light VAUXHALL CROSSLAND X 2018 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: CROSSLAND X, Model: VAUXHALL CROSSLAND X 2018Pages: 255, PDF Size: 7.57 MB

Page 198 of 255

196Vehicle care

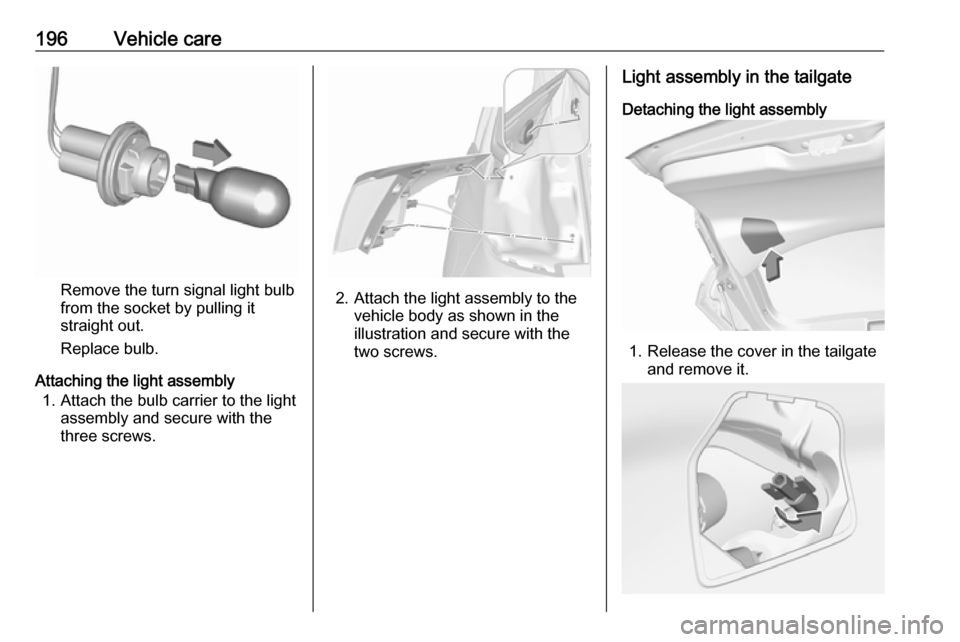

Remove the turn signal light bulb

from the socket by pulling it

straight out.

Replace bulb.

Attaching the light assembly 1. Attach the bulb carrier to the light assembly and secure with the

three screws.2. Attach the light assembly to the vehicle body as shown in the

illustration and secure with the

two screws.

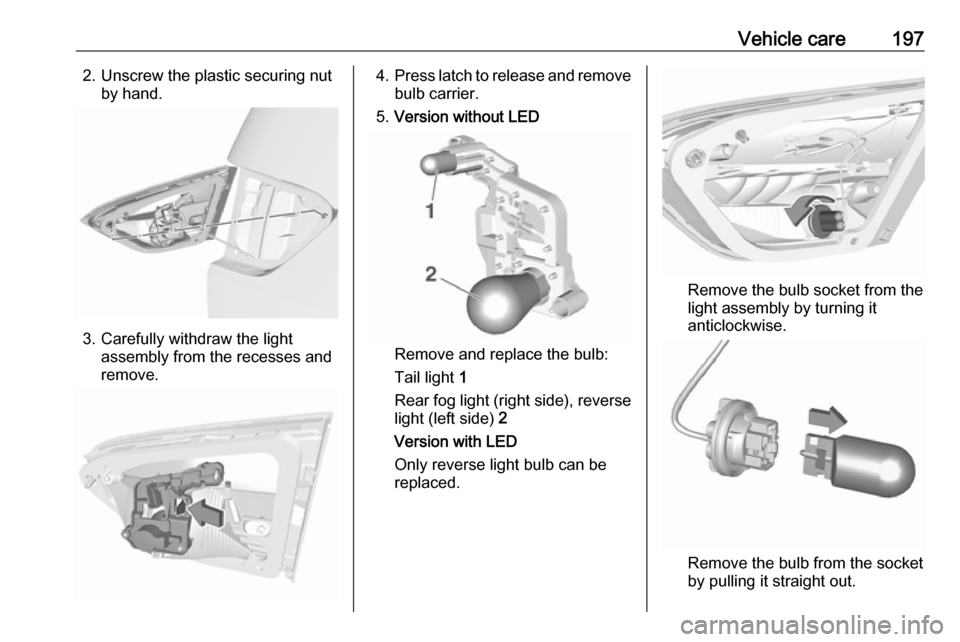

Light assembly in the tailgate

Detaching the light assembly

1. Release the cover in the tailgate and remove it.

Page 199 of 255

Vehicle care1972. Unscrew the plastic securing nutby hand.

