wheel size VAUXHALL CROSSLAND X 2020 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2020, Model line: CROSSLAND X, Model: VAUXHALL CROSSLAND X 2020Pages: 245, PDF Size: 21.85 MB

Page 155 of 245

Driving and operating153Caution

Performance of the system can bereduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

system can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles in the vicinity

(e.g. off-road vehicles, mini vans,

vans). Object identification and correct distance indication in the

upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross-section, e.g. objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist systems do not

detect objects outside the

detection range.

Notice

Make sure that the front number

plate is properly mounted (not bent

and no gaps to the bumper on the left or right side) and the sensors are

firmly in place.

Advanced parking assist9 Warning

The driver bears full responsibility

for accepting the parking slot

suggested by the system and the

parking manoeuvre.

Always check the surrounding

area in all directions when using

the advanced parking assist.

The advanced parking assist

measures a suitable parking slot

while passing, calculates the

trajectory and automatically steers

the vehicle while parking.

Advanced parking assist provides

assistance for the following

manoeuvres:

● entry into a parallel parking slot

● entry into a perpendicular parking

slot

● exit from a parallel parking slot

The driver must control acceleration, braking and gear shifting, while

steering is done automatically. The driver can take control at any time by

gripping the steering wheel.

It may be necessary to move forwards and backwards more than once.

Instructions are given in the Info

Display 3 91.

Advanced parking assist can only be activated when driving forwards.

Page 176 of 245

174Vehicle careVehicle careGeneral Information...................174

Accessories and vehicle modifications .......................... 174

Vehicle storage ........................175

End-of-life vehicle recovery .....175

Vehicle checks ........................... 176

Performing work ......................176

Bonnet ..................................... 176

Engine oil ................................. 177

Engine coolant ......................... 178

Washer fluid ............................ 178

Brakes ..................................... 179

Brake fluid ............................... 179

Vehicle battery ......................... 179

Diesel fuel system bleeding .....181

Wiper blade replacement ........181

Bulb replacement .......................182

Halogen headlights ..................182

LED headlights ........................ 185

Front fog lights ......................... 185

Tail lights ................................. 186

Side turn lights ......................... 190

Number plate light ...................190

Interior lights ............................ 190Electrical system........................191

Fuses ....................................... 191

Engine compartment fuse box . 191

Instrument panel fuse box .......193

Vehicle tools .............................. 195

Tools ........................................ 195

Wheels and tyres .......................196

Winter tyres ............................. 196

Tyre designations ....................196

Tyre pressure .......................... 196

Tyre deflation detection system .................................... 197

Tread depth ............................. 198

Changing tyre and wheel size . 199

Wheel covers ........................... 199

Tyre chains .............................. 199

Tyre repair kit .......................... 200

Wheel changing .......................203

Spare wheel ............................ 204

Jump starting ............................. 208

Towing ....................................... 209

Towing the vehicle ...................209

Towing another vehicle ...........210

Appearance care .......................211

Exterior care ............................ 211

Interior care ............................. 213

Floor mats ............................... 214General Information

Accessories and vehicle modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for this

vehicle type. We cannot assess or

guarantee reliability of other products - even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other

changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control units) may invalidate the warranty

offered by Vauxhall.

Furthermore, such changes may

affect driver assistance systems, may

impact fuel consumption, CO 2

emissions and other emissions of the

vehicle and cause the vehicle to no

longer conform to the operating

permit, impacting the validity of your

vehicle registration.

Page 198 of 245

196Vehicle careWheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and shouldtherefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 229.Tyre designations

E.g. 195/65 R 15 91 T195:tyre width, mm65:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat15:wheel diameter, inches91:load index e.g. 95 is equivalent

to 615 kgT:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropriate for the

maximum speed of this vehicle. Refer

to the EEC Certificate of Conformity

provided with the vehicle or other

national registration documents.

Optional equipment could reduce the

maximum speed of the vehicle.

