VAUXHALL CROSSLAND X 2017.75 Owner's Manual

Manufacturer: VAUXHALL, Model Year: 2017.75, Model line: CROSSLAND X, Model: VAUXHALL CROSSLAND X 2017.75Pages: 245, PDF Size: 7.38 MB

Page 191 of 245

Vehicle care189

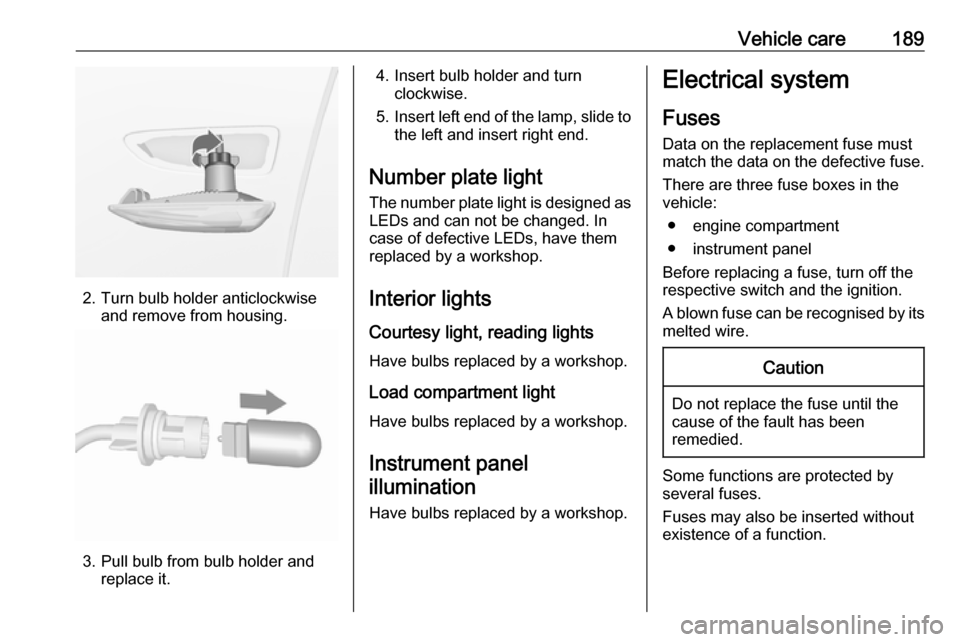

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder andreplace it.

4. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light The number plate light is designed as

LEDs and can not be changed. In

case of defective LEDs, have them

replaced by a workshop.

Interior lights

Courtesy light, reading lights

Have bulbs replaced by a workshop.

Load compartment light

Have bulbs replaced by a workshop.

Instrument panel illumination

Have bulbs replaced by a workshop.Electrical system

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

● engine compartment

● instrument panel

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its melted wire.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Page 192 of 245

190Vehicle care

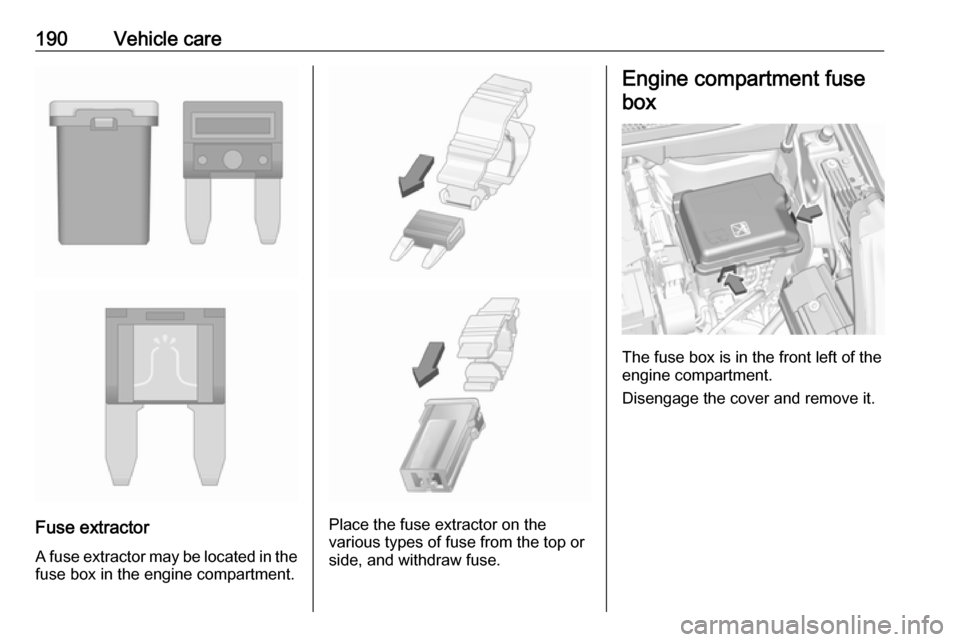

Fuse extractorA fuse extractor may be located in the fuse box in the engine compartment.Place the fuse extractor on the

various types of fuse from the top or

side, and withdraw fuse.