3. Carefully withdraw the lightassembly from the recesses and

remove.

4. Press latch to release and remove

bulb carrier.

5. Version without LED

Remove and replace the bulb:

Tail light 1

Rear fog light (right side), reverse

light (left side) 2

Version with LED

Only reverse light bulb can be

replaced.

Remove the bulb socket from the

light assembly by turning it

anticlockwise.

Remove the bulb from the socket by pulling it straight out.

Page 200 of 255

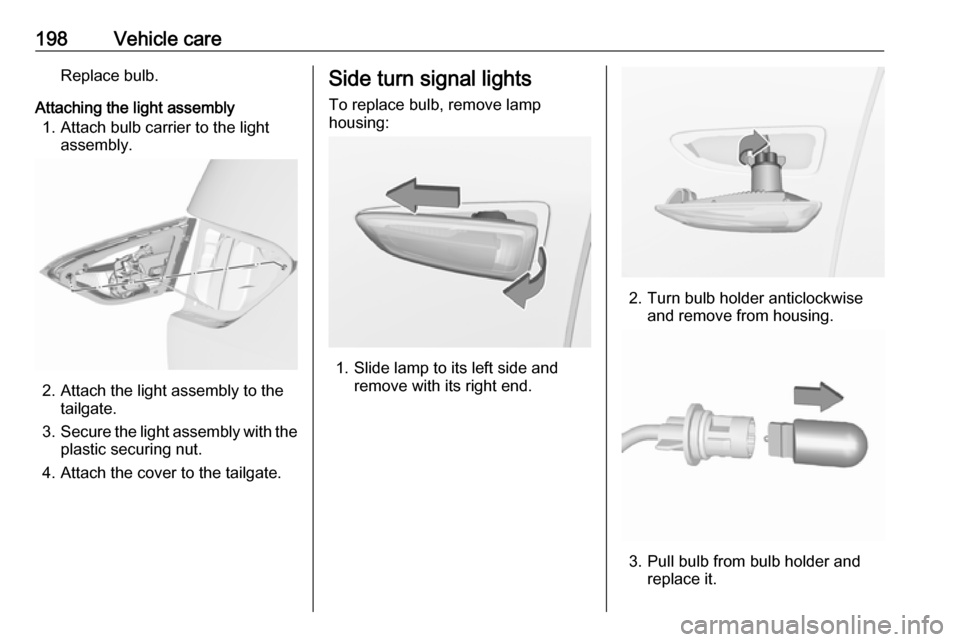

198Vehicle careReplace bulb.

Attaching the light assembly 1. Attach bulb carrier to the light assembly.

2. Attach the light assembly to thetailgate.

3. Secure the light assembly with the

plastic securing nut.

4. Attach the cover to the tailgate.

Side turn signal lights

To replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder and replace it.

Page 201 of 255

Vehicle care1994. Insert bulb holder and turnclockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light

The number plate light is designed as LEDs and can not be changed. Incase of defective LEDs, have them

replaced by a workshop.

Interior lights

Courtesy light, reading lights Have bulbs replaced by a workshop.

Load compartment light

Have bulbs replaced by a workshop.