Directional tyres

Directional tyres should be mounted so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

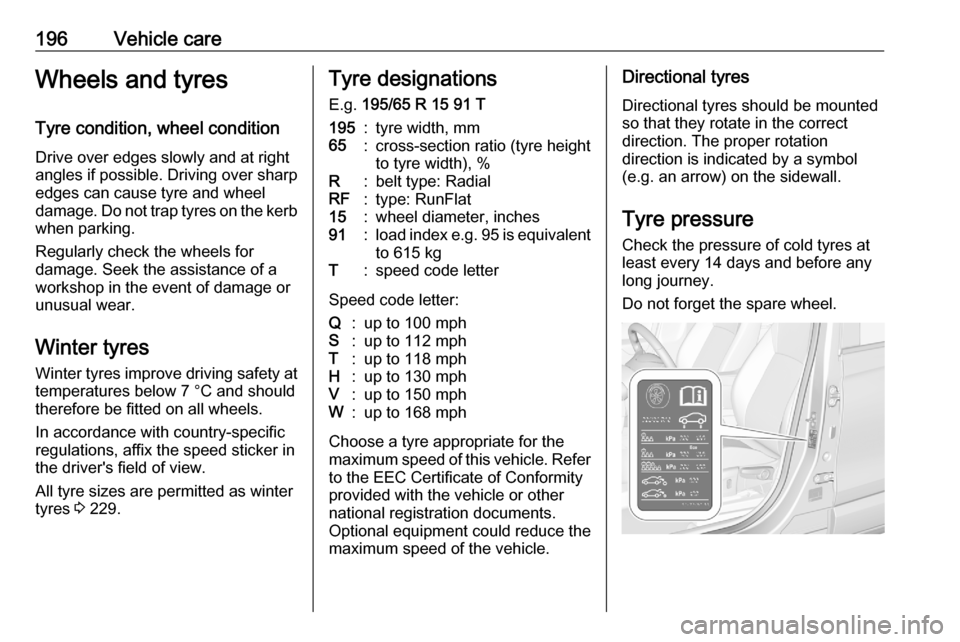

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey.

Do not forget the spare wheel.

Page 199 of 245

Vehicle care197The tyre pressure information label

on the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter

tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

The tyre pressure table indicates the

required pressure for a specific tyre

size only and shows all possible tyre

combinations 3 229.

For the tyres approved for this

vehicle, refer to the EEC Certificate of Conformity provided with the vehicle

or other national registration

documents.

The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

Tyre deflation detectionsystem

The tyre deflation detection system

continually checks the rotation speed

of all four wheels and warns on low

tyre pressure condition once vehicle

is driving. This is achieved by

comparing tyre rolling circumference

with reference values and further

signals.

If a tyre loses pressure the control

indicator w illuminates and a warning

message is displayed in the Driver Information Centre.

In this case reduce speed, avoid

sharp cornering and strong braking.

Stop at next safe opportunity and

check tyre pressure.

Control indicator w 3 86.

After adjusting tyre pressure initialise

system to extinguish the control

indicator and restart system.

