engine VAUXHALL MERIVA 2015 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: MERIVA, Model: VAUXHALL MERIVA 2015Pages: 245, PDF Size: 7.76 MB

Page 174 of 245

172Vehicle careCaution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Brakes

In the event of minimum thickness ofthe brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

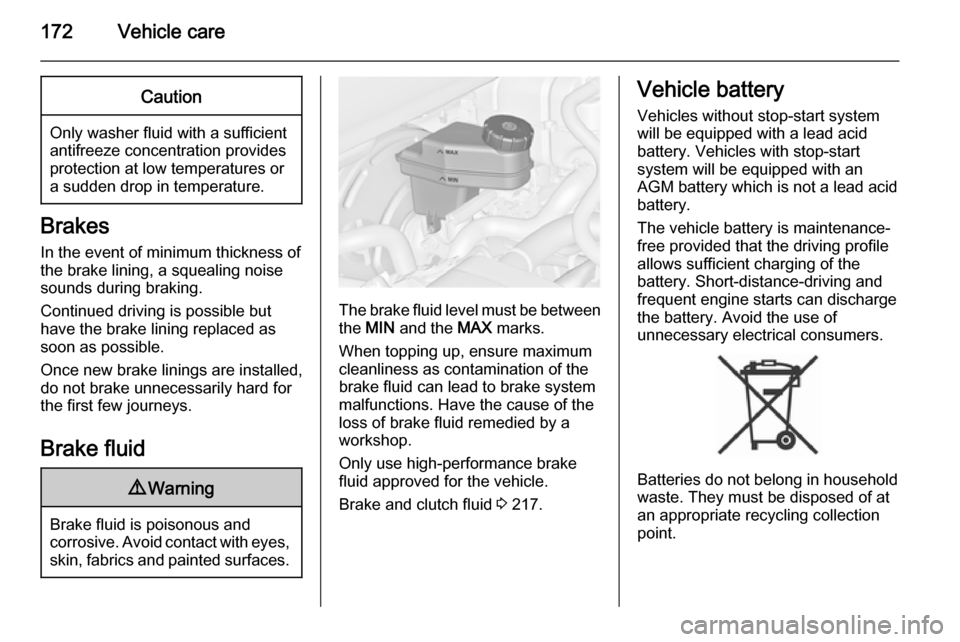

Brake fluid

9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MIN and the MAX marks.

When topping up, ensure maximum cleanliness as contamination of the

brake fluid can lead to brake system

malfunctions. Have the cause of the

loss of brake fluid remedied by a

workshop.

Only use high-performance brake

fluid approved for the vehicle.

Brake and clutch fluid 3 217.

Vehicle battery

Vehicles without stop-start systemwill be equipped with a lead acid

battery. Vehicles with stop-start

system will be equipped with an

AGM battery which is not a lead acid

battery.

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance-driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Page 176 of 245

174Vehicle care

Stop-start system 3 137.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 209.

