spare wheel VAUXHALL CORSA F 2018 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: CORSA F, Model: VAUXHALL CORSA F 2018Pages: 271, PDF Size: 7.86 MB

Page 71 of 271

Storage69To remove rear cover, unhook

retaining strings from tailgate.

Lift cover at the rear and push it

upwards at the front. Remove the cover.

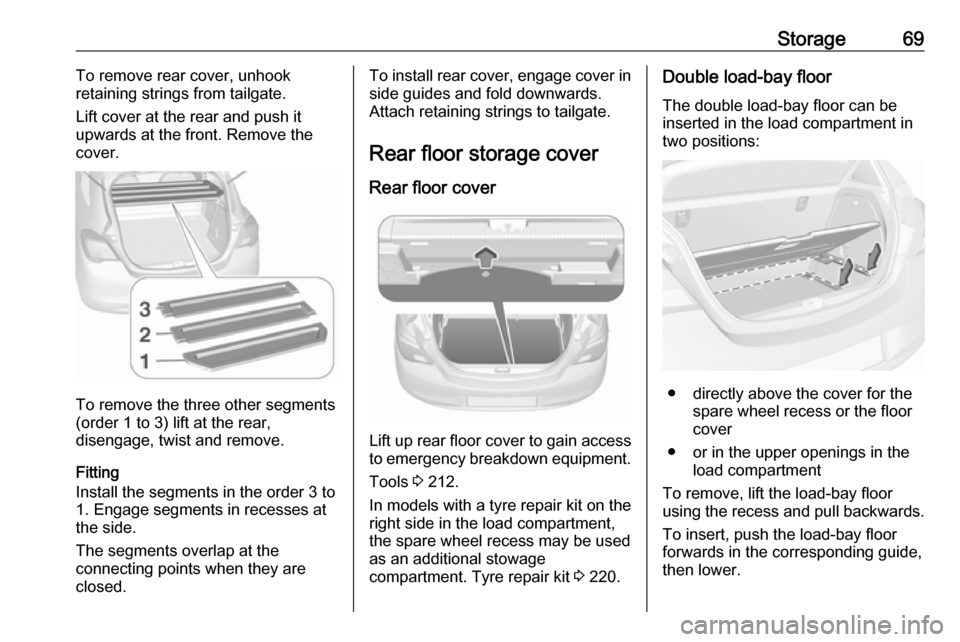

To remove the three other segments

(order 1 to 3) lift at the rear,

disengage, twist and remove.

Fitting

Install the segments in the order 3 to

1. Engage segments in recesses at

the side.

The segments overlap at the

connecting points when they are

closed.

To install rear cover, engage cover in side guides and fold downwards.

Attach retaining strings to tailgate.

Rear floor storage cover

Rear floor cover

Lift up rear floor cover to gain access

to emergency breakdown equipment.

Tools 3 212.

In models with a tyre repair kit on the

right side in the load compartment,

the spare wheel recess may be used

as an additional stowage

compartment. Tyre repair kit 3 220.

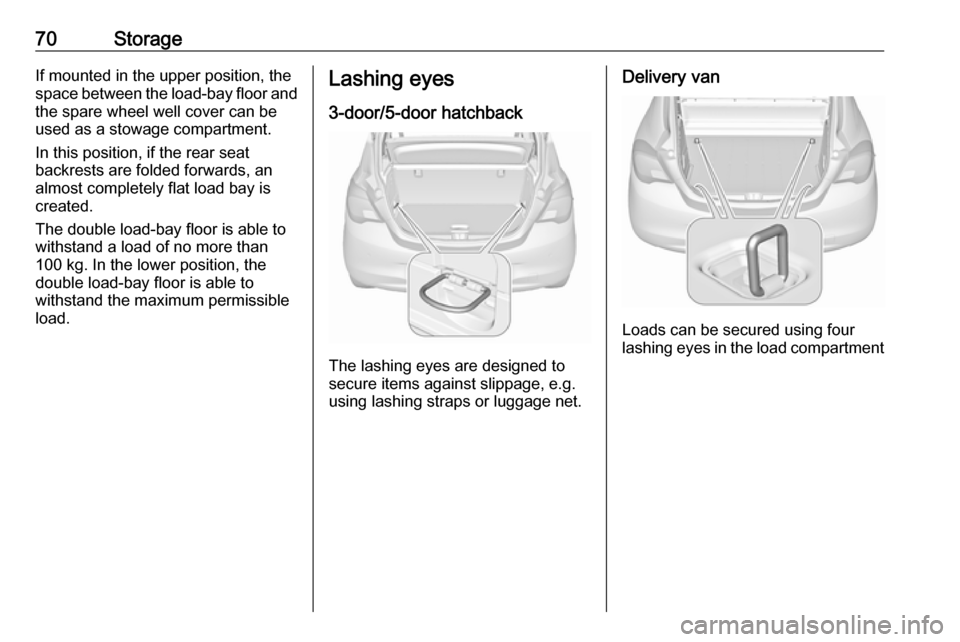

Double load-bay floor

The double load-bay floor can be

inserted in the load compartment in

two positions:

● directly above the cover for the spare wheel recess or the floor

cover

● or in the upper openings in the load compartment

To remove, lift the load-bay floor

using the recess and pull backwards.