Page 201 of 245

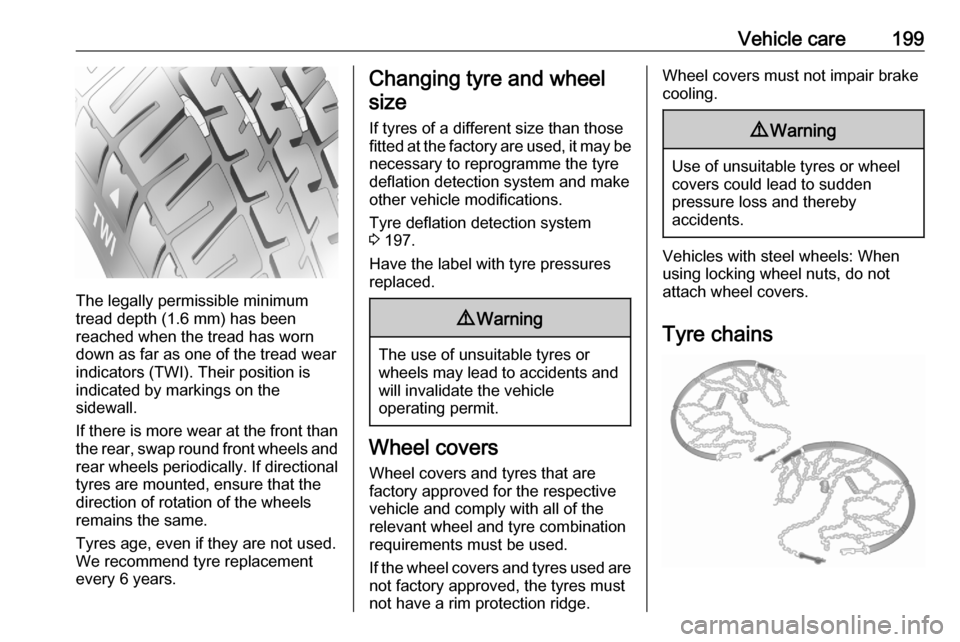

Vehicle care199

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. If directional

tyres are mounted, ensure that the

direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the tyre

deflation detection system and make other vehicle modifications.

Tyre deflation detection system

3 197.

Have the label with tyre pressures

replaced.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

Tyre chains

Page 202 of 245

200Vehicle careTyre chains are only permitted on thefront wheels.

Always use fine mesh chains that add

no more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 195/65 R15 91 and

195/60 R16 89

Temporary spare wheel

The use of tyre chains is not permitted on the temporary spare wheel.

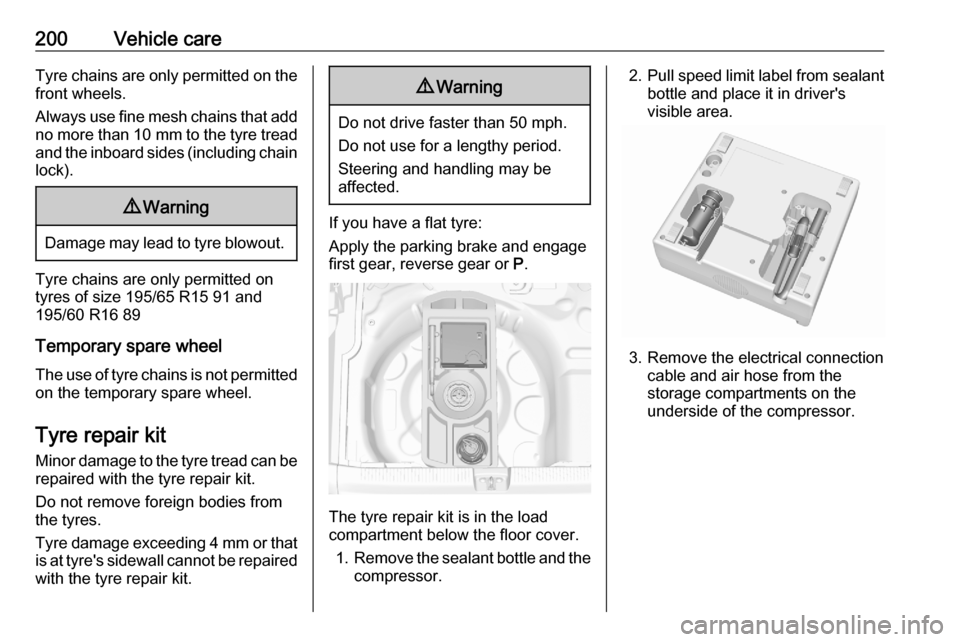

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.

9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is in the load

compartment below the floor cover.

1. Remove the sealant bottle and the

compressor.

2. Pull speed limit label from sealant

bottle and place it in driver's

visible area.

3. Remove the electrical connection cable and air hose from the

storage compartments on the

underside of the compressor.