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover and remove it.

Page 193 of 245

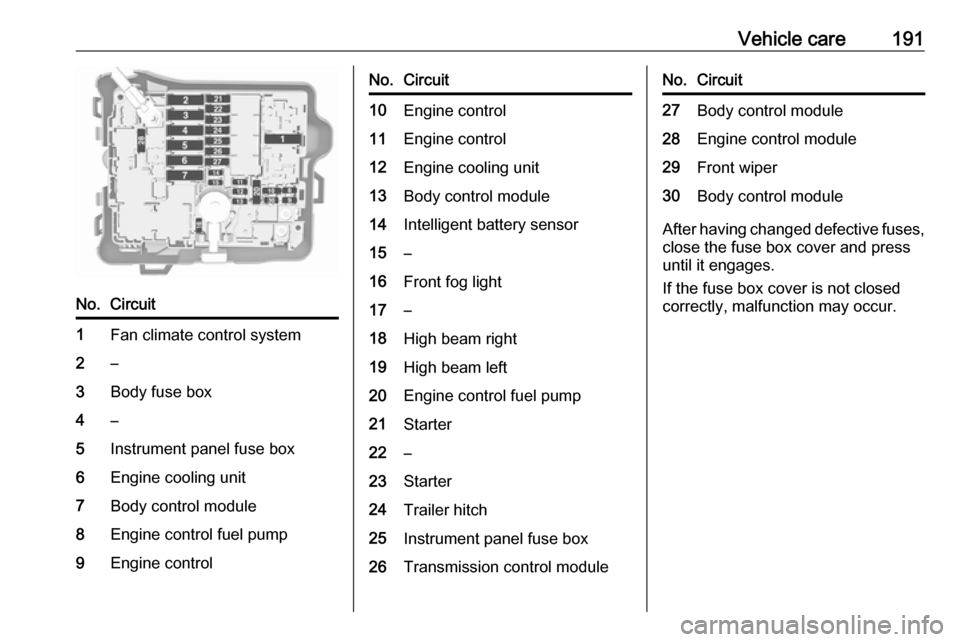

Vehicle care191No.Circuit1Fan climate control system2–3Body fuse box4–5Instrument panel fuse box6Engine cooling unit7Body control module8Engine control fuel pump9Engine controlNo.Circuit10Engine control11Engine control12Engine cooling unit13Body control module14Intelligent battery sensor15–16Front fog light17–18High beam right19High beam left20Engine control fuel pump21Starter22–23Starter24Trailer hitch25Instrument panel fuse box26Transmission control moduleNo.Circuit27Body control module28Engine control module29Front wiper30Body control module

