Reverse VAUXHALL GRANDLAND X 2019 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2019, Model line: GRANDLAND X, Model: VAUXHALL GRANDLAND X 2019Pages: 275, PDF Size: 7.63 MB

Page 188 of 275

186Driving and operatingThe panoramic view system may not

operate properly when:

● The surrounding is dark.

● The sun or the beam of headlights is shining directly into

the camera lenses.

● Weather limits visibility, such as fog, rain, or snow.

● The camera lenses are blocked by snow, ice, slush, mud, dirt.

● The vehicle is towing a trailer.

● The vehicle had an accident.

● There are extreme temperature changes.

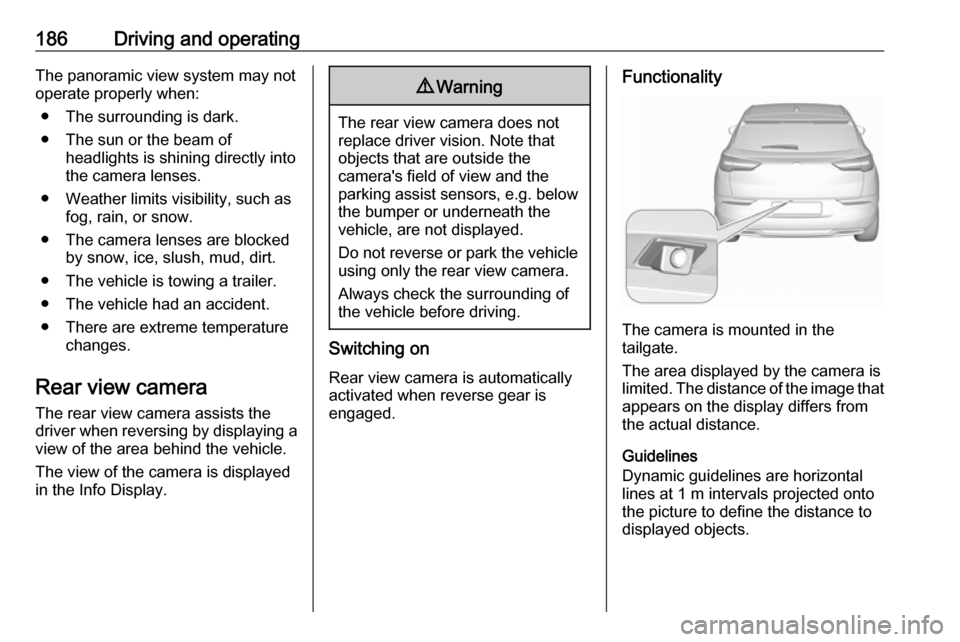

Rear view camera

The rear view camera assists the

driver when reversing by displaying a view of the area behind the vehicle.

The view of the camera is displayed

in the Info Display.9 Warning

The rear view camera does not

replace driver vision. Note that

objects that are outside the

camera's field of view and the

parking assist sensors, e.g. below

the bumper or underneath the

vehicle, are not displayed.

Do not reverse or park the vehicle

using only the rear view camera.

Always check the surrounding of

the vehicle before driving.

Switching on

Rear view camera is automatically

activated when reverse gear is

engaged.

Functionality

The camera is mounted in the

tailgate.

The area displayed by the camera is

limited. The distance of the image that

appears on the display differs from

the actual distance.

Guidelines

Dynamic guidelines are horizontal

lines at 1 m intervals projected onto

the picture to define the distance to displayed objects.

Page 203 of 275

Vehicle care201Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Cold protection covers

In order to prevent the accumulation

of snow at the radiator cooling fan, it is recommended to install removable

protection covers.

The protection covers must be

professionally installed, consult a

workshop.

Caution

The protection covers must be removed when one of the

following conditions occur:

● The ambient temperature is abbove 10 °C.

● When the vehicle is towed.

● The vehicle is driven at speeds

above 75 mph.