Instrument panelillumination

Have bulbs replaced by a workshop.Electrical system

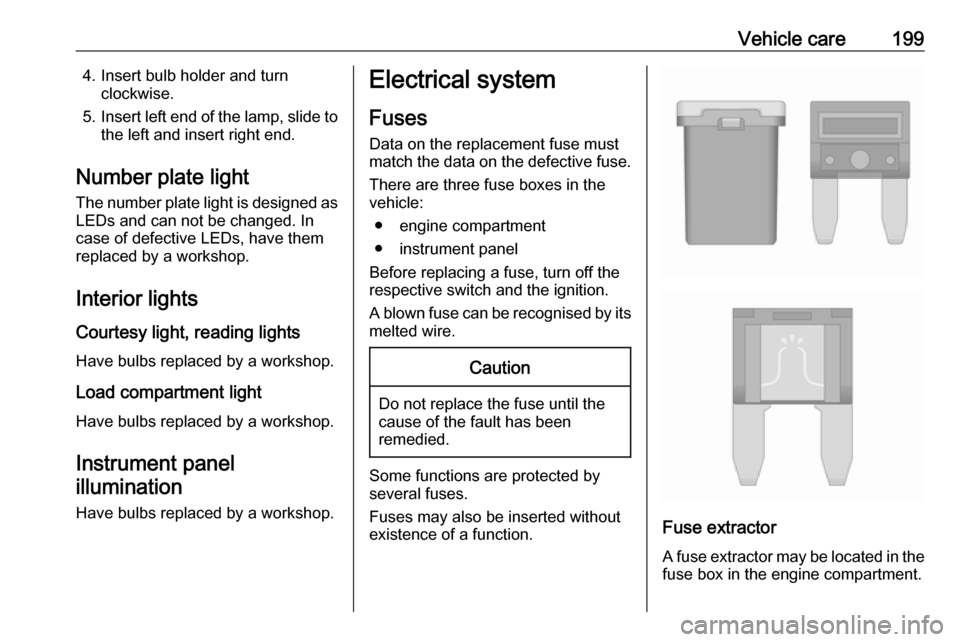

Fuses Data on the replacement fuse mustmatch the data on the defective fuse.

There are three fuse boxes in the

vehicle:

● engine compartment

● instrument panel

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its melted wire.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

Page 203 of 255

Vehicle care201No.Circuit10Engine control11Engine control12Engine cooling unit13Body control module14Intelligent battery sensor15–16Front fog light17–18High beam right19High beam left20Engine control fuel pump21Starter22–23Starter24Trailer hitch25Instrument panel fuse box26Transmission control moduleNo.Circuit27Body control module28Engine control module29Front wiper30Body control module

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Instrument panel fuse box

Fuse box on the left side of the

instrument panel

In right-hand drive vehicles, the fuse

box is located behind a cover in the

glovebox. Open the glovebox and

remove the cover.

Page 205 of 255

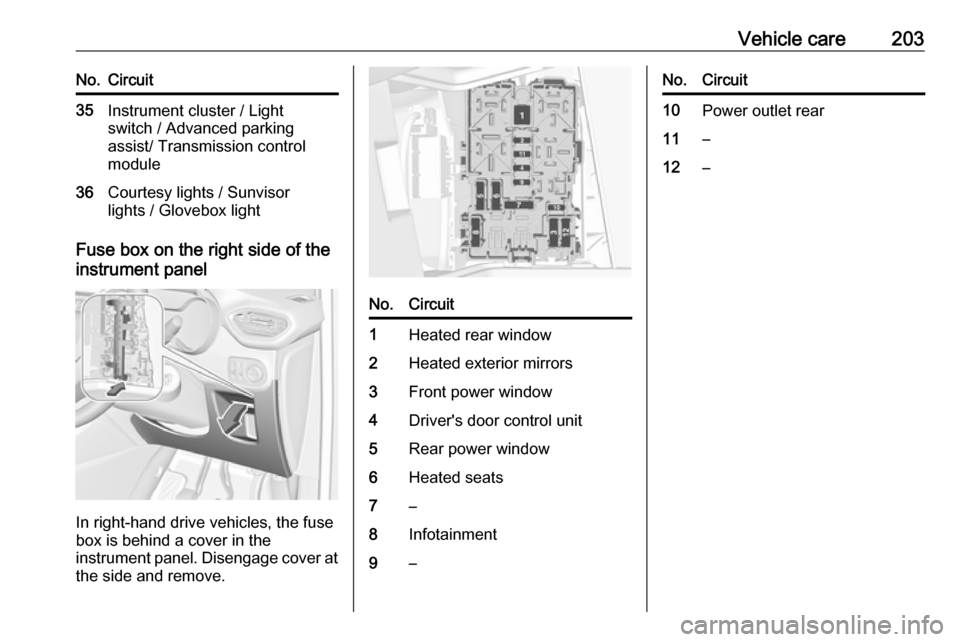

Vehicle care203No.Circuit35Instrument cluster / Light

switch / Advanced parking

assist/ Transmission control

module36Courtesy lights / Sunvisor

lights / Glovebox light

Fuse box on the right side of the

instrument panel

In right-hand drive vehicles, the fuse

box is behind a cover in the

instrument panel. Disengage cover at

the side and remove.