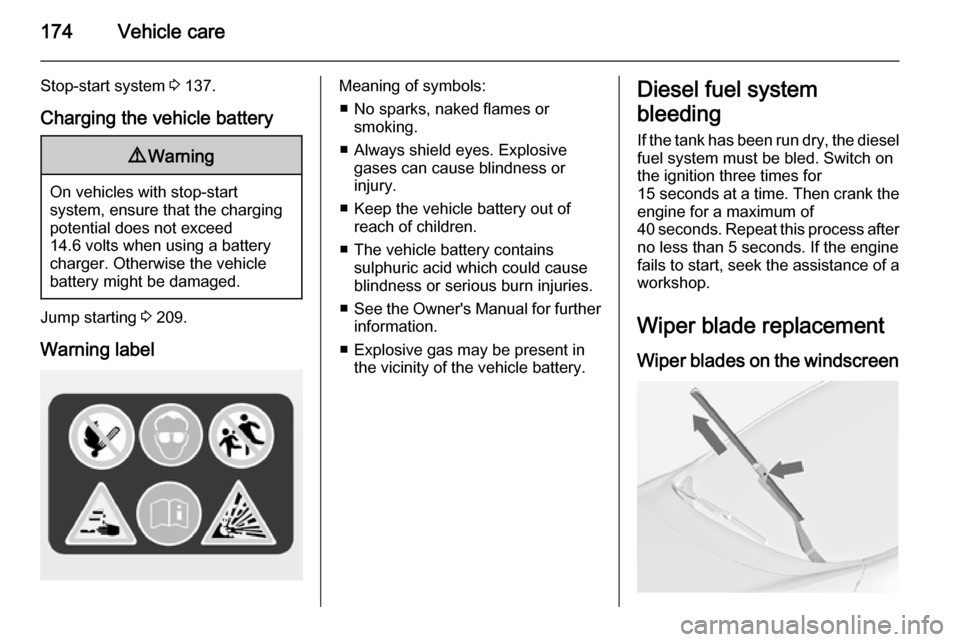

Warning label

Meaning of symbols: ■ No sparks, naked flames or smoking.

■ Always shield eyes. Explosive gases can cause blindness or

injury.

■ Keep the vehicle battery out of reach of children.

■ The vehicle battery contains sulphuric acid which could cause

blindness or serious burn injuries.

■ See the Owner's Manual for further

information.

■ Explosive gas may be present in the vicinity of the vehicle battery.Diesel fuel system

bleeding

If the tank has been run dry, the diesel

fuel system must be bled. Switch on

the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. Repeat this process after

no less than 5 seconds. If the engine fails to start, seek the assistance of a

workshop.

Wiper blade replacement Wiper blades on the windscreen

Page 177 of 245

Vehicle care175

Lift the wiper arm, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

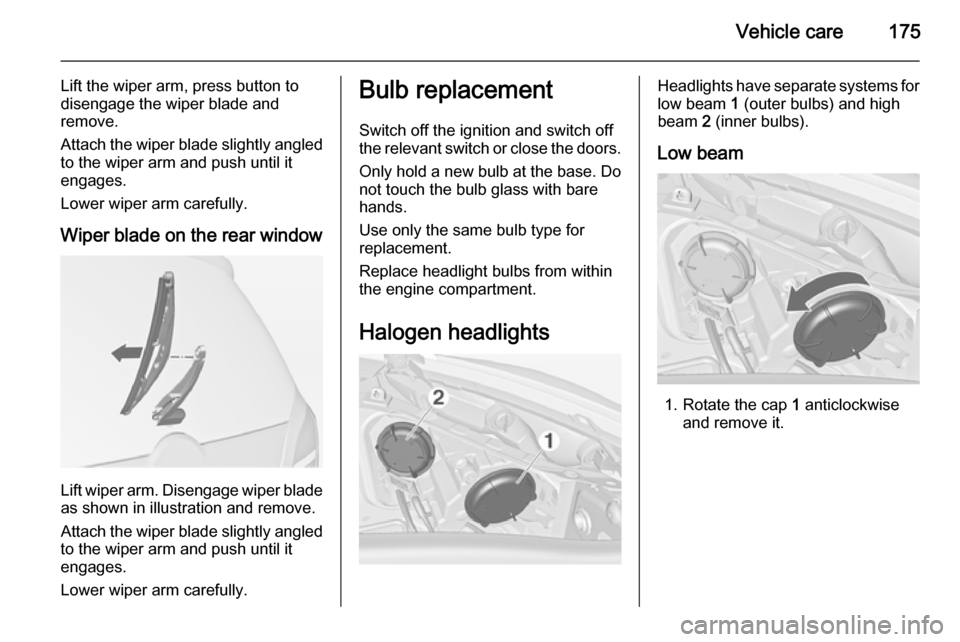

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Halogen headlightsHeadlights have separate systems for low beam 1 (outer bulbs) and high

beam 2 (inner bulbs).

Low beam

1. Rotate the cap 1 anticlockwise

and remove it.