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Page 194 of 245

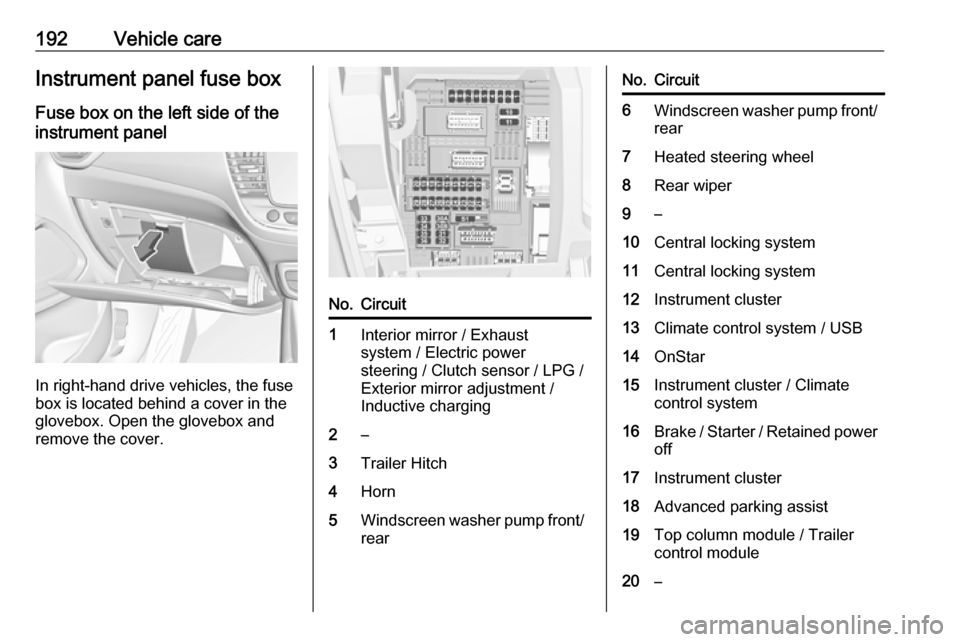

192Vehicle careInstrument panel fuse boxFuse box on the left side of the

instrument panel

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox and

remove the cover.

No.Circuit1Interior mirror / Exhaust

system / Electric power

steering / Clutch sensor / LPG /

Exterior mirror adjustment /

Inductive charging2–3Trailer Hitch4Horn5Windscreen washer pump front/

rearNo.Circuit6Windscreen washer pump front/

rear7Heated steering wheel8Rear wiper9–10Central locking system11Central locking system12Instrument cluster13Climate control system / USB14OnStar15Instrument cluster / Climate

control system16Brake / Starter / Retained power off17Instrument cluster18Advanced parking assist19Top column module / Trailer

control module20–

Page 195 of 245

Vehicle care193No.Circuit21Anti-theft alarm system / Start

button22Rain sensor / Camera23Door module24Advanced parking assist /

Camera / Infotainment25Airbag26Top column module27Anti-theft alarm system28–29Infotainment30–31Infotainment32Power outlet front33–34Heated exterior mirrors / Door

moduleNo.Circuit35Instrument cluster / Light

switch / Advanced parking

assist/ Transmission control

module36Courtesy lights / Sunvisor

lights / Glovebox light

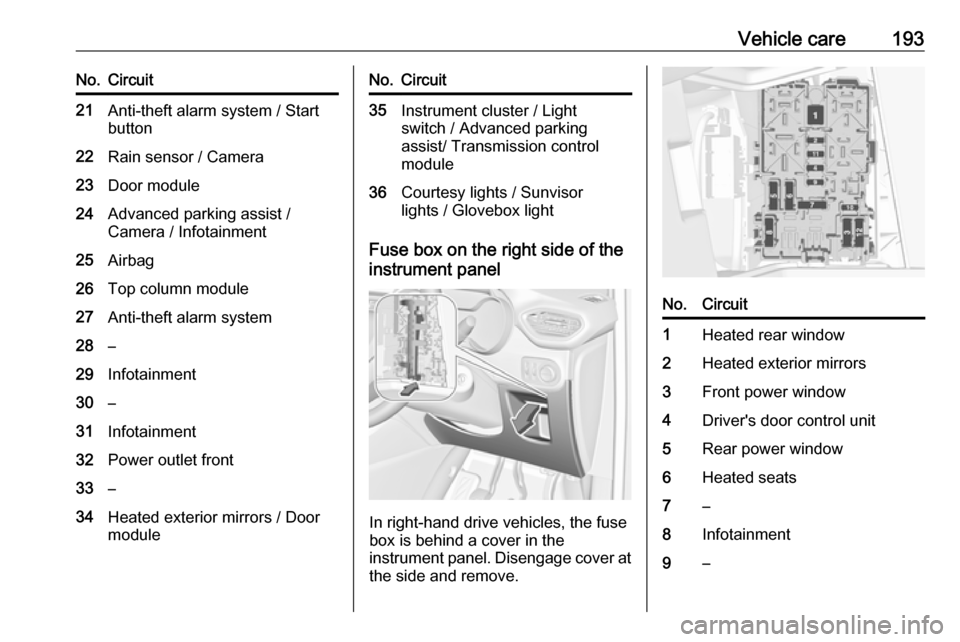

Fuse box on the right side of the

instrument panel

In right-hand drive vehicles, the fuse

box is behind a cover in the

instrument panel. Disengage cover at

the side and remove.