No.Circuit1Heated rear window2Heated exterior mirrors3Front power window4Driver's door control unit5Rear power window6Heated seats7–8Infotainment9–No.Circuit10Power outlet rear11–12–

Page 212 of 255

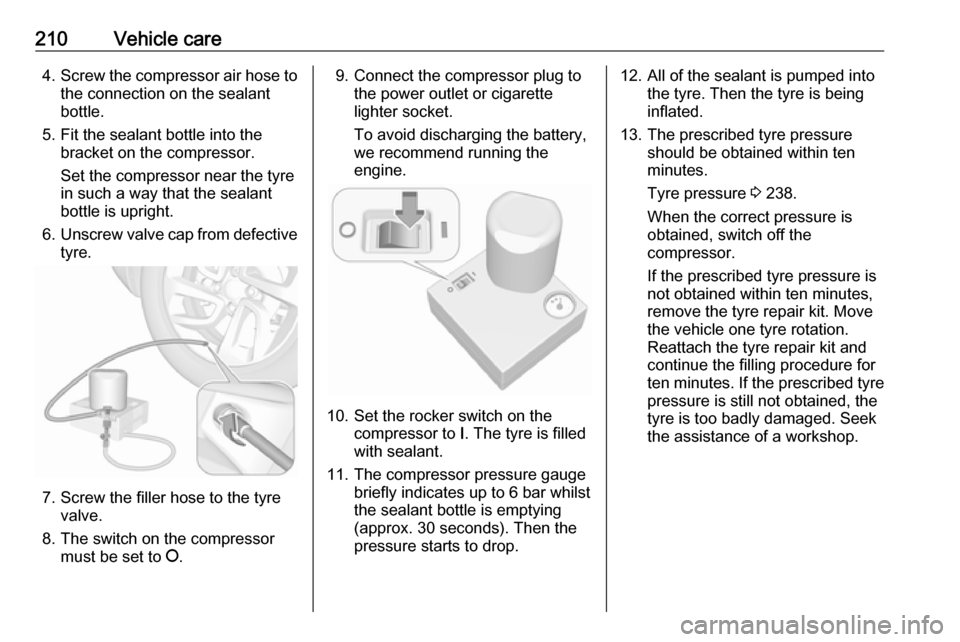

210Vehicle care4.Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the bracket on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to

the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is being

inflated.

13. The prescribed tyre pressure should be obtained within ten

minutes.

Tyre pressure 3 238.

When the correct pressure is

obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within ten minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