Vehicle storage

Storage for a long period of timeIf the vehicle is to be stored for several

months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or set selector lever to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Note that all systems are

not functional, e.g. anti-theft

alarm system.

Putting back into operation When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Initialize the power

windows 3 39.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.

Page 214 of 275

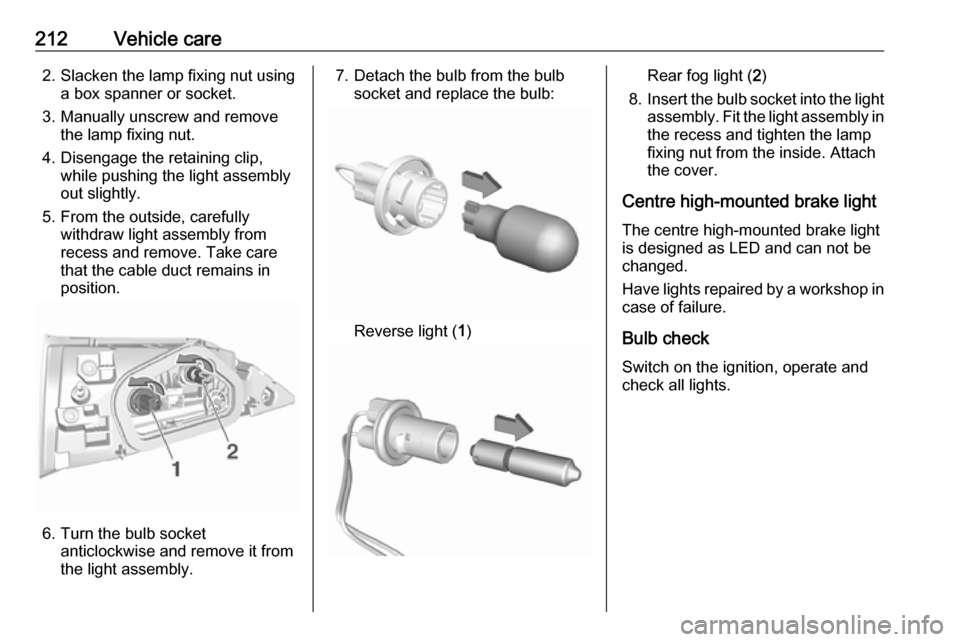

212Vehicle care2. Slacken the lamp fixing nut usinga box spanner or socket.

3. Manually unscrew and remove the lamp fixing nut.

4. Disengage the retaining clip, while pushing the light assembly

out slightly.

5. From the outside, carefully withdraw light assembly from

recess and remove. Take care

that the cable duct remains in

position.

6. Turn the bulb socket anticlockwise and remove it from

the light assembly.

7. Detach the bulb from the bulb socket and replace the bulb:

Reverse light ( 1)

Rear fog light ( 2)

8. Insert the bulb socket into the light

assembly. Fit the light assembly in the recess and tighten the lamp

fixing nut from the inside. Attach

the cover.

Centre high-mounted brake light The centre high-mounted brake light

is designed as LED and can not be

changed.

Have lights repaired by a workshop in

case of failure.

Bulb check

Switch on the ignition, operate and

check all lights.

Page 225 of 275

Vehicle care223Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, do not

attach wheel covers.

