Esc VAUXHALL INSIGNIA 2018 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: INSIGNIA, Model: VAUXHALL INSIGNIA 2018Pages: 323, PDF Size: 9.25 MB

Page 265 of 323

Vehicle care263The tyre pressure tables show all

possible tyre combinations 3 300.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

After adjusting tyre pressure, select

the according tyre loading setting on

the page Tyre load in the Driver

Information Centre, 3 112.

Temperature dependency The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which

means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down

tyre will show a decreased value,

which does not indicate an air leak.Tyre pressure monitoring

system

The tyre pressure monitoring system

checks the pressure of all four wheels once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns just about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with

pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

Select the Tyre pressure monitoring

page under the Info Menu in the

Driver Information Centre 3 112.

Page 267 of 323

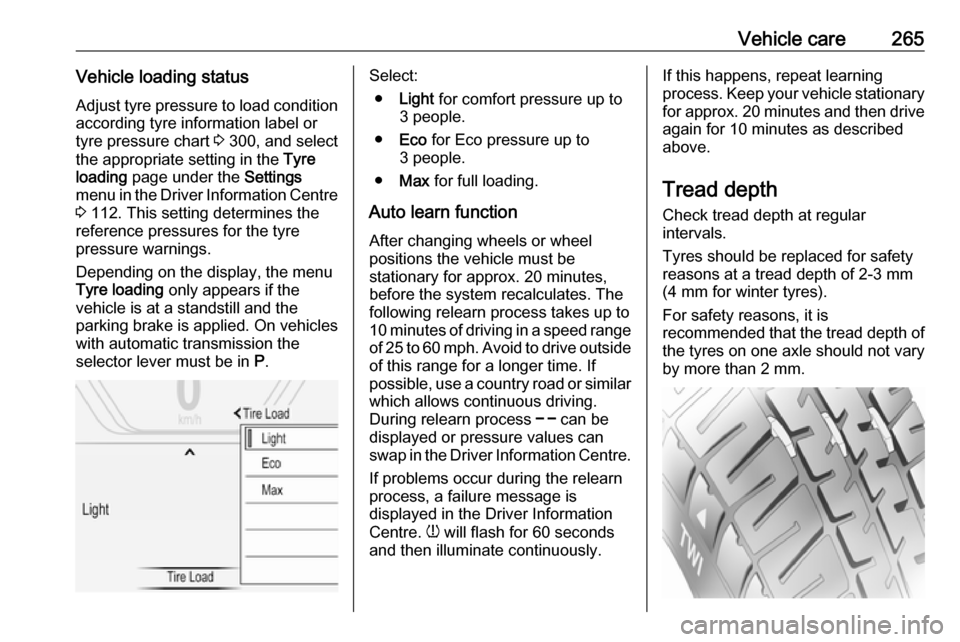

Vehicle care265Vehicle loading statusAdjust tyre pressure to load condition

according tyre information label or

tyre pressure chart 3 300, and select

the appropriate setting in the Tyre

loading page under the Settings

menu in the Driver Information Centre 3 112. This setting determines the

reference pressures for the tyre

pressure warnings.

Depending on the display, the menu

Tyre loading only appears if the

vehicle is at a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever must be in P.Select:

● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full loading.

Auto learn function After changing wheels or wheel

positions the vehicle must be

stationary for approx. 20 minutes,

before the system recalculates. The

following relearn process takes up to

10 minutes of driving in a speed range

of 25 to 60 mph. Avoid to drive outside

of this range for a longer time. If

possible, use a country road or similar which allows continuous driving.

During relearn process $ can be

displayed or pressure values can

swap in the Driver Information Centre.