To insert, push the load-bay floor

forwards in the corresponding guide,

then lower.

Page 72 of 271

70StorageIf mounted in the upper position, the

space between the load-bay floor and

the spare wheel well cover can be

used as a stowage compartment.

In this position, if the rear seat

backrests are folded forwards, an

almost completely flat load bay is

created.

The double load-bay floor is able to

withstand a load of no more than

100 kg. In the lower position, the

double load-bay floor is able to

withstand the maximum permissible

load.Lashing eyes

3-door/5-door hatchback

The lashing eyes are designed to

secure items against slippage, e.g.

using lashing straps or luggage net.

Delivery van

Loads can be secured using four

lashing eyes in the load compartment

Page 97 of 271

Instruments and controls95Tyre pressure monitoringsystem

w illuminates or flashes yellow.

Illuminates

Tyre pressure loss. Stop immediately

and check tyre pressure.

Flashes

Fault in system or tyre without pressure sensor mounted ( e.g. spare

wheel). After 60-90 seconds the

control indicator illuminates

continuously. Consult a workshop.

Tyre pressure monitoring system

3 215.

Engine oil pressure

I illuminates red.

Illuminates when the ignition is

switched on and extinguishes shortly

after the engine starts.Illuminates when the engine is

runningCaution

Engine lubrication may be

interrupted. This may result in

damage to the engine and/or

locking of the drive wheels.

1. Depress the clutch.

2. Set selector lever to neutral.

3. Move out of the flow of traffic as quickly as possible without

impeding other vehicles.

4. Switch off the ignition.

9 Warning

When the engine is off,

considerably more force is needed

to brake and steer.

During an Autostop, the brake

servo unit will still be operational.

Do not remove key until vehicle is stationary, otherwise the steeringwheel lock could engage

unexpectedly.

Check oil level before seeking the

assistance of a workshop 3 193.

Low fuel

Y illuminates or flashes yellow.

Illuminates

Level in fuel tank is too low.

Flashes

Fuel used up. Refuel immediately.

Never run the fuel tank dry.

Refuelling 3 181.

Catalytic converter 3 142.

Bleeding the diesel fuel system

3 198.

Immobiliser d flashes yellow.

Fault in the immobiliser system. The

engine cannot be started.

Reduced engine power

# illuminates yellow.

Page 188 of 271

186Driving and operatingThe permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 242.

Vertical coupling load The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.Petrol and diesel engines

The maximum permissible vertical

coupling load (55 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Engine B14XEL LPG

The maximum permissible vertical

coupling load (45 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.Rear axle loadPetrol and diesel engines

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 60 kg for the 3-door

vehicle, the gross vehicle weight

rating by 55 kg.Engine B14XEL LPG

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 70 kg for the 5-

door vehicle and 70 kg for the 3-door

vehicle and the gross vehicle weight

rating by 45 kg.Delivery van

When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) for passenger vehicles

may be exceeded by 60 kg and the

gross vehicle weight rating by 55 kg.General

If the permitted rear axle load is

exceeded a maximum speed of

60 mph applies. If lower national

maximum speeds are specified for

trailer operation, they must be

complied with.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of coupling ball bar

The coupling ball bar is stowed in a

bag in the spare wheel well and

secured to the lashing eyes in the

load compartment.

Page 192 of 271

190Vehicle careVehicle careGeneral Information...................191

Accessories and vehicle modifications .......................... 191

Vehicle storage ........................191

End-of-life vehicle recovery .....192

Vehicle checks ........................... 192

Performing work ......................192

Bonnet ..................................... 192

Engine oil ................................. 193

Engine coolant ......................... 194

Washer fluid ............................ 196

Brakes ..................................... 196

Brake fluid ............................... 196

Vehicle battery ......................... 196

Diesel fuel system bleeding .....198

Wiper blade replacement ........198

Bulb replacement .......................199

Halogen headlights ..................199

Xenon headlights .....................201

Fog lights ................................. 202

Front turn signal lights .............203

Tail lights ................................. 203

Side turn signal lights ..............205

Centre high-mounted brake light ......................................... 206Number plate light...................206

Interior lights ............................ 206

Instrument panel illumination ...206

Electrical system ........................207

Fuses ....................................... 207

Engine compartment fuse box . 208

Instrument panel fuse box .......210

Vehicle tools .............................. 212

Tools ........................................ 212

Wheels and tyres .......................213

Winter tyres ............................. 213

Tyre designations ....................213

Tyre pressure .......................... 213

Tyre pressure monitoring system .................................... 215

Tread depth ............................. 219

Changing tyre and wheel size . 219

Wheel covers ........................... 220

Tyre chains .............................. 220

Tyre repair kit .......................... 220

Wheel changing .......................225

Spare wheel ............................ 228

Jump starting ............................. 230

Towing ....................................... 231

Towing the vehicle ...................231

Towing another vehicle ...........232Appearance care .......................233

Exterior care ............................ 233

Interior care ............................. 236

Page 214 of 271

212Vehicle careVehicle tools

Tools

Vehicles without spare wheel

The tools are located together with

the towing eye in the load

compartment below the floor cover.