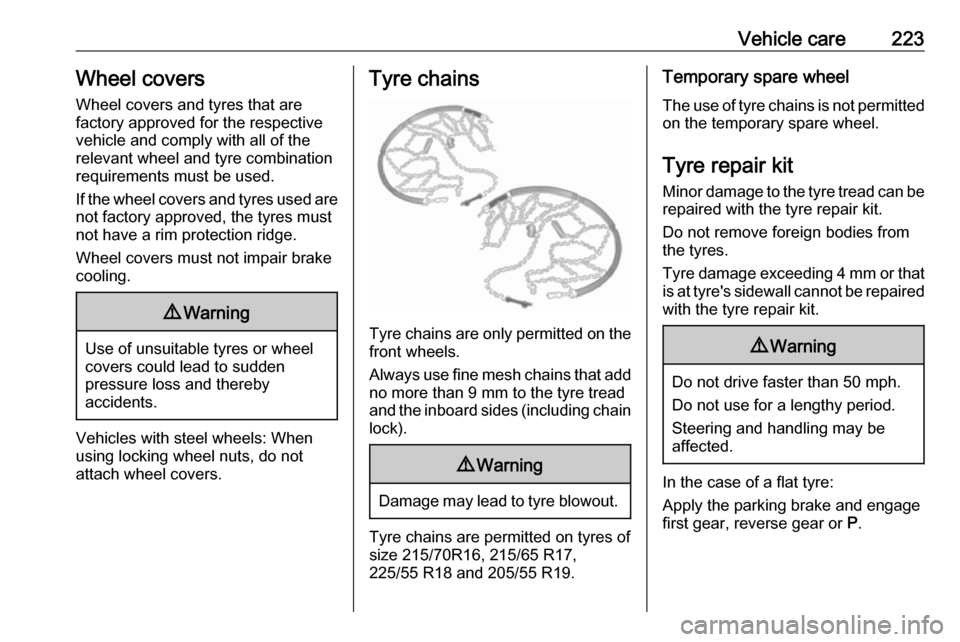

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 9 mm to the tyre tread

and the inboard sides (including chain

lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 215/70R16, 215/65 R17,

225/55 R18 and 205/55 R19.

Temporary spare wheel

The use of tyre chains is not permitted

on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

In the case of a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

Page 228 of 275

226Vehicle care

16. Continue driving immediately sothat sealant is evenly distributed

in the tyre. After driving approx.

3 miles but no more than

10 minutes, stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve when

doing this. Fill tyre as described

before. Drain excess tyre

pressure with the button on the air

hose.

If tyre pressure hasn't decreased

under 150 kPa (1.5 bar), set it to

the correct value. Otherwise the

vehicle must not be used. Seek

assistance of a workshop 3 255.

Repeat the checking procedure

once more after driving further

3 miles but no more than

10 minutes to check that there is

no more loss of pressure.

If the tyre pressure has fallen

below 150 kPa (1.5 bar), the

vehicle must not be used. Seek

the assistance of a workshop.

17. Stow away tyre repair kit in load compartment.

Notice

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30 min.

The built-in safety valve opens at a

pressure of seven bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

Wheel changing

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear orP .

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

Page 230 of 275

228Vehicle careFront arm position of the lifting

platform centrically under the relevant vehicle jacking point.

Spare wheel

The spare wheel can be classified as

a temporary spare wheel depending

on the size compared to the other

mounted wheels and country

regulations. In this case a permissible maximum speed applies, even

though no label at the spare wheel

indicates this.

Only mount one temporary spare

wheel. Do not drive faster than

50 mph. Take curves slowly. Do not

use for a long period of time.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

The spare wheel is located in the load

compartment beneath the floor

covering.

To remove: 1. Open the floor cover 3 71.

2. Remove the tool box.

3. The temporary spare wheel is secured with a wing nut. Unscrew

nut and take out the spare wheel.

4. When, after a wheel change, no wheel is placed in the spare wheelwell, secure the tool box by

tightening the wing nut as far as it

will go and close floor cover.

5. After wheel change back to full size wheel, place the temporary

spare wheel outside up in the well and secure with the wing nut.

Only mount one temporary spare

wheel. The permissible maximum

speed on the label on the temporary

spare wheel is only valid for the

factory-fitted tyre size.

Fitting the spare wheel

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight- ahead position.

● If necessary, place a chock under

the wheel diagonally opposite the

wheel to be changed.

● Apply the parking brake and engage first gear, reverse gear or

P .

Page 234 of 275

232Vehicle care● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 V). Its capacity

(Ah) must not be much less than

that of the discharged vehicle

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

Open the positive terminal protection

caps of both vehicle batteries.

Lead connection order: 1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the boosterbattery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers e.g. headlights, heated rear

window of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.