No.Circuit1Heated rear window2Heated exterior mirrors3Front power window4Driver's door control unit5Rear power window6Heated seats7–8Infotainment9–

Page 196 of 245

194Vehicle careNo.Circuit10Power outlet rear11–12–Vehicle tools

Tools

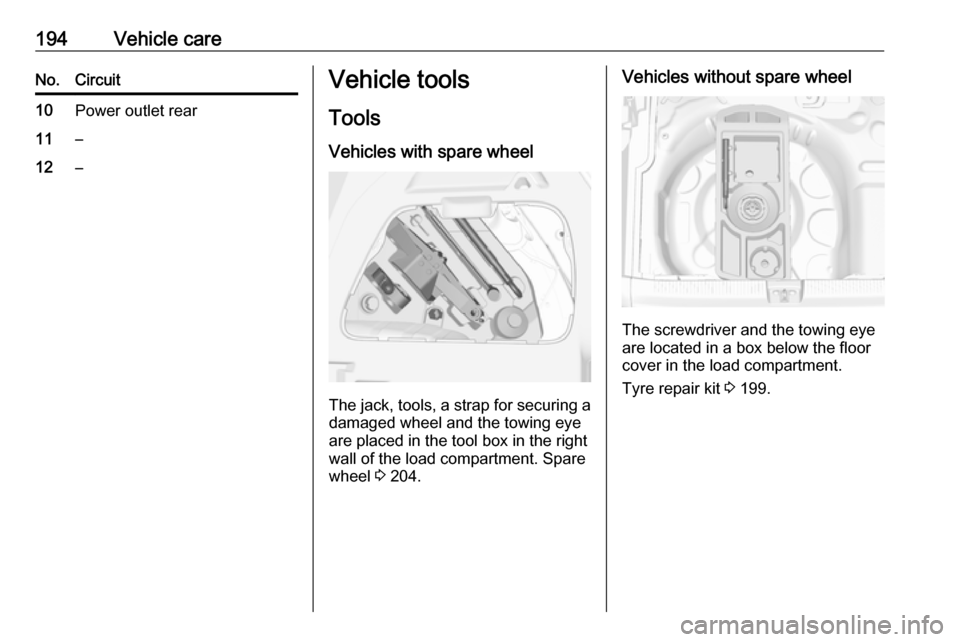

Vehicles with spare wheel

The jack, tools, a strap for securing a damaged wheel and the towing eye

are placed in the tool box in the right

wall of the load compartment. Spare

wheel 3 204.

Vehicles without spare wheel

The screwdriver and the towing eye

are located in a box below the floor

cover in the load compartment.

Tyre repair kit 3 199.

Page 197 of 245

Vehicle care195Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 228.Tyre designations

E.g. 195/65 R 15 91 T195:tyre width, mm65:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat15:wheel diameter, inches91:load index e.g. 95 is equivalent

to 615 kgT:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 224.

Directional tyres

Directional tyres should be mounted

so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Unscrew the valve cap.

Tyre pressure 3 228.

Page 198 of 245

196Vehicle careThe tyre pressure information labelon the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify drive axle and body style.

2. Identify the engine identifier code.

Engine data 3 222.

3. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 228.For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down

tyre will show a decreased value,

which does not indicate an air leak.

Tyre deflation detectionsystem

The tyre deflation detection system continually checks the rotation speed

of all four wheels and warns on low

tyre pressure condition once vehicle

is driving. This is achieved by

comparing tyre rolling circumference

with reference values.

Page 199 of 245

Vehicle care197If a tyre loses pressure the control

indicator w illuminates and a warning

message is displayed in the Driver

Information Centre.

In this case reduce speed, avoid

sharp cornering and strong braking.

Stop at next safe opportunity and

check tyre pressure.

Control indicator w 3 90.

After adjusting tyre pressure initialise

system to extinguish the control

indicator and restart system.Caution

Deflation detection system warns

just about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

In case of a system malfunction a

message is displayed in the Driver

Information Centre. Set correct tyre

pressure and reinitialise system. If the

failure continues to be displayed,

contact a workshop. The system is

inoperable when ABS or ESC has a

malfunction or a temporary spare

wheel is used. Once the road tyre has

been refitted, check the tyre pressure with cold tyres and initialise the

system.