The tools and the towing eye are

located on the right side of the load compartment behind a cover.

On VXR or LPG version or versions

with rear carrier system, the tools are located together with the towing eye

on the right side of the load

compartment, behind a cover.

Vehicles with spare wheel

The jack, wheel bolt wrench and

some tools are located on the right

side of the load compartment, behind a cover 3 69.

Page 215 of 271

Vehicle care213Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

We recommend not swapping the

front wheels with the rear wheels and vice versa, as this can affect vehicle

stability. Always use less worn tyres

on the rear axle.

Winter tyres Winter tyres improve driving safety at

temperatures below 7 °C and should

therefore be fitted on all wheels.

All tyre sizes are permitted as winter

tyres 3 254.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.Tyre designations

E.g. 195/55 R 16 95 H195:tyre width, mm55:cross-section ratio (tyre height

to tyre width), percentageR:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent to 690 kgH:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at

kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 248.

Directional tyres

Directional tyres must be mounted so

that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel.

This also applies to vehicles with tyre pressure monitoring system.

Tyre pressure 3 254.

Page 218 of 271

216Vehicle careThe tyre pressures for all tyres are

displayed on one page.

System status and pressure warnings are displayed by a message

indicating the corresponding tyre in the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 213.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 95.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 254.

If w flashes for 60-90 seconds then

illuminates continuously, there is a

fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 103.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.The use of commercially-available liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor; replace

valve core and sealing ring. For the

clipped sensor; replace complete

valve stem.

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information label

or tyre pressure chart 3 254, and

select the appropriate setting in the

menu Tyre Load in the Driver

Information Centre, Vehicle

Information Menu 3 97 . This setting is

the reference for the tyre pressure warnings.

Page 219 of 271

Vehicle care217The menu Tyre Load only appears

when the vehicle is at a standstill and

the parking brake is applied. On

vehicles with automatic transmission, the selector lever must be in P.

Midlevel display:

Select ● LO for comfort pressure up to

three people.

● ECO for Eco pressure up to

three people.

● Hi for full loading.

Uplevel display:

Select ● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to

three people.

● Max for full loading.

Tyre pressure sensor matching process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new

wheel position after rotating the

wheels or exchanging the complete

wheel set and if one or more tyre

pressure sensors were replaced. The

tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure

sensor.

The malfunction light w and the

warning message or code should

extinguish at the next ignition cycle.

The sensors are matched to the

wheel positions, using a relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult a workshop for service. There are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

Page 222 of 271

220Vehicle careWheel coversWheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Steel wheels: When using locking

wheel nuts don't attach wheel covers.

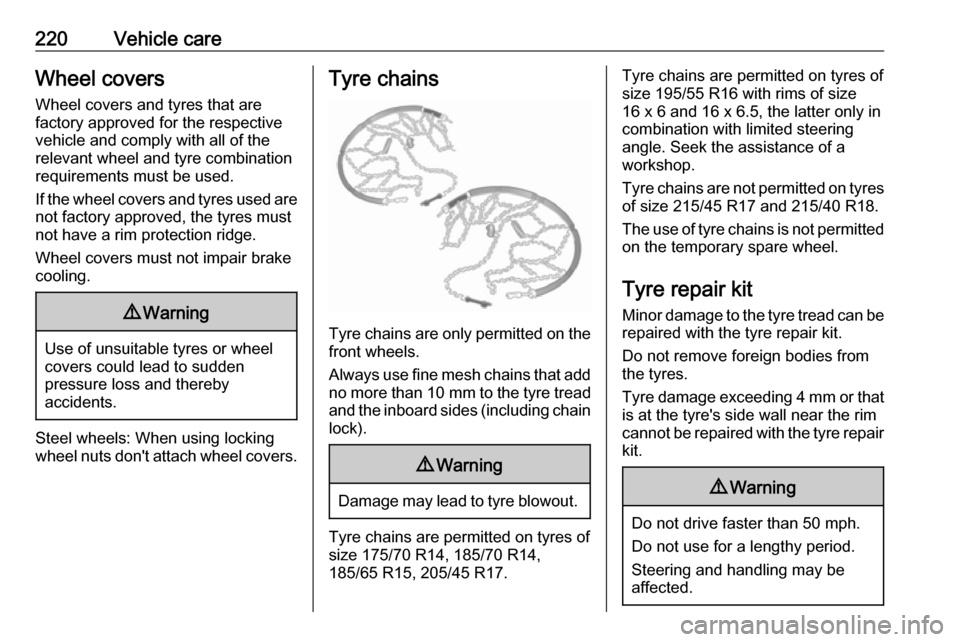

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 175/70 R14, 185/70 R14,

185/65 R15, 205/45 R17.

Tyre chains are permitted on tyres of

size 195/55 R16 with rims of size

16 x 6 and 16 x 6.5, the latter only in combination with limited steering

angle. Seek the assistance of a

workshop.

Tyre chains are not permitted on tyres of size 215/45 R17 and 215/40 R18.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that is at the tyre's side wall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.