lock VAUXHALL MOKKA 2014.5 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014.5, Model line: MOKKA, Model: VAUXHALL MOKKA 2014.5Pages: 219, PDF Size: 6 MB

Page 152 of 219

150Driving and operating

Press the button of the liquid gas

supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Bayonet adapter: Netherlands,

Norway, Spain, United Kingdom

EURO adapter: Spain

Page 157 of 219

Vehicle care155

■ Open the bonnet, close all doorsand lock the vehicle.

■ Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are

not functional, e.g. anti-theft alarm

system.

Putting back into operation

When the vehicle is to be put back into

operation:

■ Connect the clamp to the negative terminal of the vehicle battery.

Activate the electronics of the

power windows.

■ Check tyre pressure.

■ Fill up the washer fluid reservoir.

■ Check the engine oil level.

■ Check the coolant level.

■ Fit the number plate if necessary.

End-of-life vehicle

recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on ourwebsite, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

Page 166 of 219

164Vehicle care

3. When fitting a new bulb, engagethe lugs in the recesses on the

reflector.

4. Reinstall the headlight assembly.

5. Place headlight protective cover in position and close.

Sidelights

1. Remove the socket from the assembly by turning

counterclockwise.

2. Remove bulb socket from reflector.

3. Detach plug connector from bulb.

4. Remove bulb from socket.

5. Insert new bulb.

6. Plug connector onto bulb.

7. Insert socket in reflector.

8. Reinstall the assembly.

Xenon headlights

9 Danger

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Cornering lights

1. Remove the protective cover.

Page 167 of 219

Vehicle care165

2. Remove the bulb socket bypulling.

3. Remove the bulb from the bulb socket and replace the bulb.

4. When fitting a new bulb, engage the lugs in the recesses on the

reflector.

5. Reinstall the headlight assembly.

6. Place headlight protective cover in position and close.

Fog lights

Have bulbs replaced by a workshop.

Front turn signal lights

1. Rotate bulb holder counterclockwise and disengage.

2. Push bulb into socket slightly,rotate counterclockwise, removeand renew bulb.

3. Insert bulb holder in reflector, rotate clockwise to engage.

Tail lights

Left-hand side

1. Remove both covers and unscrew

screws. Remove the panel.

Page 169 of 219

Vehicle care167Side turn signal lights

If the lights do not operate, have themchecked by a workshop.

Centre high-mounted

brake light

If the centre high-mounted brake light does not operate, have it checked by

a workshop.

Number plate light

1. Prise the light out with a screwdriver.

2. Remove bulb housing downward, taking care not to pull on thecable.

Rotate bulb holder counterclockwise to disengage.

3. Remove bulb from holder and renew bulb.

4. Insert bulb holder in bulb housing and rotate clockwise.

5. Insert bulb housing and secure using a screwdriver.

Page 172 of 219

170Vehicle care

No.Circuit18Engine control module19Fuel pump20–21Cooling fan22–23Ignition coil, Engine control

module24Washer pump25Headlamp actuator (right hand)26Engine control module27–28Engine control module29Engine control module30Exhaust system31Left-hand high beam32Right-hand high beam33Engine control moduleNo.Circuit34Horn35Climate control, air conditioning

system36Front fog lamp

J-cases Fuses

No.Circuit1Electrical brake control module2Front wiper3Engine control module4Engine control module5–6Fuel heater7–8Cooling fan9Cooling fanNo.Circuit10Engine control module, Glow

plug11Starter

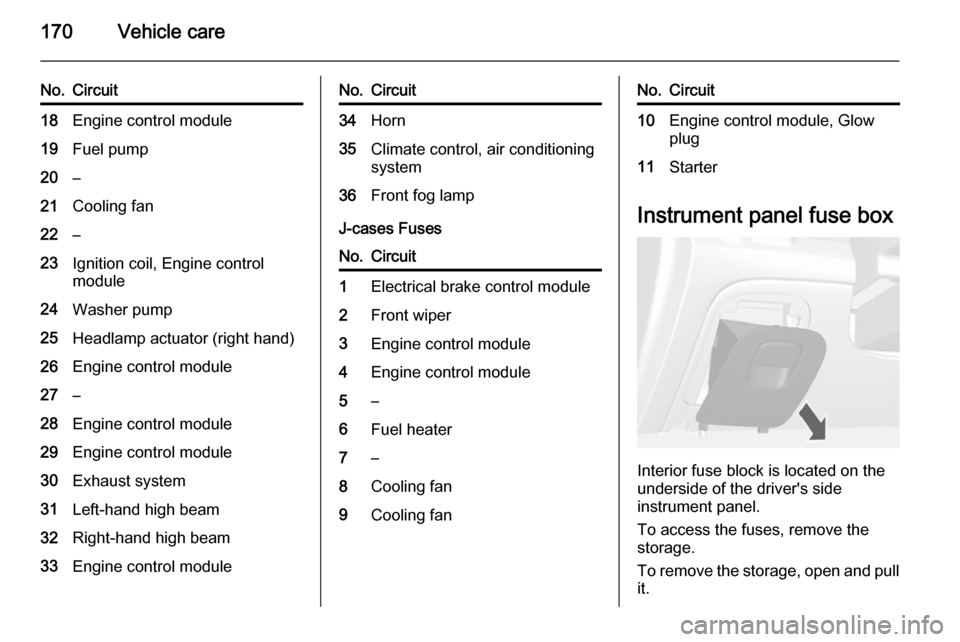

Instrument panel fuse box

Interior fuse block is located on the

underside of the driver's side

instrument panel.

To access the fuses, remove the

storage.

To remove the storage, open and pull it.

Page 173 of 219

Vehicle care171

Mini Fuses

No.Circuit1Body control module2Body control module3Body control module4Body control module5Body control module6Body control module7Body control module8Body control module9Door locks10Safety diagnosis module11Door locks12Climate control13Tailgate14Park assist15Lane departure warning, Interior

mirror16Adaptive forward lightingNo.Circuit17Power window driver18Rain sensor19Spare20Steering wheel21Transmission control module22Cigarette lighter23Spare24Spare25Spare26Display27Instrument panel cluster28Adaptive forward lighting29Spare30Spare31Instrument panel cluster32Infotainment, auxiliary, power

outlet

Page 181 of 219

Vehicle care179Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be

necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory-approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory-approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with alloy wheels: When

mounting steel wheels with alloy

wheel nuts, e.g. when changing to

winter tyres, the wheel covers cannot

be attached to the steel wheels.

Tyre chains

Use tyre chains only on front wheels.

9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 195/70 R16.

Always use fine mesh chains suitable

for sport utility vehicles that add no

more than 12 mm to the tyre tread and the inboard sides (including chain

lock).

Page 190 of 219

188Vehicle care

■ Apply the parking brake,transmission in neutral, automatic

transmission in P.

■ Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 191 of 219

Vehicle care189Towing

Towing the vehicle

Disengage cap by using a

screwdriver and remove.

The towing eye is stowed with the vehicle tools 3 173.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.

Caution

Never tow your vehicle equipped

with All Wheel Drive (AWD) with the front or rear tyres on the road.

If you tow the vehicle equipped with AWD while the front or rear

tyres are rolling on the road the

drive system in the vehicle could

be severely damaged. When

towing vehicles equipped with

AWD all 4 tyres may not be in

contact with the road.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation system 3 113 and

close the windows.