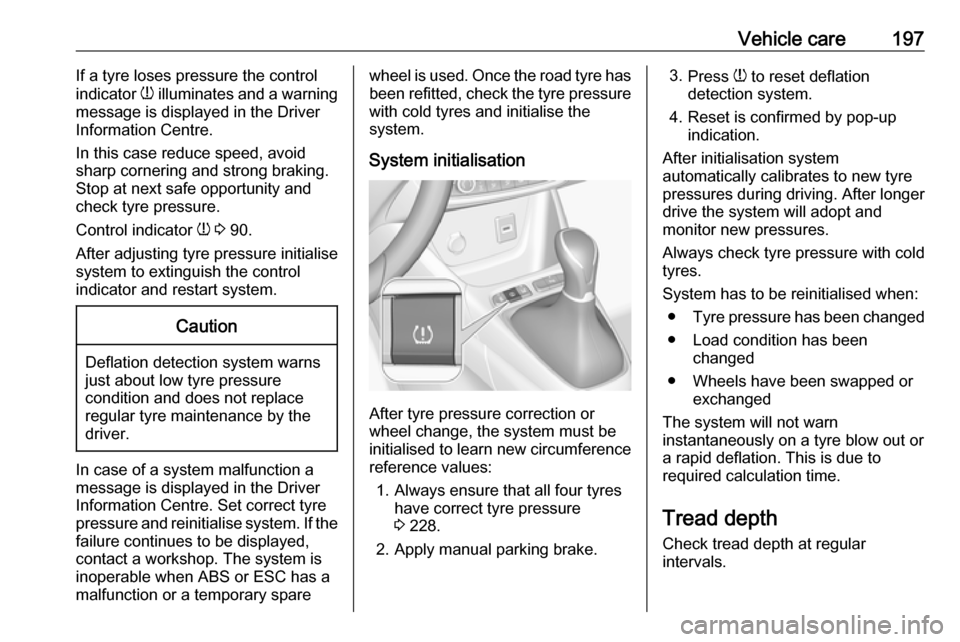

System initialisation

After tyre pressure correction or

wheel change, the system must be

initialised to learn new circumference reference values:

1. Always ensure that all four tyres have correct tyre pressure3 228.

2. Apply manual parking brake.

3. Press w to reset deflation

detection system.

4. Reset is confirmed by pop-up indication.

After initialisation system

automatically calibrates to new tyre

pressures during driving. After longer

drive the system will adopt and

monitor new pressures.

Always check tyre pressure with cold

tyres.

System has to be reinitialised when: ● Tyre pressure has been changed

● Load condition has been changed

● Wheels have been swapped or exchanged

The system will not warn instantaneously on a tyre blow out or

a rapid deflation. This is due to

required calculation time.

Tread depthCheck tread depth at regular

intervals.

Page 200 of 245

198Vehicle careTyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

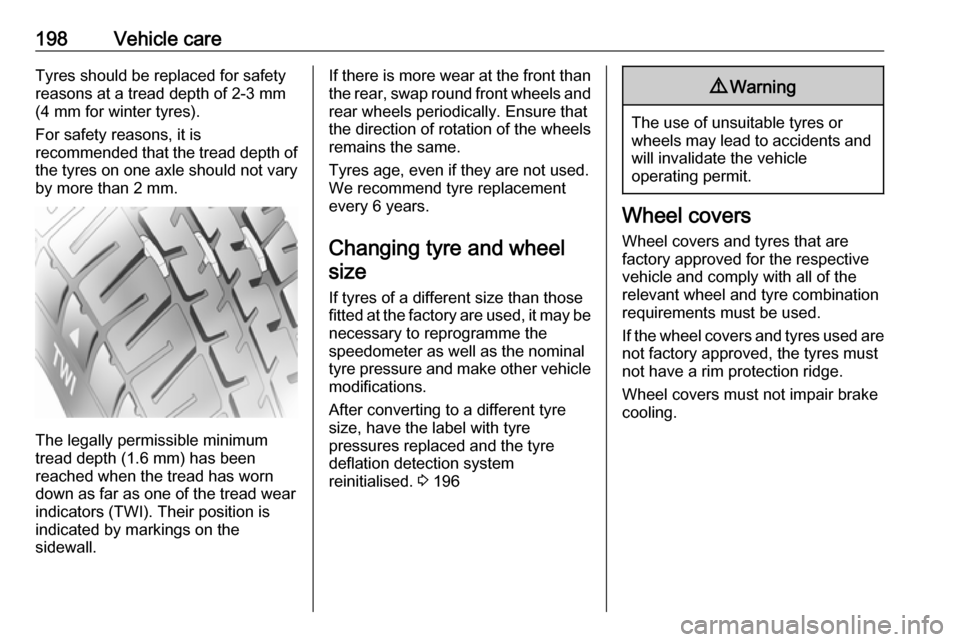

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced and the tyre

deflation detection system

reinitialised. 3 1969 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.