If problems occur during the relearn

process, a failure message is

displayed in the Driver Information

Centre. w will flash for 60 seconds

and then illuminate continuously.If this happens, repeat learning

process. Keep your vehicle stationary for approx. 20 minutes and then drive

again for 10 minutes as described

above.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

Page 272 of 323

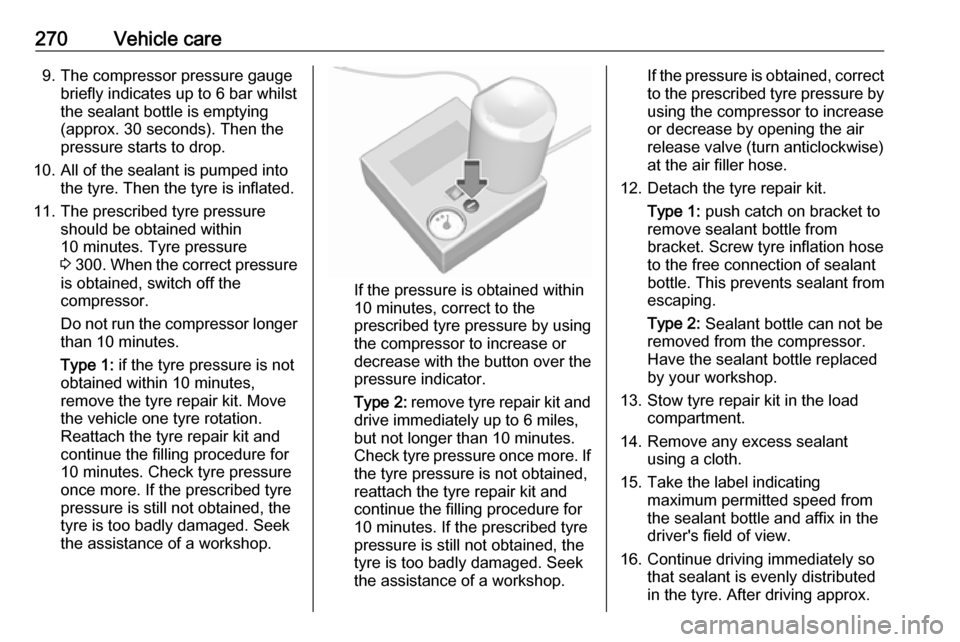

270Vehicle care9. The compressor pressure gaugebriefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

10. All of the sealant is pumped into the tyre. Then the tyre is inflated.

11. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 300 . When the correct pressure

is obtained, switch off the

compressor.

Do not run the compressor longer

than 10 minutes.

Type 1: if the tyre pressure is not

obtained within 10 minutes, remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. Check tyre pressure

once more. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

If the pressure is obtained within

10 minutes, correct to the prescribed tyre pressure by using

the compressor to increase or

decrease with the button over the

pressure indicator.

Type 2: remove tyre repair kit and

drive immediately up to 6 miles,

but not longer than 10 minutes.

Check tyre pressure once more. If

the tyre pressure is not obtained,

reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

If the pressure is obtained, correct to the prescribed tyre pressure byusing the compressor to increase

or decrease by opening the air

release valve (turn anticlockwise)

at the air filler hose.

12. Detach the tyre repair kit. Type 1: push catch on bracket to

remove sealant bottle from

bracket. Screw tyre inflation hose

to the free connection of sealant

bottle. This prevents sealant from

escaping.

Type 2: Sealant bottle can not be

removed from the compressor.

Have the sealant bottle replaced

by your workshop.

13. Stow tyre repair kit in the load compartment.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

16. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

Page 273 of 323

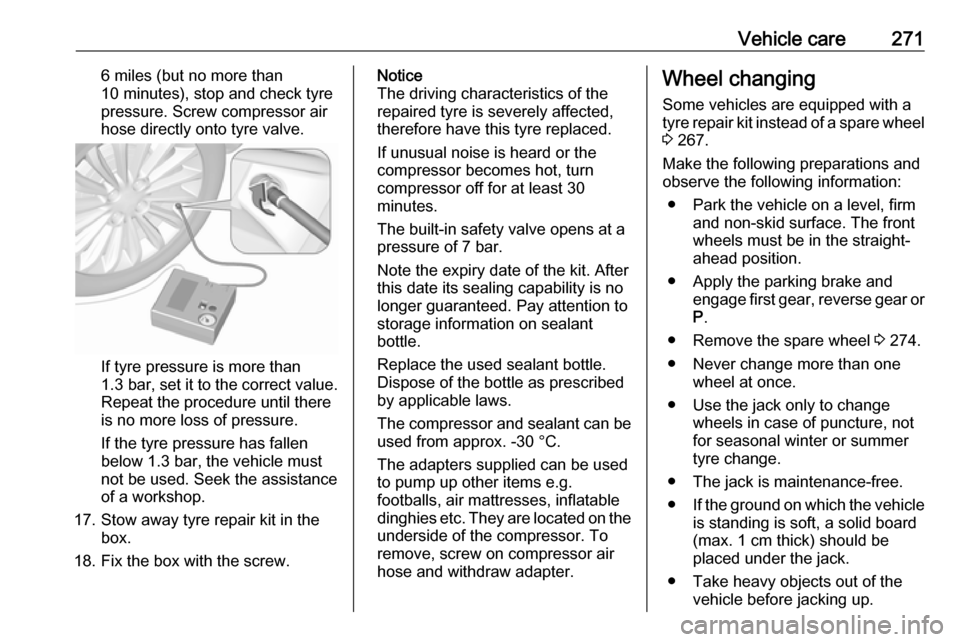

Vehicle care2716 miles (but no more than10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve.

If tyre pressure is more than

1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

17. Stow away tyre repair kit in the box.

18. Fix the box with the screw.

Notice

The driving characteristics of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30

minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatable

dinghies etc. They are located on the

underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 267.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-skid surface. The front

wheels must be in the straight-

ahead position.

● Apply the parking brake and engage first gear, reverse gear or

P .

● Remove the spare wheel 3 274.

● Never change more than one wheel at once.

● Use the jack only to change wheels in case of puncture, not

for seasonal winter or summer

tyre change.

● The jack is maintenance-free.

● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Take heavy objects out of the vehicle before jacking up.