Page 206 of 245

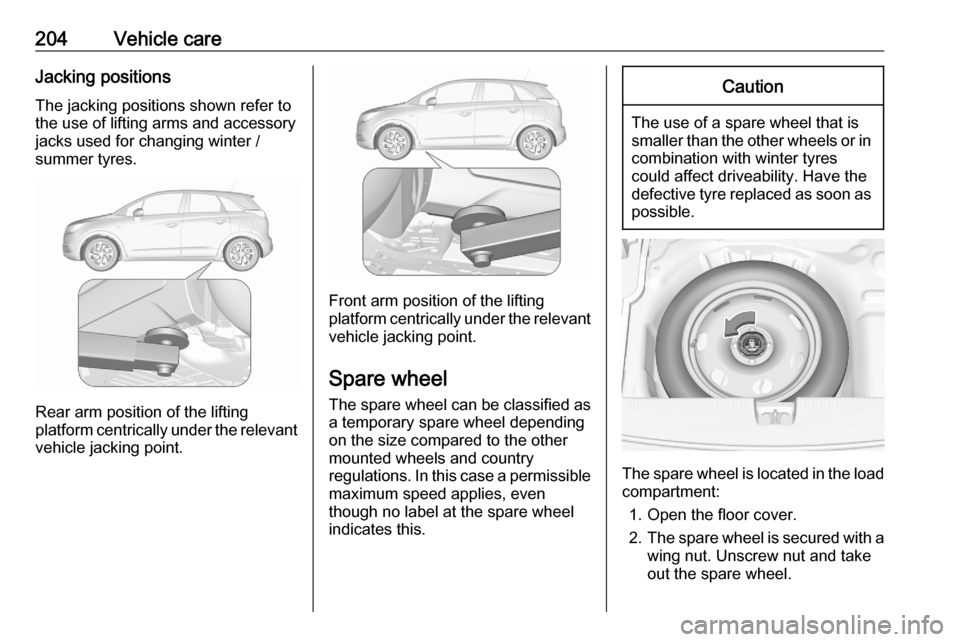

204Vehicle careJacking positions

The jacking positions shown refer to

the use of lifting arms and accessory

jacks used for changing winter /

summer tyres.

Rear arm position of the lifting

platform centrically under the relevant vehicle jacking point.

Front arm position of the lifting

platform centrically under the relevant vehicle jacking point.

Spare wheel The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment:

1. Open the floor cover.

2. The spare wheel is secured with a

wing nut. Unscrew nut and take

out the spare wheel.

Page 207 of 245

Vehicle care205There is a box with tools in the

right wall of the load compartment.

Vehicle tools 3 195.

3. When, after a wheel change, no wheel is placed in the spare wheelwell, fasten the wing nut and close

the floor cover.

4. After a wheel change back to a full

size wheel, place the spare wheel

outside up in the well and secure

with the wing nut.

Temporary spare wheelCaution

If driving with a temporary spare

wheel, active emergency braking

has to deactivated.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Do not drive faster than 50 mph. Take curves slowly. Do not use for a long

period of time.

Fitting the spare wheel

Make the preparations given for

wheel changing 3 203 and observe

the following information:

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

1. Disengage wheel bolt caps with a

screwdriver and remove.

Steel wheels with cover: Pull off

the wheel cover.

Alloy wheels: Disengage wheel

bolt caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

bolt by half a turn.

The wheels might be protected by

locking wheel bolts. To loosen

these specific bolts, first attach

the adapter for the locking wheel

bolts onto the head of the bolt

before installing the wheel

wrench. The adapter is located in

the glovebox or in the load

compartment under the rear floor

cover.

Page 209 of 245

Vehicle care207bolts can also be used for the steelspare wheel. In this case, the

spare wheel is secured by the

conical contact of each bolt. In this case, the washers do not come

into contact with the spare wheel.

10. Align the valve hole in the wheel cover with the tyre valve before

installing.

Install wheel nut caps.

11. Stow and secure the replaced wheel and the tools.

12. Check the tyre pressure of the installed tyre and the tightening

torque as soon as possible.

Stowing a damaged full size

wheel in the load compartment

The spare wheel well is not designed

for other tyre sizes than the temporary spare wheel. A damaged full size

wheel must be stowed in the load compartment and secured with a

strap.

Vehicle tools 3 195.To secure the wheel:

1. Position the wheel outside up close to one sidewall of the load

compartment.

2. Place the loop end of the strap through the front lashing eye on

the appropriate side.

3. Place the hook end of the strap through the loop and pull it until

the strap is fastened securely to

the lashing eye.

4. Insert the strap through the spokes of the wheel as shown in

the illustration.

5. Mount the hook to the rear lashing

eye.

6. Tighten the strap and secure it using the buckle.

If no strap is available, make sure to

store the wheel securely in the load

compartment.

Loading information 3 67

Page 210 of 245

208Vehicle care9Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the vehicle battery

to naked flames or sparks.

● A discharged vehicle battery can already freeze at a temperature

of 0 °C. Defrost the frozen battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 V). Its capacity

(Ah) must not be much less than

that of the discharged vehicle battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.