ten minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Page 219 of 255

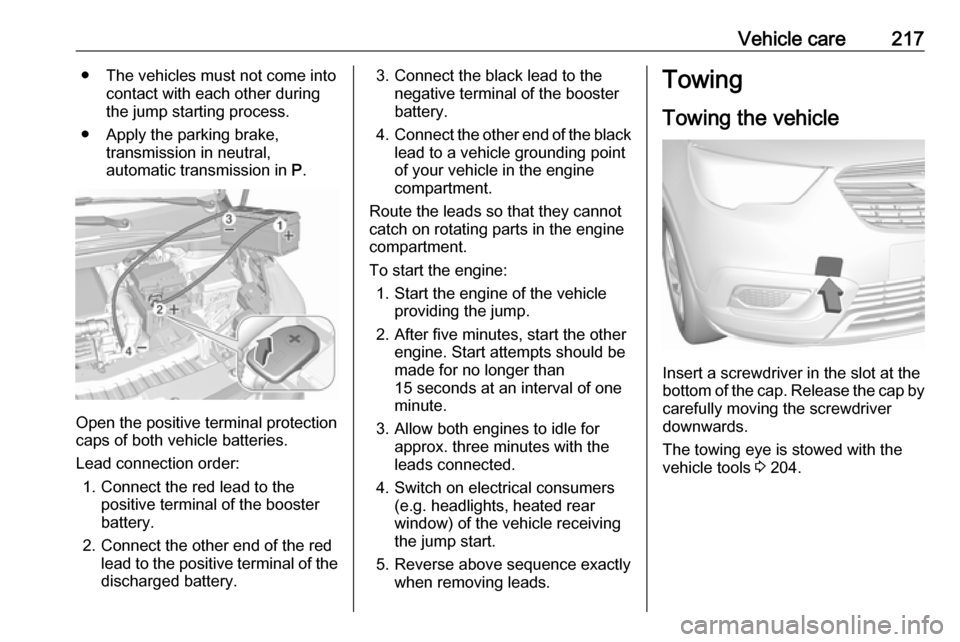

Vehicle care217● The vehicles must not come intocontact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

Open the positive terminal protection

caps of both vehicle batteries.

Lead connection order: 1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the boosterbattery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of one

minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle

Insert a screwdriver in the slot at the

bottom of the cap. Release the cap by

carefully moving the screwdriver

downwards.

The towing eye is stowed with the vehicle tools 3 204.

Page 220 of 255

218Vehicle care

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Switch the selector lever to neutral.

Release the parking brake.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye.

Insert cap with the outer flange into

the recess and fix cap by pushing.

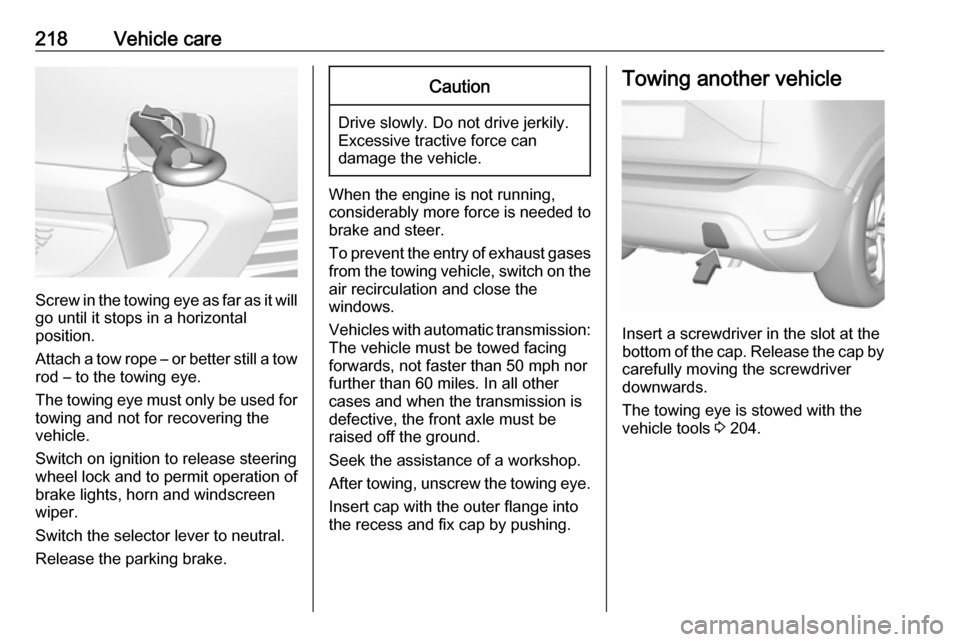

Towing another vehicle

Insert a screwdriver in the slot at the

bottom of the cap. Release the cap by carefully moving the screwdriver

downwards.

The towing eye is stowed with the vehicle tools 3 204.

Page 222 of 255

220Vehicle careIf using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wiper and rear window wiper must be

switched off. Remove antenna and

external accessories such as roof

racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Wax painted parts of the vehicle

regularly.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.

Clean bright metal mouldings with a

cleaning solution approved for

aluminium to avoid damages.Caution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Do not clean the engine compartmentwith a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Have the door hinges of all doors

greased by a workshop.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.Plastic body parts must not be treated with wax or polishing agents.

Windows and windscreen wiper

blades

Use a soft lint-free cloth or chamois

leather together with window cleaner

and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Remove dirt residues from smearing

wiper blades by using a soft cloth and window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Ice residues, pollution and continuous

wiping on dry windows will damage or

even destroy the wiper blades.