Page 187 of 245

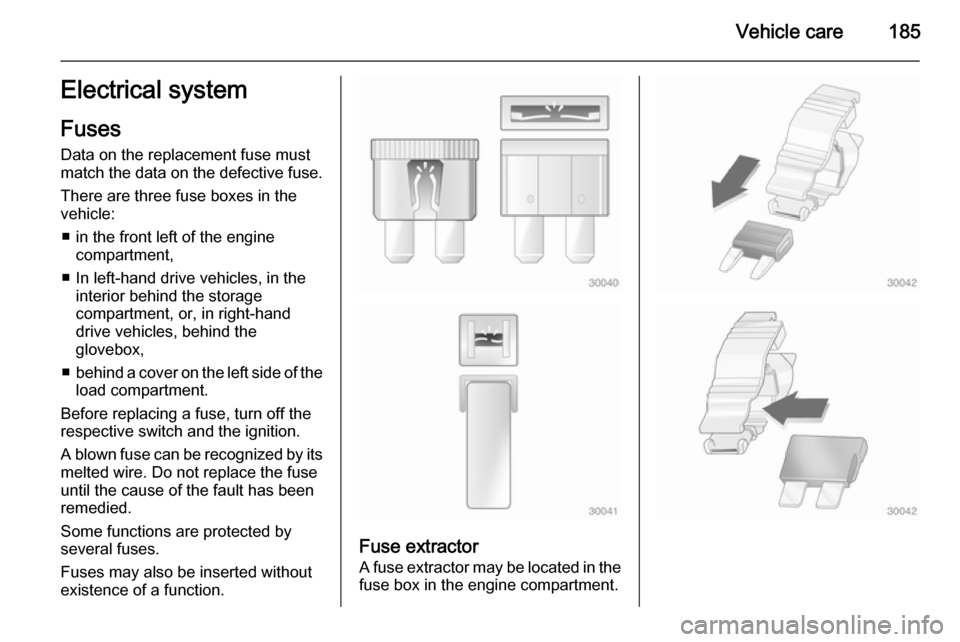

Vehicle care185Electrical systemFuses

Data on the replacement fuse must match the data on the defective fuse.

There are three fuse boxes in the

vehicle:

■ in the front left of the engine compartment,

■ In left-hand drive vehicles, in the interior behind the storage

compartment, or, in right-hand

drive vehicles, behind the

glovebox,

■ behind a cover on the left side of the

load compartment.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognized by its melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

Page 188 of 245

186Vehicle care

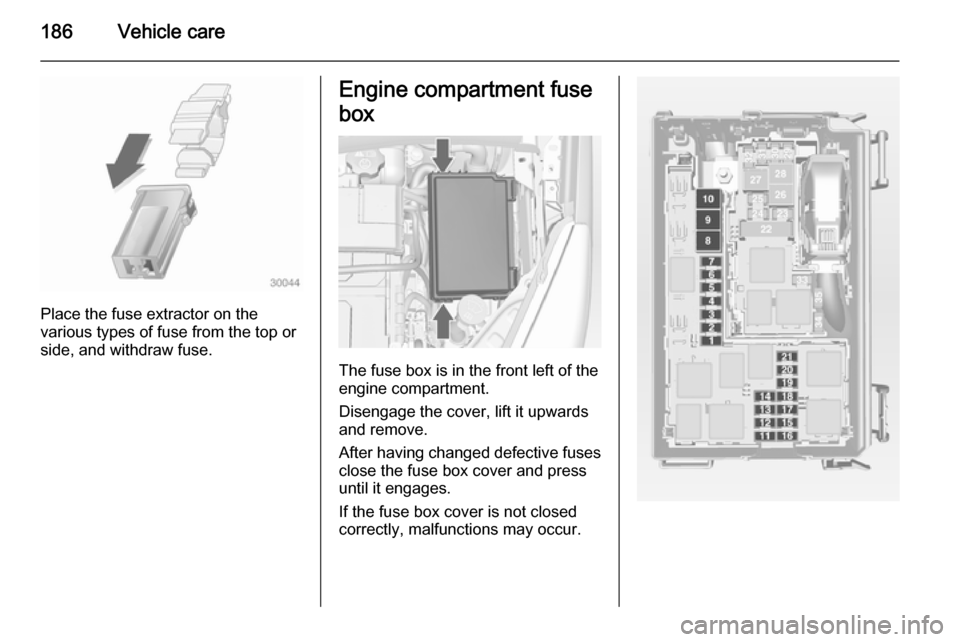

Place the fuse extractor on the

various types of fuse from the top or

side, and withdraw fuse.

