tools are located on the right

side of the load compartment, behind a cover 3 69.

Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 252.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Page 219 of 271

Vehicle care217Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 175/70 R14, 185/70 R14,

185/65 R15, 205/45 R17.

Tyre chains are permitted on tyres of

size 195/55 R16 with rims of size

16 x 6 and 16 x 6.5, the latter only in combination with limited steering

angle. Seek the assistance of a

workshop.

Tyre chains are not permitted on tyres of size 215/45 R17 and 215/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's side wall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is stowed in the load

compartment.

Depending on the equipment, the tyre repair kit is in a compartment in the

right sidewall or in a compartment

under the floor cover.

Vehicles with tyre repair kit under

the floor cover

1. Take the tyre repair kit from the compartment.

2. Remove the compressor.

Page 220 of 271

218Vehicle care

3. Remove the electrical connectioncable and air hose from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.