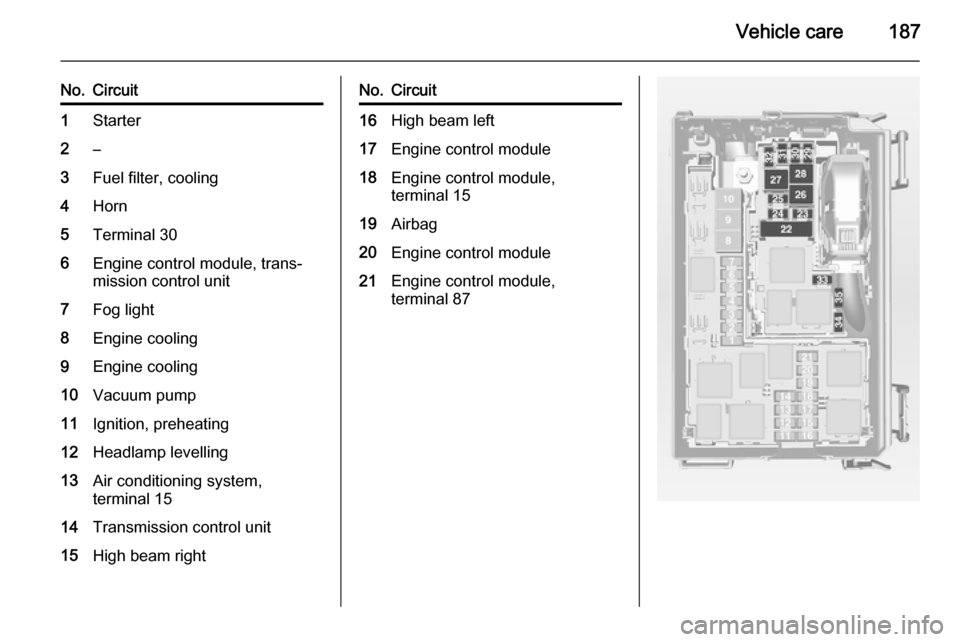

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover, lift it upwards

and remove.

After having changed defective fuses

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

Page 189 of 245

Vehicle care187

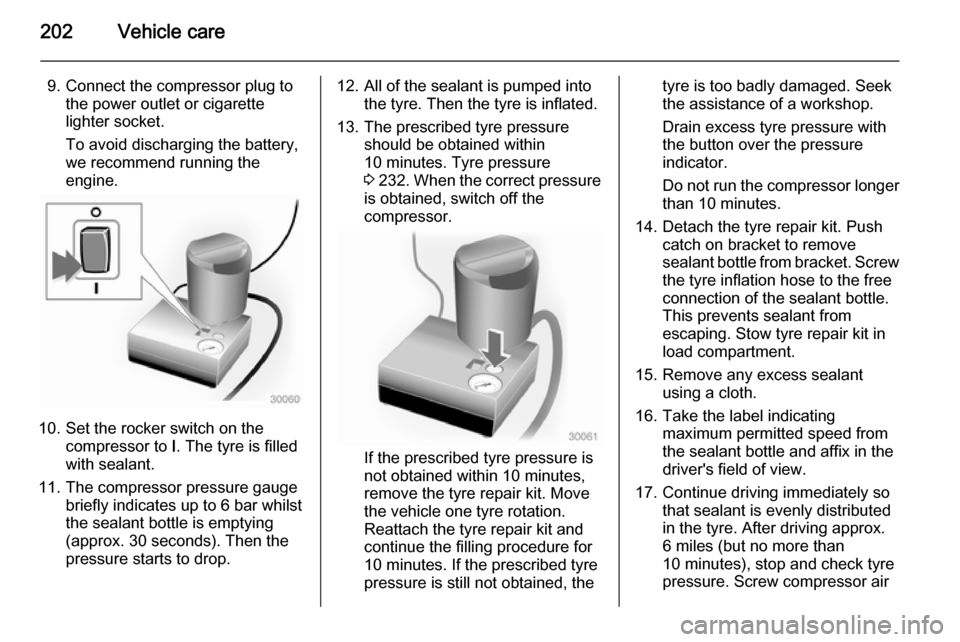

No.Circuit1Starter2–3Fuel filter, cooling4Horn5Terminal 306Engine control module, trans‐

mission control unit7Fog light8Engine cooling9Engine cooling10Vacuum pump11Ignition, preheating12Headlamp levelling13Air conditioning system,

terminal 1514Transmission control unit15High beam rightNo.Circuit16High beam left17Engine control module18Engine control module,

terminal 1519Airbag20Engine control module21Engine control module,

terminal 87

Page 195 of 245

Vehicle care193

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 224.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 232.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Tyre pressure monitoring system The tyre pressure monitoring system

(TPMS) checks the pressure of all

four wheels once a minute when

vehicle speed exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information Centre

(DIC).

The menu can be selected by the

buttons on the turn signal lever.

Press the MENU button to select the

Vehicle Information Menu X .

Page 201 of 245

Vehicle care199

1. Take the sealant bottle andbracket with air hose from the

insert.

2. Detach air hose from bracket and screw onto sealant bottle

connection.

3. Position the sealant bottle on the bracket. Make sure that the bottle

does not fall.

4. Unscrew valve cap from defective

tyre.

5. Screw tyre inflation hose to valve.

6. Screw air hose onto compressor connection.

7. Switch on ignition. To avoid discharging the vehicle

battery, we recommend running

the engine.

Page 204 of 245

202Vehicle care

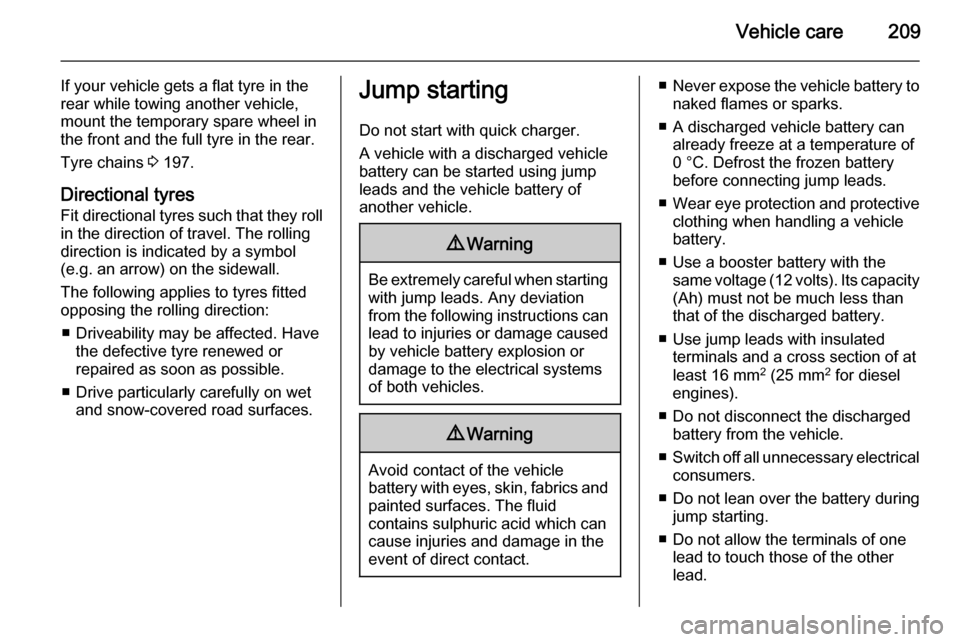

9. Connect the compressor plug tothe power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.

10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 232 . When the correct pressure

is obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor longer

than 10 minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw the tyre inflation hose to the freeconnection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

6 miles (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

Page 211 of 245

Vehicle care209

If your vehicle gets a flat tyre in the

rear while towing another vehicle,

mount the temporary spare wheel in

the front and the full tyre in the rear.

Tyre chains 3 197.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Drive particularly carefully on wet and snow-covered road surfaces.Jump starting

Do not start with quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by vehicle battery explosion or

damage to the electrical systems

of both vehicles.

9 Warning

Avoid contact of the vehicle

battery with eyes, skin, fabrics and painted surfaces. The fluid

contains sulphuric acid which can

cause injuries and damage in the

event of direct contact.

■ Never expose the vehicle battery to

naked flames or sparks.

■ A discharged vehicle battery can already freeze at a temperature of

0 °C. Defrost the frozen battery

before connecting jump leads.

■ Wear eye protection and protective

clothing when handling a vehicle

battery.

■ Use a booster battery with the same voltage (12 volts). Its capacity(Ah) must not be much less than

that of the discharged battery.

■ Use jump leads with insulated terminals and a cross section of at

least 16 mm 2

(25 mm 2

for diesel

engines).

■ Do not disconnect the discharged battery from the vehicle.

■ Switch off all unnecessary electrical

consumers.

■ Do not lean over the battery during jump starting.

■ Do not allow the terminals of one lead to touch those of the other

lead.